3D printing device and method for super high-rise building

A 3D printing, high-rise building technology, applied in the direction of construction, building structure, building materials processing, etc., can solve the problem that the core tube and the outer frame of the core tube cannot be printed at the same time, achieve high construction efficiency, expand the scope of work, and automate high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

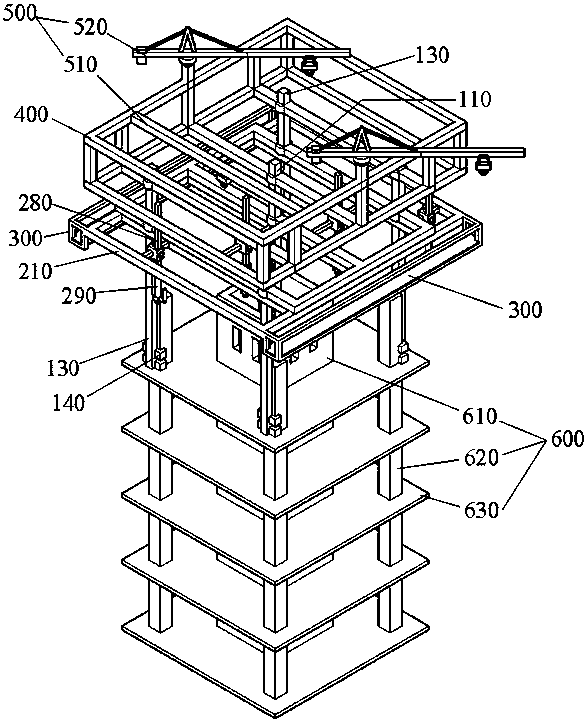

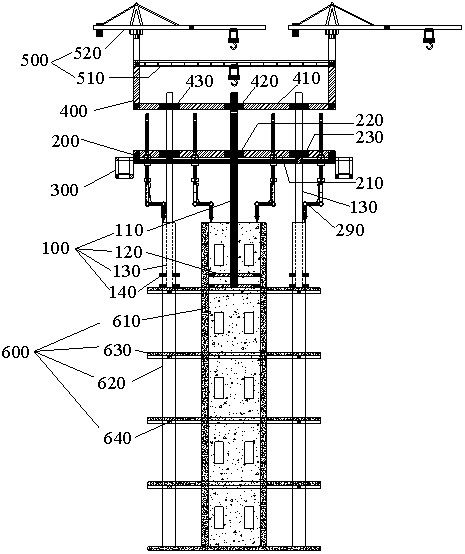

[0046] combine figure 1 and figure 2 As shown, the super high-rise building 600 includes a core tube 610 in the middle and an outer frame 620 located on the periphery of the core tube 610. The outer frame 620 includes columns and horizontal beams (not shown), and steel beams are also provided at the height of a standard floor 640 , lay profiled steel plates (not shown) on the steel beam 640 , and then pour concrete to form the floor slab 630 . The super high-rise building 3D printing device provided by the present invention can be used to print the core tube 610, the outer frame 620, and the floor plate 630, and can be used to install the steel beam 640 and the profiled steel plate, thereby realizing the integrated printing of the super high-rise building 600.

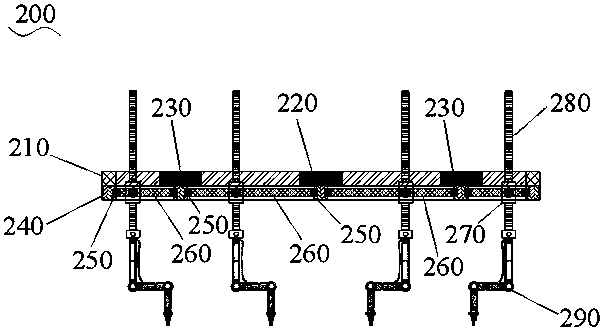

[0047] The 3D printing device for a super high-rise building provided in this embodiment includes a guide rail assembly 100 , an alternate climbing 3D printing assembly 200 , a guide rail lifting assembly 400 , and a...

Embodiment 2

[0055] The present embodiment provides a kind of super high-rise building 3D printing method, refer to below Figure 5 to Figure 8 and combine Figure 1 to Figure 4 This 3D printing method is further introduced. The 3D printing method comprises the steps of:

[0056] Step 1: If Figure 5 As shown, the core cylinder 610 and the outer frame 620 of the super high-rise building 600 are printed synchronously by using the alternate climbing 3D printing assembly 200 of the super high-rise building 3D printing device in the first embodiment. Specifically, the following steps may be included:

[0057] (1) Start the core lifting driving brake 1 220 and the peripheral lifting driving braking 1 230 through the control command, and drive the lifting frame 1 210 to slide and brake along the outer walls of the core guide rail 110 and the peripheral guide rail 130 respectively, so that the 3D printing head 290 is lifted to a predetermined height;

[0058] (2) Start the horizontal driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com