Manual feeding-discharging steel cylinder roll-printing device

A manual, cylinder technology, applied in printing, stamping and other directions, can solve the problems of not being able to achieve printing, unable to automatically adjust the engraving angle of the rolling dial, and achieve the effect of improving work efficiency, high intelligence, and simple and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

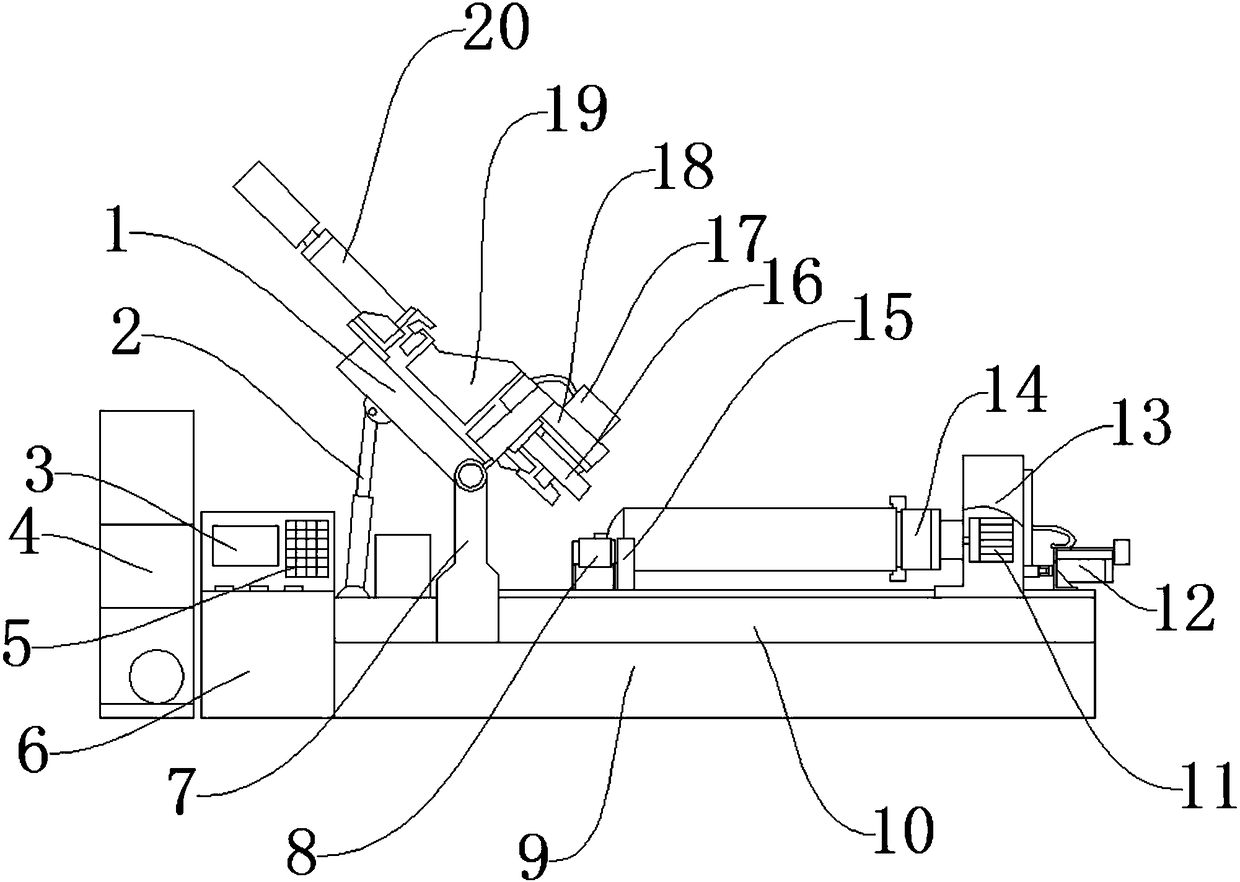

[0018] Such as figure 1 As shown, a manual loading and unloading steel cylinder roll printing device includes the base 9 and the rolling dial 16, the slide rail 10 is arranged above the base 9, and the slide rail 10 tail is provided with a The sliding seat 13 is provided with the servo motor 11 inside the sliding seat 13, the fixed chuck 14 is provided at the front end of the sliding seat 13, and the tail oil cylinder 12 is provided at the rear of the sliding seat 13. The bottle head rotating roller 8 is arranged above the head of the slide rail 10, and the bottle body support 15 is arranged on a side of the bottle head rotating roller 8 close to the sliding seat 13. Above the head of the slide rail 10 The support seat 7 is provided, the upper seat 1 is arranged above the support seat 7, the upper slide seat 19 is arranged on the upper seat 1, and the letter press cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com