Equipment and method for coating surfaces of objects with three-dimensional patterns

A technology of object surface and equipment, which is applied in the field of printing equipment, can solve the problems of complicated process, inability to paint three-dimensional patterns, and difficult realization, etc., and achieve the effect of high bonding strength, clear pattern, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

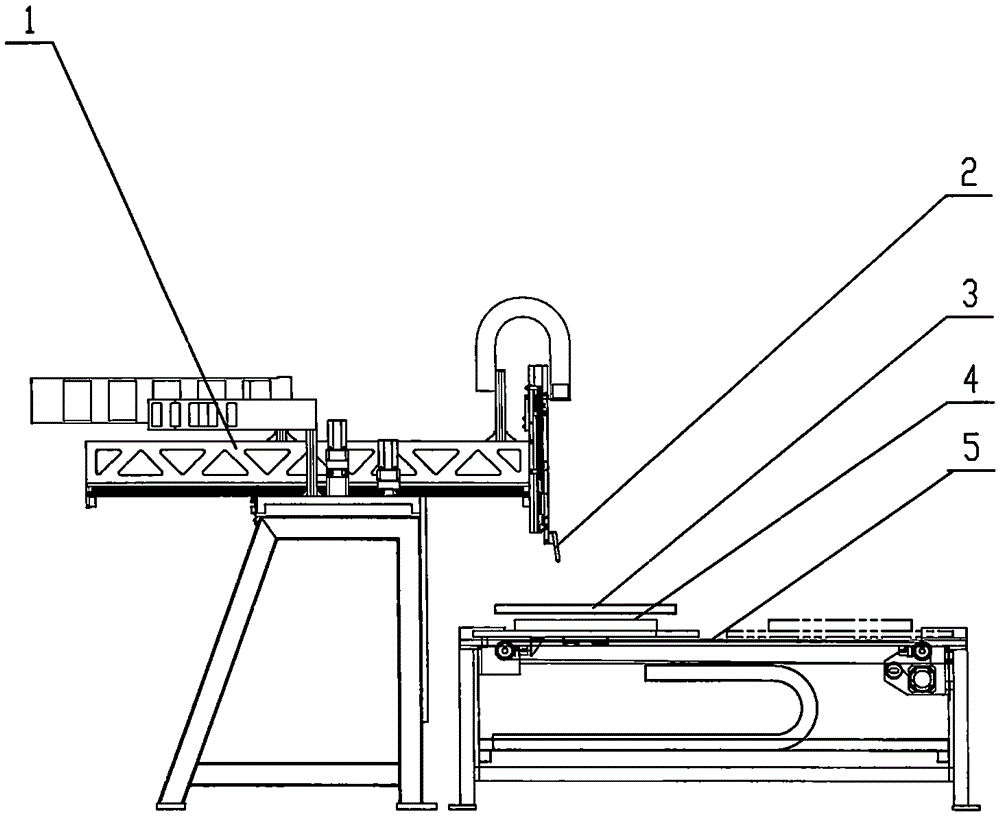

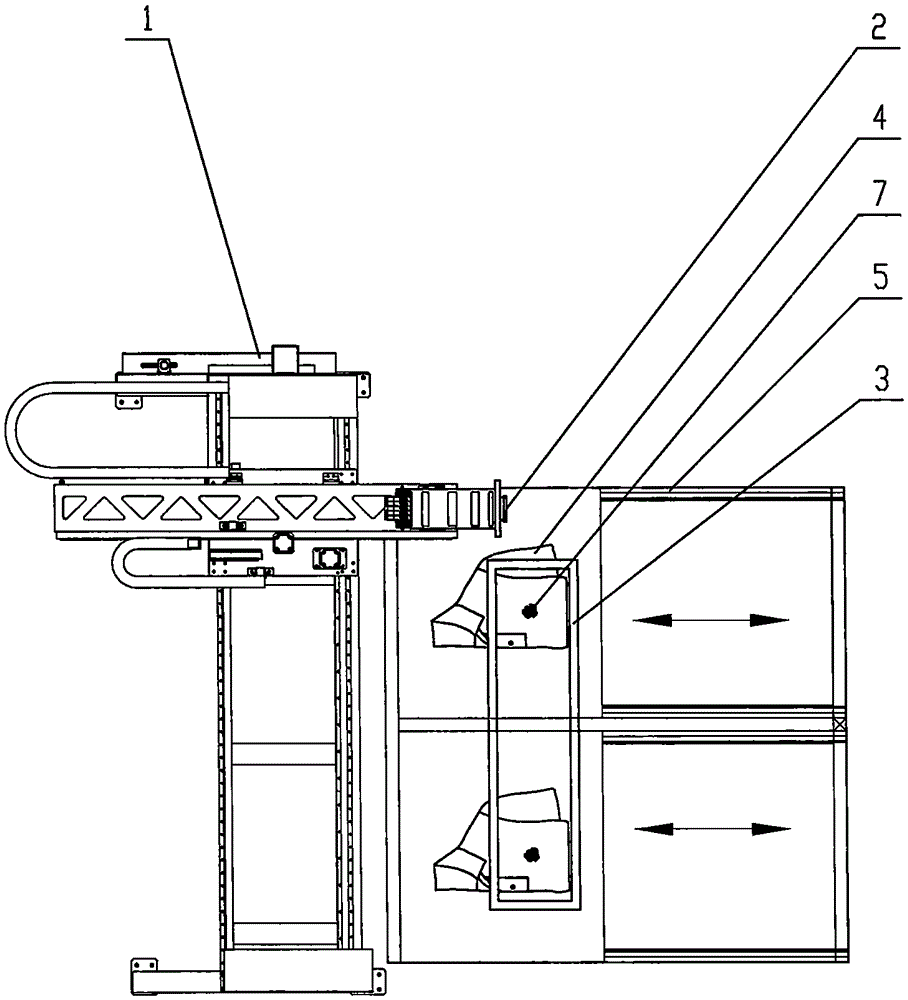

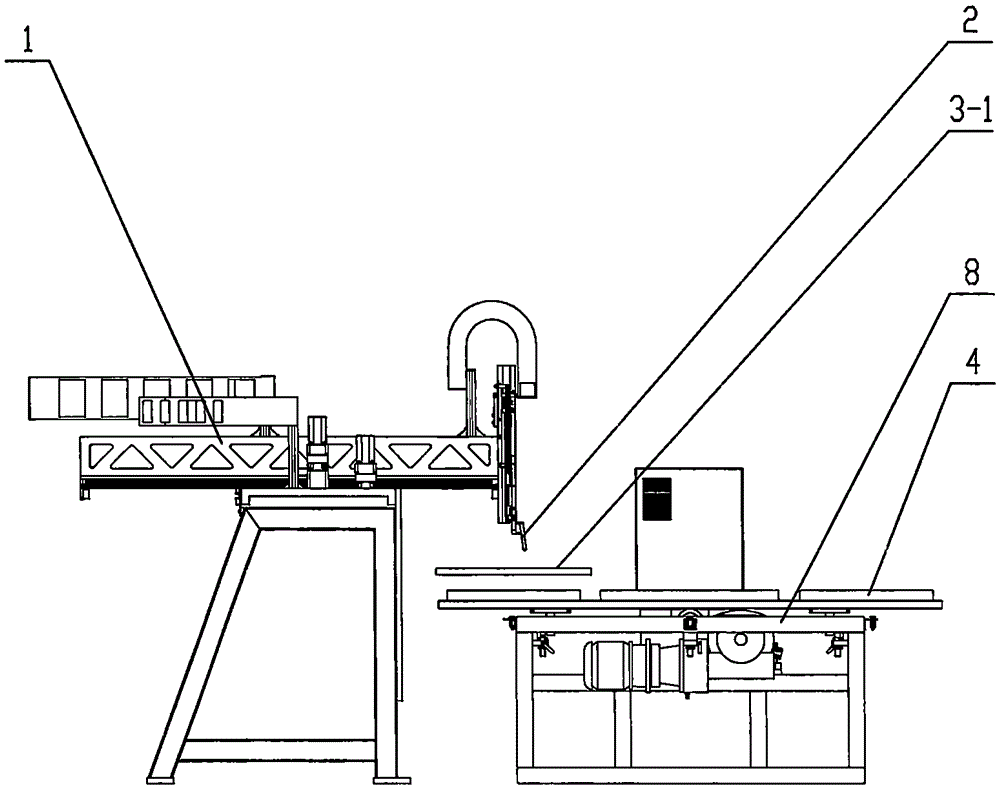

[0034] Embodiment one: if Figure 1-7 As shown, a device for coating three-dimensional patterns on the surface of an object includes screen printing equipment, a double-station worktable 5 or a multi-station rotary workbench 8, and the screen printing equipment has three-axis linkage functions of X, Y, and Z. The screen printing scraper 2 is fixed on the Z-axis of the screen printing equipment, the screen printing plate A3-1 or the screen printing plate B3-2 has patterns or cartoon pictures or trademark leakage holes, and the cutting edge of the screen printing scraper 2 is against the screen printing plate A3-1 or screen board B3-2 moves; polyurethane ink contains color or fluorescent or luminescent or foaming materials, which can quickly react and solidify when heated to form a foaming three-dimensional pattern; polyurethane ink passes through screen board A3-1 or screen The board B3-2 is printed on the workpiece 4, and the screen board A3-1 or the screen board B3-2 is fixed...

Embodiment 2

[0039] Embodiment two: if Figure 1-7 As shown, a method for coating a three-dimensional pattern on the surface of an object uses screen printing equipment, a double-station workbench 5 or a multi-station rotary workbench 8, and evenly, quickly and efficiently coats the surface of the workpiece 4. The steps of coating the three-dimensional pattern on the surface of the object are:

[0040] 1) Slurry the color paste or fluorescent powder or light-storing luminescent pigment on the disperser;

[0041] 2) Add the same kind of color paste or fluorescent powder paste or luminescent paste into polyurethane ink, and disperse evenly;

[0042] 3) Put the workpiece 4 to be printed on the double-station workbench 5 or the multi-station rotary workbench 8;

[0043] 4) Put polyurethane ink into screen board A3-1 or screen board B3-2, and turn on the screen printing equipment; the edge of screen printing scraper 2 moves against screen board A3-1 or screen board B3-2, The polyurethane ink...

Embodiment 3

[0045] Embodiment three: as Figure 1-7 As shown, in the equipment and method for coating three-dimensional patterns on the surface of objects, four-axis, five-axis or six-axis robots or joint robots can be used to replace the cantilever screen printing equipment 1 or the gantry screen printing equipment 6 . Other compositions and connections are the same as those in Embodiment 1 and Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com