Building 3D printing robot equipment and control method and system therefor

A 3D printing and robot technology, applied in the field of construction 3D printing robot equipment and its control, can solve the problems of complicated installation and dismantling procedures, high labor costs, and cumbersome construction, and achieve good flexibility, high degree of automation, and reduced manual labor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

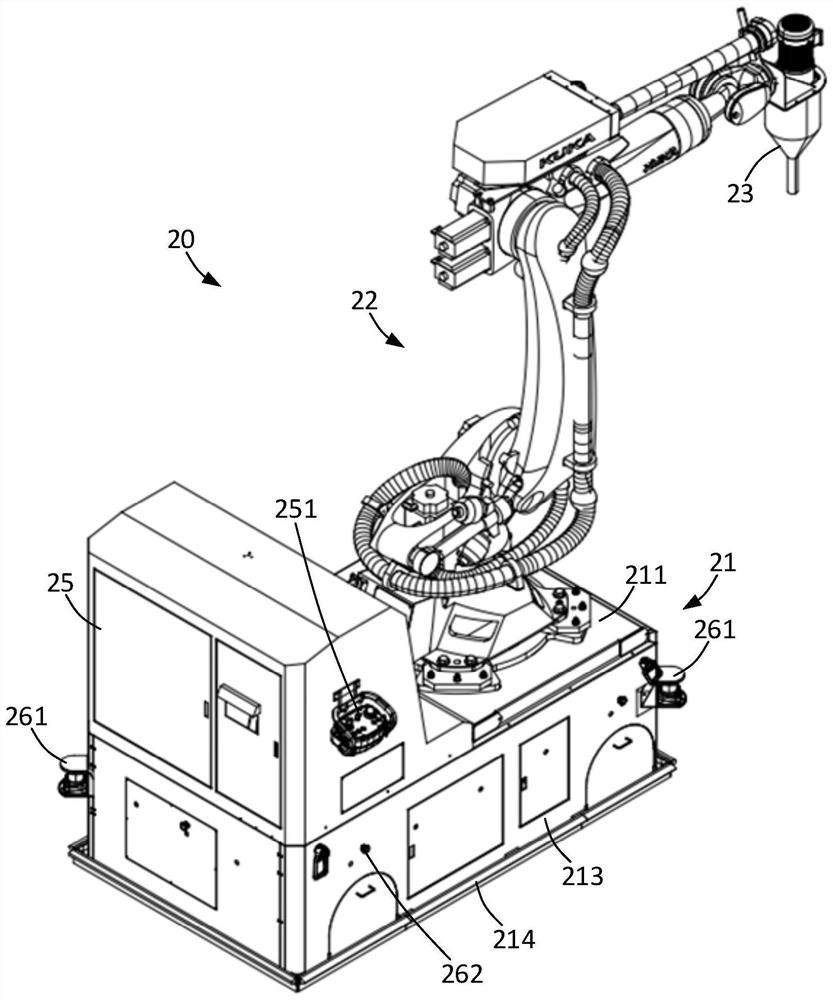

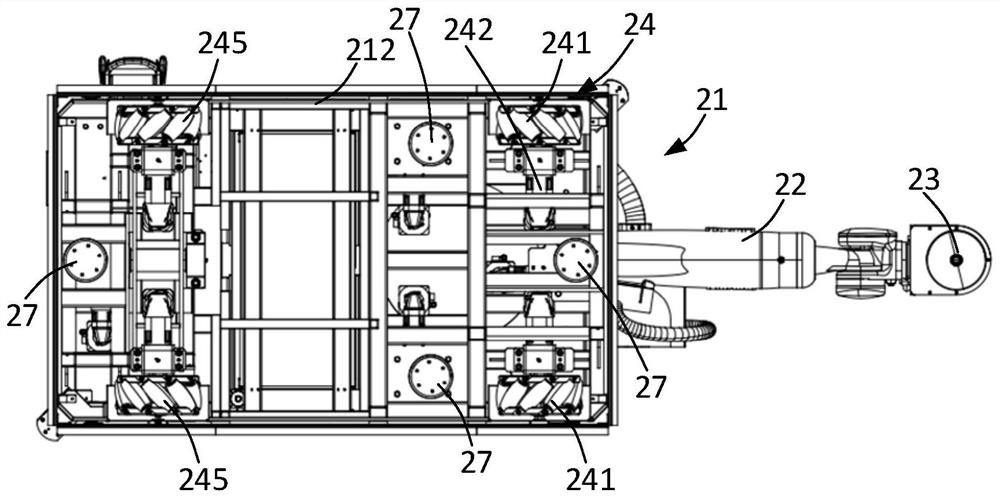

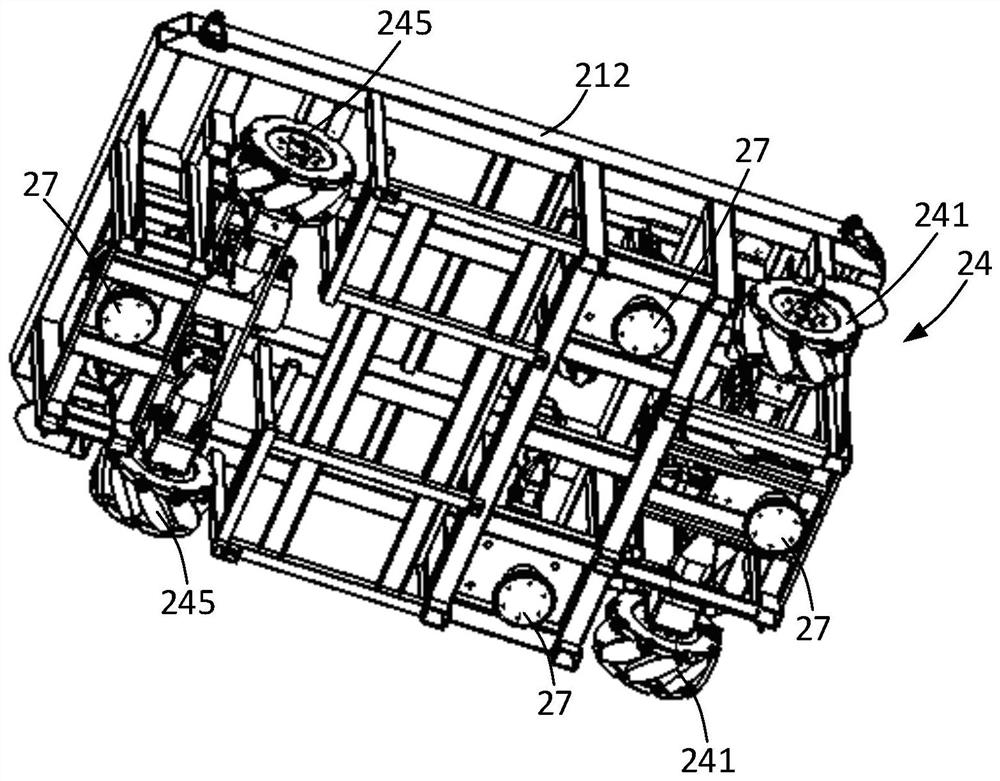

[0052] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0053] refer to figure 1, the present invention provides a construction 3D printing robot device and its control method and system, which combines 3D printing technology with the characteristics of robot intelligence and is applied in the construction field to solve the problems of low construction efficiency and high labor costs. The construction 3D printing robot equipment of the present invention realizes the self-propelling function through the set moving mechanism. In the moving mechanism, the two rear wheels on the rear side of the frame are installed on a rotatable and adjustable swing bridge, and the rotation adjustment of the swing bridge makes the The two rear wheels on the rear side can be adjusted up and down to adapt to complex working conditions. When the working surface is uneven, the two rear wheels can be adjusted up and down t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com