Unattended operation automatic weighing system for mines

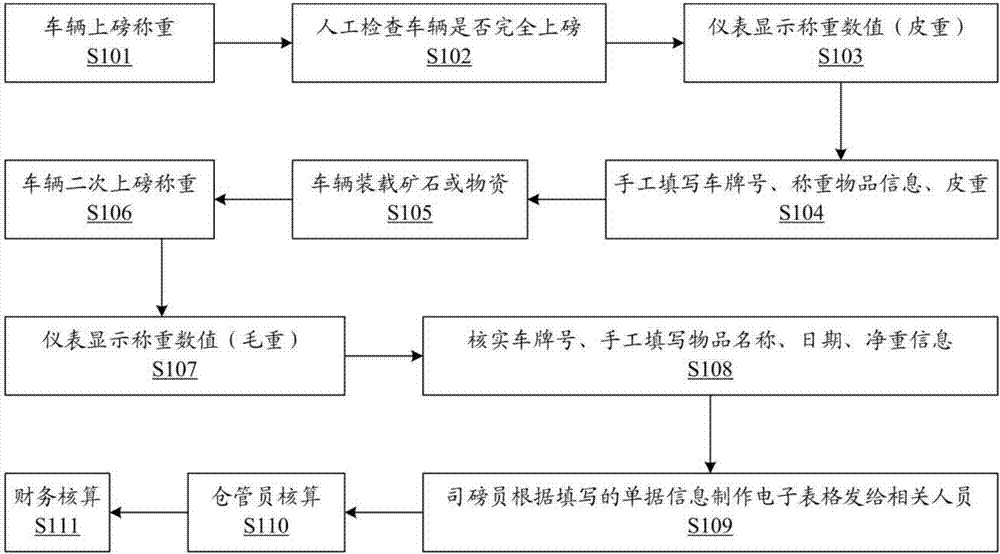

An automatic weighing and weighing system technology, which is applied to the detailed information of weighing equipment, weighing, and weighing auxiliary equipment, etc., can solve the problems of inconvenient school team and search, unable to find, and economic loss of the company, and achieve The effect of shortening the time to obtain information, reducing the trouble of reporting, and protecting the interests of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0065] First, a general explanation——

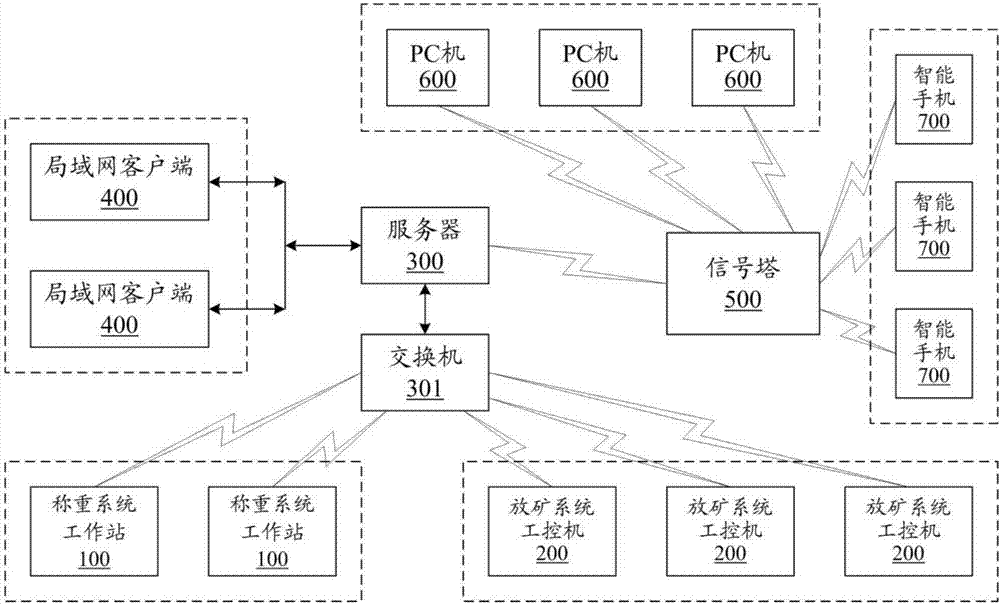

[0066] The mine unattended automatic weighing system of the present invention mainly includes three parts: an ore-drawing terminal, a weighing terminal and an inquiry terminal. end, of which,

[0067] The ore-drawing terminal includes: ore-drawing management software, industrial computer, camera, card reader, etc., which are used to automatically collect ore-drawing information such as license plate number, ore-drawing time, ore-drawing location, and snapshot images. In the case of optical fiber, it is directly transmitted to the server at the query end for storage through optical fiber. In the case of no optical fiber, the mining information is saved to the on-site industria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com