Automatic midsole printing machine

A printing machine and automatic technology, applied in printing machines, rotary printing machines, screen printing machines, etc., can solve the problems of high labor consumption and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

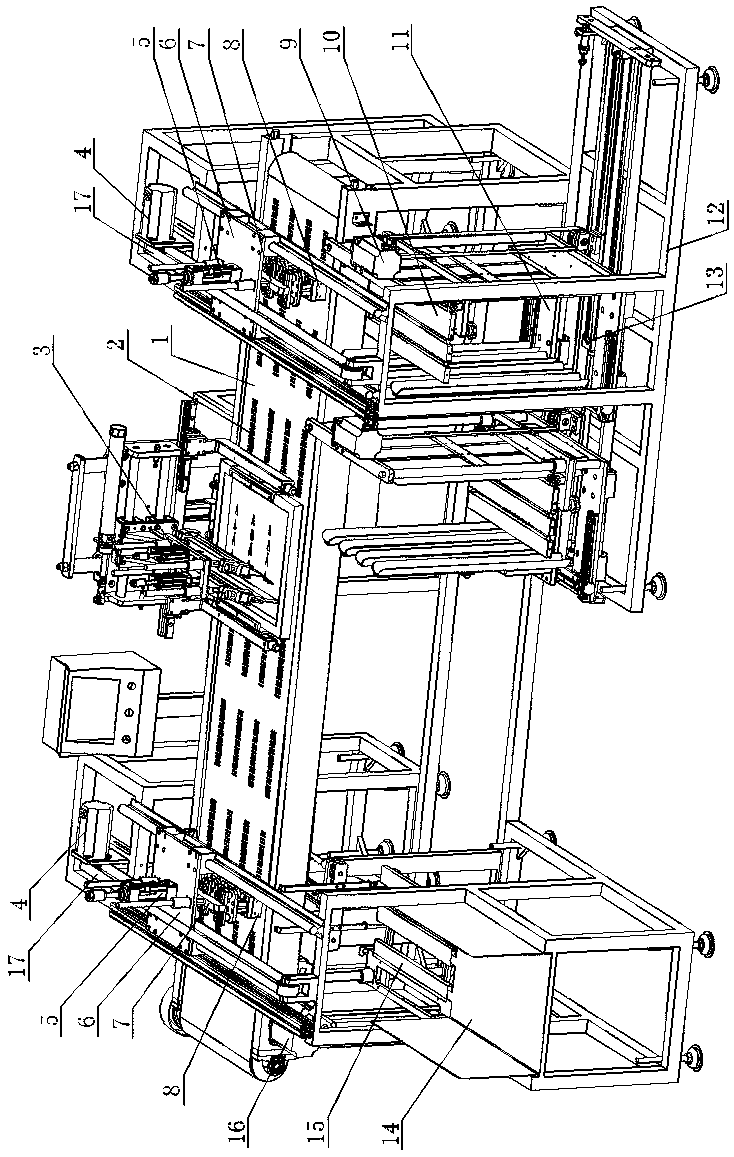

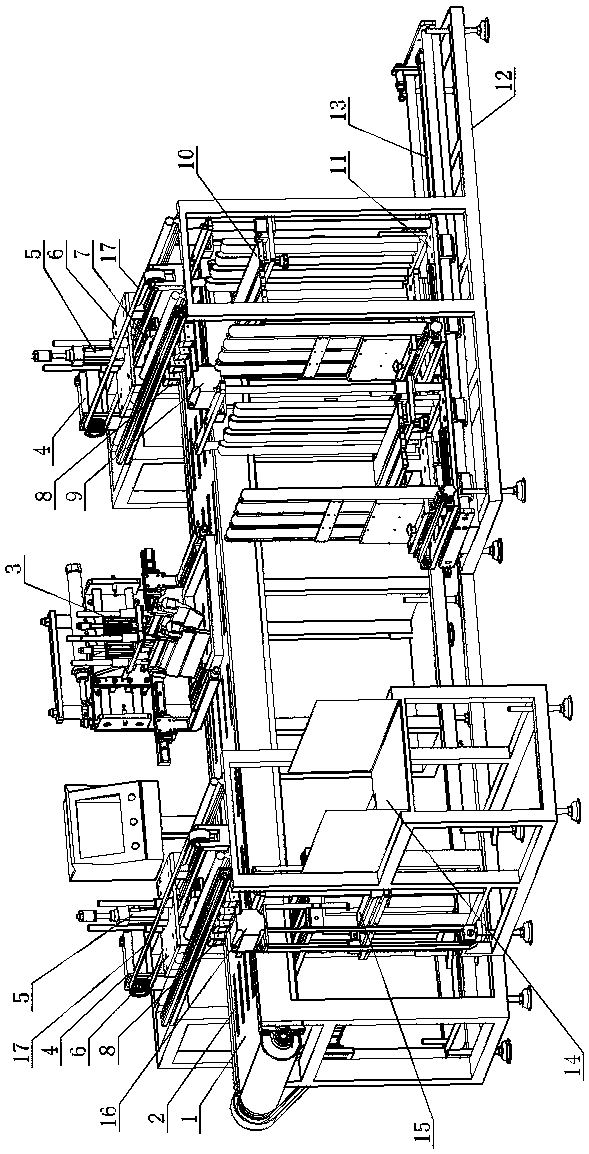

[0018] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

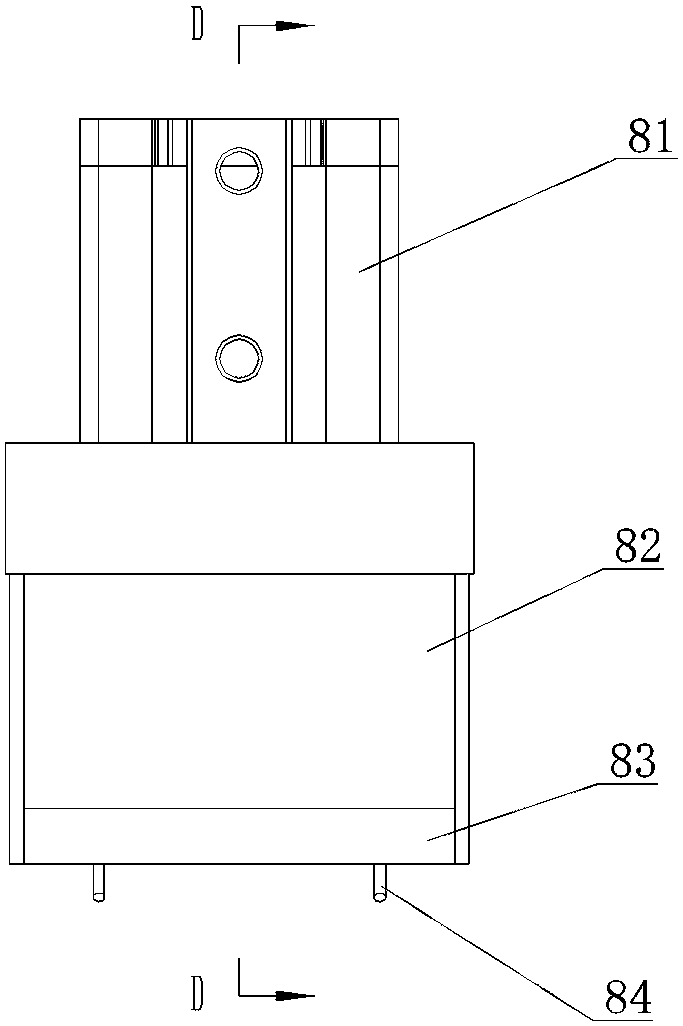

[0019] As shown in the figure, the automatic midsole printing machine of the present invention includes a midsole conveyor belt 1 arranged horizontally and a midsole printing part 3 arranged above the midsole conveyor belt, and the midsole conveyor belt 1 is driven by a main motor for stepping Feeding action, the surface of the midsole conveyor belt 1 is provided with a vacuum suction hole 2, the feeding end (right end) of the midsole conveyor belt 1 is provided with a feeding part and a loading and clamping part, and the discharge end of the midsole conveyor belt 1 (Left end) There is a blanking part and a blanking clamping part; the upper and lower material clamping parts adopt the same structure, and the upper and lower material clamping parts include the clamping slide 6 and the pinning assembly 8, and the clamping slide 6 Sliding action in the longitudinal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com