Patching method and device

A patch and sheet technology, which is applied in the direction of assembling printed circuits with electrical components, electrical components, and printed circuit manufacturing, etc., can solve the problems of difficult to guarantee the quality of the placement and difficult to accurately position the placement head, so as to ensure the quality and adapt to the The effect of strong performance and accurate printing position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

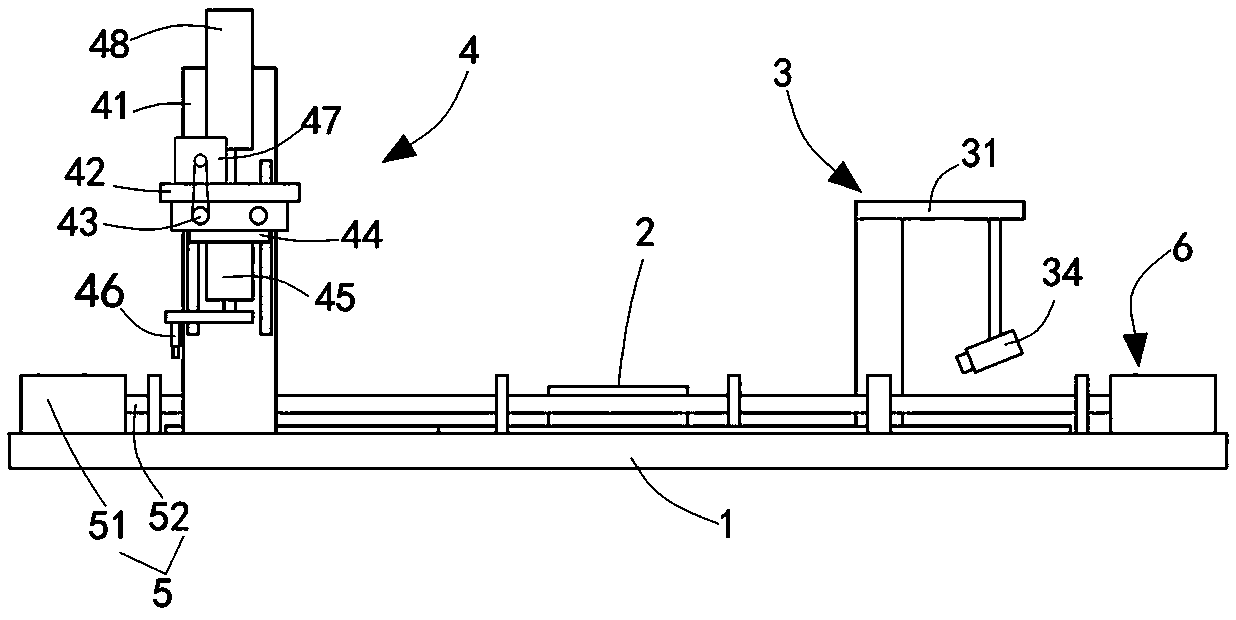

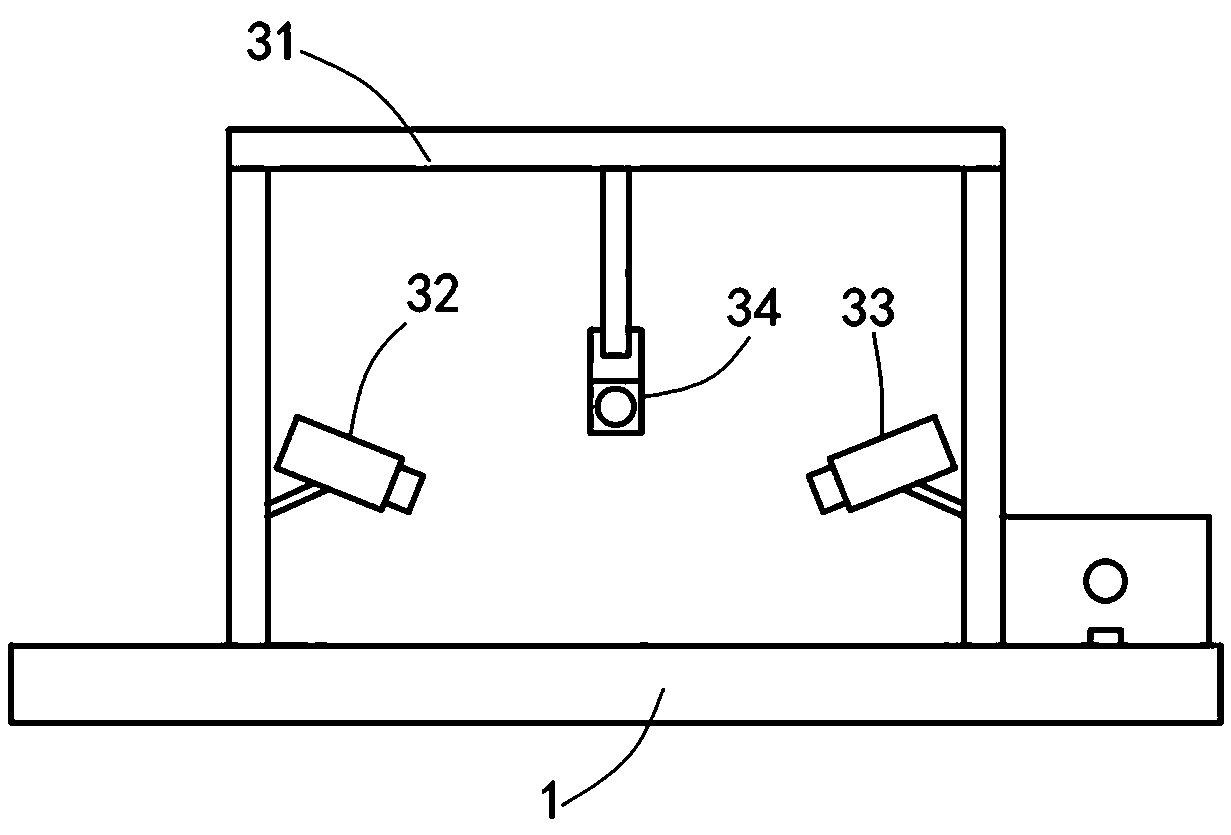

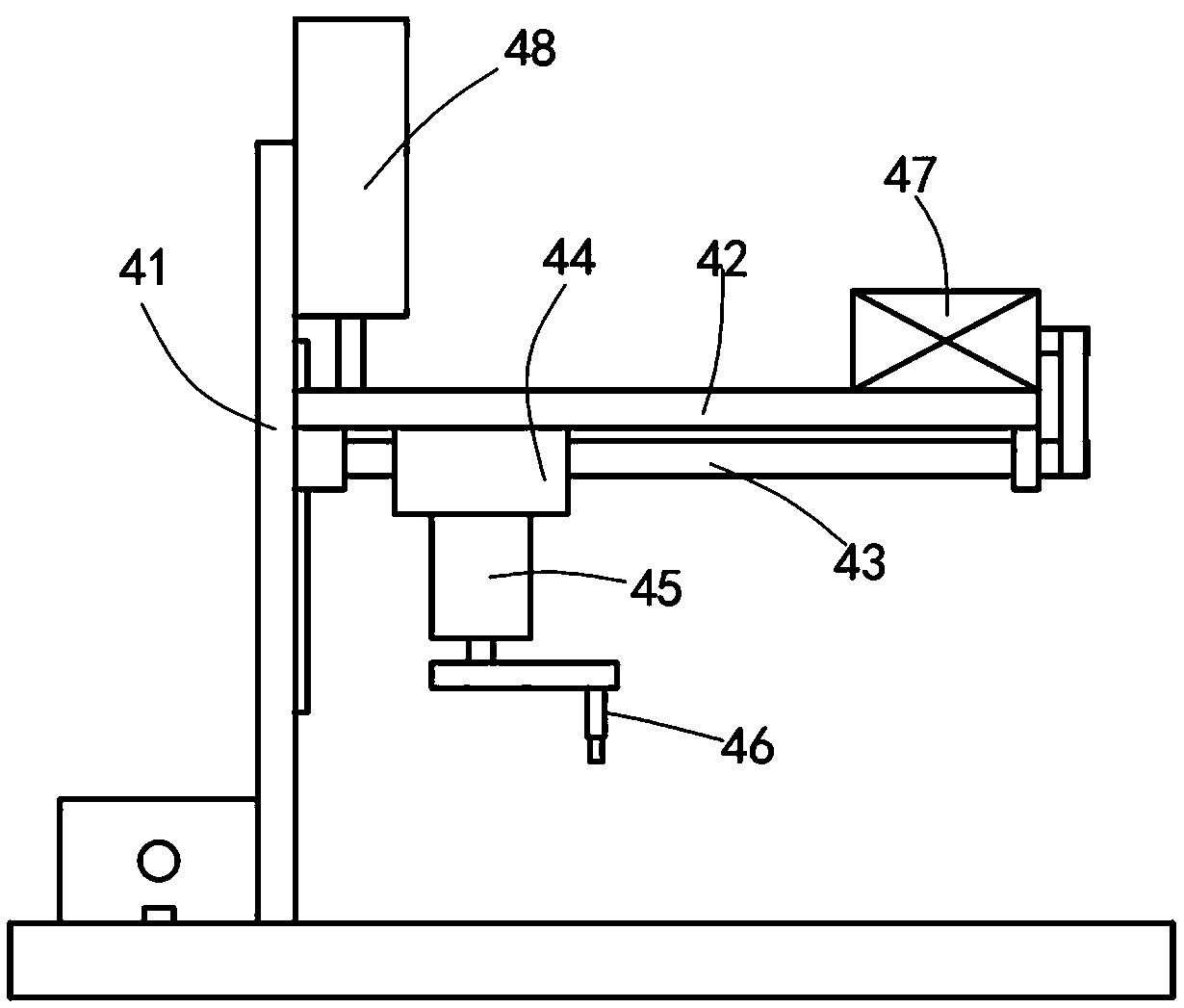

[0032] In order to facilitate those skilled in the art to understand the present invention, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

[0033] A patch method and device provided by the present invention comprise the following steps:

[0034] Step 1, screening chip components, and screening out unqualified chip components;

[0035] Step 2: Select the corresponding component tray according to the shape and size of the chip components, and place the chip components neatly on the component tray;

[0036] Step 3, according to the position of the patch on the circuit board, make a solder paste positioner with the same size as the circuit board for auxiliary printing of solder paste;

[0037] Step 4, cover the positioning part on the circuit board, and print solder paste on the patch position;

[0038] Step 5, put the circuit board printed with solder paste on the circuit board fixing jig of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com