Workpiece positioning mechanism of coding machine

A positioning mechanism and coding machine technology, applied in typewriters, printing devices, printing, etc., can solve problems such as workpiece shaking, unsatisfactory coding effect, and difficult to identify coding information, so as to avoid the effect of workpiece falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

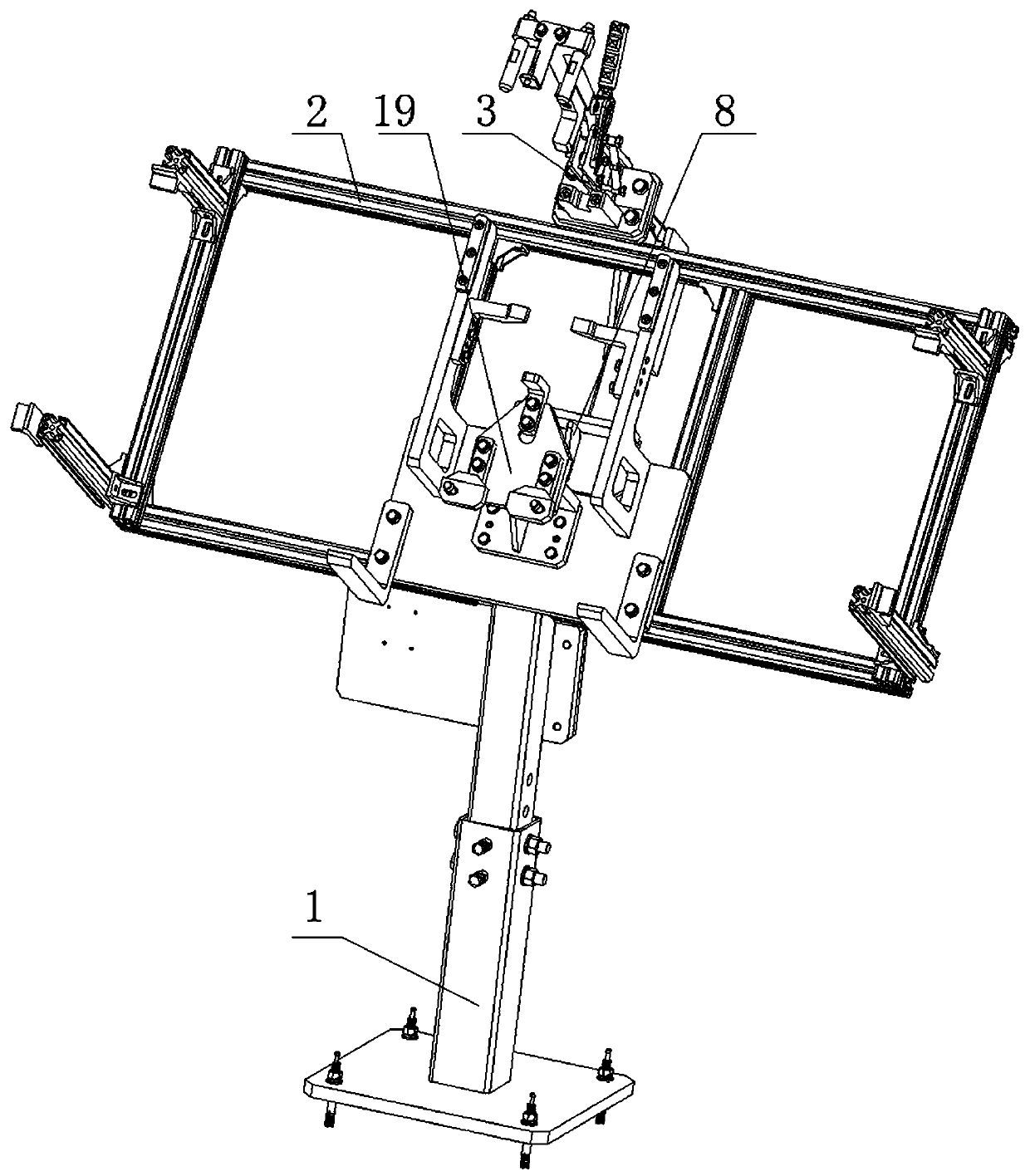

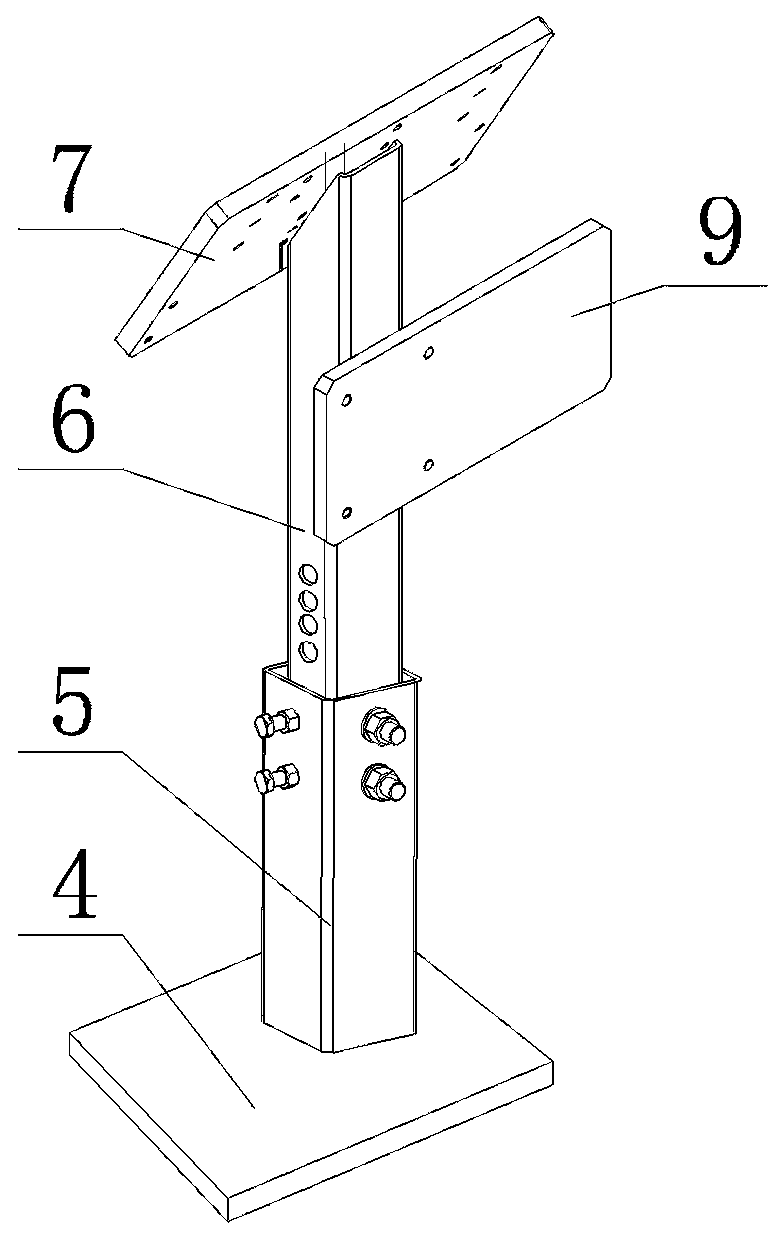

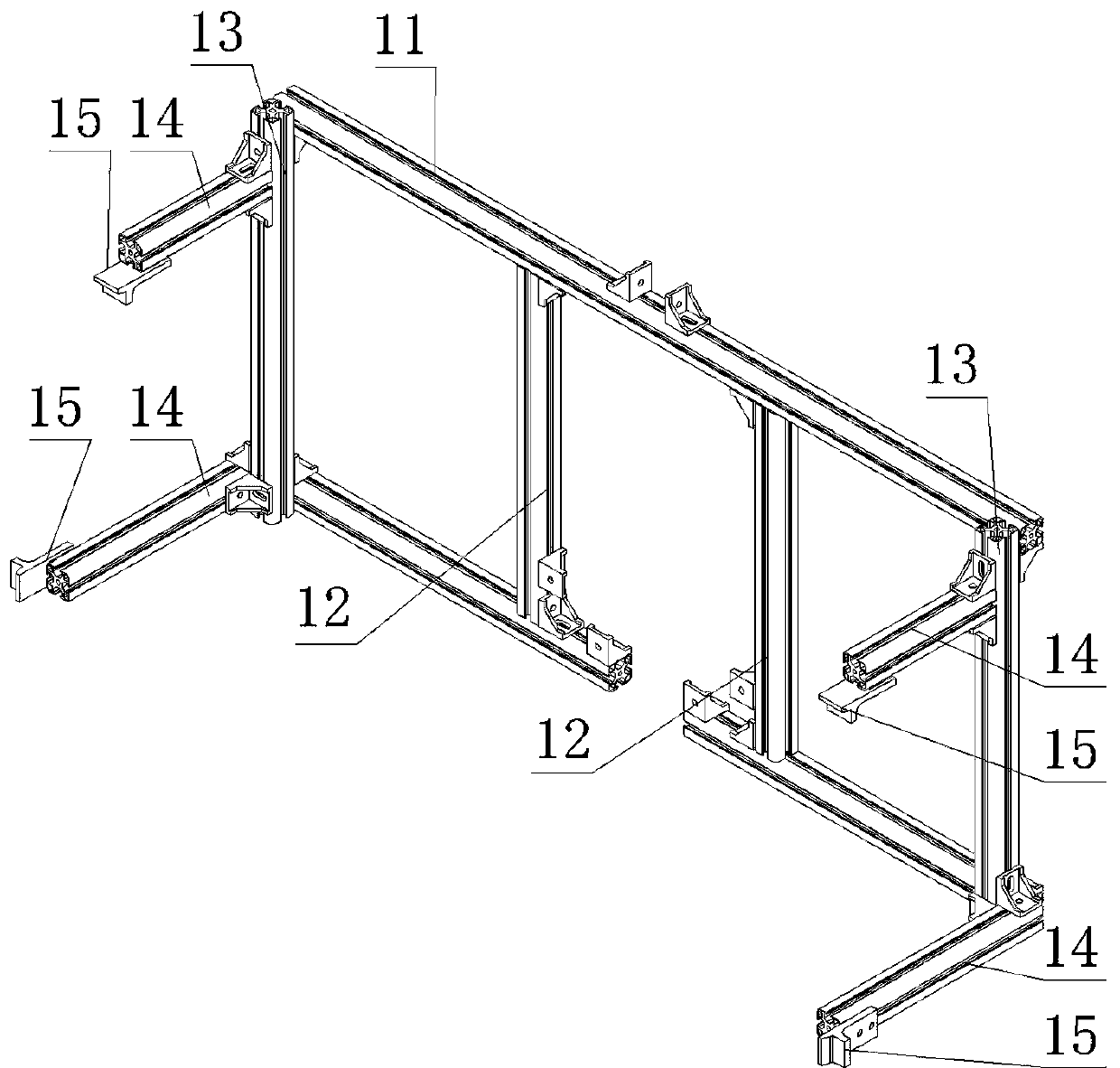

[0034] according to Figure 1-11The specific structure of the present invention will be described in detail. The workpiece positioning mechanism of the coding machine includes an adjustable mounting base 1, a support frame body 2 and a pressing device 3, and is characterized in that: the adjustable mounting base 1 includes a base plate 4, and the base plate 4 is fixed above A square steel pipe 5 is provided, and two connection through holes can be vertically arranged on the square steel pipe 5. An adjustment square steel 6 is embedded in the square steel pipe 5. The position of the connection through hole of the corresponding square steel pipe 5 of the adjustment square steel 6 can be There are four adjustment holes for adjusting the height position vertically, and the adjustment square steel 6 is connected with the square steel pipe 5 through the bolts arranged in the holes; the upper part of the adjustment square steel 6 is provided with a component fixing plate 7 for compon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com