An automatic prestressing fixture

A prestressing and fixture technology, which is applied in the direction of manufacturing tools, workpiece clamping devices, used abrasive processing devices, etc., can solve problems such as high labor intensity, affecting work efficiency, and bulky structure, so as to avoid loading prestressing, Guarantee product quality and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

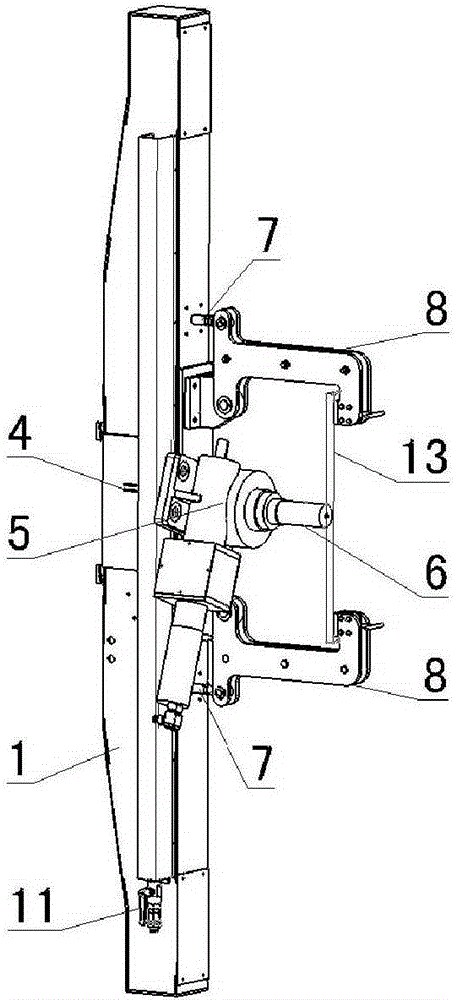

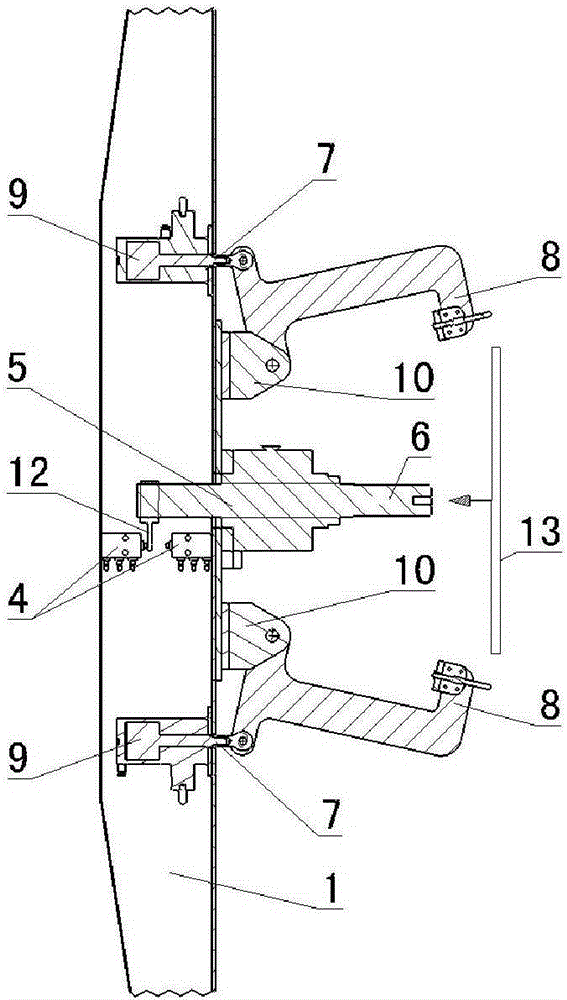

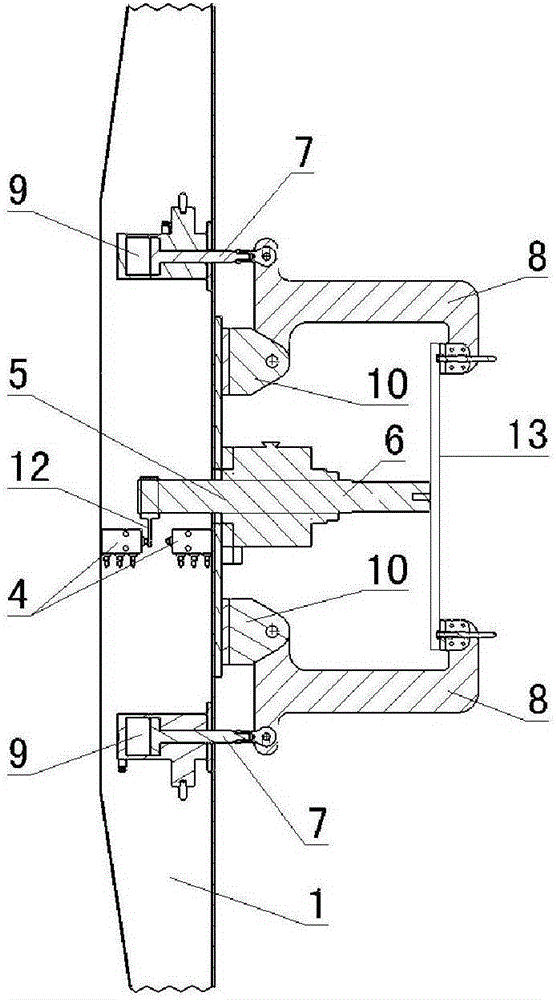

[0014] Referring to the accompanying drawings, the automatic prestressing fixture of the present application includes a force-bearing column 1, a force-applying mechanism 2 and a force-bearing mechanism 3, and the force-applying mechanism 2 and the force-bearing mechanism 3 are fixed on the force-bearing column 1, and the combination is applied to the workpiece 13. Prestressed, the load-bearing column 1 in the implementation is preferably a rigid cavity columnar structure,

[0015] The force-bearing mechanism 3 consists of a group of symmetrical mechanical arms 8. The force-bearing mechanism 3 can open and close the mechanical arm 8 according to the set trajectory through automatic control. It is the supporting basis for prestressed loading. Two mechanical forces The arms 8 are respectively fixed at appropriate positions on the side of the load-bearing column 3, and the front ends of the two mechanical arms 8 are respectively bent to form load-bearing points, and the other end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com