Energy rating label and production method thereof

An energy-efficiency and labeling technology, applied in the field of energy-efficiency labeling, can solve the problems of rising plate-making costs and machine-time costs, ghosting, and increased costs, and achieve the effects of accurate printing positions and fonts, reducing production management expenses, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the drawings and examples.

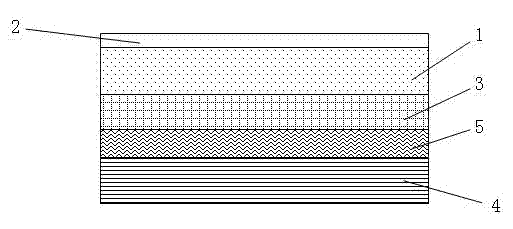

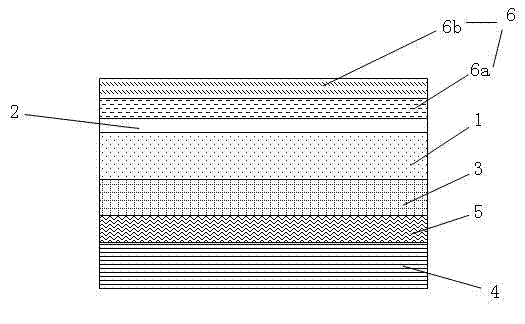

[0029] figure 2 It is a schematic cross-sectional view of the energy efficiency label of the present invention.

[0030] Such as figure 2 As shown, in the energy efficiency label of the present invention, the face paper 1 forms the upper surface material of the above energy efficiency label, and the face paper is made of thermal paper, which can be placed on the thermal paper by a thermal printer or an ordinary printer that does not use a carbon ribbon. Print information on the surface. When the thermal paper meets the heating print head, the color developer and the leuco dye at the print head will react chemically and change color to form graphics. Thermal printing is more convenient than traditional printing. Environmental protection, the lower surface of the face paper 1 is coated with an adhesive to form a backing layer 3; the backing paper 4 is located at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com