Printing device for plates

A printing and plate technology, applied in the field of plate printing devices, can solve problems such as low printing efficiency, and achieve the effect of improving efficiency and reducing manual operation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

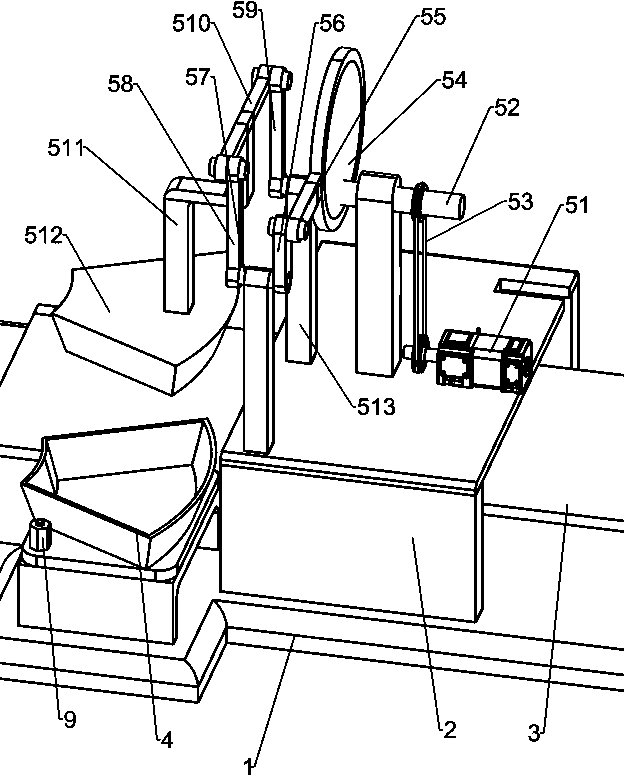

[0046] A plate printing device, such as Figure 1-2 As shown, it includes a base 1, an installation platform 2, a workbench 3, an ink pad plate 4, and a printing mechanism 5. The left side of the base 1 is provided with an installation platform 2, and a workbench 3 is installed between the left and right sides of the base 1. The workbench 3 Located below the installation platform 2, an ink pad plate 4 is provided on the rear side of the right part of the base 1, and a printing mechanism 5 is provided on the rear side of the top of the installation platform 2.

[0047] When it is necessary to print the surface of the plate, the ink pad is first poured into the ink pad plate 4, and the plate is placed on the workbench 3 so that it is located under the printing part of the printing mechanism 5, and then the parts in the printing mechanism 5 are started, and the ink pad is placed on the printing mechanism. Under the action of other components in the printing mechanism 5, the print...

Embodiment 2

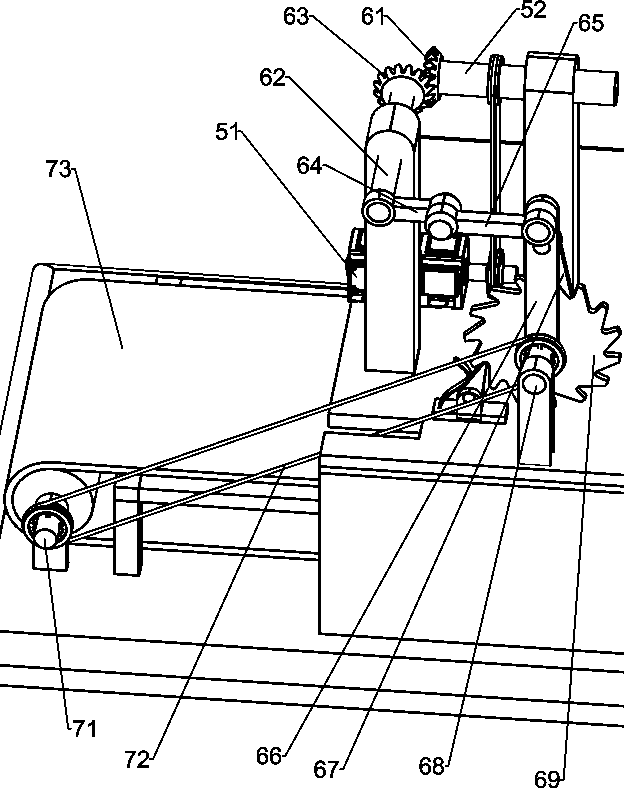

[0049] special reference Figure 1-3 and Figure 5The printing mechanism 5 includes a motor 51, a rotating rod 52, a first belt assembly 53, a rotating disk 54, an annular push rod 55, a first swinging rod 56, a first rotating shaft 57, a second swinging rod 58, a third swinging rod 59, a horizontal Rod 510, connecting rod 511, sponge seal 512 and the first fixed rod 513, motor 51 is installed in the middle of mounting table 2 top left sides, and mounting table 2 top central rotation type is provided with rotating rod 52, rotating rod 52 left sides and motor 51 The first belt assembly 53 is installed between the output shafts, the right end of the rotating rod 52 is connected to the turntable 54, the outer wall of the turntable 54 is covered with an annular push rod 55, and the end of the annular push rod 55 is rotatably connected to the first swing rod 56, and the right side of the mounting table 2 The rear rotating type is provided with a first rotating shaft 57, the end of...

Embodiment 3

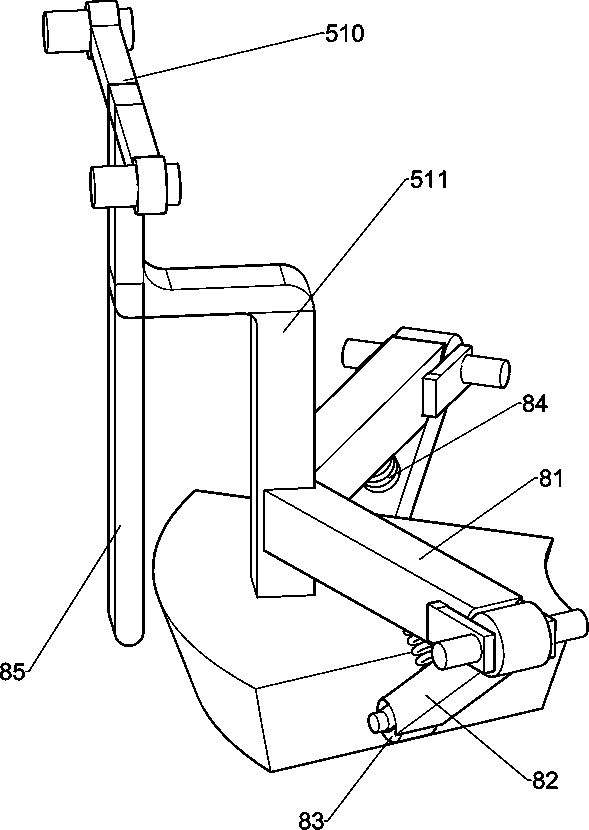

[0054] Overall, such as Figure 1-2 and Figure 4 As shown, it also includes a fixing mechanism 8, the fixing mechanism 8 includes a V-shaped rod 81, a second fixed rod 82, a roller 83, a spring 84 and a third fixed rod 85, and a V-shaped connection rod is arranged between the front and rear sides of the bottom of the connecting rod 511. Rod 81, the front and rear ends of V-shaped rod 81 are all rotatably equipped with second fixed rod 82, the second fixed rod 82 ends on both sides are all equipped with rollers 83, the second fixed rod 82 tops on both sides are connected with V-shaped rod 81 Springs 84 are connected between the bottoms, and a third fixed rod 85 is installed on the left bottom of the connecting rod 511 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com