Double-head connection installation method for flange plate of automobile axle housing and mechanism assembly of double-head connection installation method

A technology for flanges and axle housings, which is applied in the double-end connection method of automobile axle housing flanges and the field of mechanism assembly, which can solve the problems of easy occurrence of defective products, high labor intensity, and large waste of materials, etc., to achieve guaranteed Product quality, reduce labor intensity, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

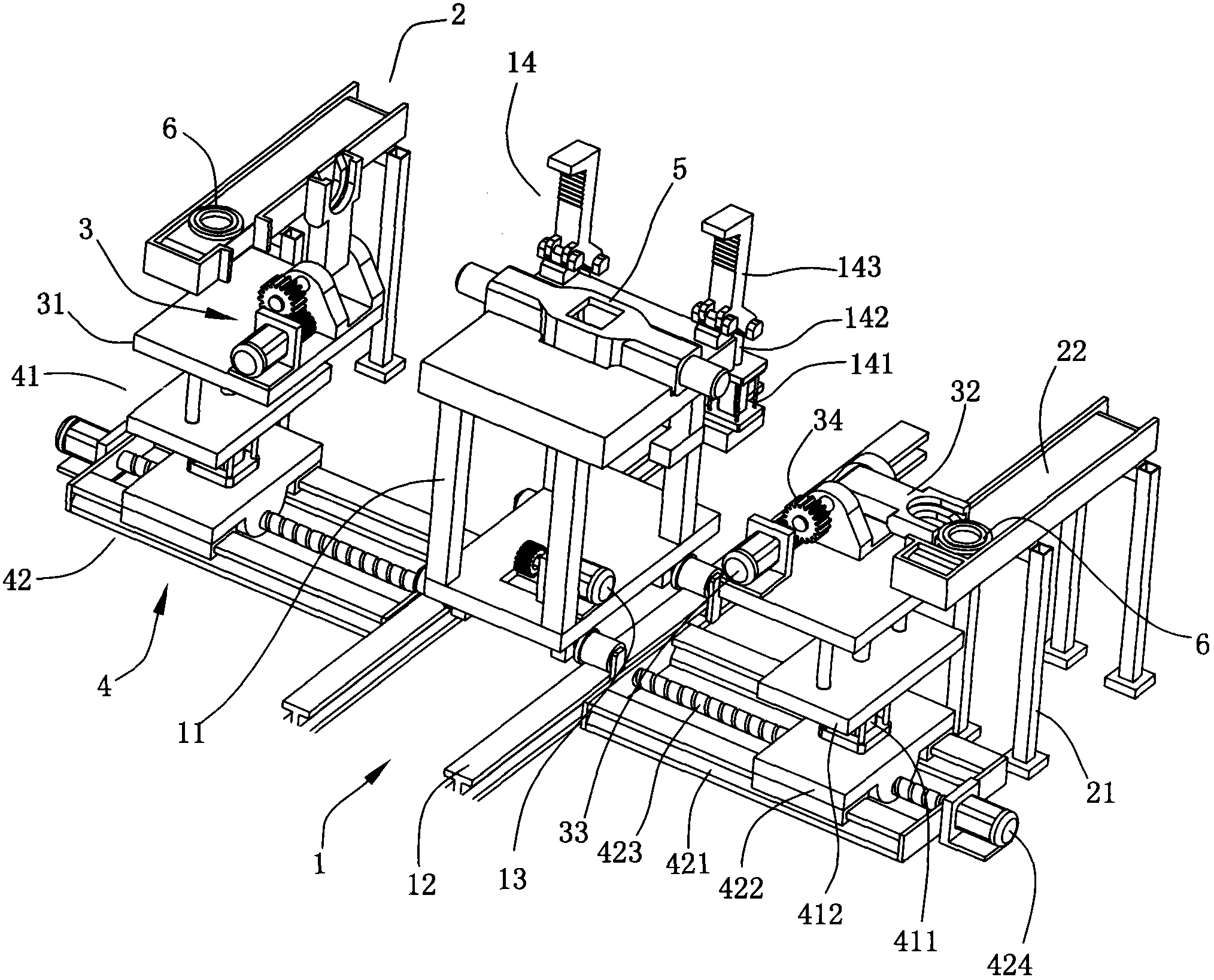

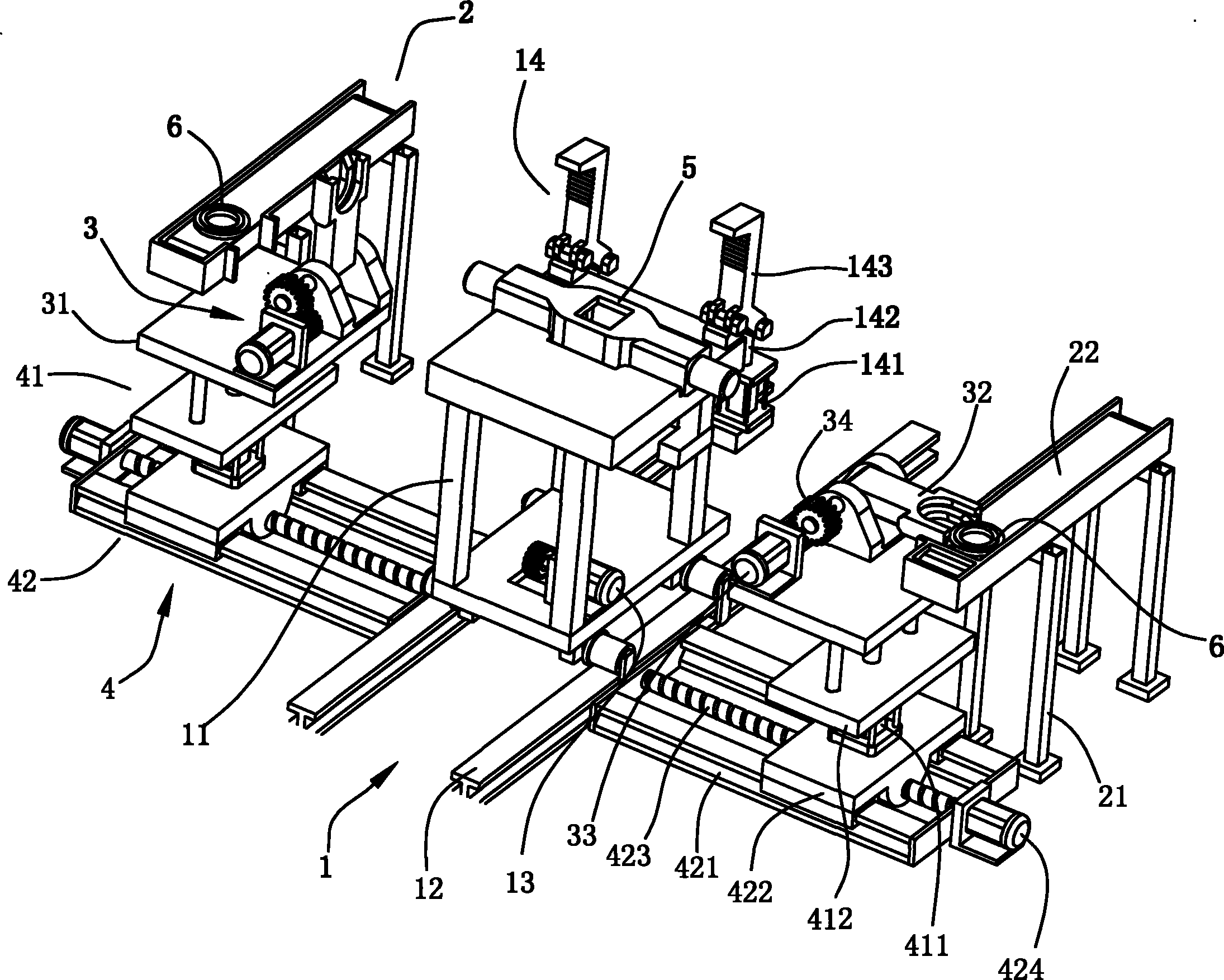

[0045] Example: see figure 1 , the embodiment of the present invention provides a kind of automobile axle housing flange double-head connection method, it comprises the following steps:

[0046] (1) Set up the pressing and grabbing machine 1, and control the work of the pressing and grabbing machine 1 to realize clamping and fixing the automobile axle housing 5;

[0047] (2) The flange plate conveying device 2 is set, and by controlling the flange plate conveying device 2 to work, to realize driving the conveying line to convey the flange plate 6 forward;

[0048] (3) The flange plate manipulator 3 is set, and by controlling the flange plate manipulator 3 to work, to realize grabbing the flange plate 6 on the conveying line, and transfer to a predetermined position, to be installed;

[0049] (4) flange plate feeding device 4 is set, by controlling the work of this flange plate feeding device 4, to realize that the flange plate 6 on the flange plate manipulator 3 is assembled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com