Rolling silk-screen printing equipment as well as multi-color printing equipment and method thereof

A technology of screen printing and equipment, which is applied to rolling screen printing equipment and its multi-color printing equipment and printing fields, which can solve the problems of large occupied space, low printing efficiency, and limited drying speed, etc. Small size, precise printing position and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific examples, but not limited thereto.

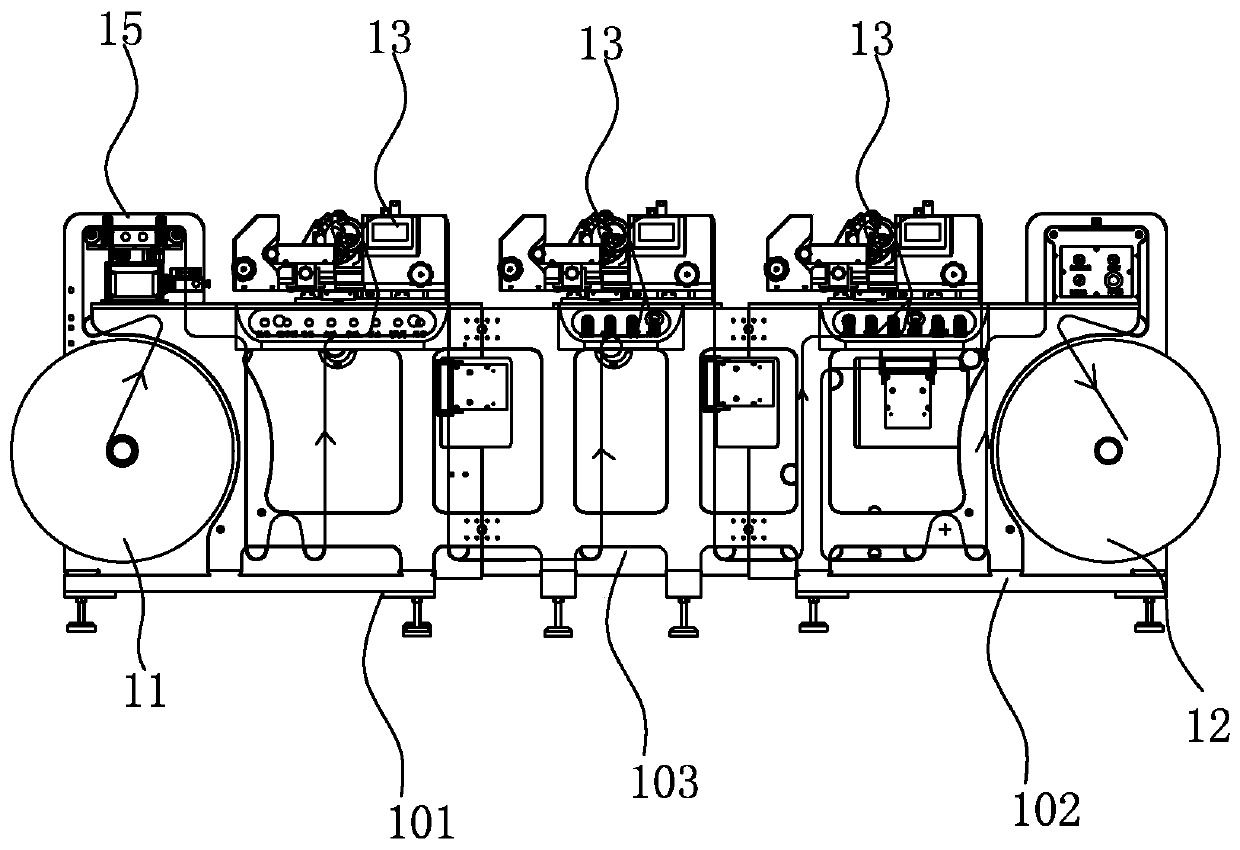

[0032] Such as Figure 1 to Figure 5 Drawings of embodiments of the invention.

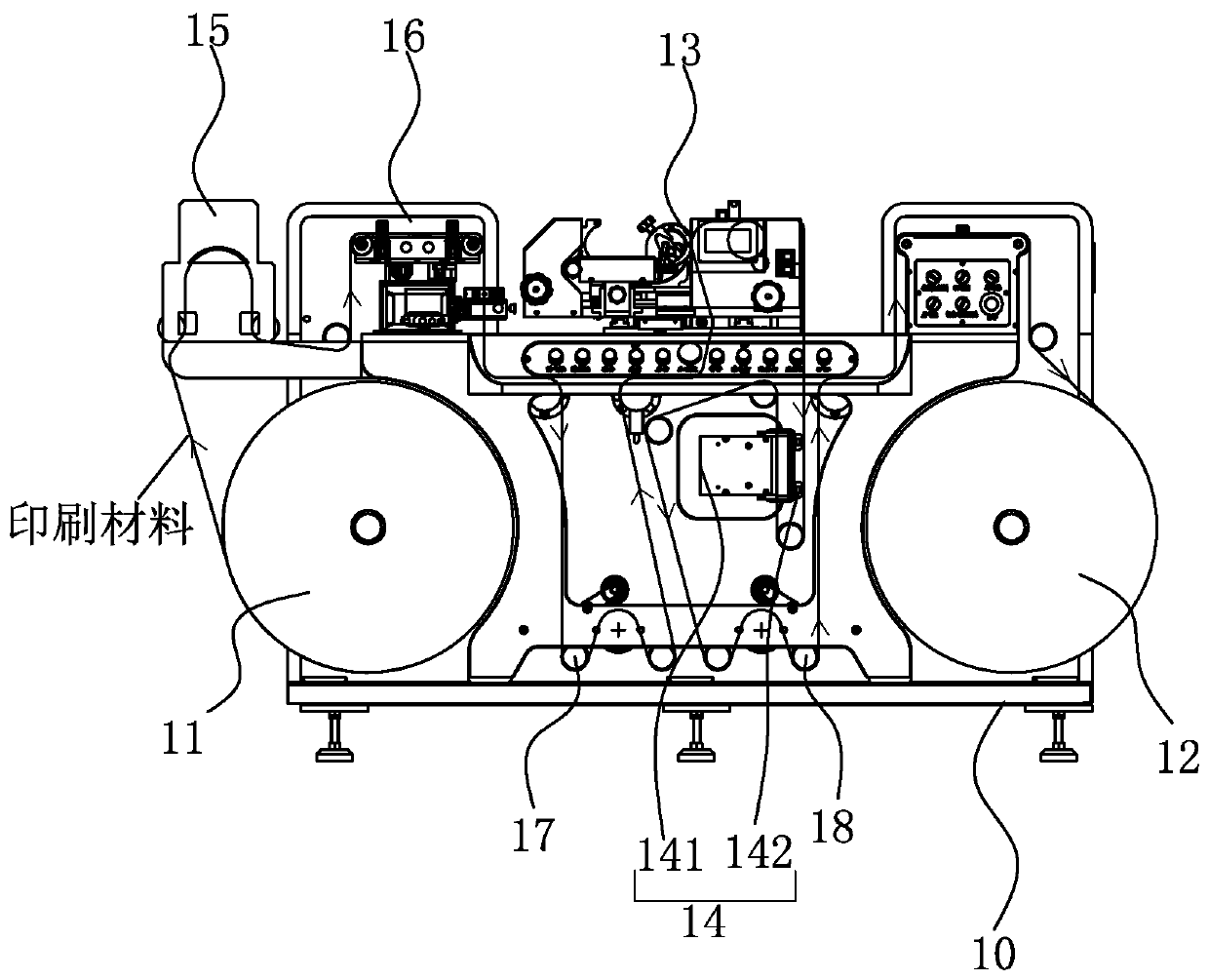

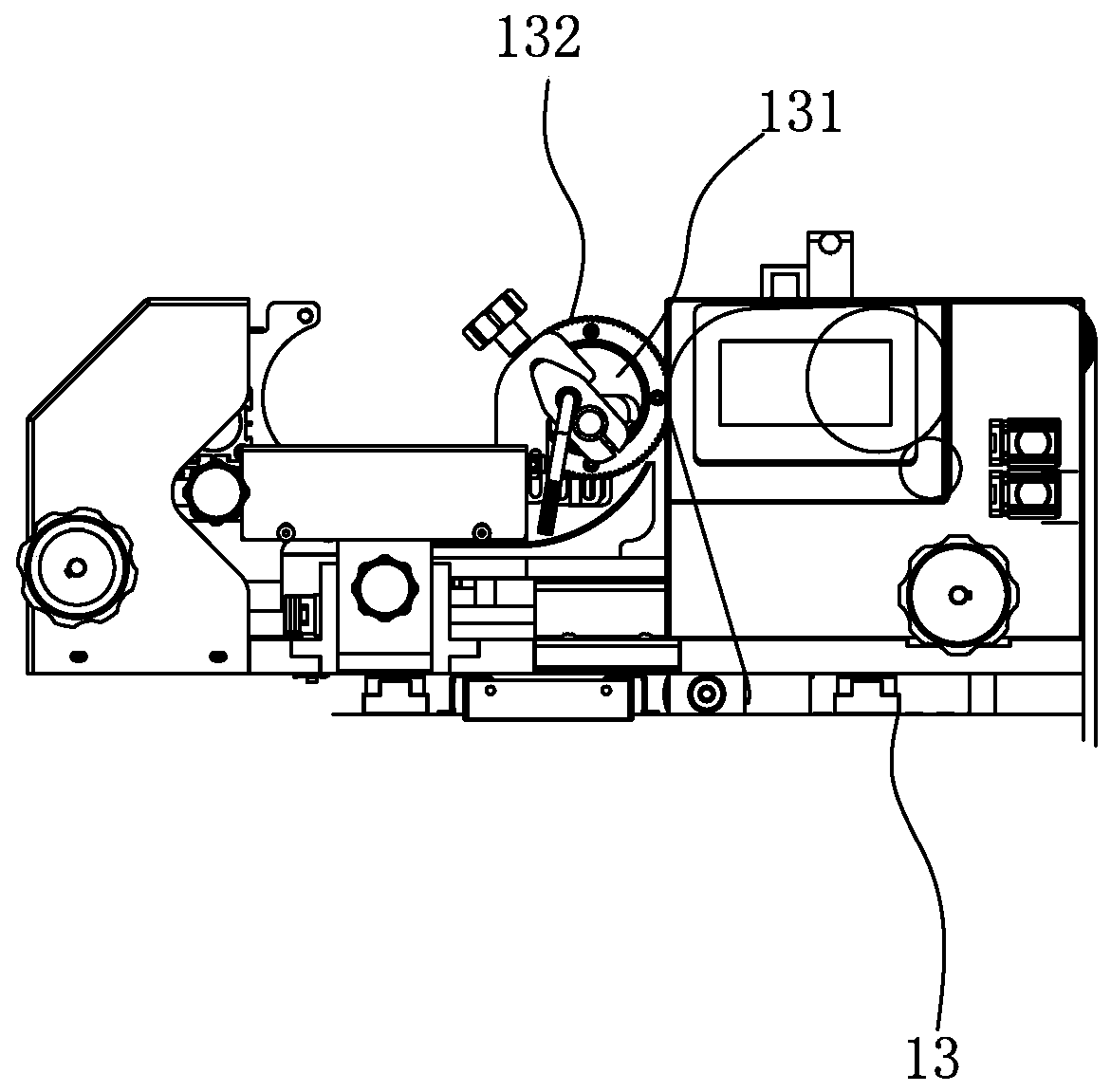

[0033] A roll screen printing device such as Figure 1 to Figure 2 , comprising a frame 10, an unwinding mechanism 11 and a winding mechanism 12 respectively arranged at both ends of the frame 10, and a screen printing mechanism 13 located between the unwinding mechanism 11 and the winding mechanism 12. The unwinding mechanism 11 unwinds the printed materials, the screen printing mechanism 13 prints the printed materials, and dries the printed materials through the provided drying mechanism 14, and the rewinding mechanism 12 rewinds the printed materials. The printing equipment works in a rolling printing mode. The unwinding mechanism 11 continuously r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com