Profile cutting method of laser cutting automatic production line

An automated production line, laser cutting technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve problems such as low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

[0041] The invention discloses a profile cutting method of a laser cutting automatic production line, which comprises the following steps:

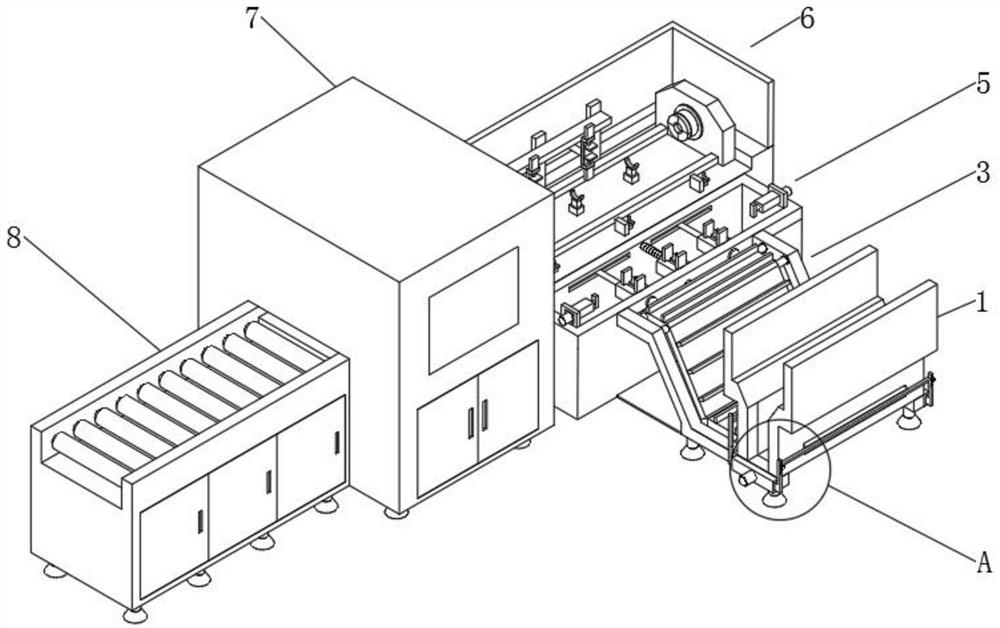

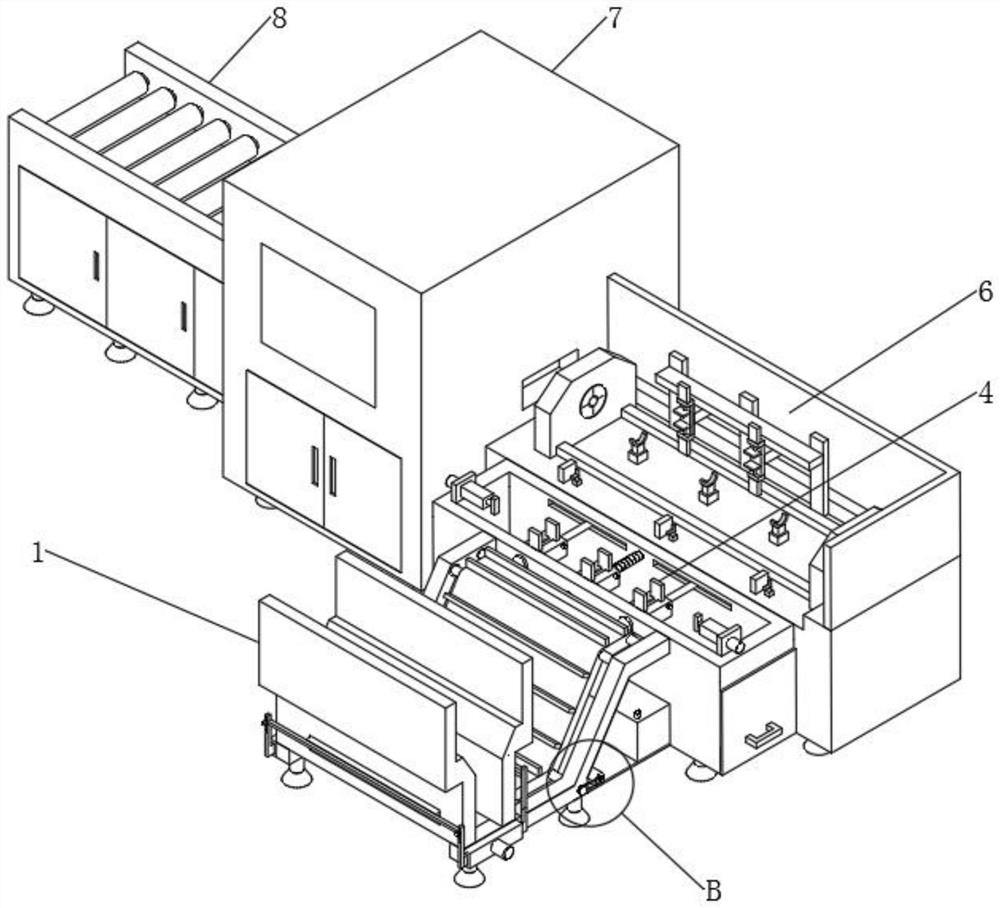

[0042] S1. The operator adjusts the parameters of the laser cutting automatic production line according to the shape and diameter of the profile to be cut. After the parameters are adjusted, add the profile to be cut to the feed rack 1;

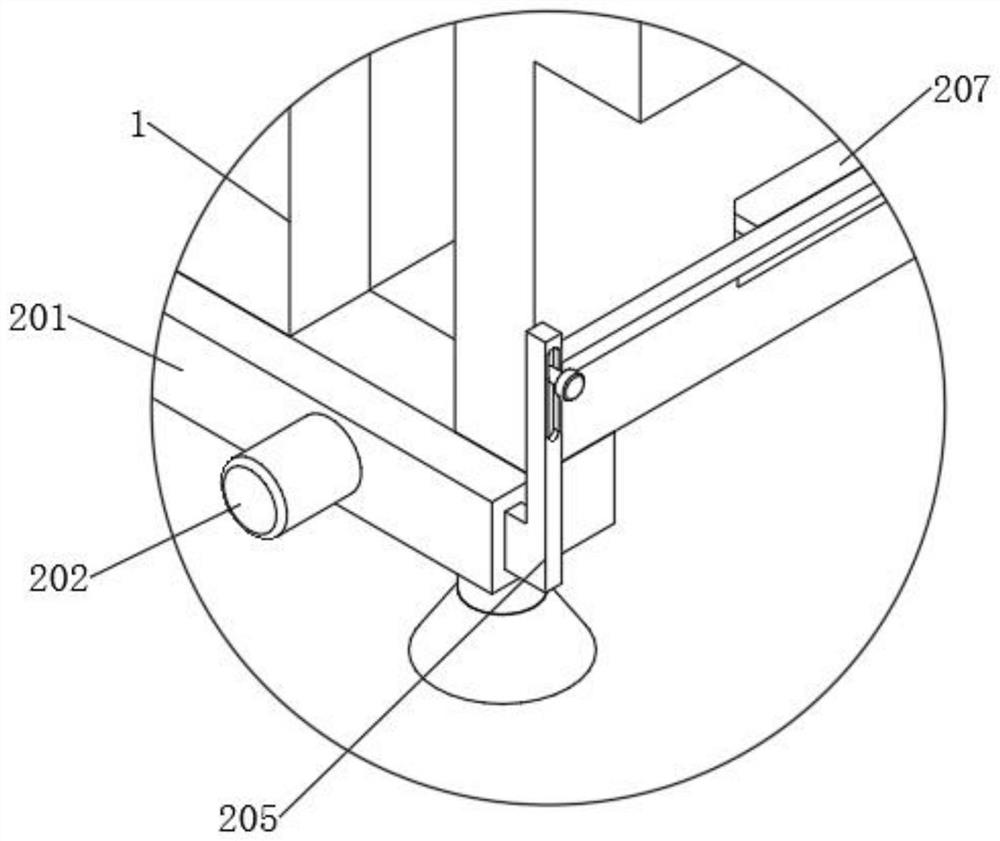

[0043] S2. A reciprocating sorting and unloading mechanism 2 is installed on the loading rack 1, and the profiles that need to be cut in the loading rack 1 are unloaded in an orderly manner through the reciprocating sorting and unloading mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com