Printer, and paper position detection method of a printer

一种检测方法、打印机的技术,应用在打印装置、印刷等方向,能够解决装置制造成本增加、难以实现装置小型化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

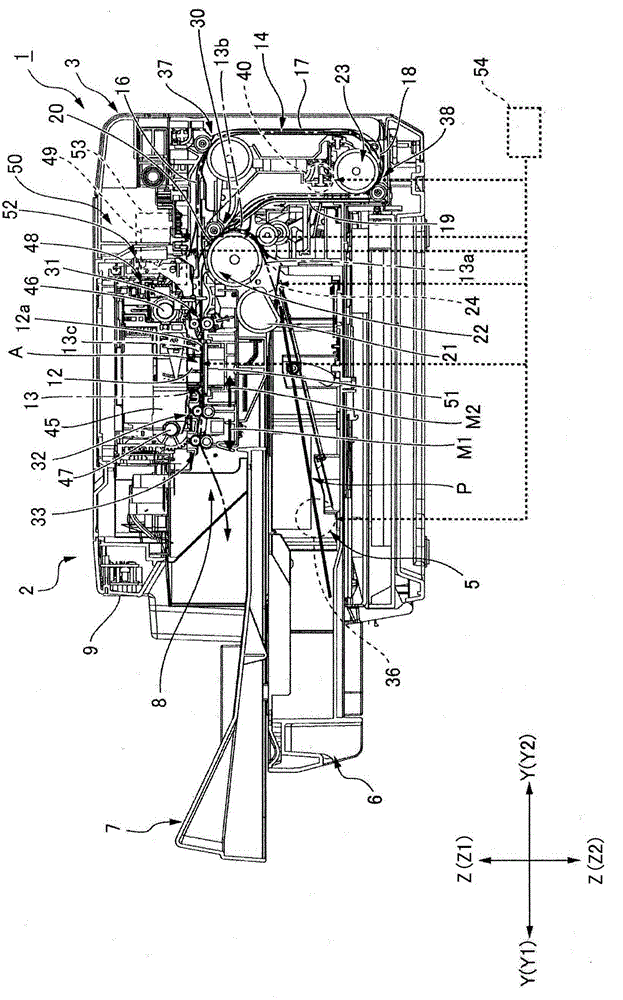

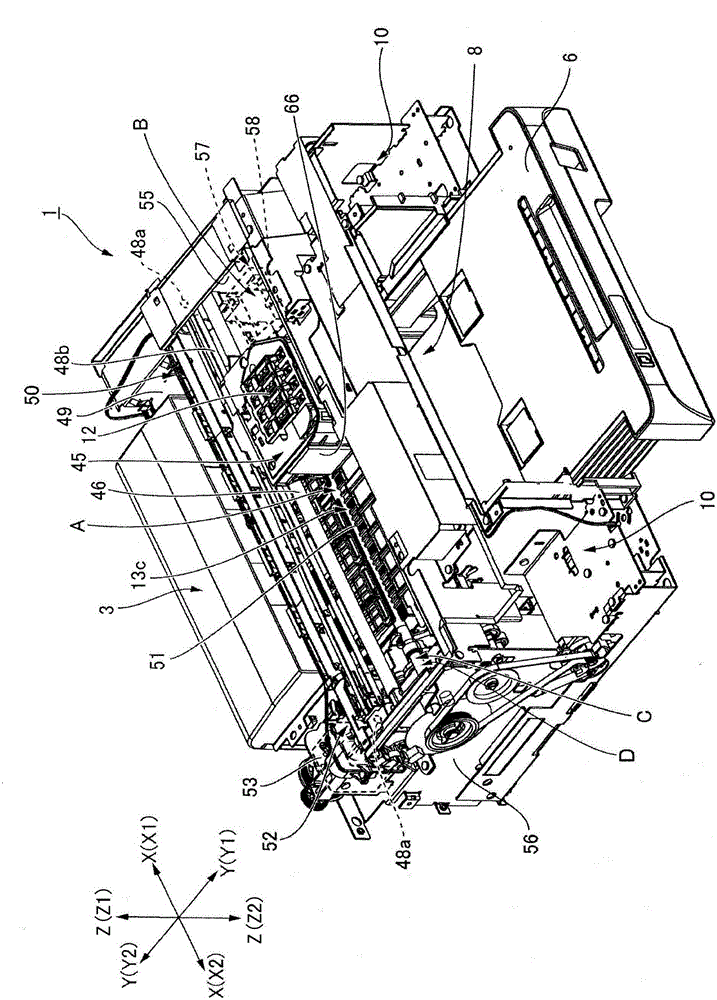

[0042] Hereinafter, an embodiment of a printer 1 to which the present invention is applied will be described with reference to the drawings.

[0043] (the whole frame)

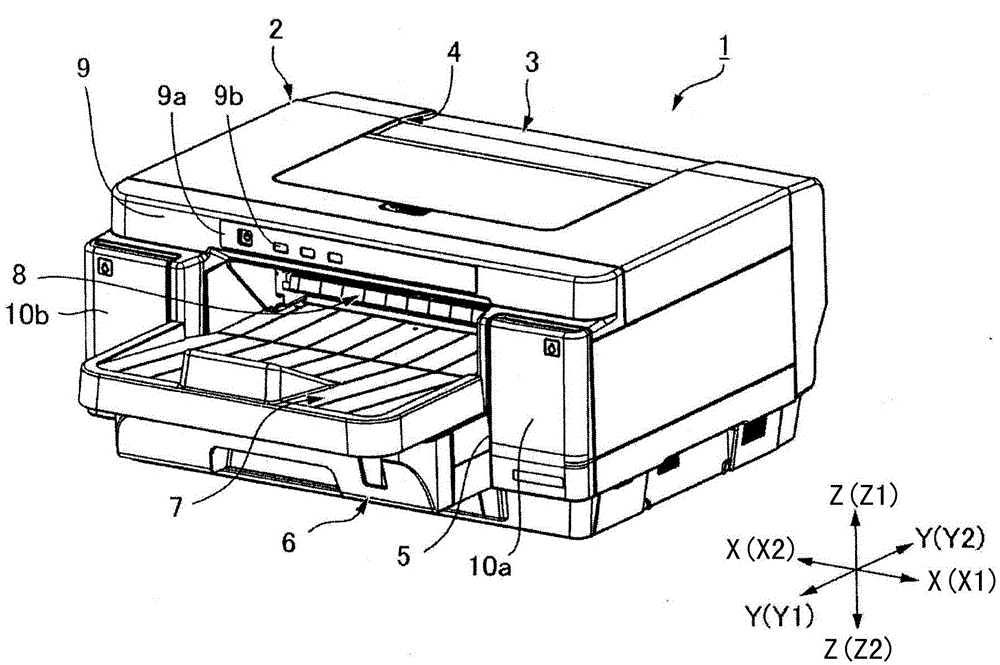

[0044] figure 1 It is an external perspective view of the printer 1 according to the first embodiment viewed from the direction of the paper discharge port 8 (referred to as the front). The printer 1 has a printer main body 2 and a reversing unit 3 . The printer main body 2 has a rectangular parallelepiped shape that is long in the printer width direction X as a whole. The reversing unit 3 is mounted to a recess 4 provided at a central portion of the rear surface of the printer main body portion 2 . The reversing unit 3 is a unit for reversing the printing paper P from the front to the back.

[0045] A paper feeding cassette mounting portion 5 is provided on the printer main body portion 2 . The paper feeding cassette mounting portion 5 opens toward the printer front Y1 (forward in the printer longitudina...

no. 2 approach

[0113] Next, refer to Figure 1 ~ Figure 4 as well as Figure 12 to Figure 17 Another embodiment of the printer 1 to which the present invention is applied will be described.

[0114] Figure 12 It is a perspective view of the carriage in which the print head 12 is mounted in the second embodiment viewed from below. Figure 13 (a), (b) are perspective views when the carriage 45 in the state which removed the paper detector cover 73 was seen from below. Figure 13 (a) shows the state where the shutter 185 is arranged at the closed position 185A, Figure 13 (b) shows the state where the shutter 185 is arrange|positioned at the open position 185B. Figure 14 It is an explanatory diagram of the shutter 185 and the shutter operating member 210 . Figure 15 It is a perspective view when the carriage 45 moved to the initial position B is seen from above. Figure 16 It is a perspective view of the carriage 45 when it moves to the shutter open position D (described later) seen fr...

no. 3 approach

[0156] Next, refer to Figure 1 ~ Figure 4 as well as Figure 19 ~ Figure 22 Another embodiment of the printer 1 to which the present invention is applied will be described.

[0157] Figure 19 It is a perspective view of the carriage in which the print head 12 is mounted in the third embodiment viewed from below. Figure 20 (a), (b) are perspective views when the carriage 45 in the state which removed the paper detector cover 73 was seen from below. Figure 20 (a) shows the state where the shutter 285 is arranged at the closed position 285A, Figure 20 (b) shows the state where the shutter 285 is arrange|positioned at the open position 285B. Figure 21 It is an explanatory diagram of the shutter 285 and the shutter moving mechanism 290 . Figure 22 It is a flowchart of the opening and closing operation of the shutter and the paper position detection operation. It should be noted that, in Figure 19 ~ Figure 22In the description, the same reference numerals are assigned...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com