Production line and printing process for printing paint on metal sheet material

A metal plate and production line technology, which is applied in the post-processing of printing, general parts of printing machinery, printing, etc., can solve the problems of increasing the scrap rate, affecting the appearance, and inaccurate painting positions, so as to improve production efficiency and production The effect of output, high degree of automation, and precise painting position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing, protection scope of the present invention is not limited to the following:

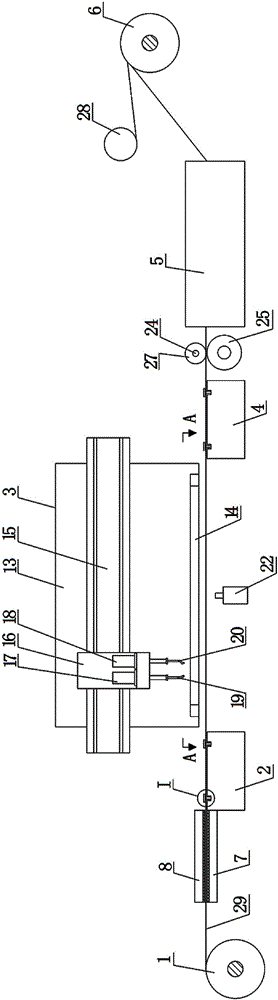

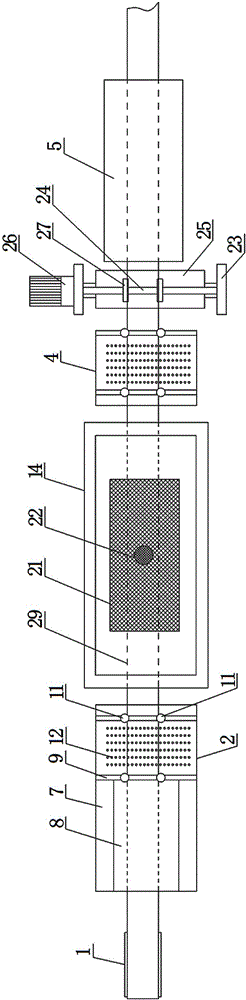

[0024] Such as Figure 2~5 As shown, a production line for printing paint on metal plates, which includes a metal plate unwinding mechanism 1, a dust wiping device, a left suction box 2, an automatic printing device 3, a right suction box 4, Traction mechanism, paint drying device 5 and finished product rewinding mechanism 6, described metal plate unwinding mechanism 1 comprises a stepper motor and a drum, the output end of the stepper motor is connected with the rotating shaft of the drum, and the described ash wiping device is composed of the following Pressing plate 7 and the upper pressing plate 8 that is arranged on the top of lower pressing plate 7 are composed, and the upper surface of upper pressing plate 8, the lower surface of lower pressing plate 7 are all provided with dust-wiping cloth, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com