Patents

Literature

48results about How to "Stable and precise rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

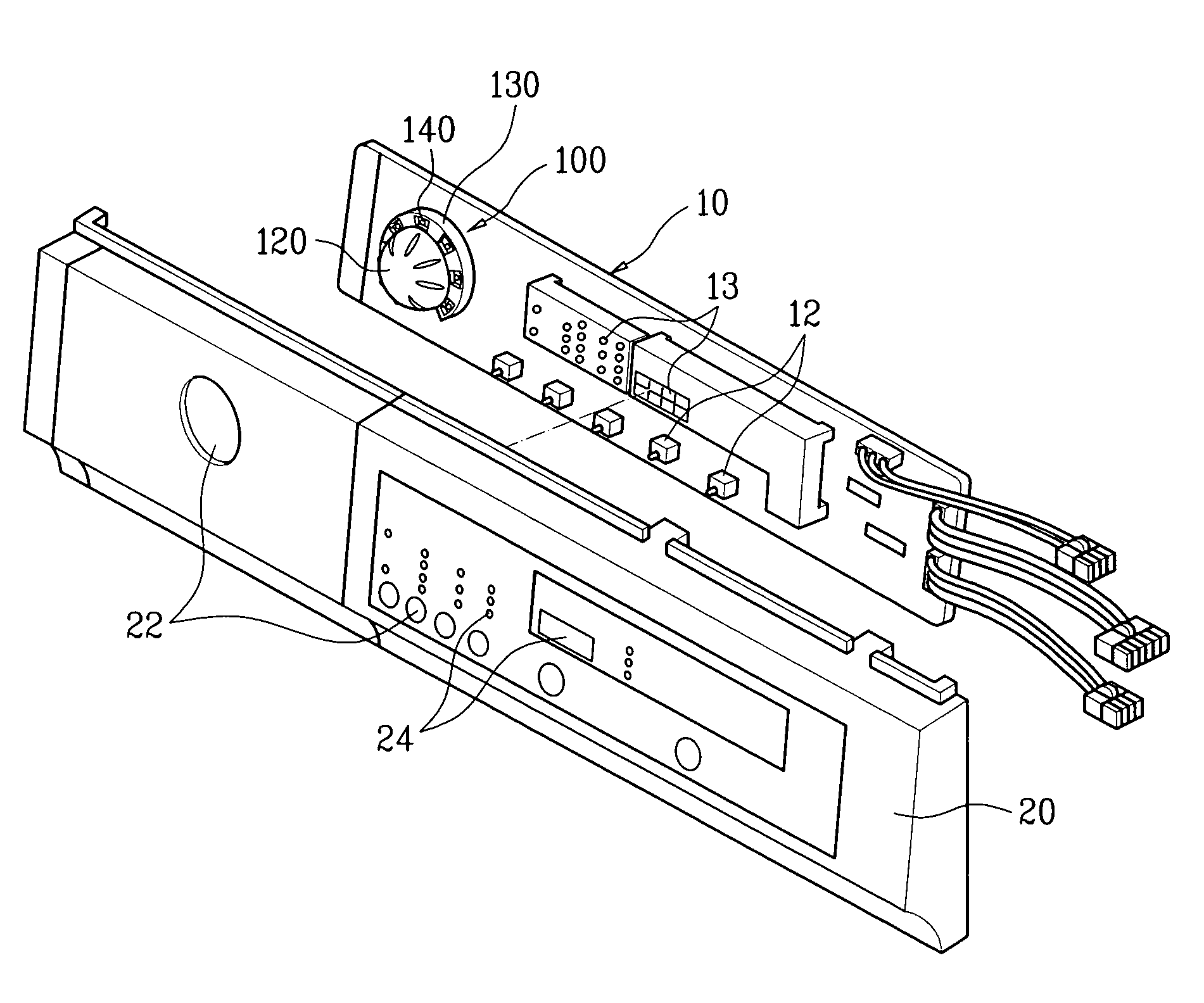

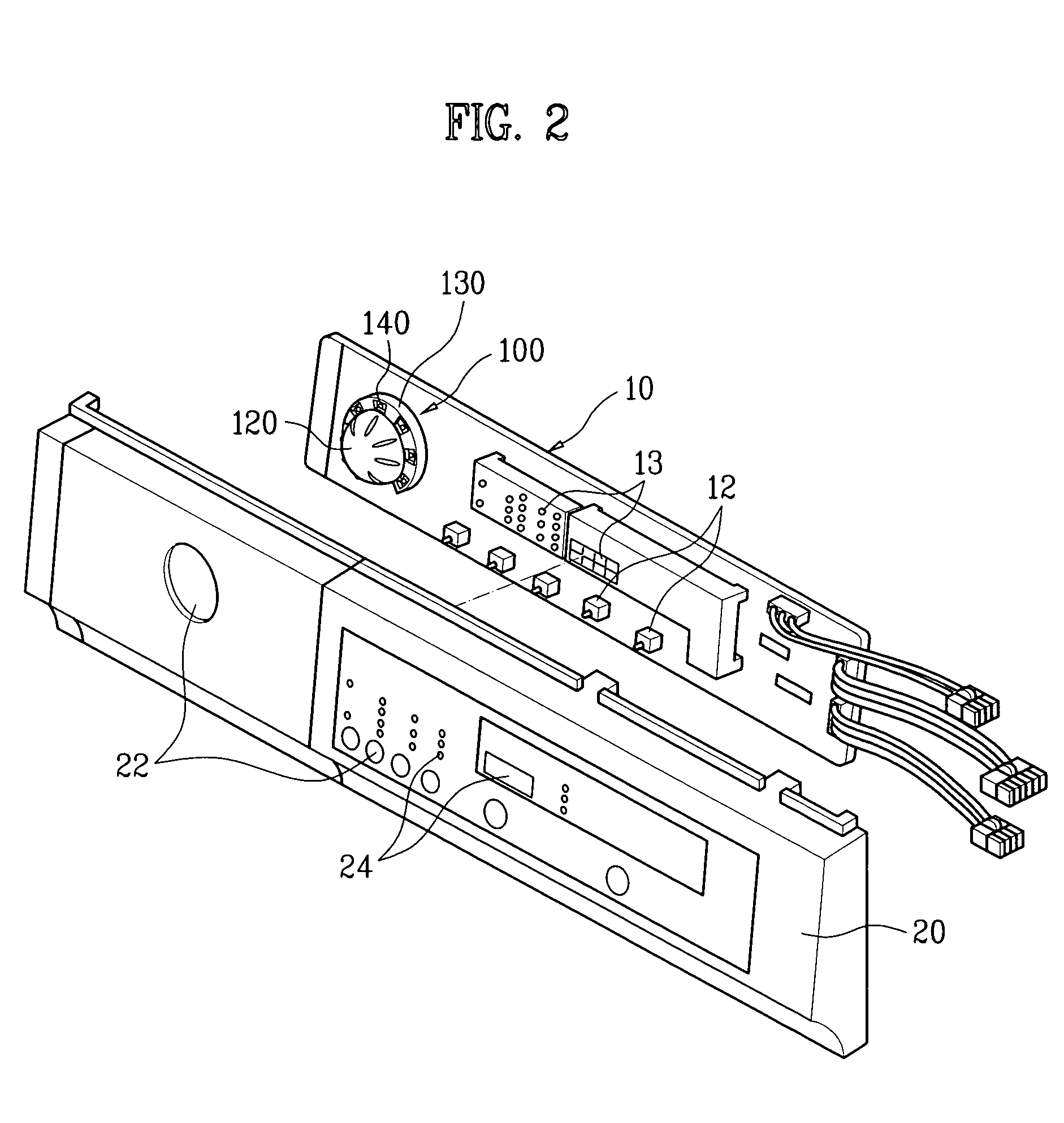

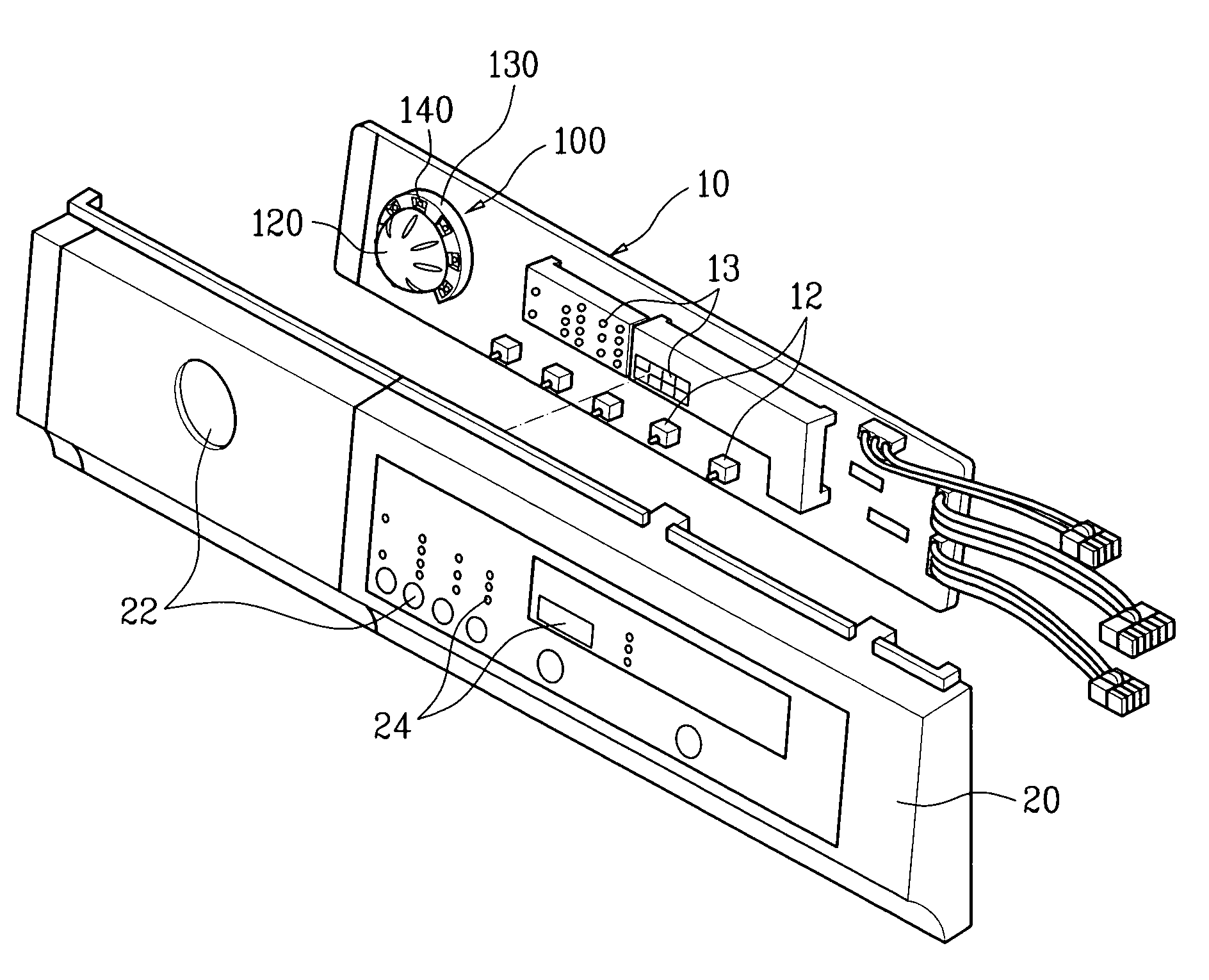

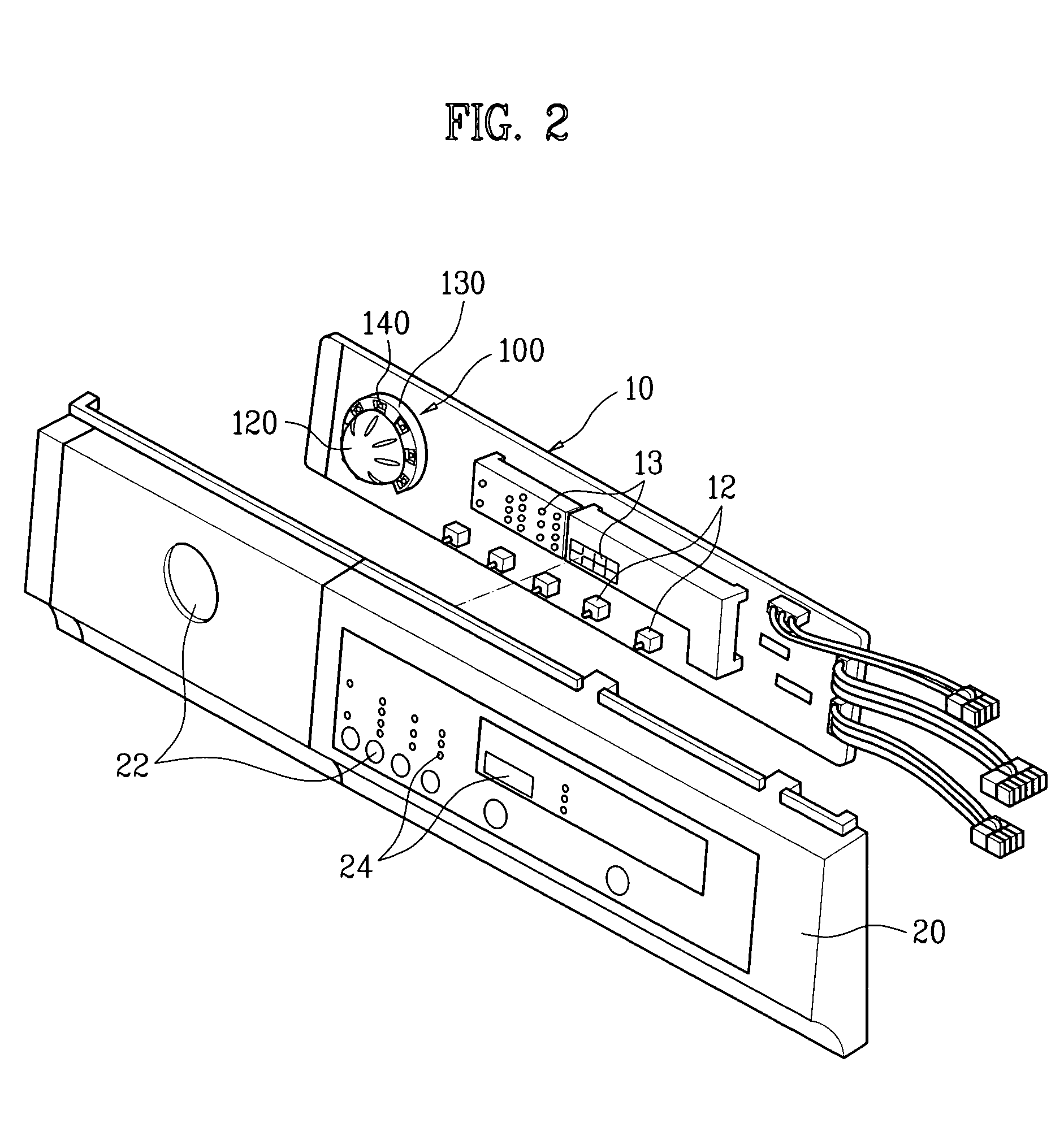

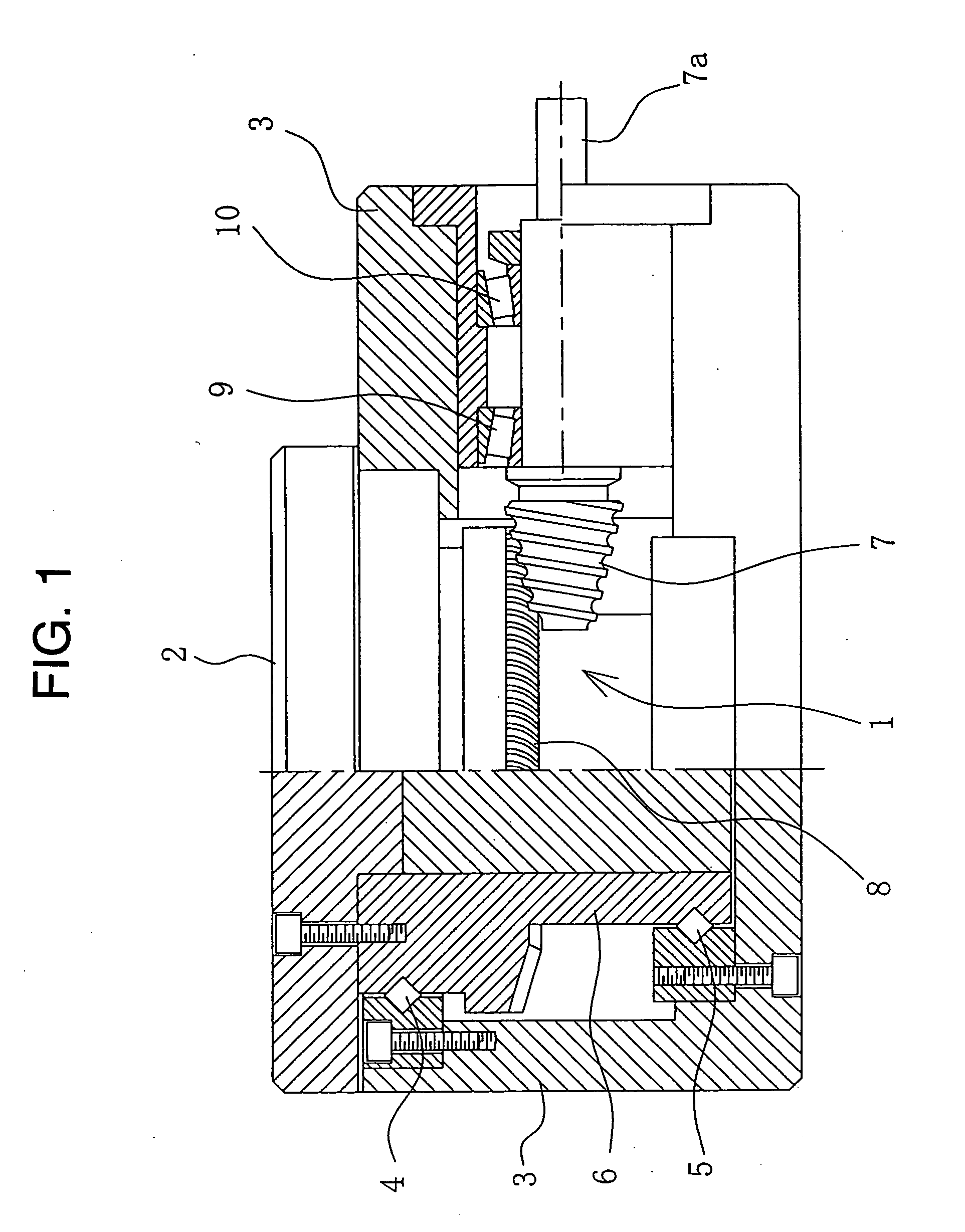

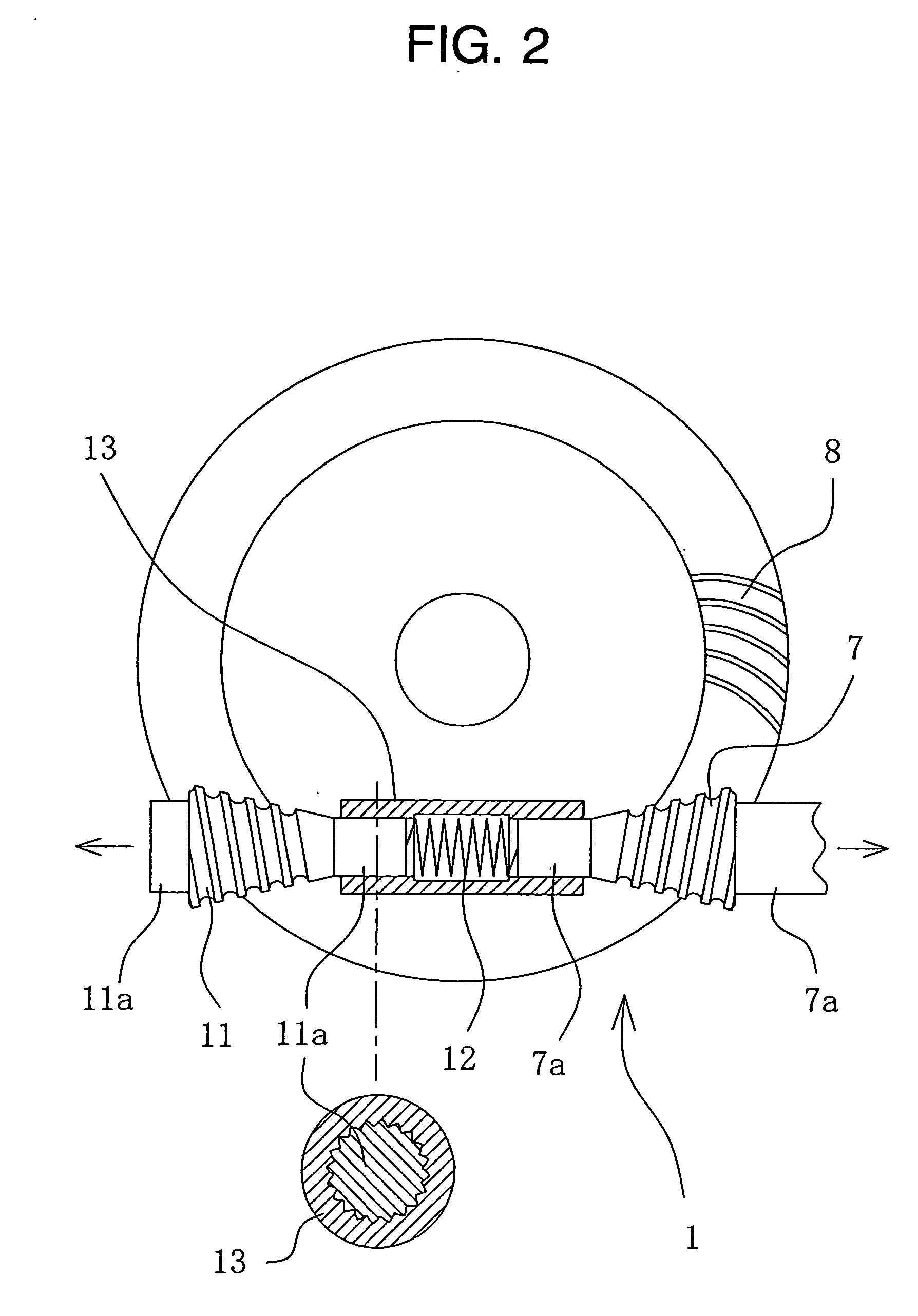

Rotary knob assembly for home appliance

ActiveUS20050077166A1Stably and accurately rotatedStable and precise rotationContact engagementsRotary switchEngineering

Disclosed is a rotary knob assembly for a home appliance. The assembly includes a rotary switch having an encoder and a shaft rotatably installed at the encoder, a knob coupled to the shaft of the rotary switch, and a support member provided around the rotary switch to support the rotary switch.

Owner:LG ELECTRONICS INC

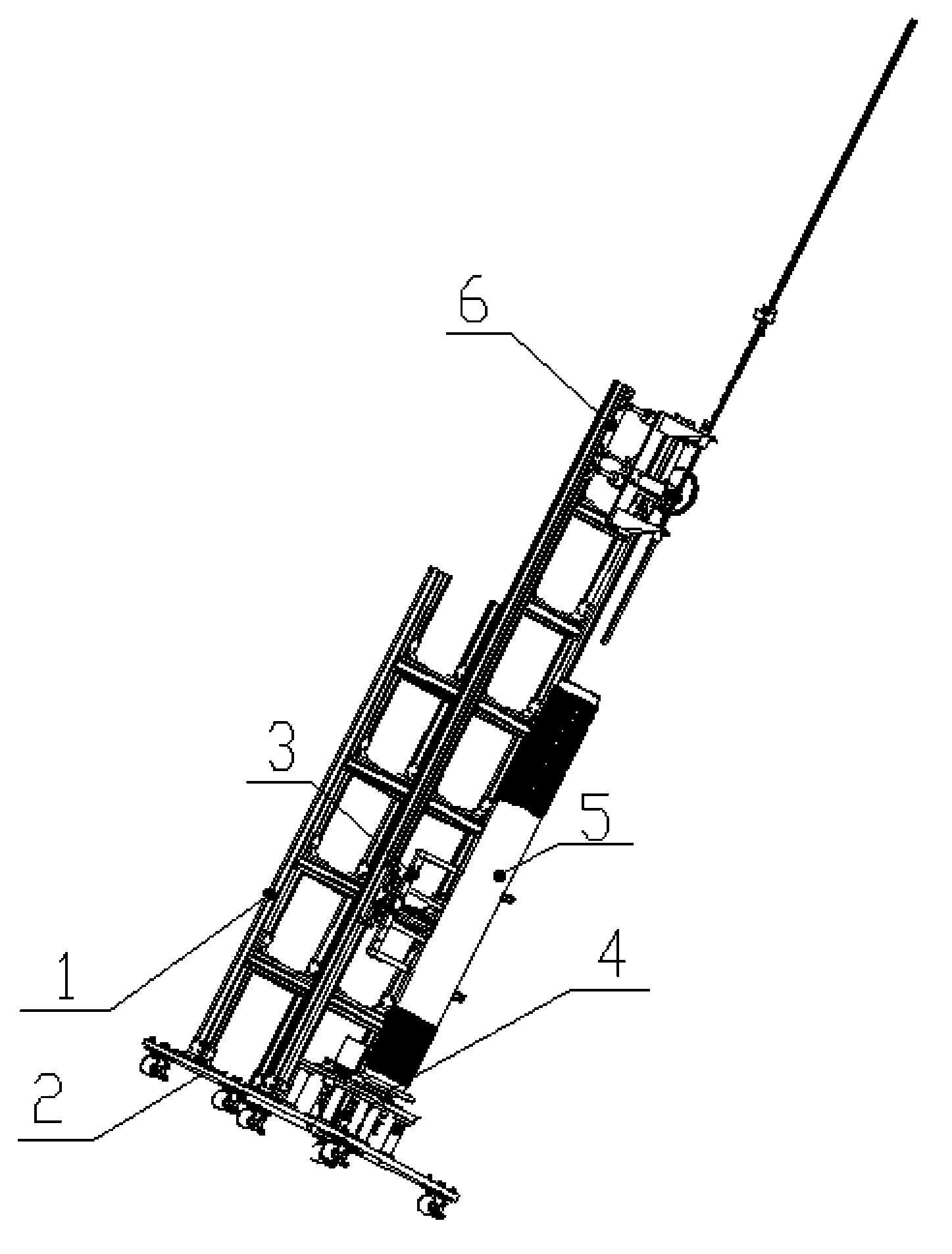

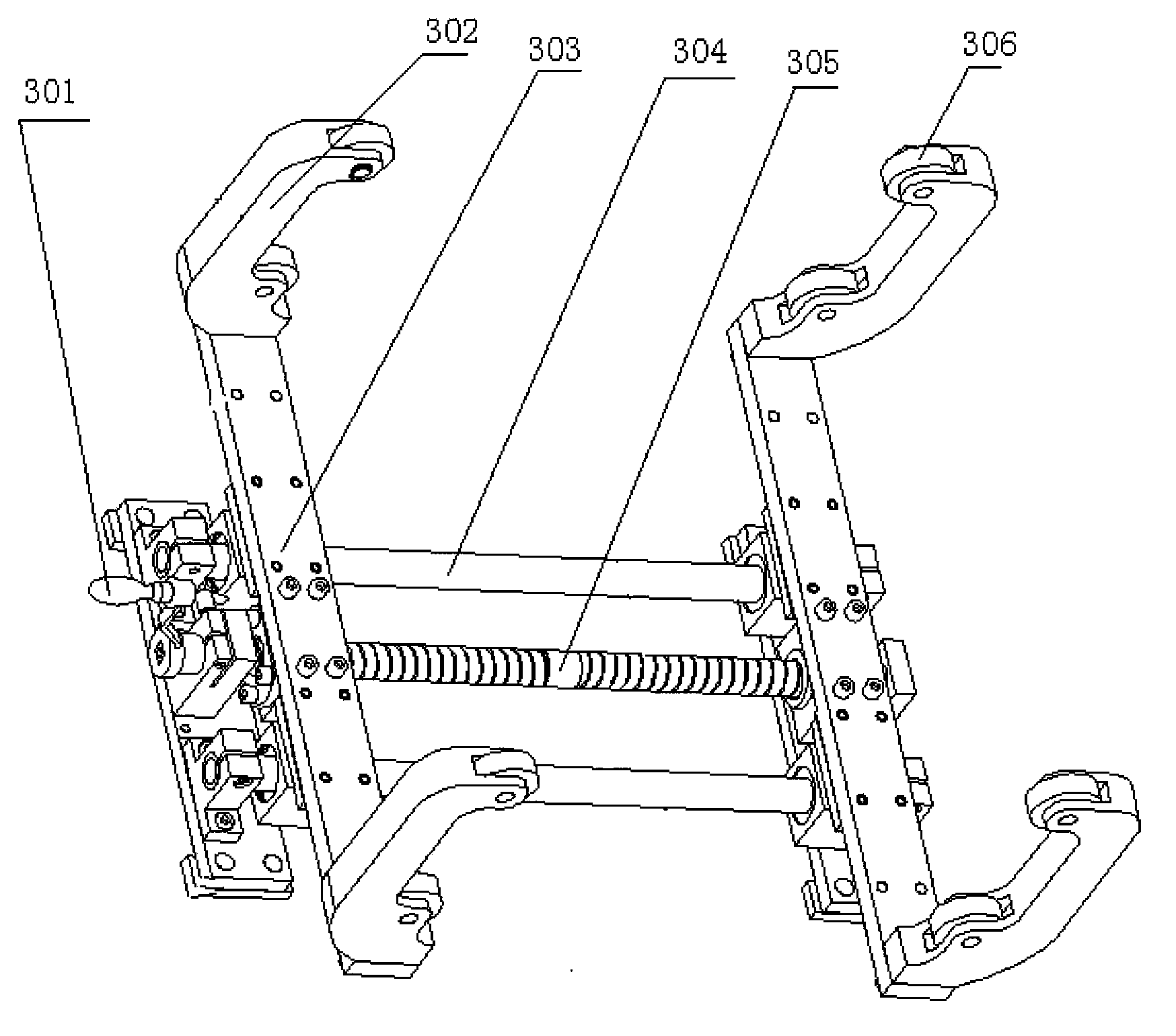

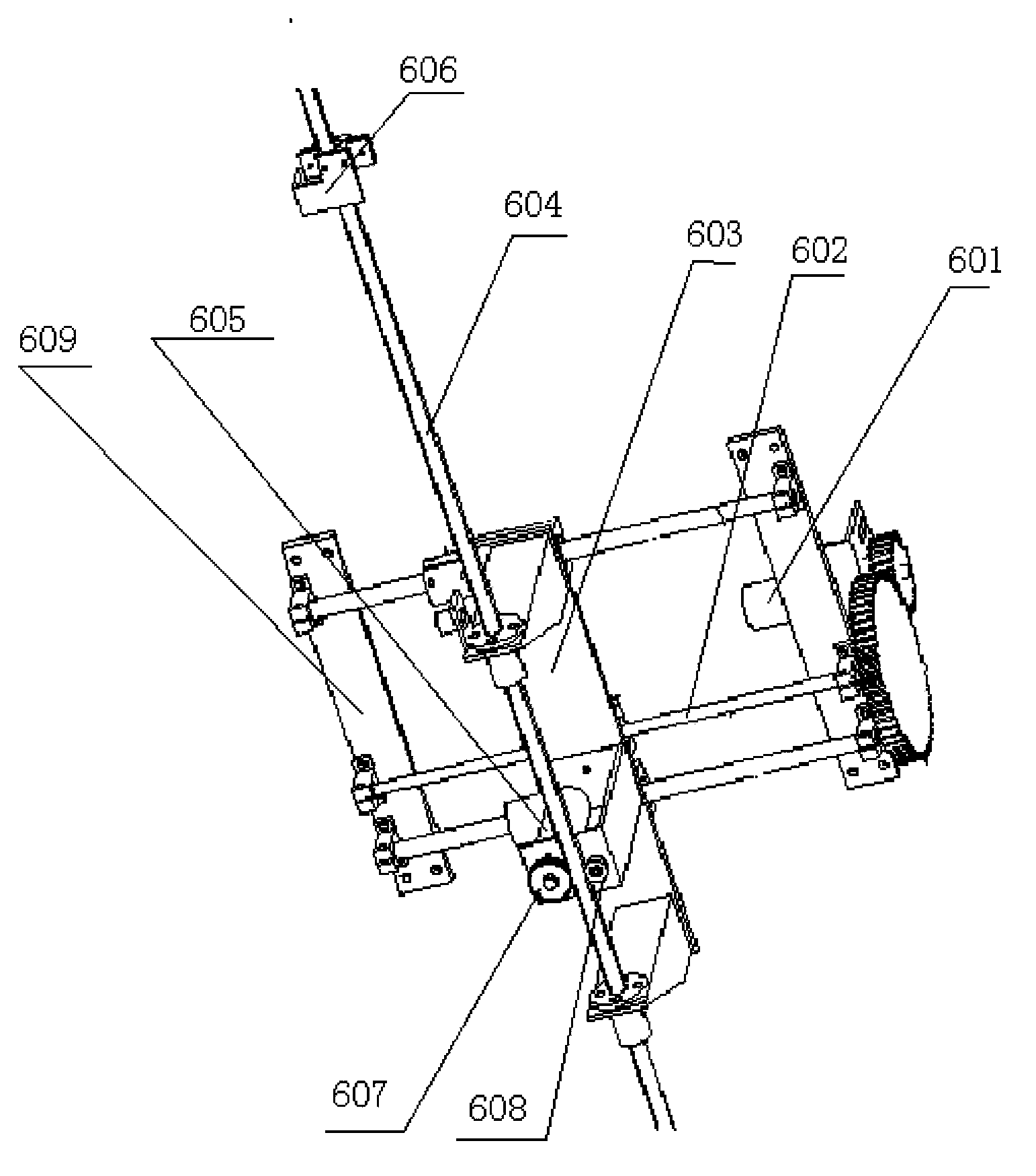

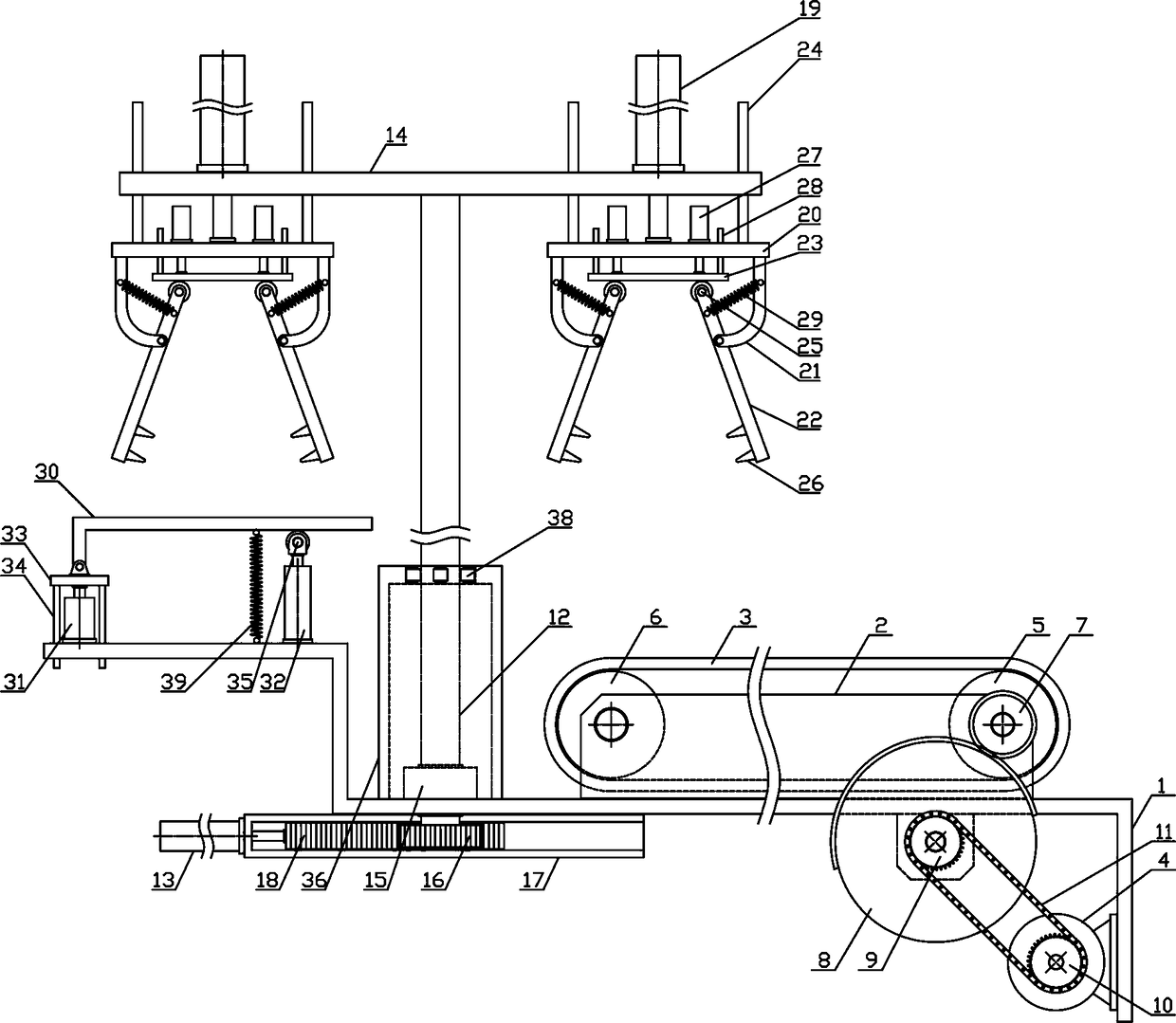

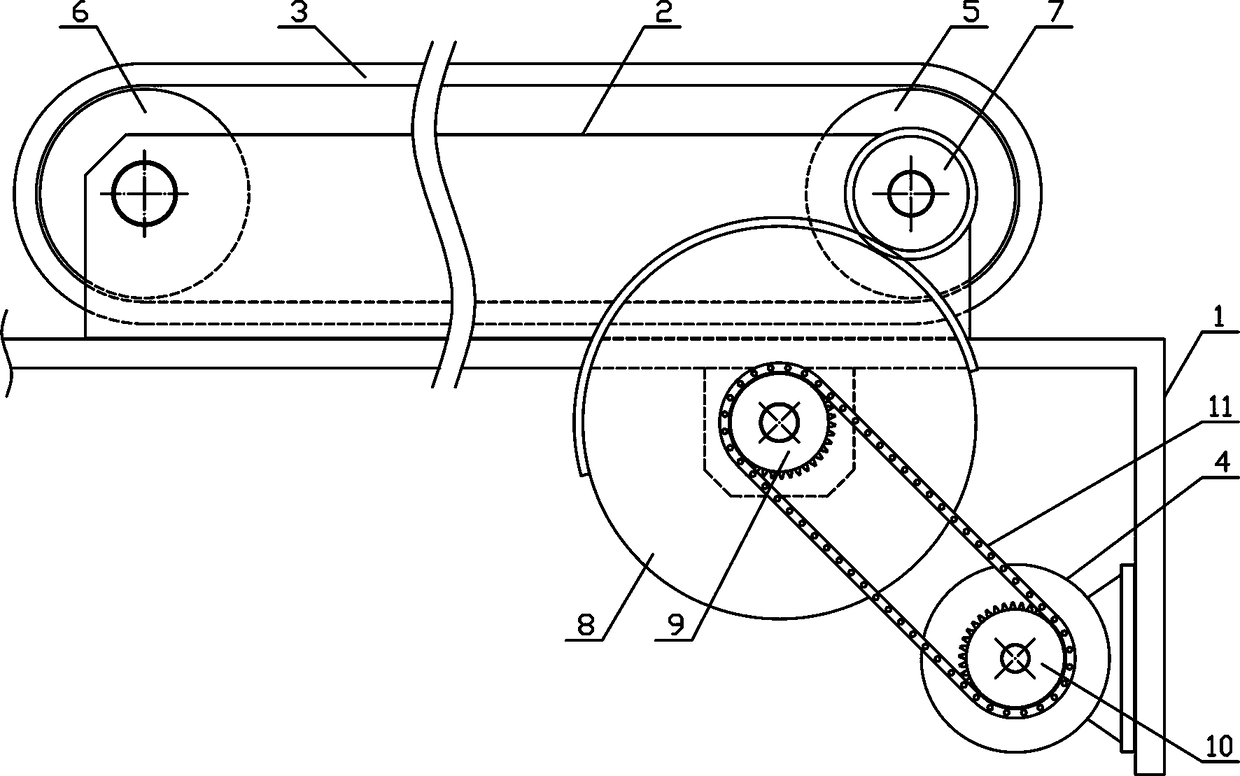

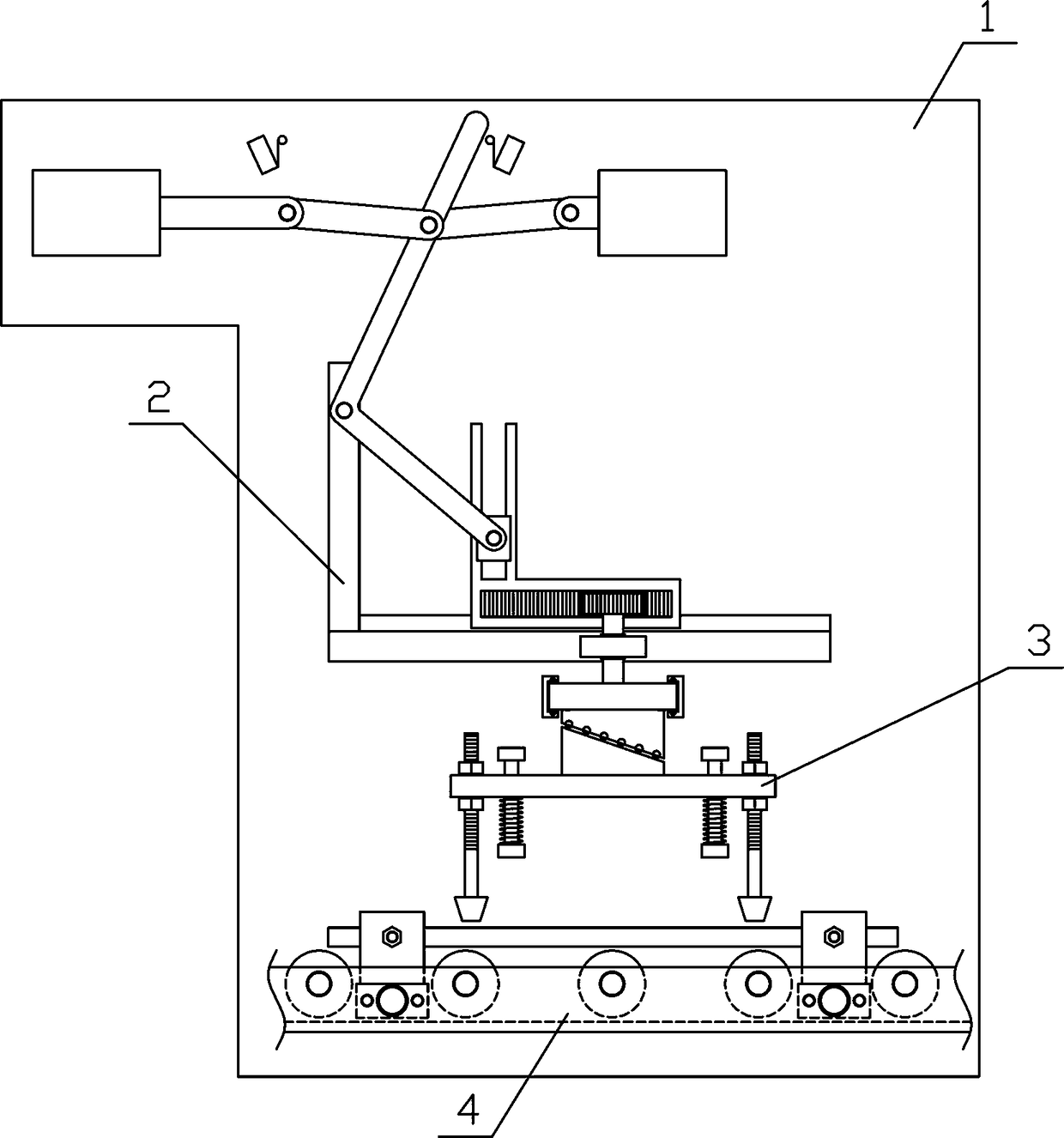

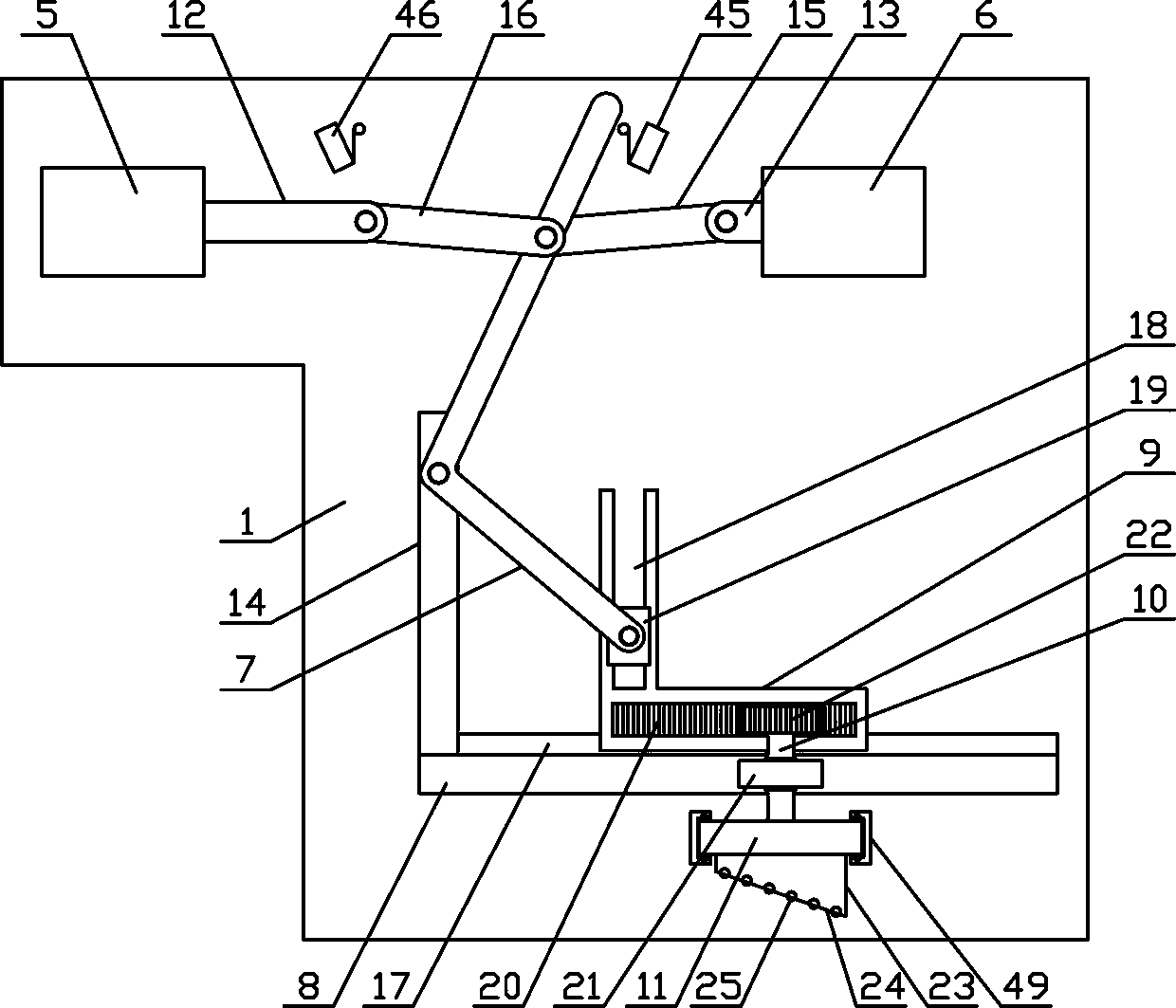

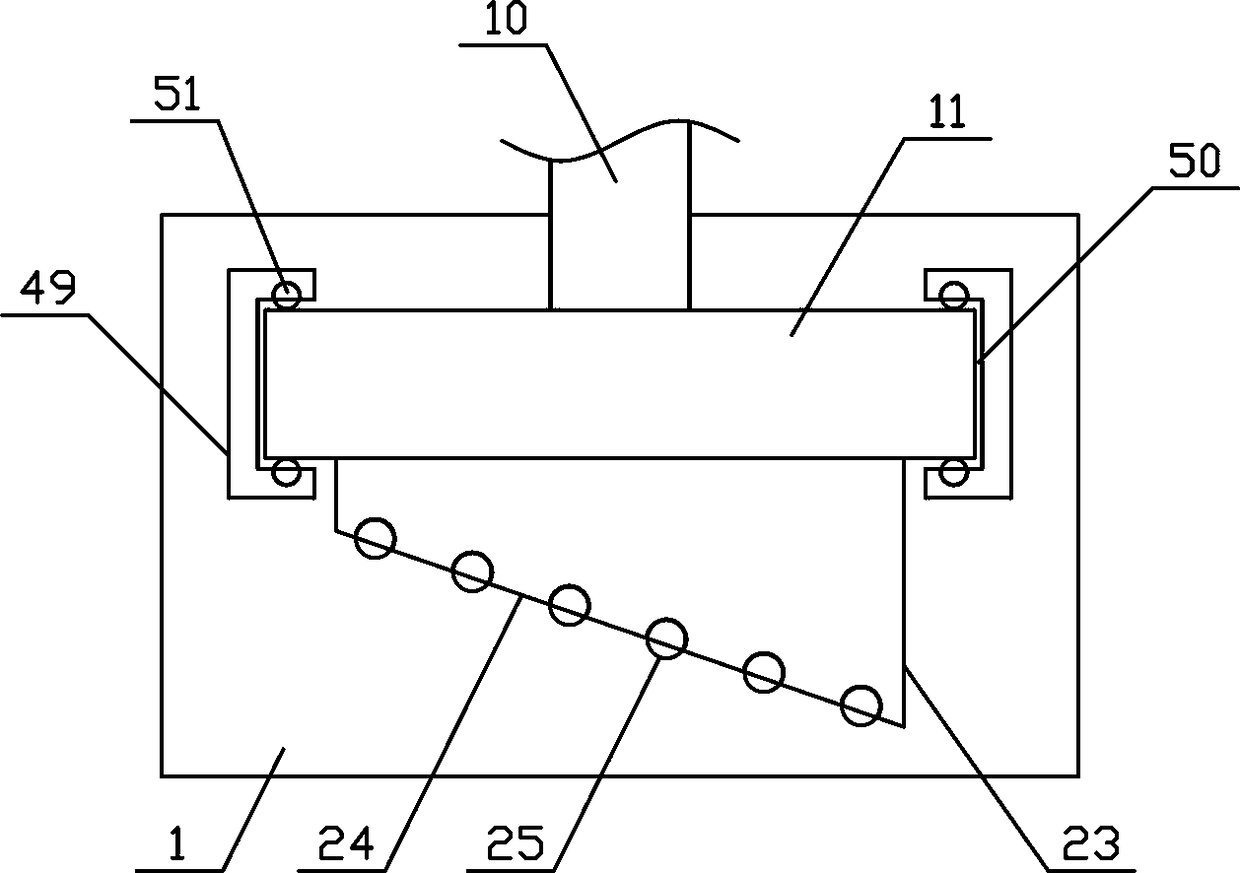

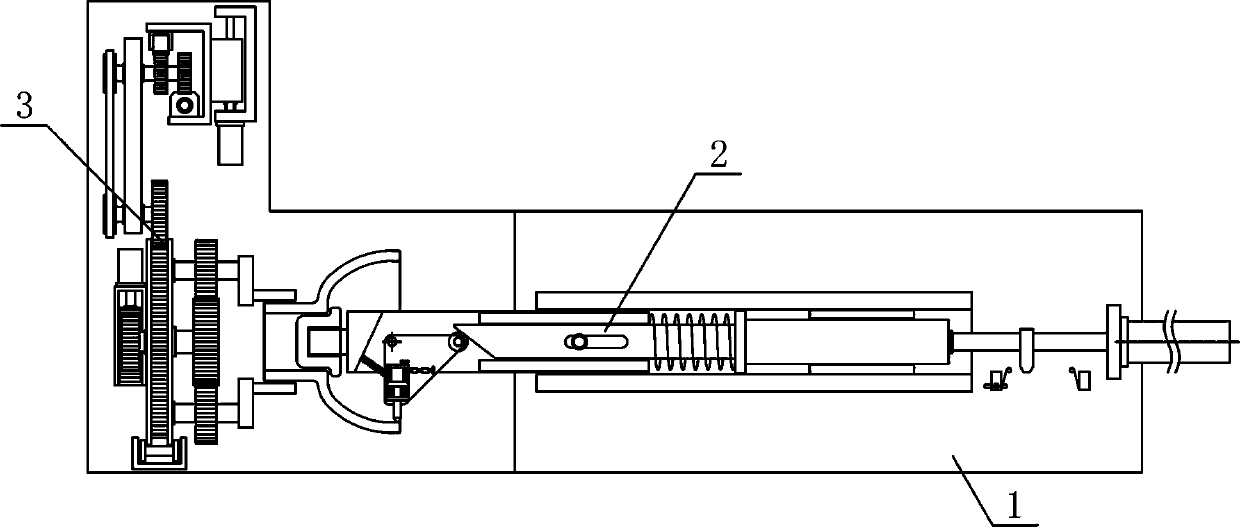

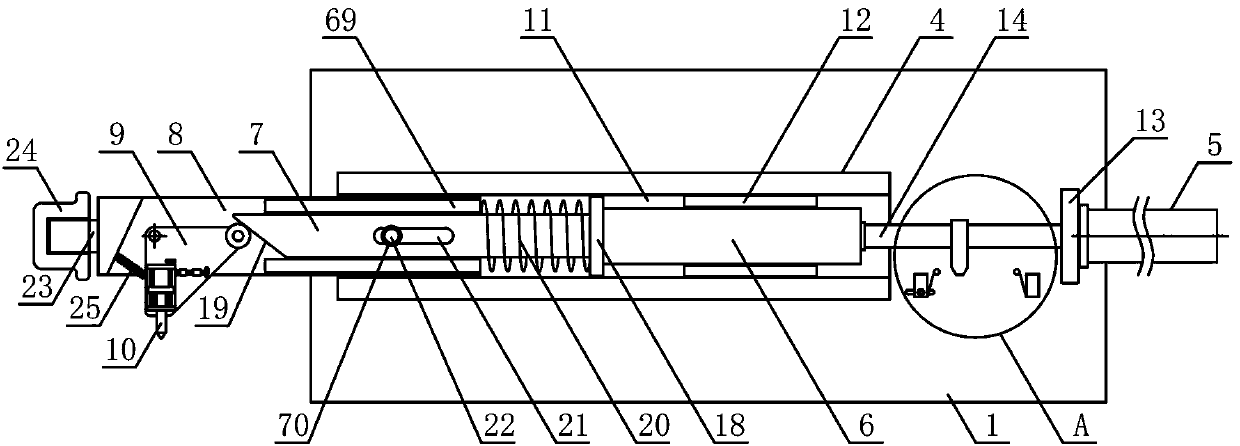

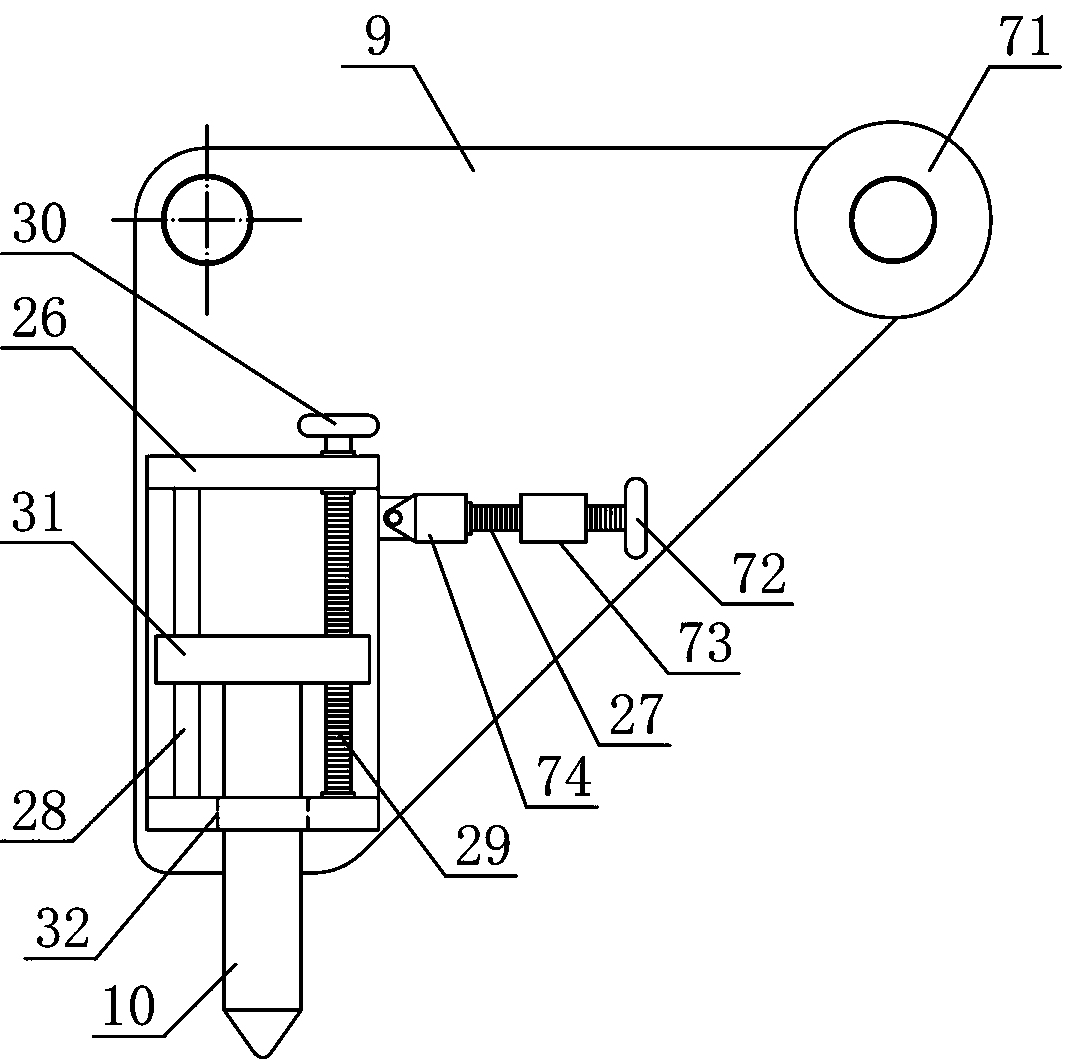

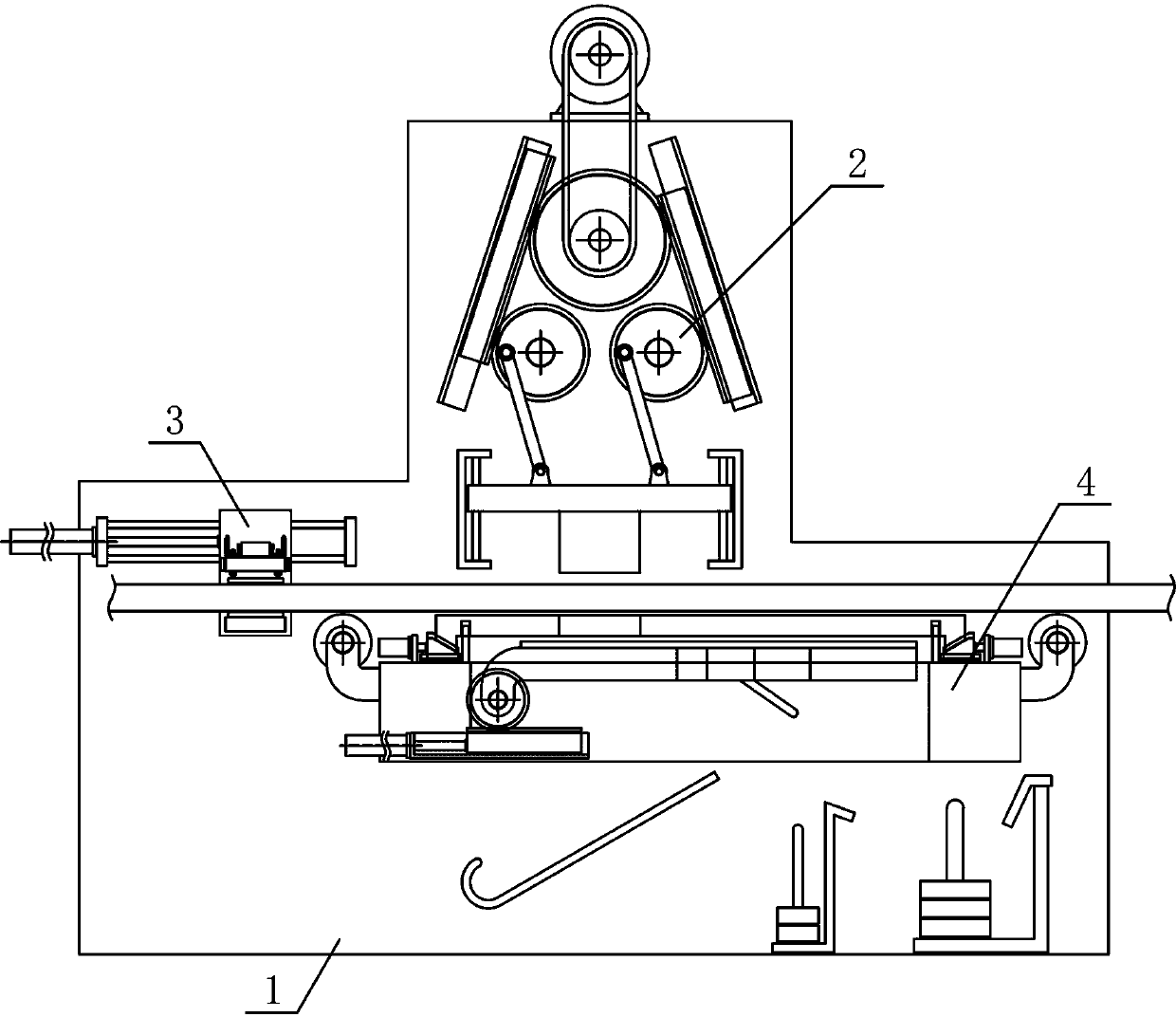

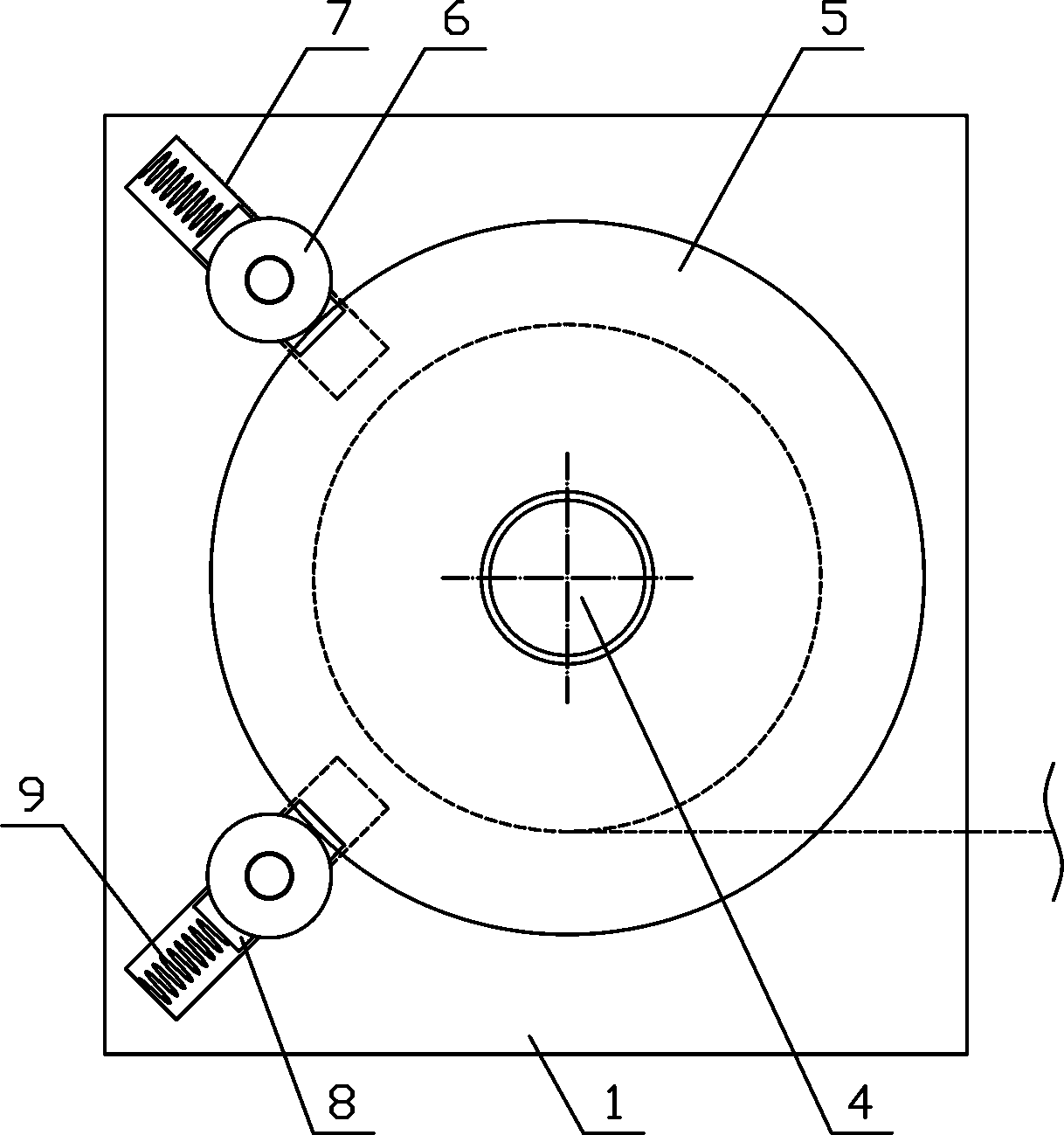

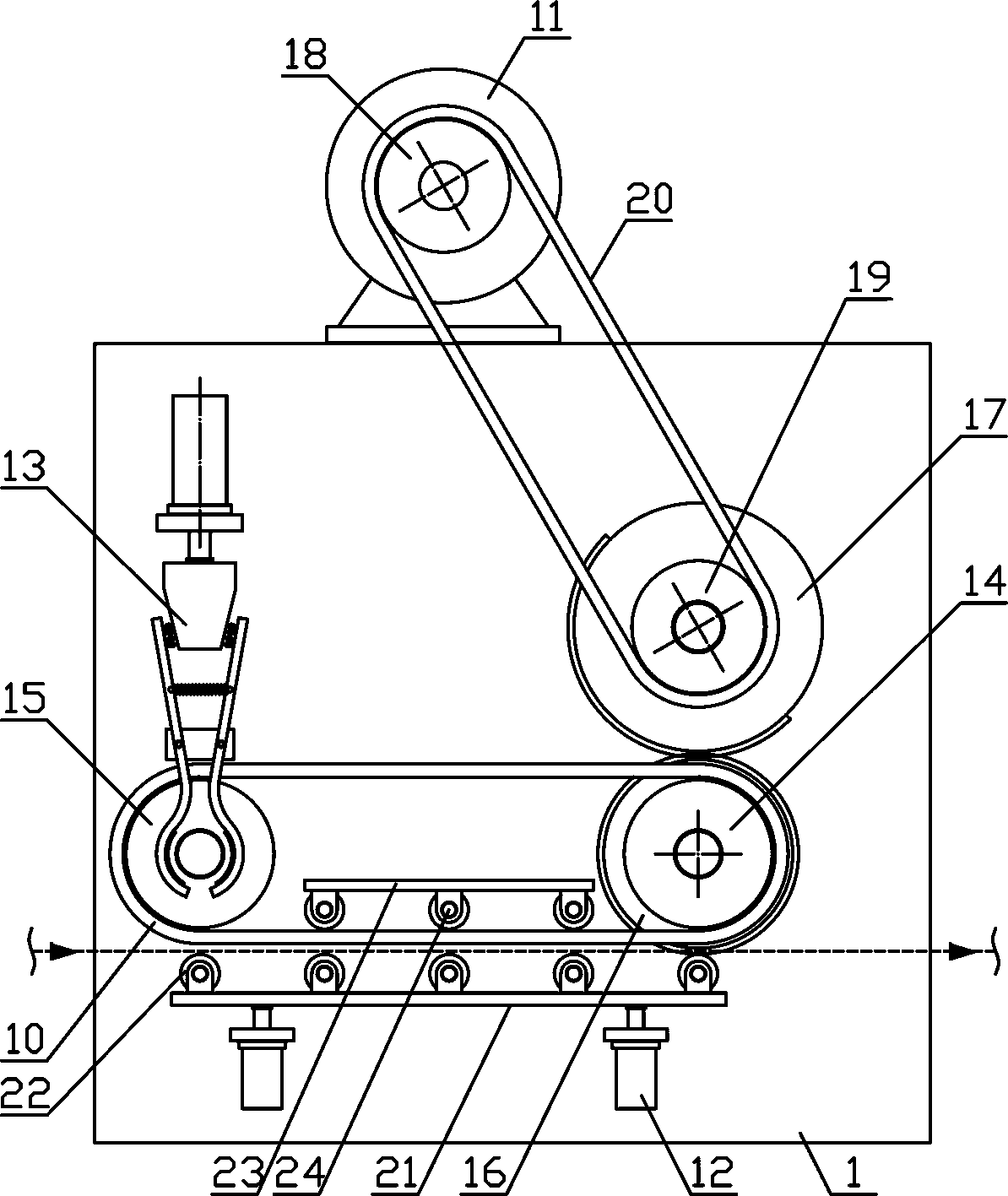

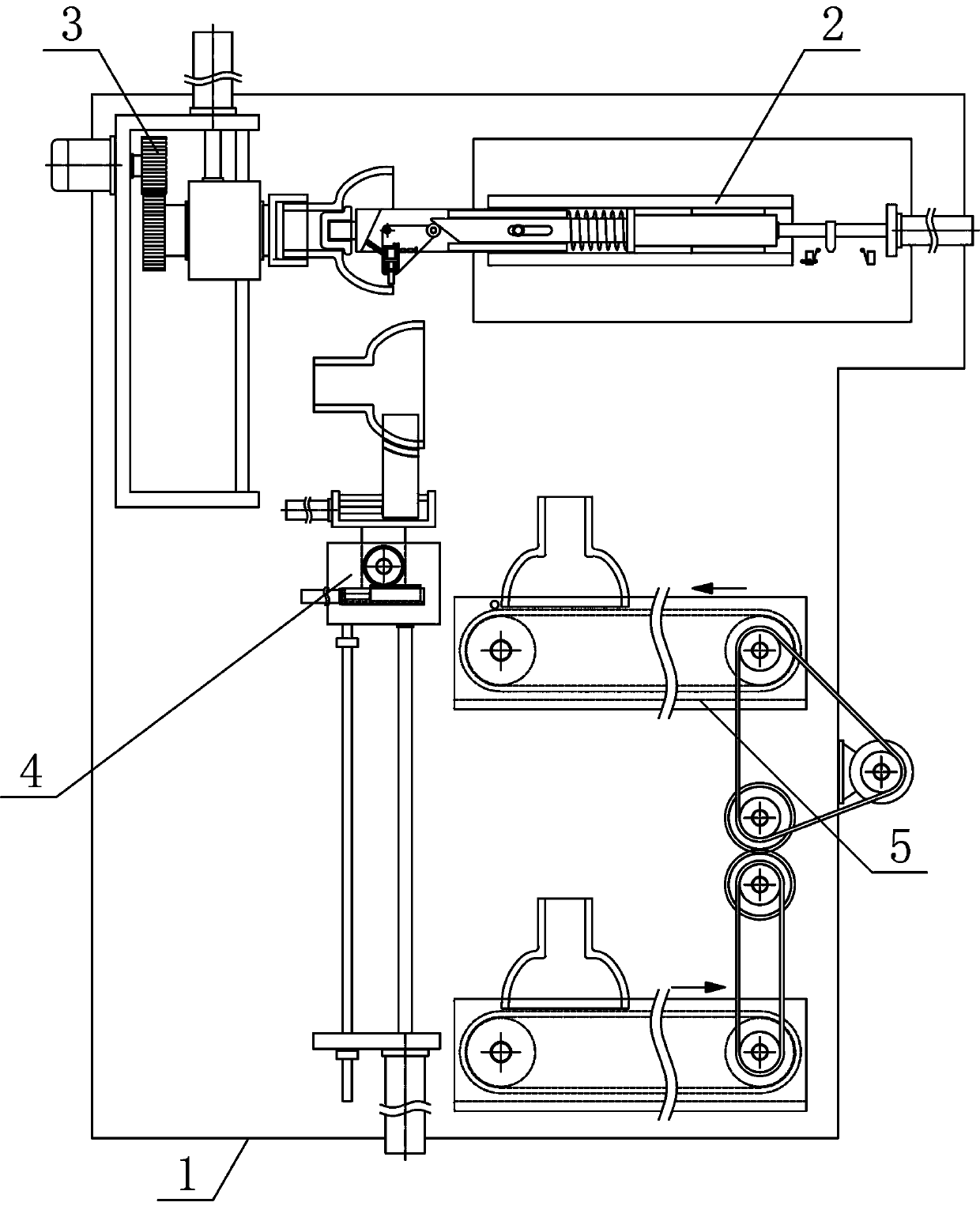

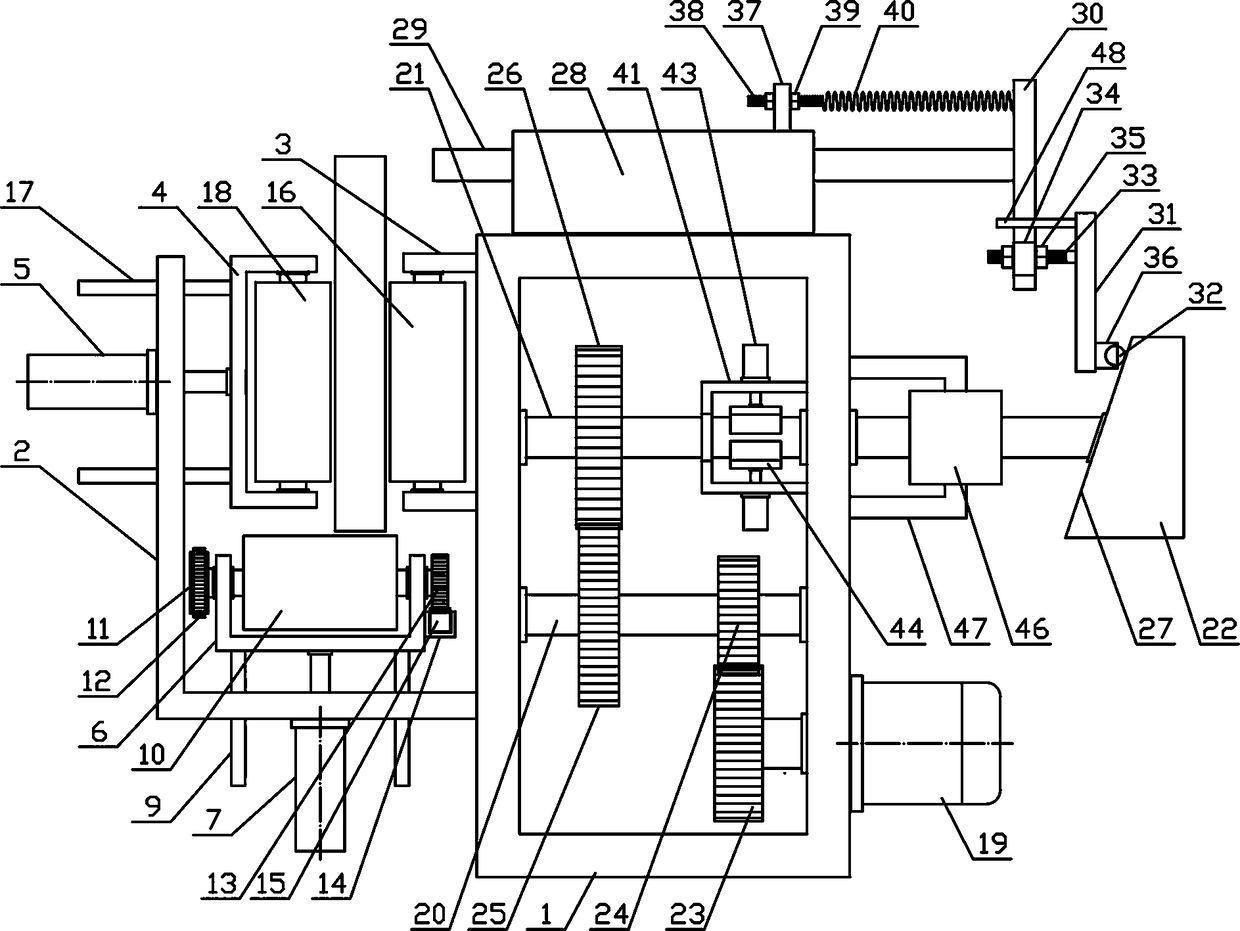

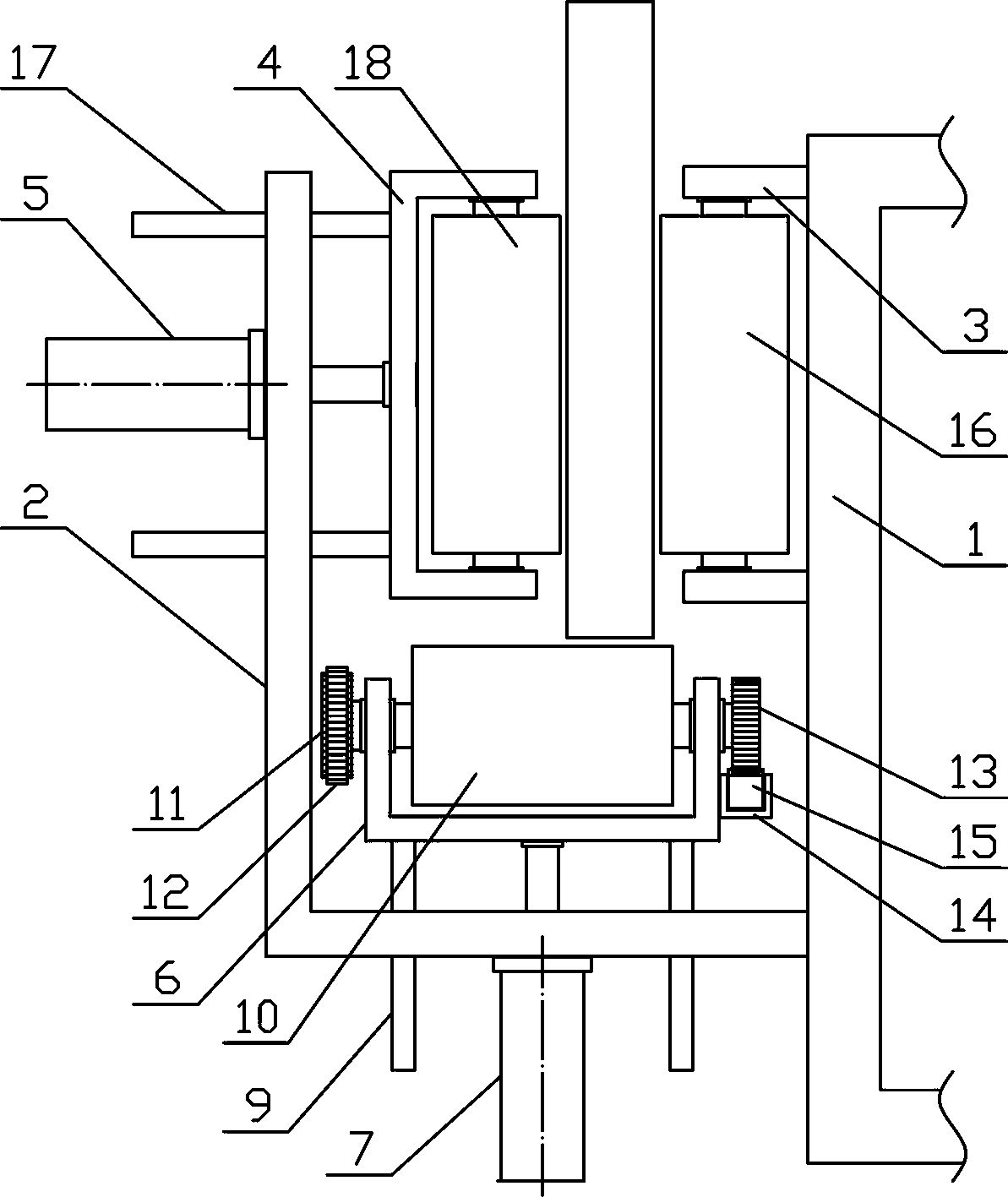

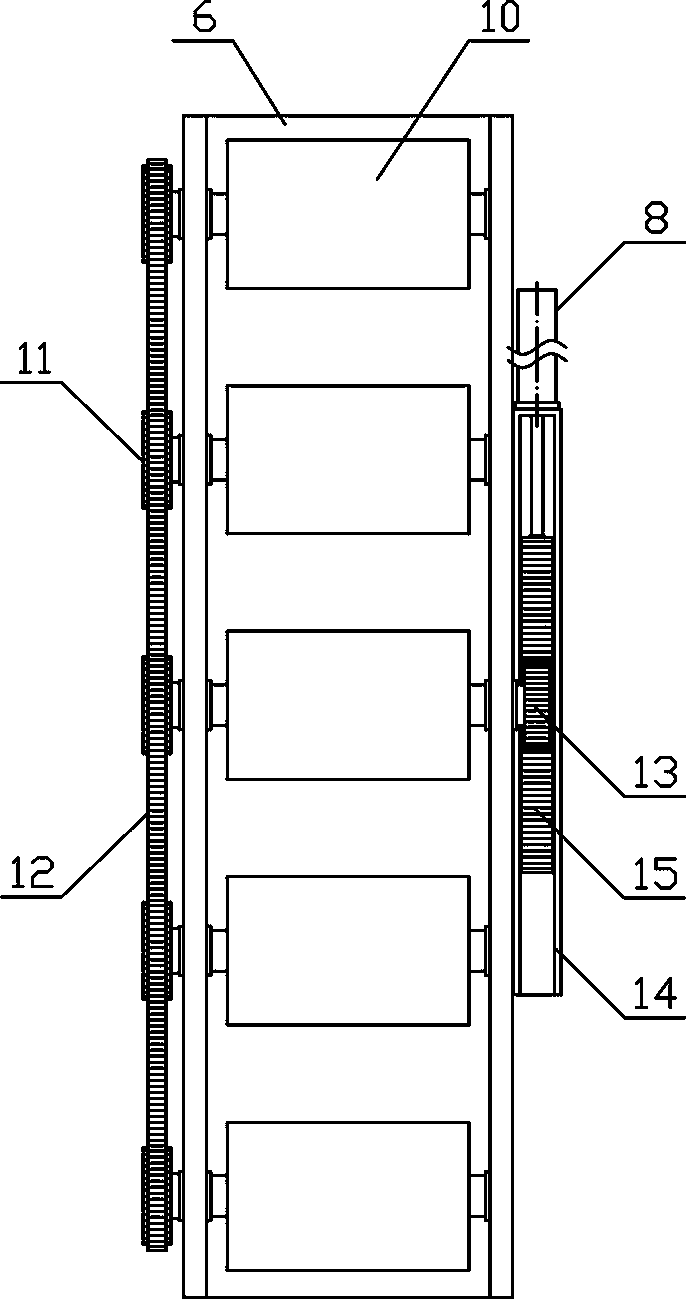

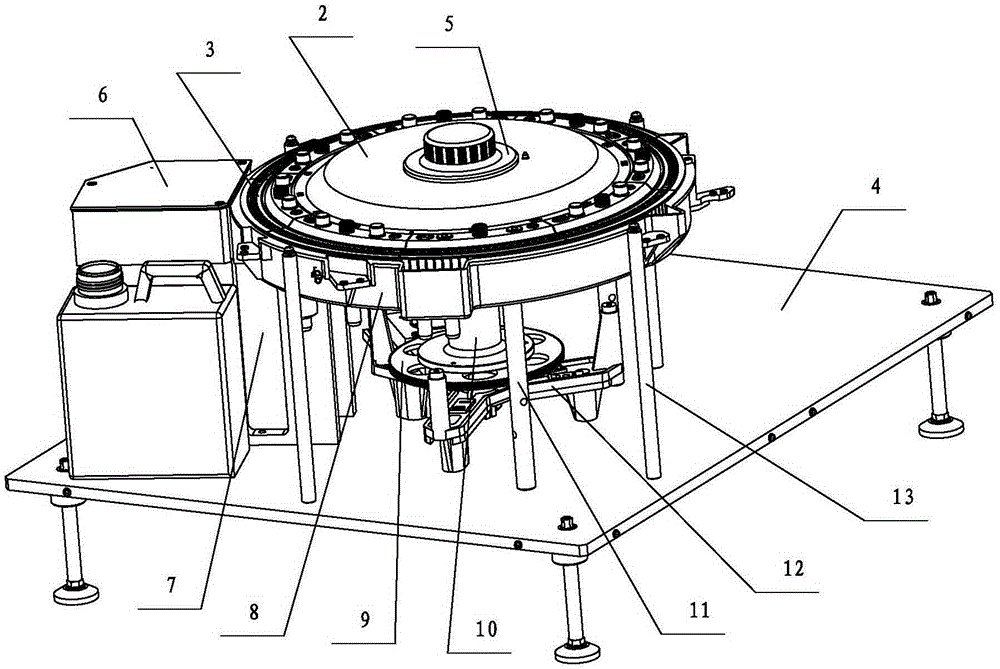

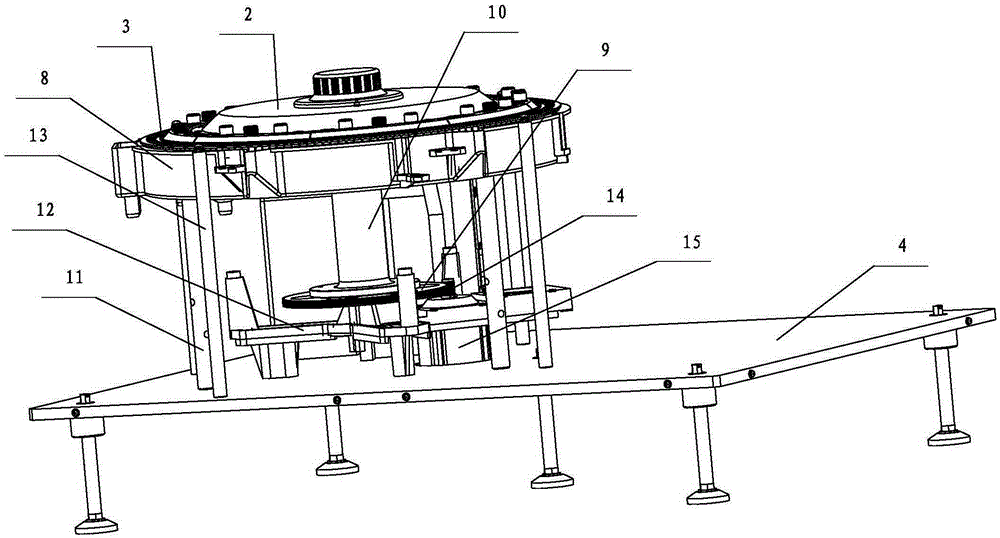

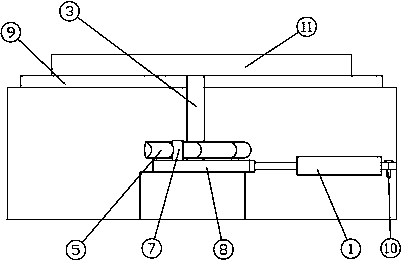

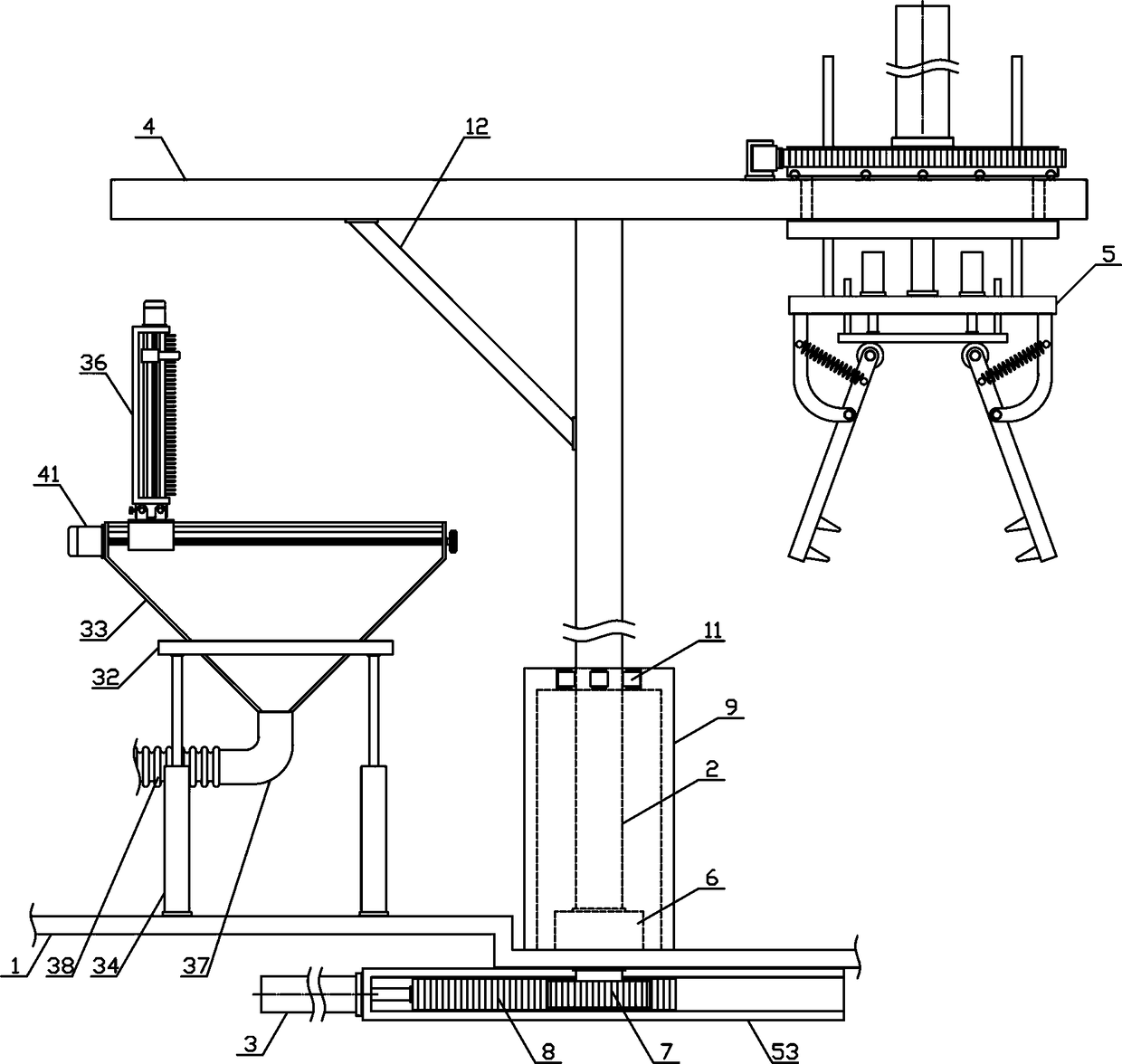

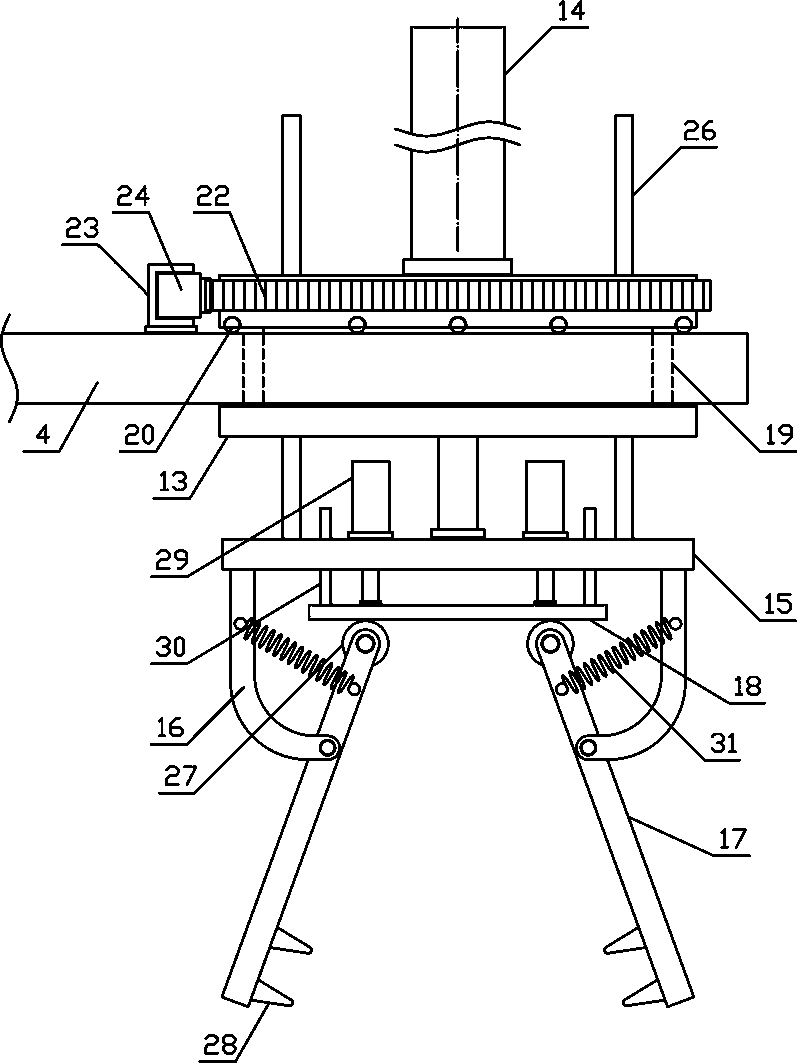

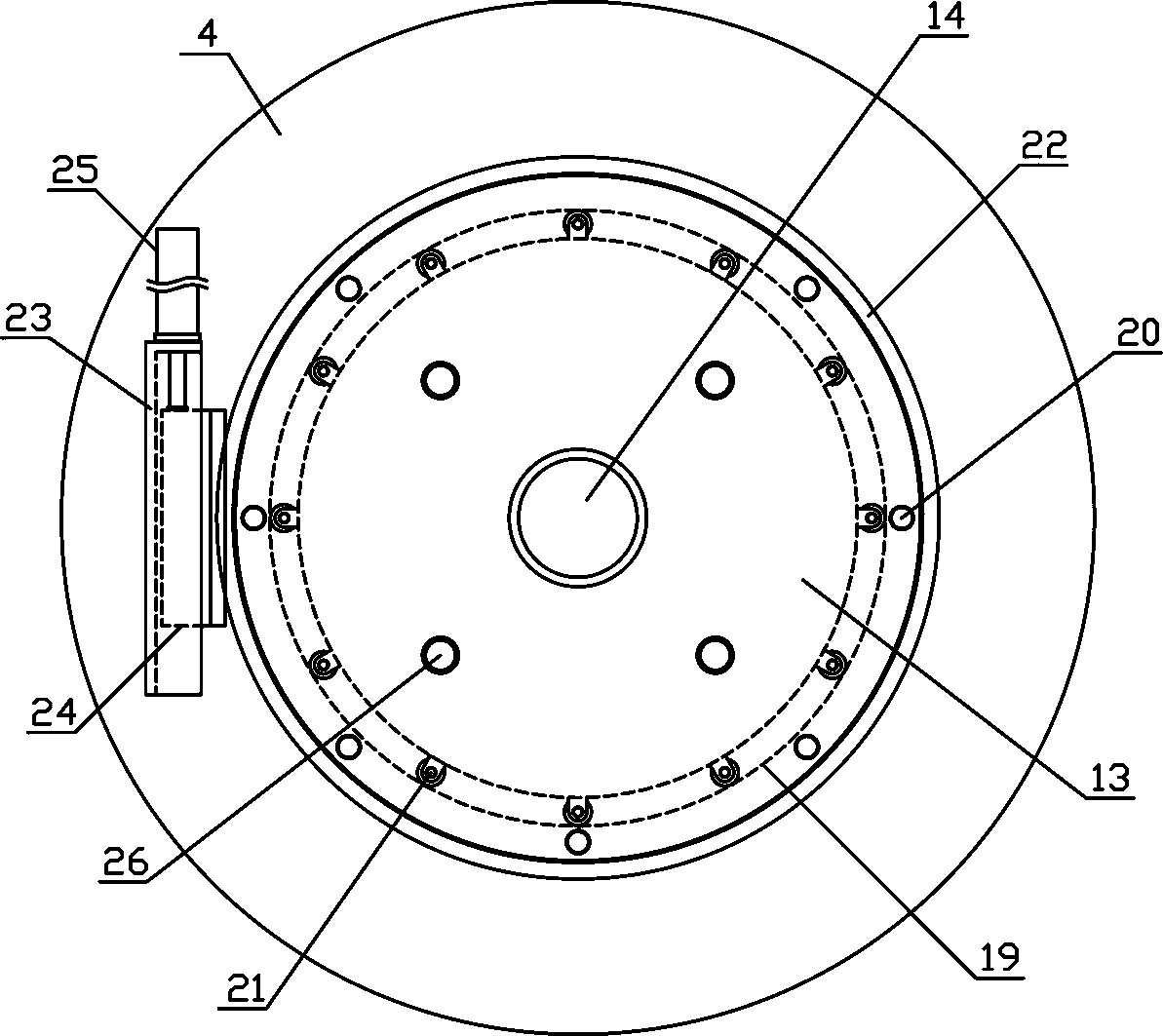

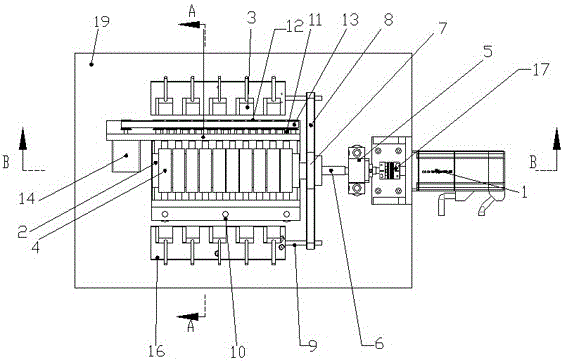

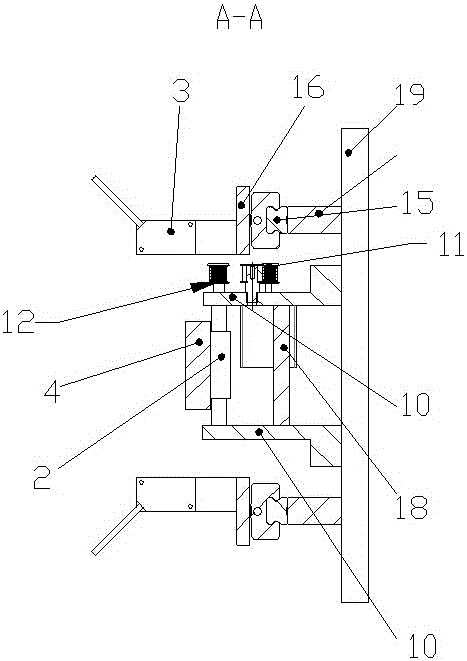

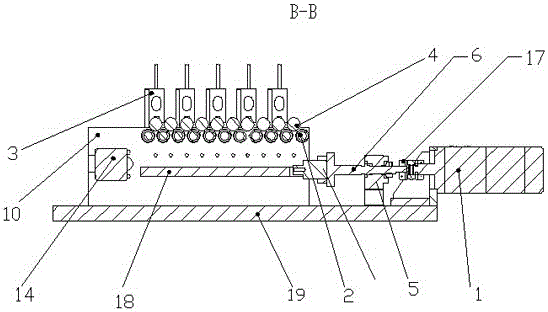

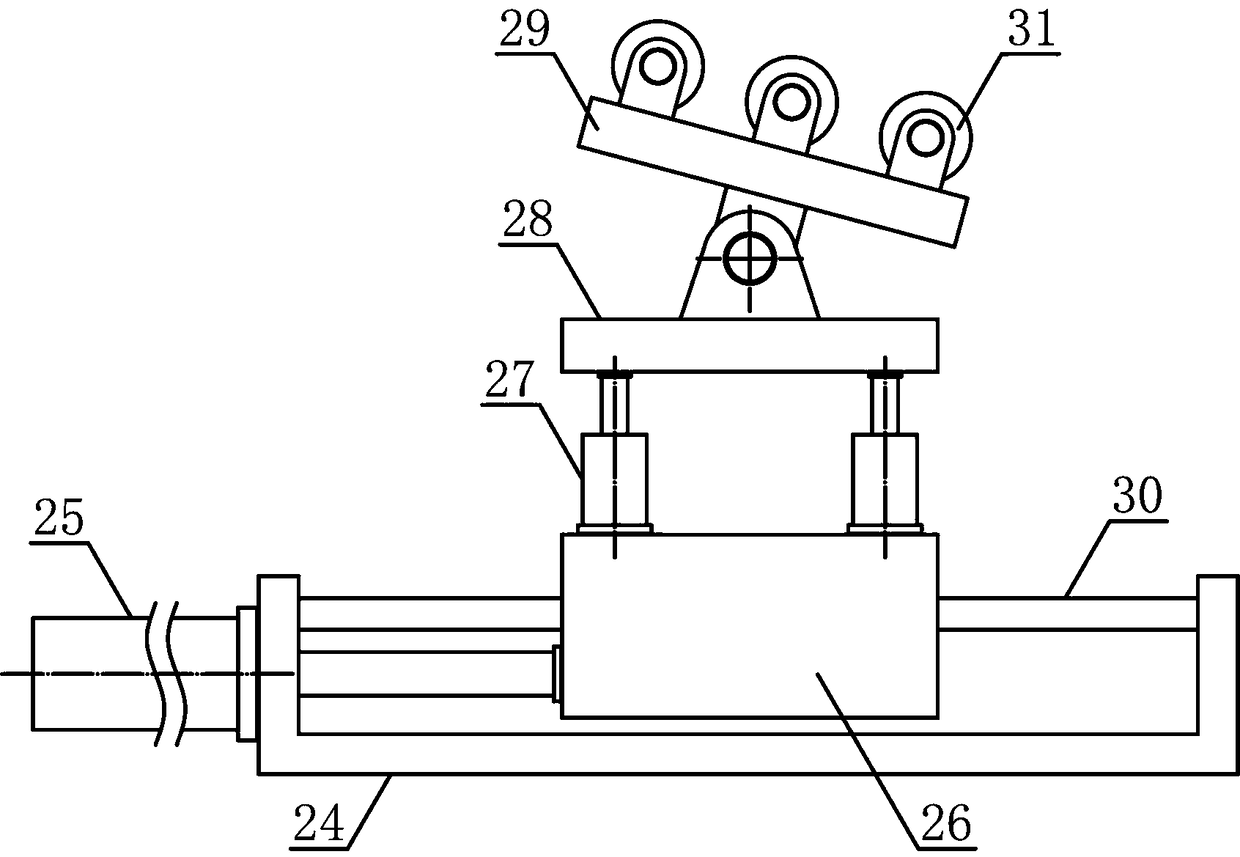

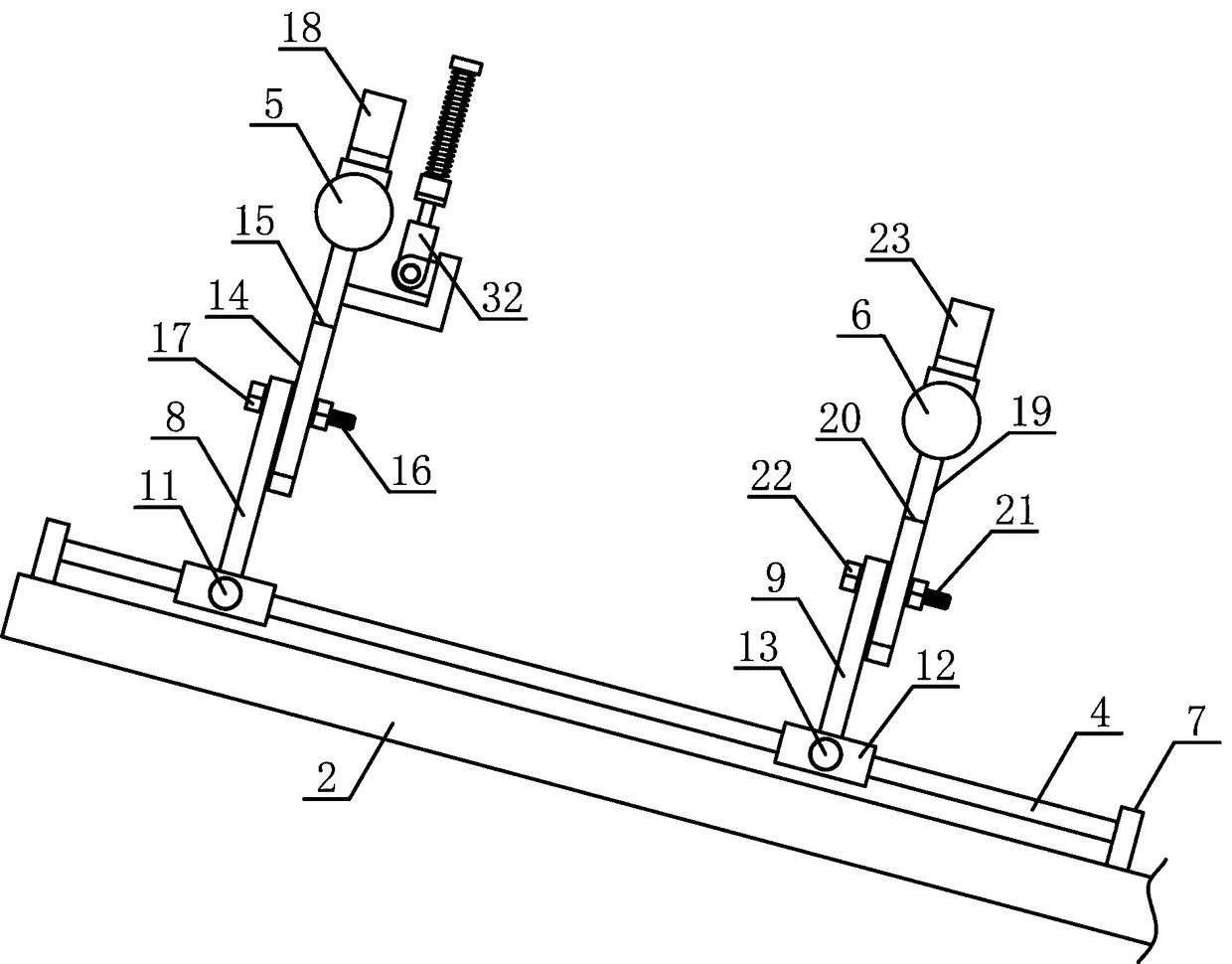

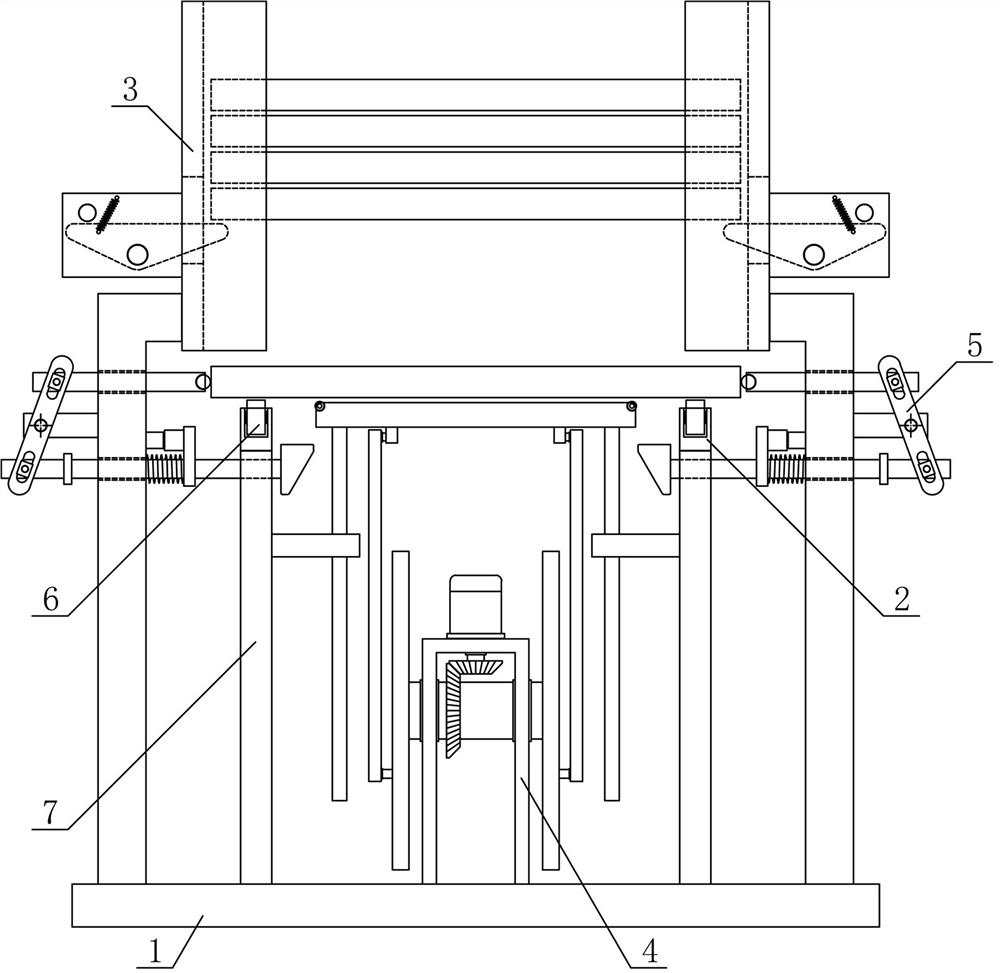

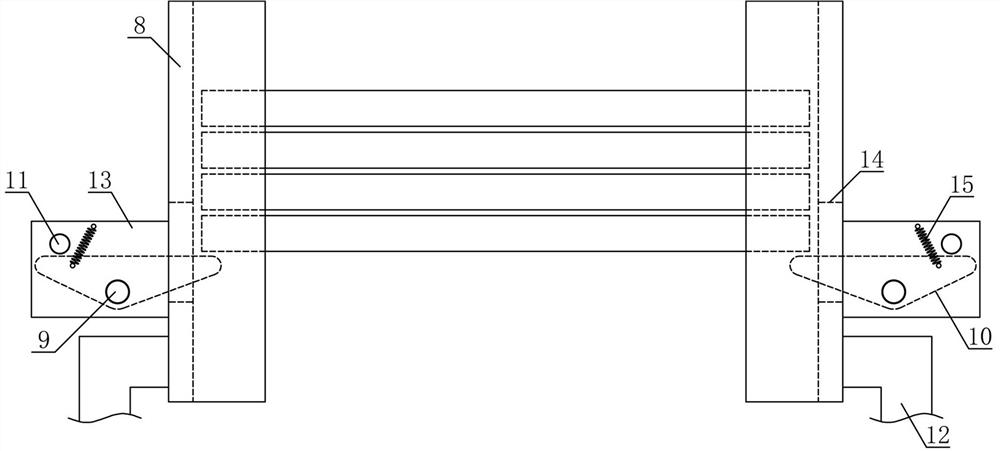

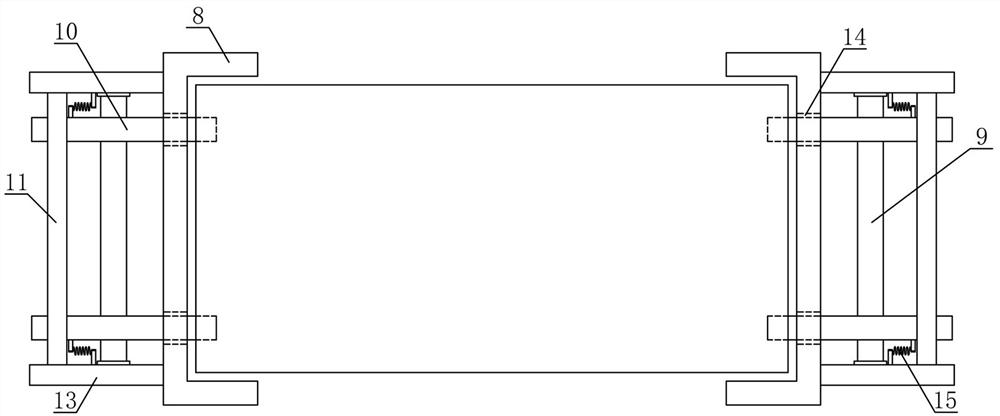

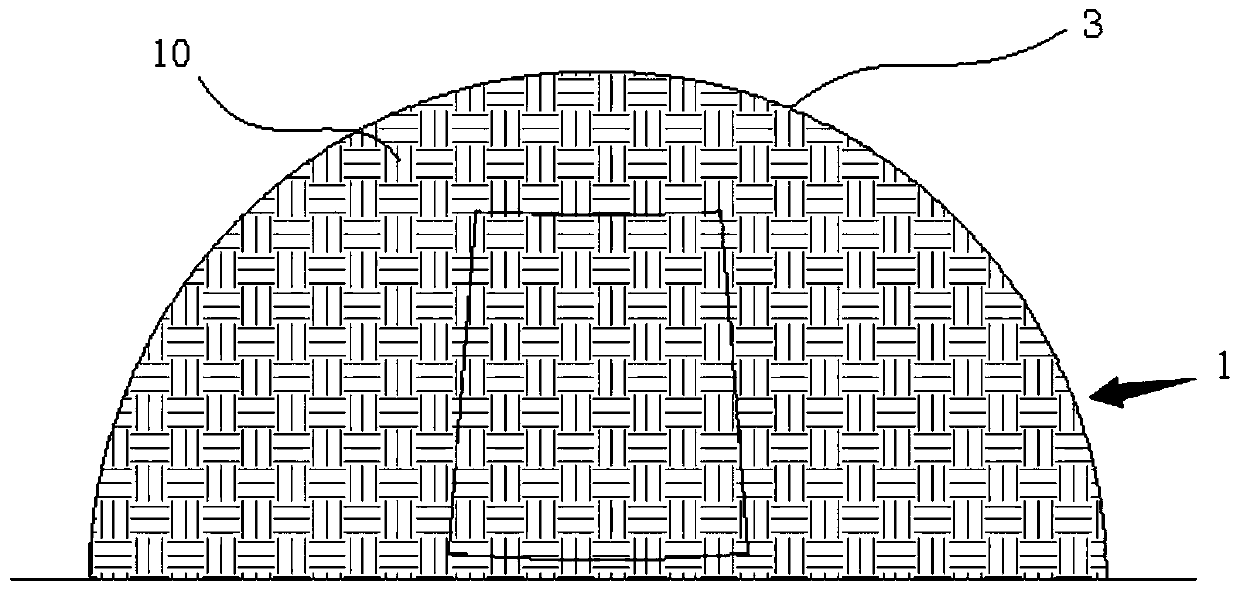

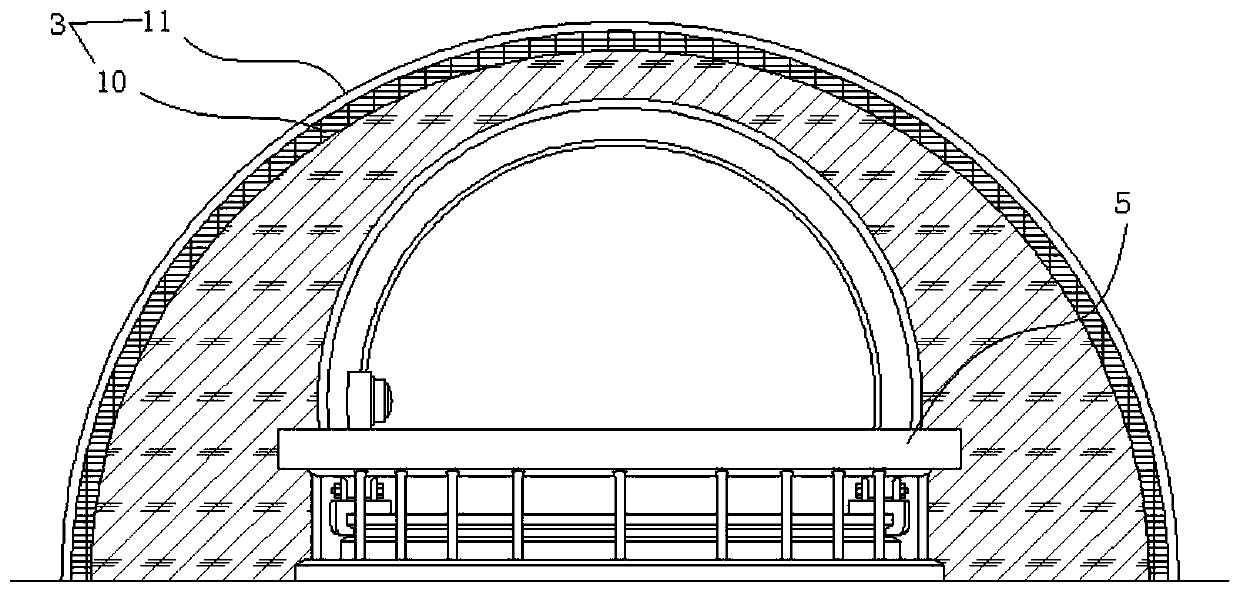

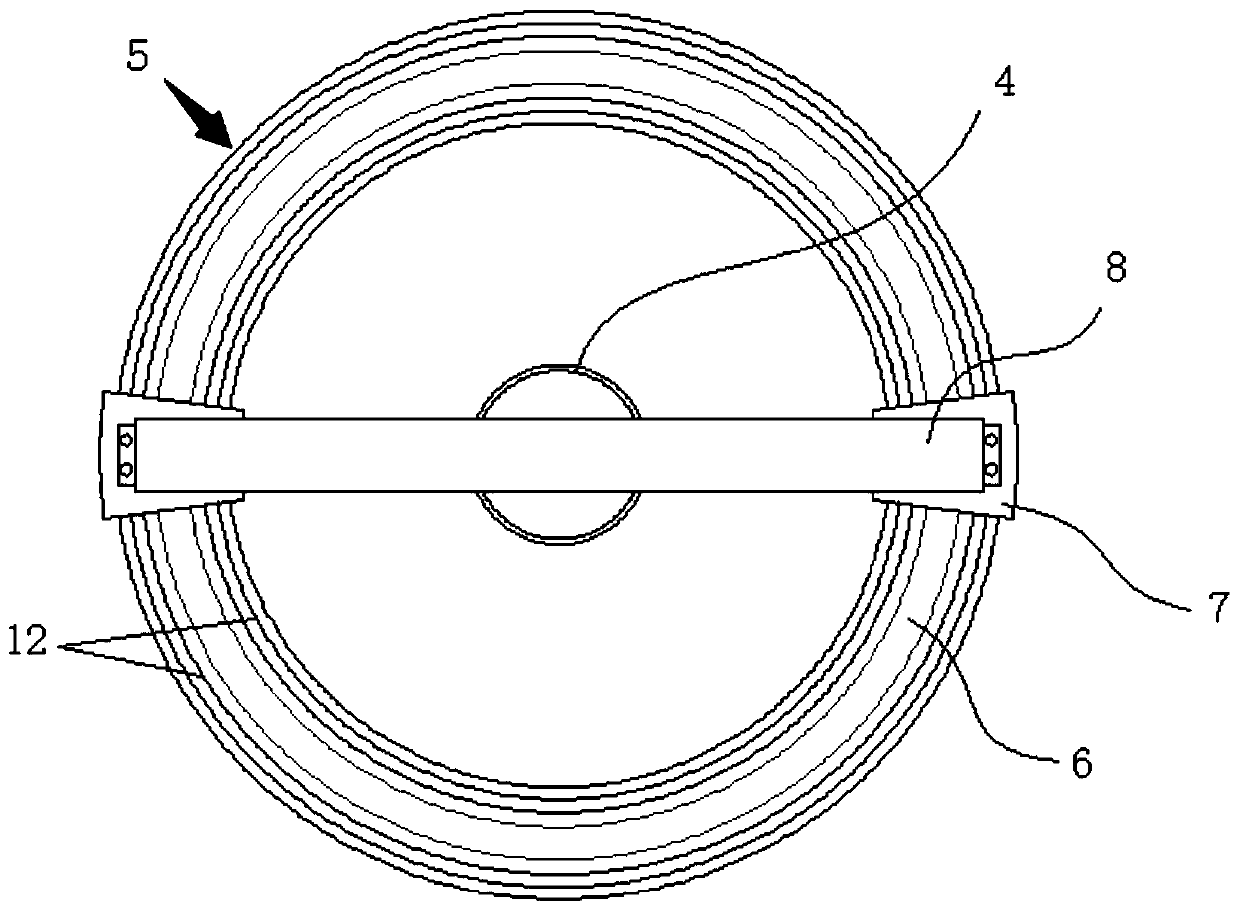

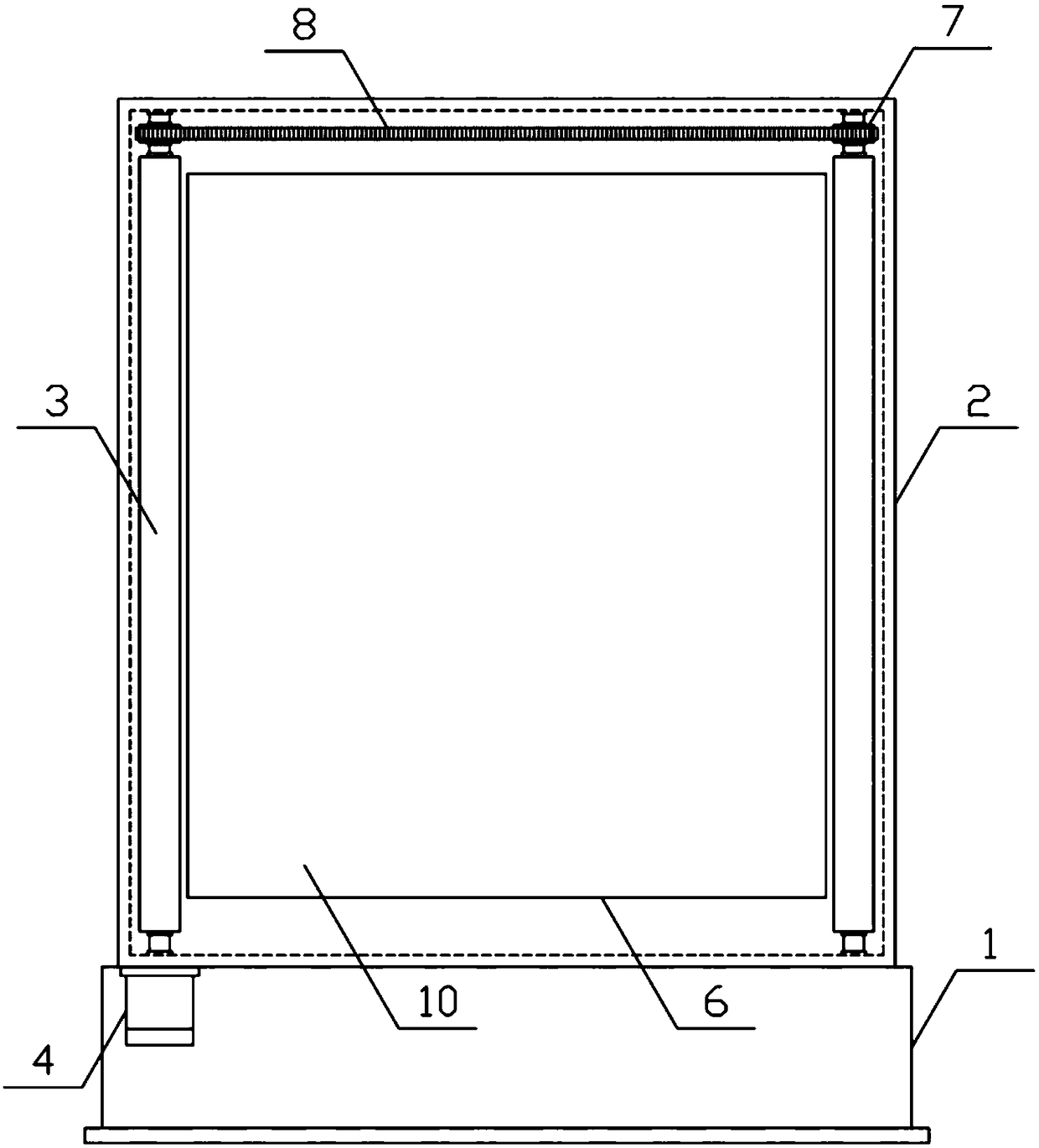

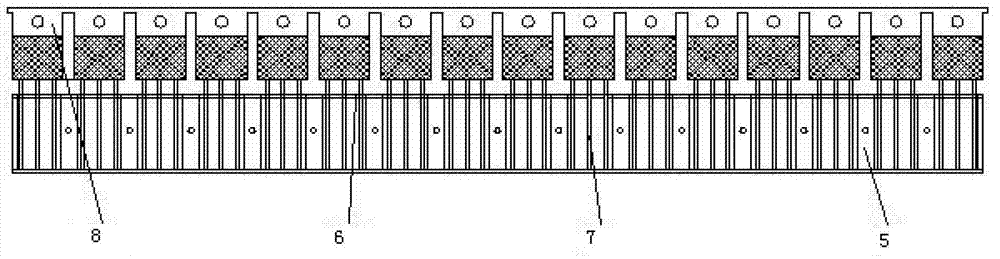

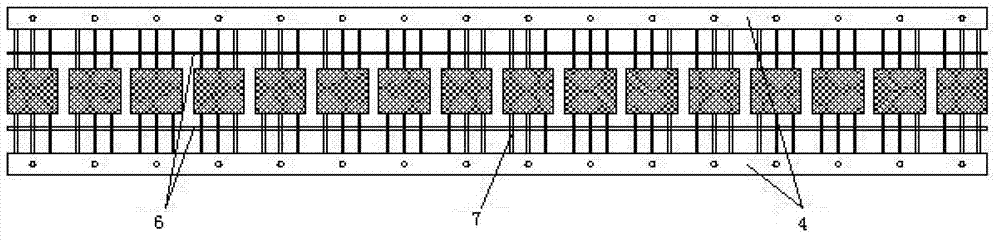

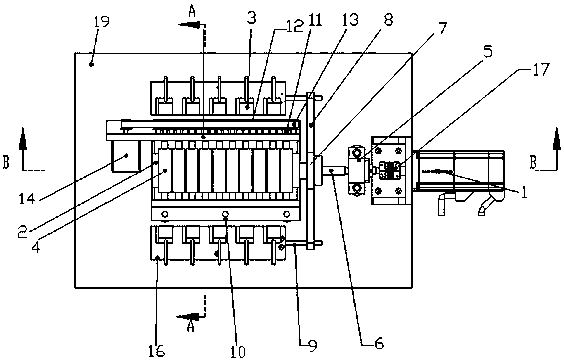

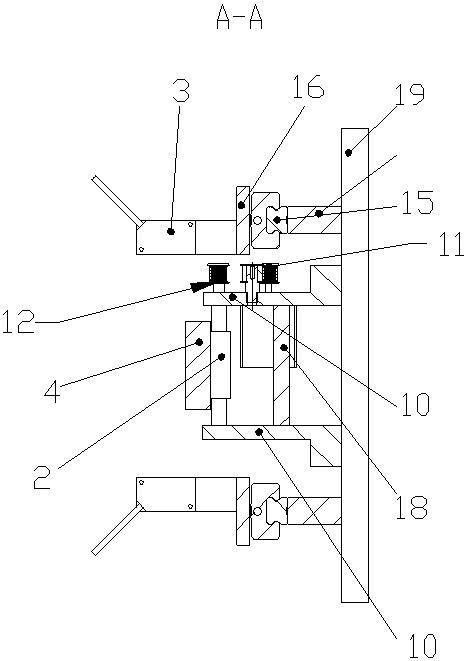

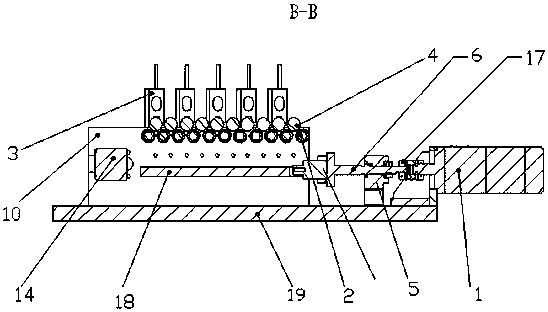

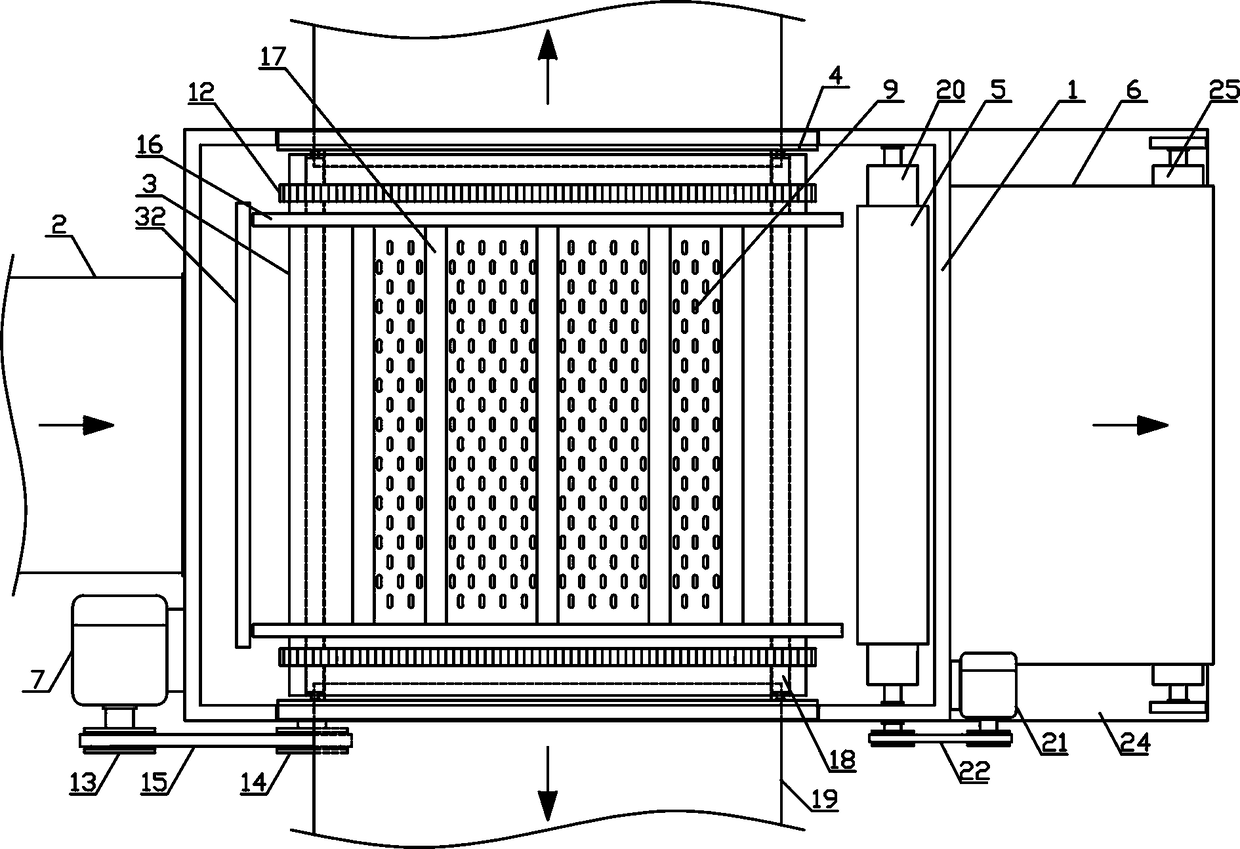

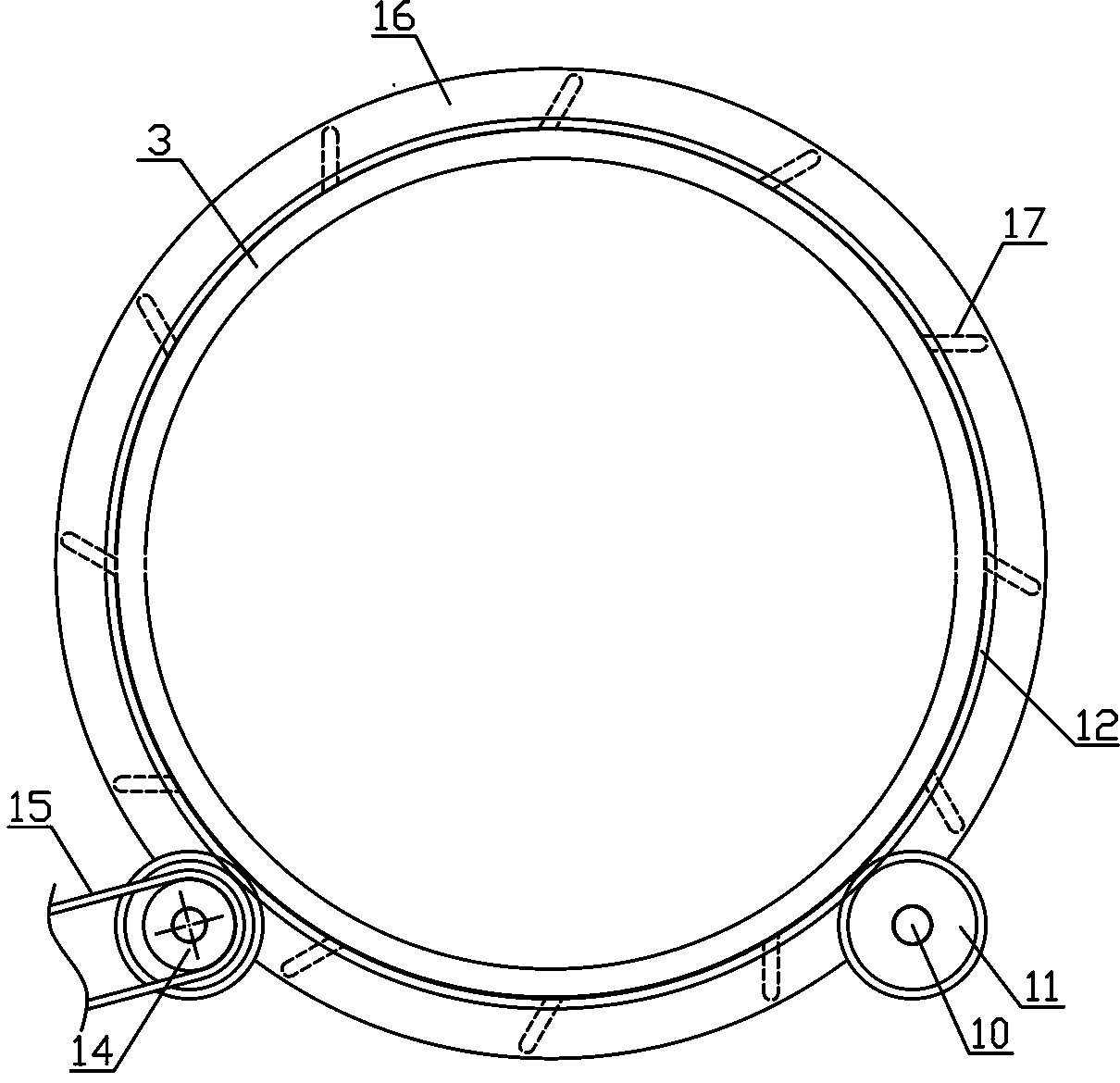

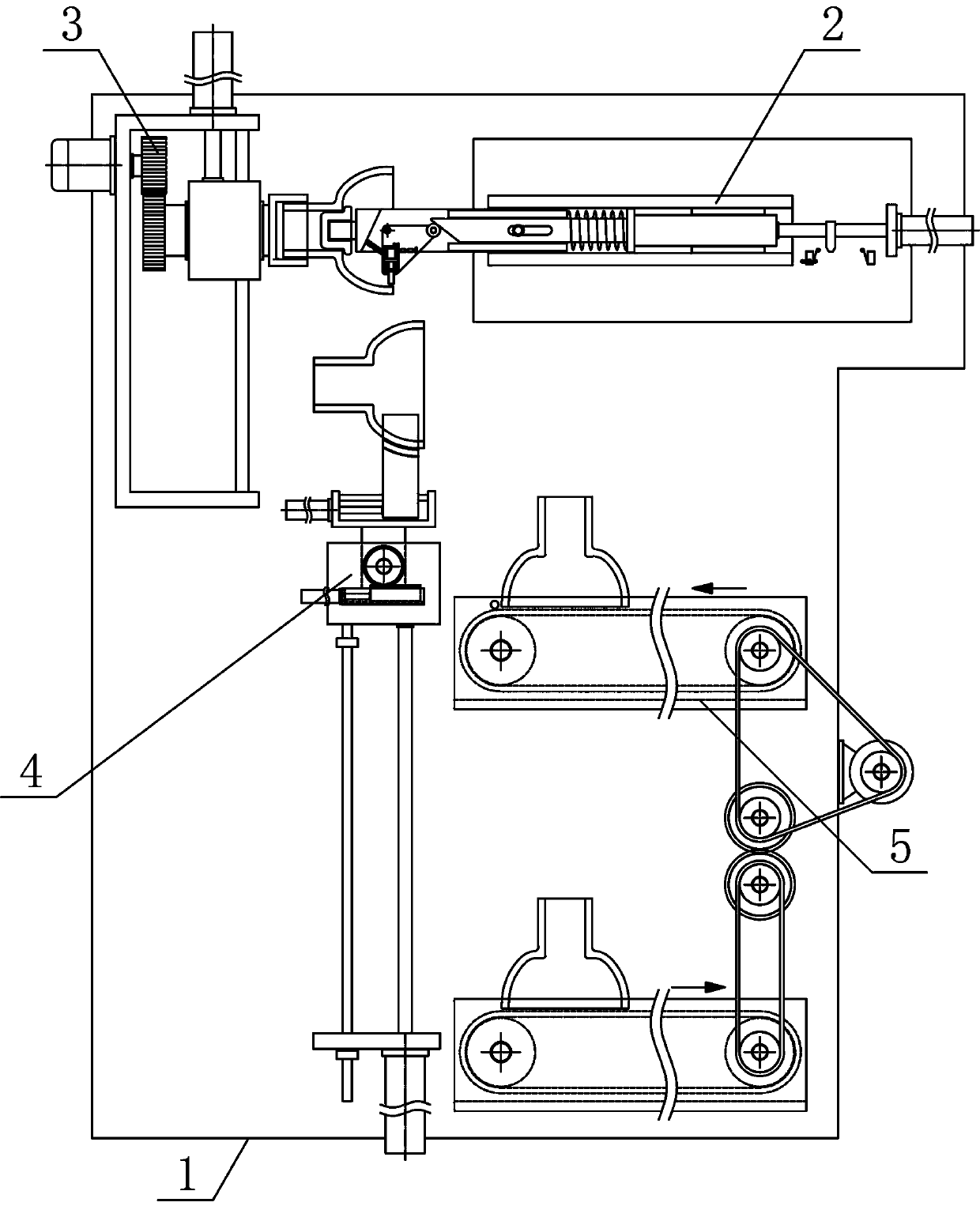

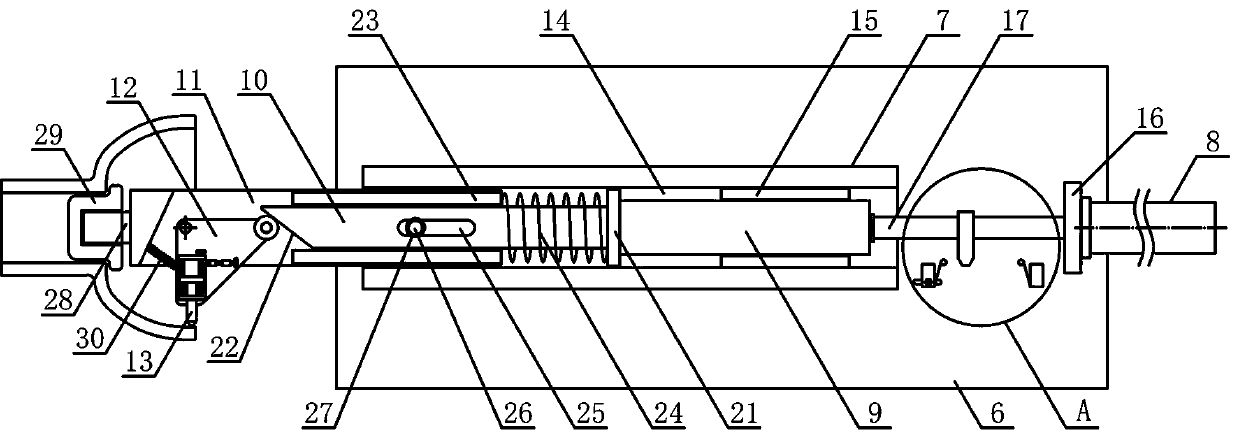

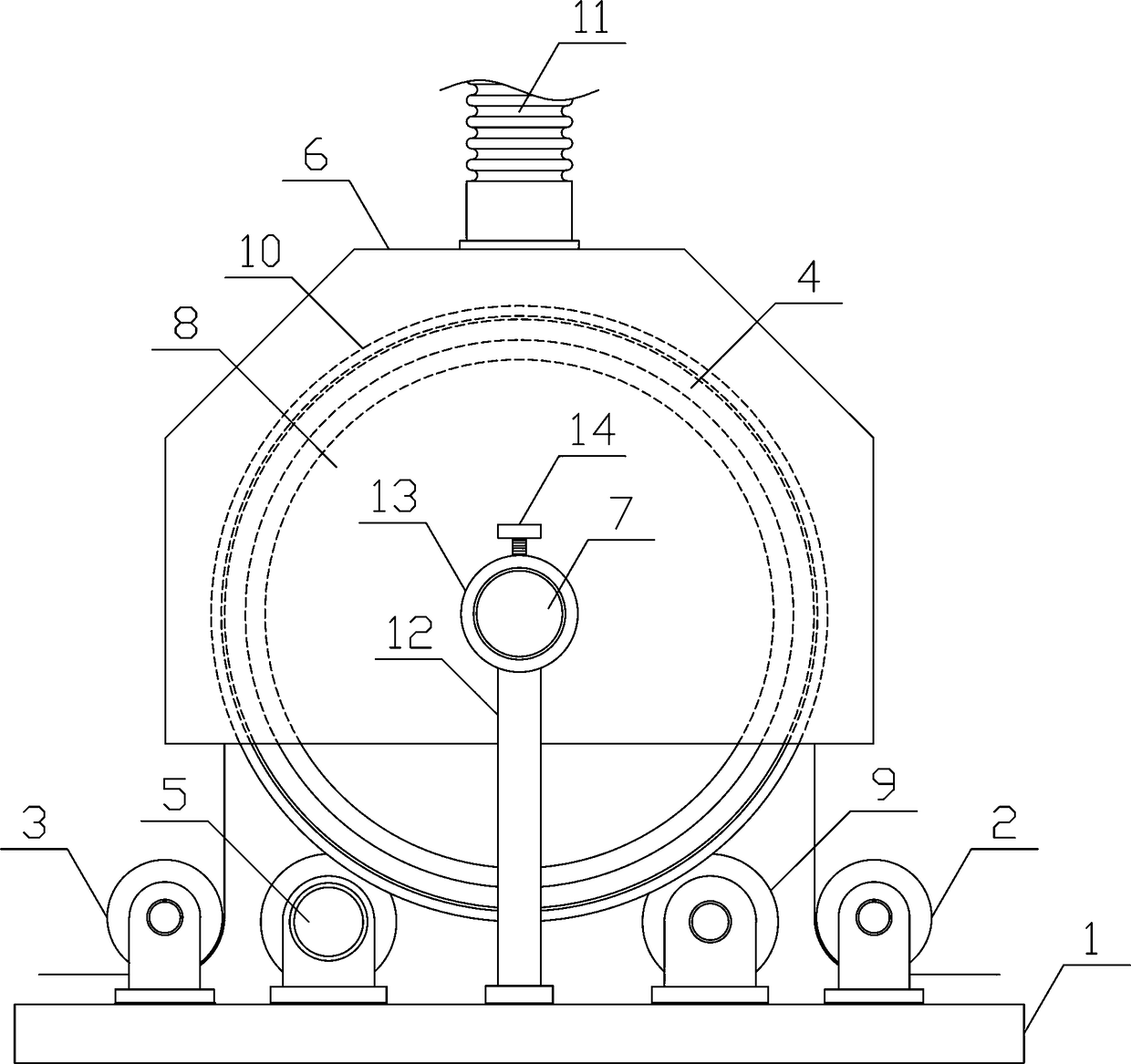

Ultrasonic testing device for king bolt of reactor pressure vessel of nuclear power station

ActiveCN103680648AQuick installationHigh positioning accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesNuclear energy generationReactor pressure vesselNuclear power plant

The invention provides an ultrasonic testing device for a king bolt of a reactor pressure vessel of a nuclear power station. The ultrasonic testing device comprises a base, a vertical frame fixed on the base, a support platform, a holding mechanism and a testing mechanism, wherein the support platform is arranged on the base by a rotating mechanism and is used for supporting the king bolt and driving the king bolt to rotate; the holding mechanism comprises a first mounting base and a holding claw which is arranged on the first mounting base and surrounds the king bolt, and the first mounting base is arranged on the vertical frame and is positioned on one side facing the support platform; the testing mechanism comprises a second mounting base, a transverse driving mechanism, a longitudinal driving mechanism, a first clamp with a center hole inner wall testing probe and a second clamp with an end surface testing probe, the transverse driving mechanism and the longitudinal driving mechanism are arranged on the second mounting base, the second mounting base is arranged on the vertical frame and is positioned above the holding mechanism. The ultrasonic testing device can realize rapid installation, clamping and centering of king bolts with different models and drive the tested king bolt to rotate stably and accurately, and is provided with an ultrasonic testing probe to achieve gross-volume ultrasonic testing of the tested king bolt.

Owner:STATE NUCLEAR POWER PLANT SERVICE

Rotary knob assembly for home appliance

ActiveUS7038156B2Not to damageStable and precise rotationContact engagementsRotary switchEngineering

Disclosed is a rotary knob assembly for a home appliance. The assembly includes a rotary switch having an encoder and a shaft rotatably installed at the encoder, a knob coupled to the shaft of the rotary switch, and a support member provided around the rotary switch to support the rotary switch.

Owner:LG ELECTRONICS INC

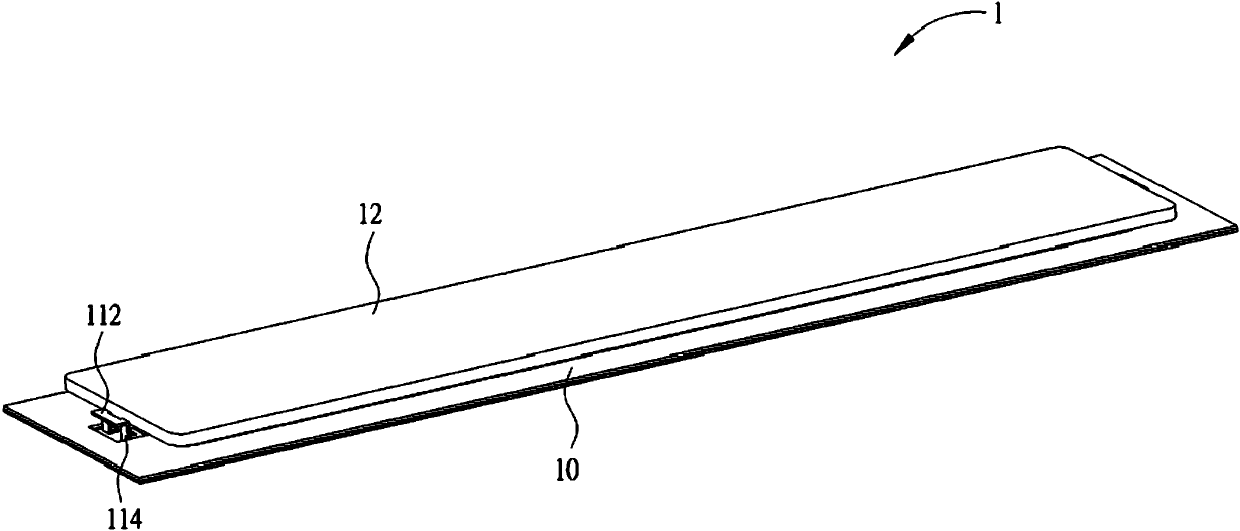

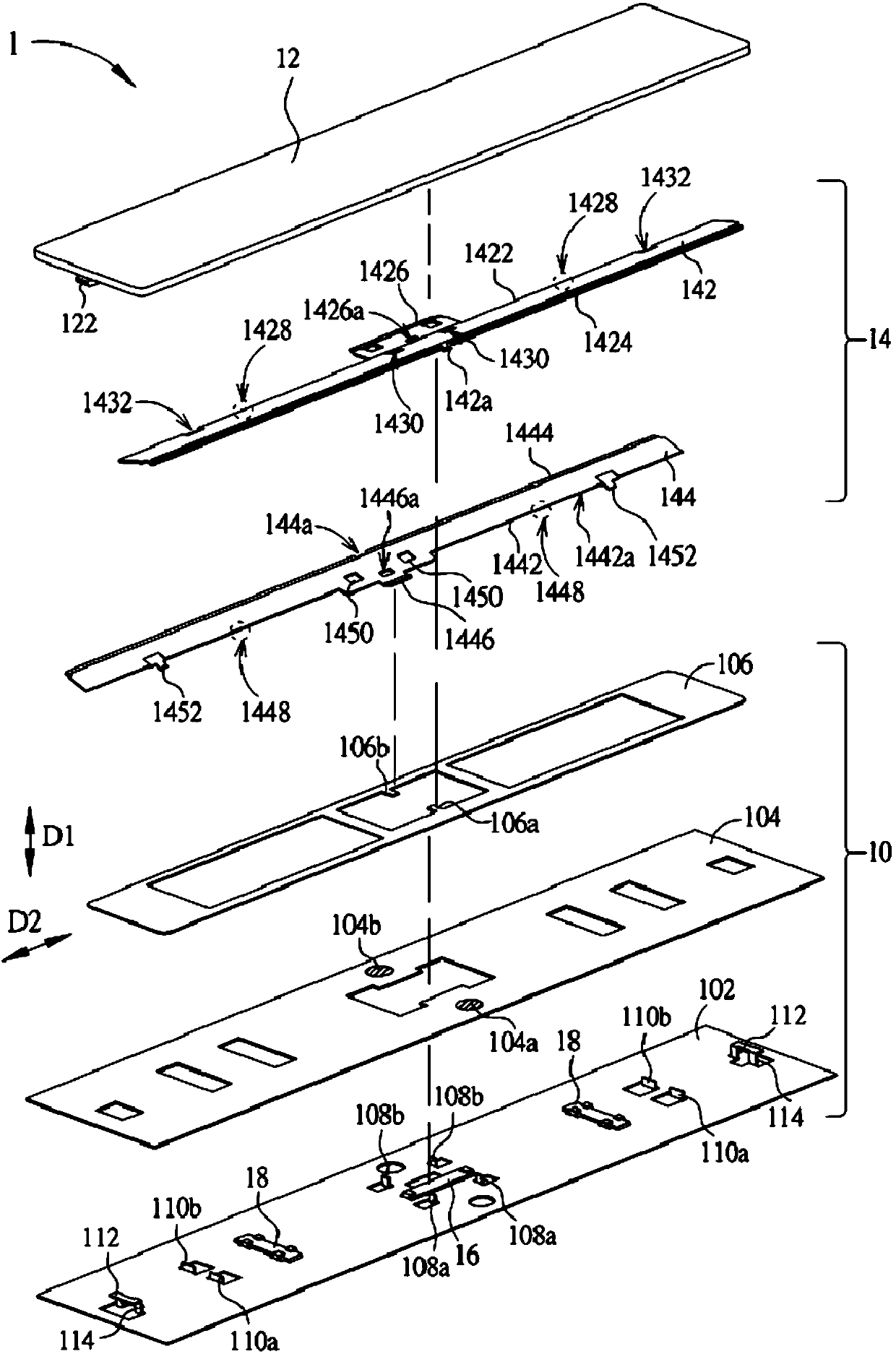

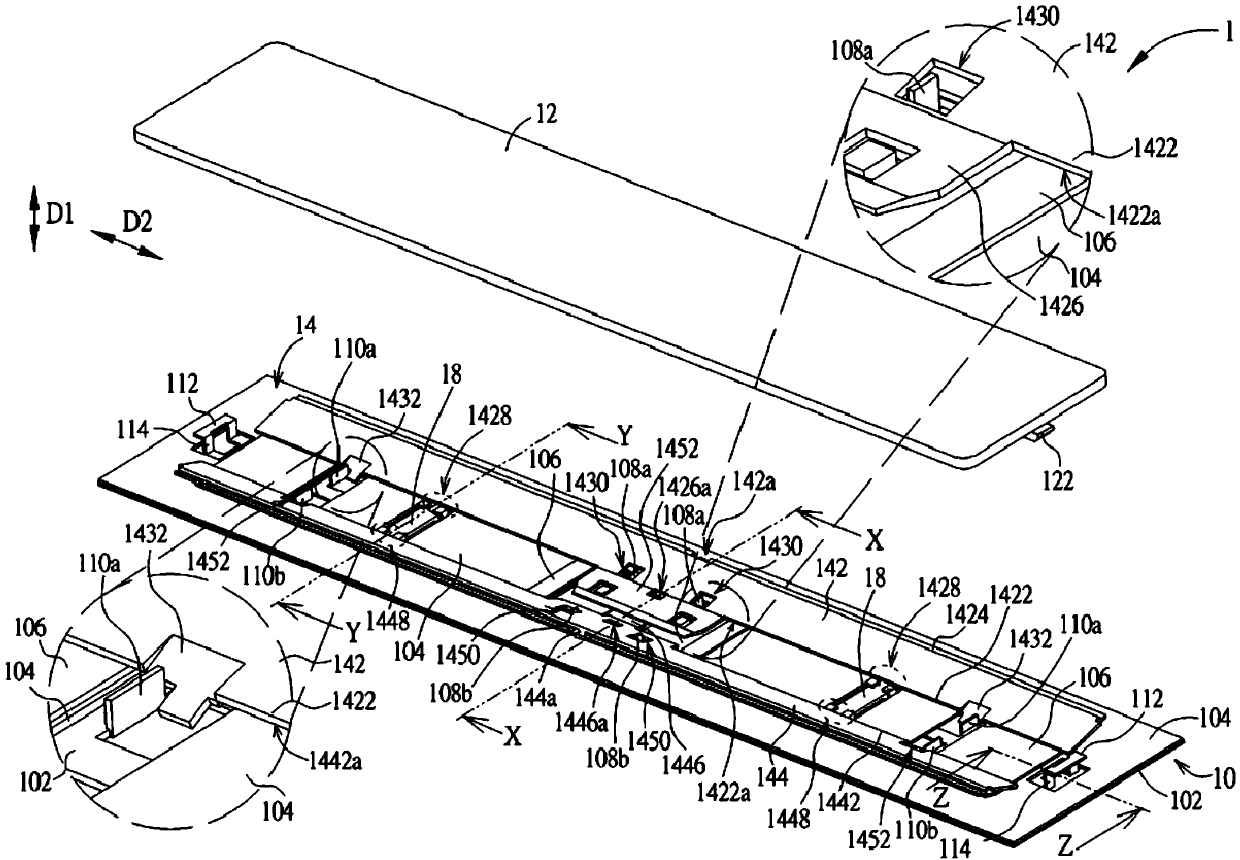

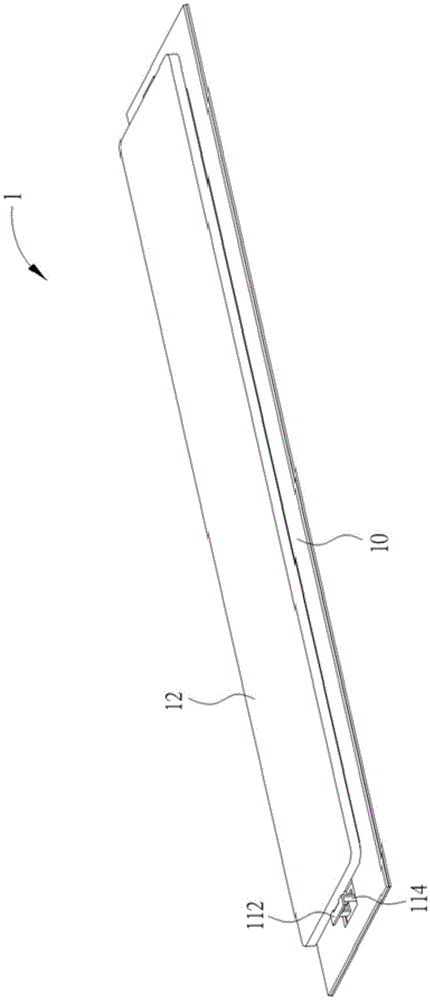

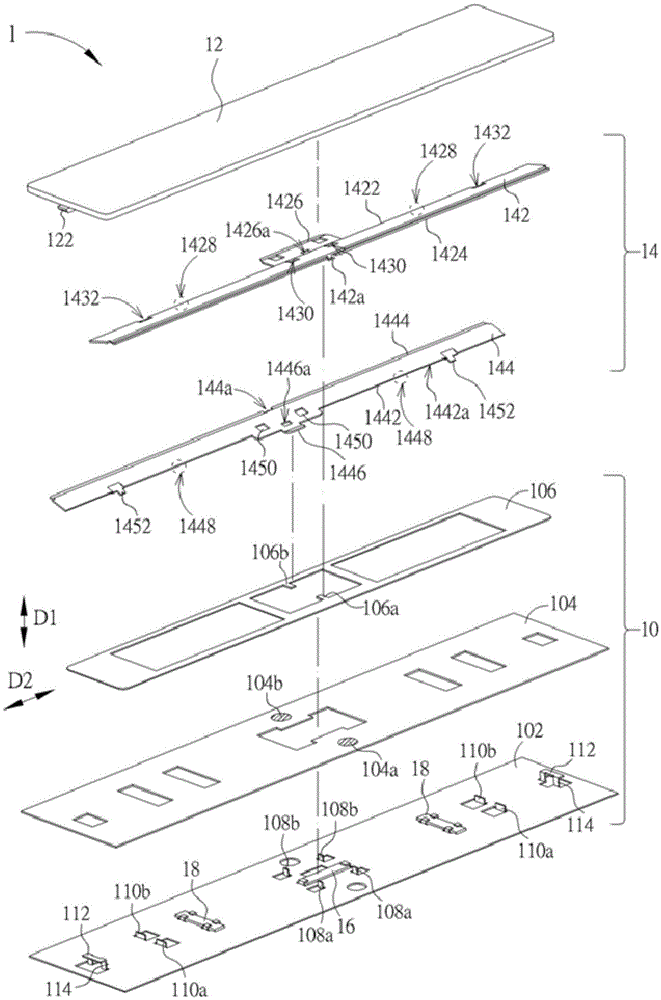

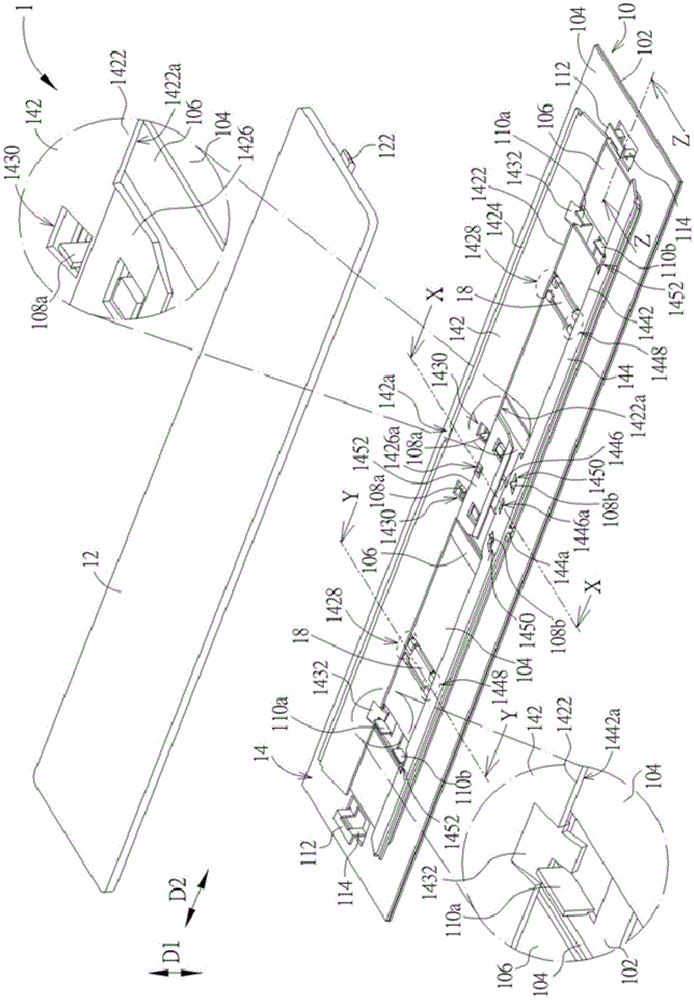

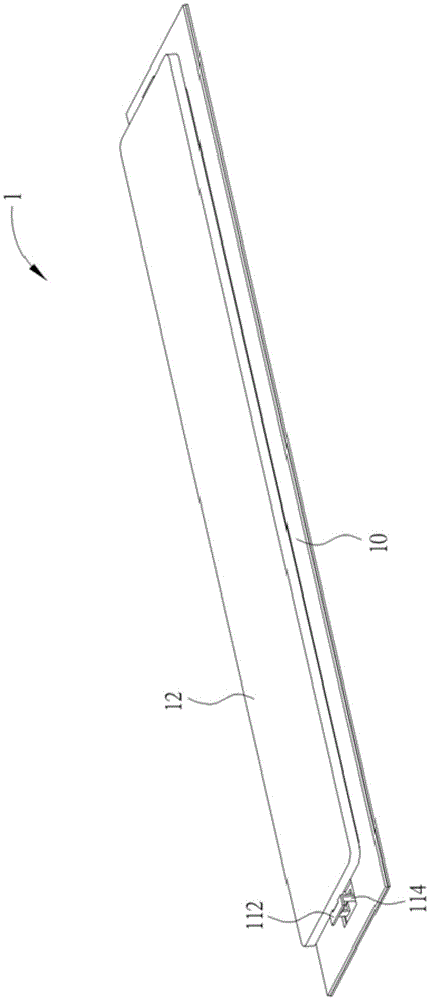

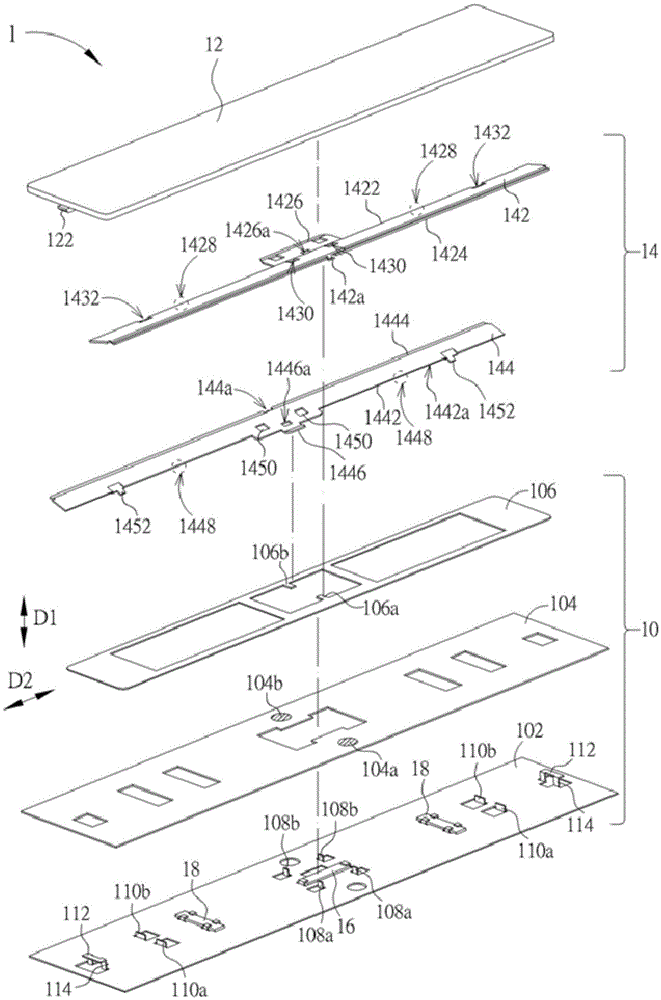

Key structure

ActiveCN104201029ALower the altitudeApproach steadilyElectric switchesTactile feedbackKey pressingSuction force

The invention relates to a key structure. The key structure comprises a base, a keycap, a lifting mechanism and a magnetic part; the keycap can move vertically relative to the base through the lifting mechanism; the lifting mechanism comprises a support; one lateral side portion of the support comprises a magnetic portion; the lateral side portion is in abutting joint with the base through a sharp edge; the magnetic portion extends outward from the lateral side portion; the support is flexibly connected with the keycap through an opposite lateral side portion; the magnetic part is arranged on the base corresponding to the magnetic portion; the magnetic suction force is produced between the magnetic part and the magnetic portion; when the keycap is pressed by the external force, the support rotates relative to the base through the sharp edge to enable the magnetic portion to be far away from the magnetic part and the keycap to be close to the base; when the external force is released, the support is driven by the magnetic suction force to rotate relative to the base through the sharp edge to enable the keycap to be far away from the base; the base can be provided with a magnetic part, wherein the magnetic suction force can be applied to the other magnetic portion of the support to drive the lateral side portion to be in abutting joint with the base.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

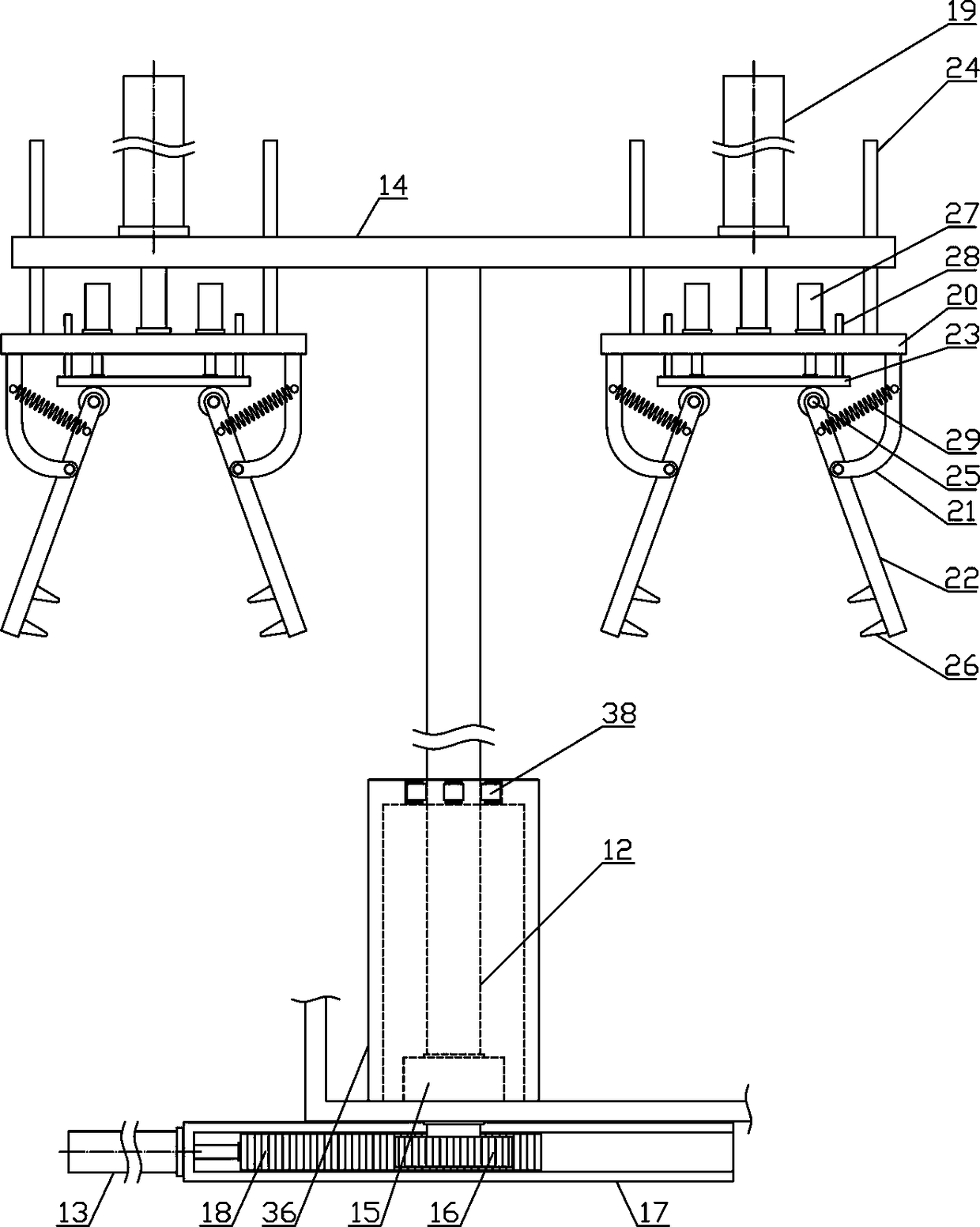

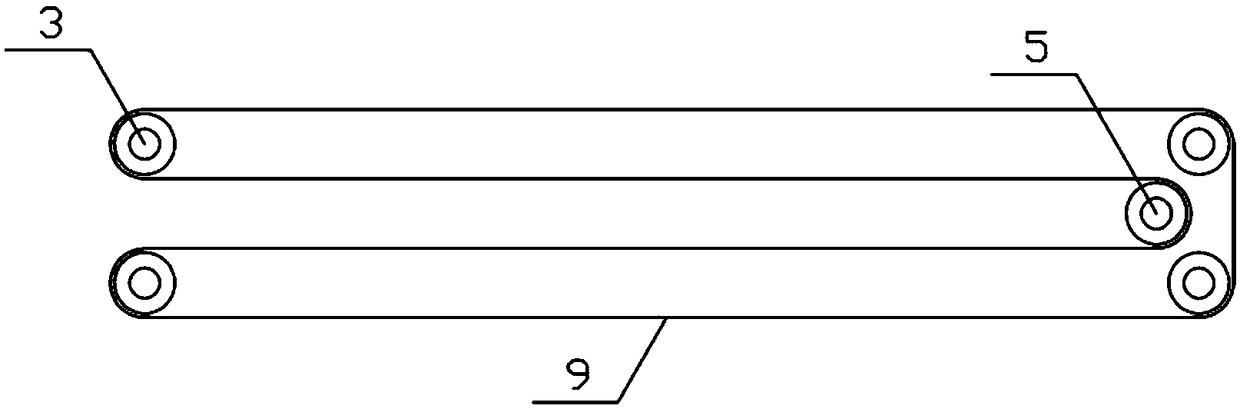

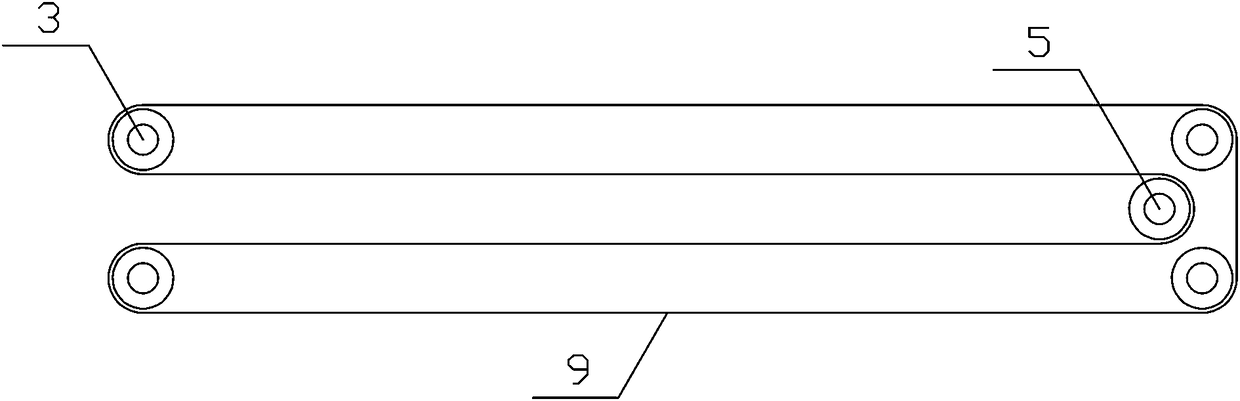

Flax coil continuous loading mechanism

InactiveCN108946035AReasonable structural designHigh degree of automationMechanical conveyorsMaterial transferLeather belt

The invention discloses a flax coil continuous loading mechanism and belongs to the field of textile processing machinery equipment. A material transferring mechanism and a bearing carrying mechanismare horizontally arranged on the two sides of the lower side of the loading mechanism respectively; the two sides of a material conveying belt are connected to a main conveying roll and an auxiliary conveying roll which are on the two sides of a fixed bracket in a coiling manner respectively; a drive gear which is adapted to a conveying gear is vertically and rotationally connected to the fixed bracket on the lower side of the conveying gear; a loading rotary shaft is vertically and rotationally connected to the middle part of a rotation truncated cone; a rotation disc is horizontally arrangedat the upper end of the loading rotary shaft; the two sides of the rotation disc are vertically and symmetrically provided with coil clamping mechanism in a radial direction of the rotation disc; oneend of a bearing carrying rotary plate is hinged to the middle part of the supper side of a carrying plate bracket; and a push plate rotary wheel is vertically and rotationally connected to the output ends of a push plate cylinder on the two sides of the lower side of one end of the material carrying rotary plate. The flax coil continuous loading mechanism provided by the invention is reasonablein structure design, can rapidly, efficiently, continuously and smoothly perform conveying and loading on a flax coil, increases the processing automation degree of the flax coil and meets the demandof production use.

Owner:戴杰

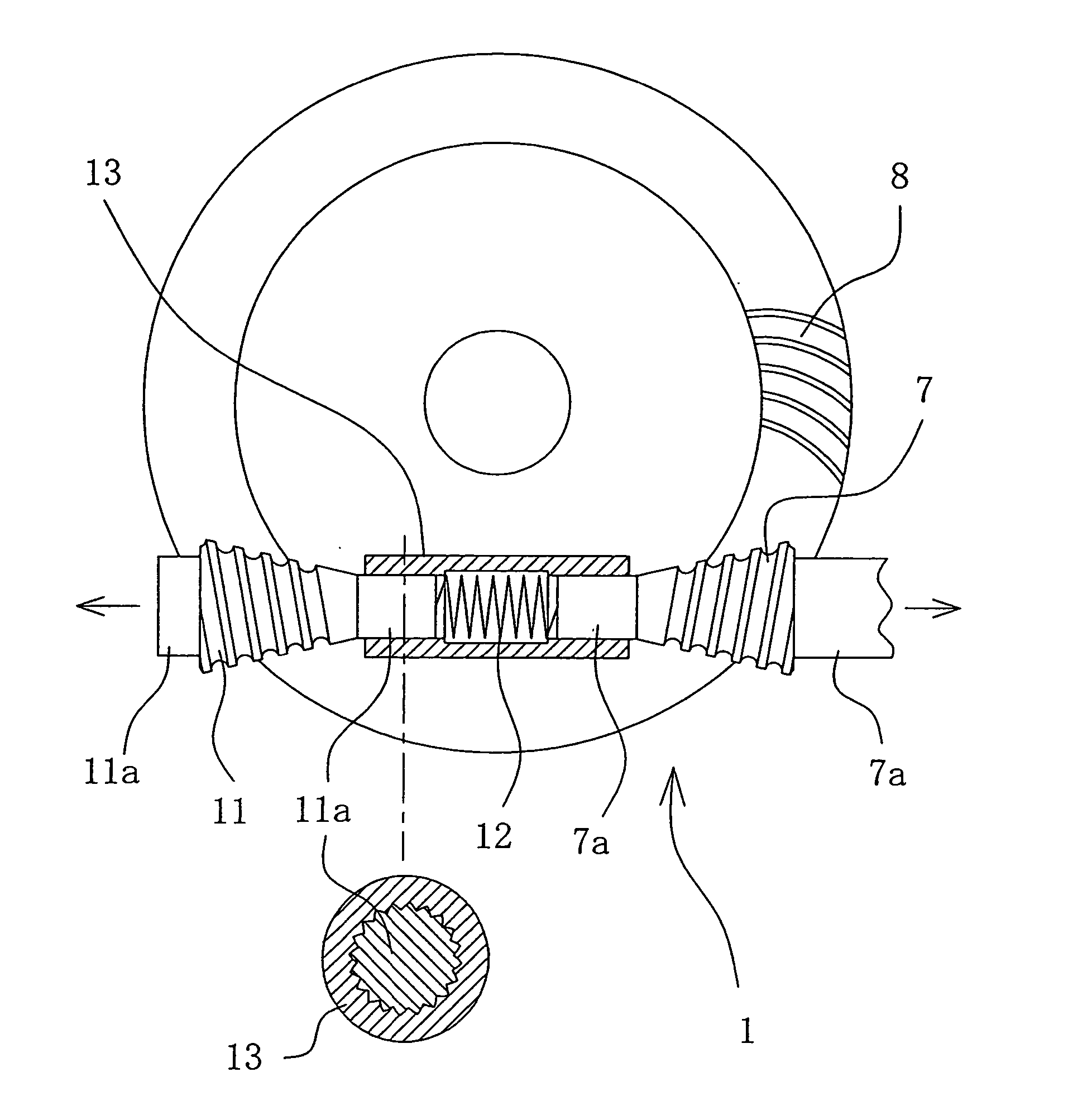

Hypoid gear device

InactiveUS20060219036A1Eliminate backlashEliminate overloadToothed gearingsPortable liftingEngineeringDrive wheel

Owner:THK CO LTD

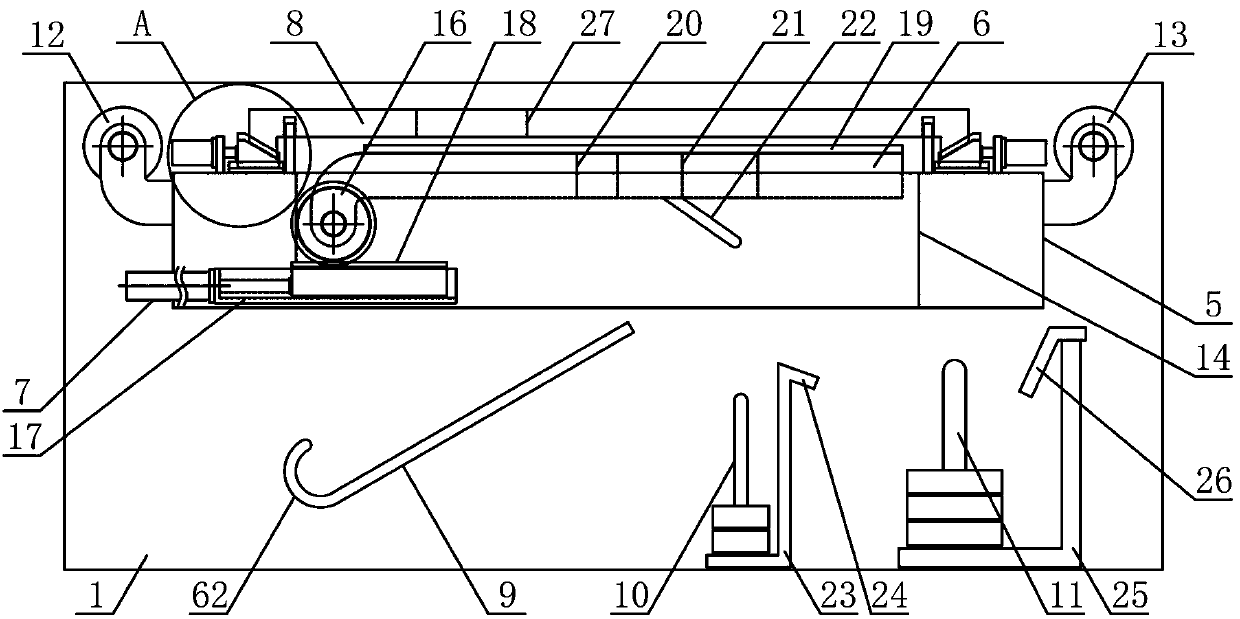

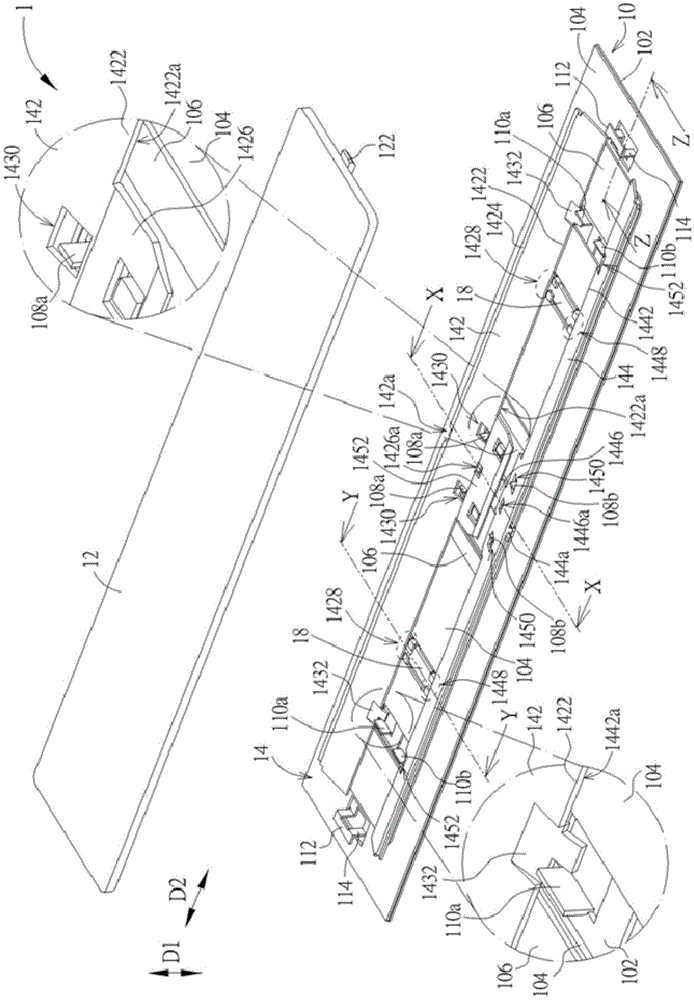

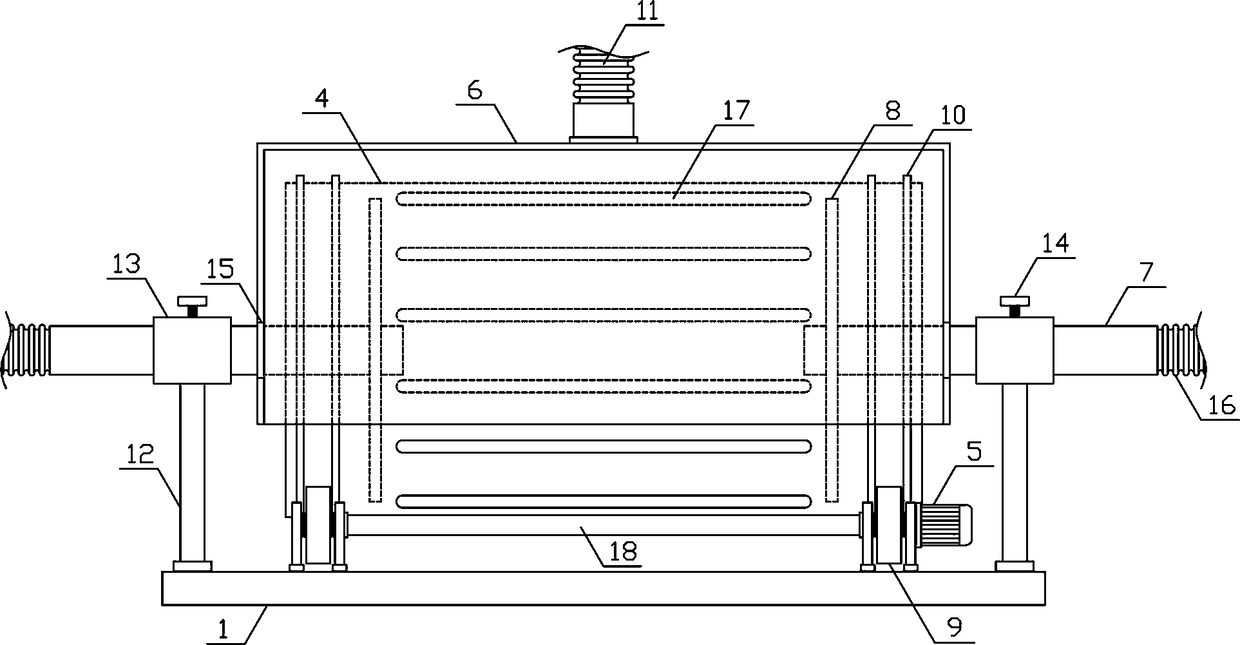

Sheet material processing pressing mechanism

InactiveCN108772726AStable and precise rotationAccurate and efficient rotationMachine tool componentsPositioning apparatusSheet materialEngineering

The invention discloses a sheet material processing pressing mechanism, and belongs to the field of sheet material processing machinery and equipment. A driving mechanism, a pressing-down mechanism and a material conveying mechanism of the sheet material processing pressing mechanism are sequentially and horizontally arranged on one side of a fixing bracket from top to bottom, and a horizontal moving connecting plate is slidably disposed at a reciprocating guide rod in the horizontal direction. A horizontal moving rack is horizontally and fixedly arranged on one side of the horizontal moving connecting plate, and rotating pressing plates of a circular arc structure are vertically and symmetrically arranged on both sides of the lower part of a pressing disc. A lifting pressing plate is slidably disposed at lifting guide rods in the vertical direction, and a plurality of pressing lead screws are vertically arranged on the outer side of the lifting pressing plate. Pressing round platformsare fixedly arranged at the lower ends of the pressing lead screws, and a material conveying bracket is horizontally and rotatably connected with a plurality of material conveying rotating rollers inthe horizontal direction in sequence. The sheet material processing pressing mechanism is reasonable in structure design, can horizontally and accurately convey sheet materials according to the needs, can conveniently and smoothly press and fix the sheet materials in the conveying process, and can be applied to the sheet materials of different sizes and specifications to meet the needs of sheet material processing and using.

Owner:嘉兴汉羿文化传播有限公司

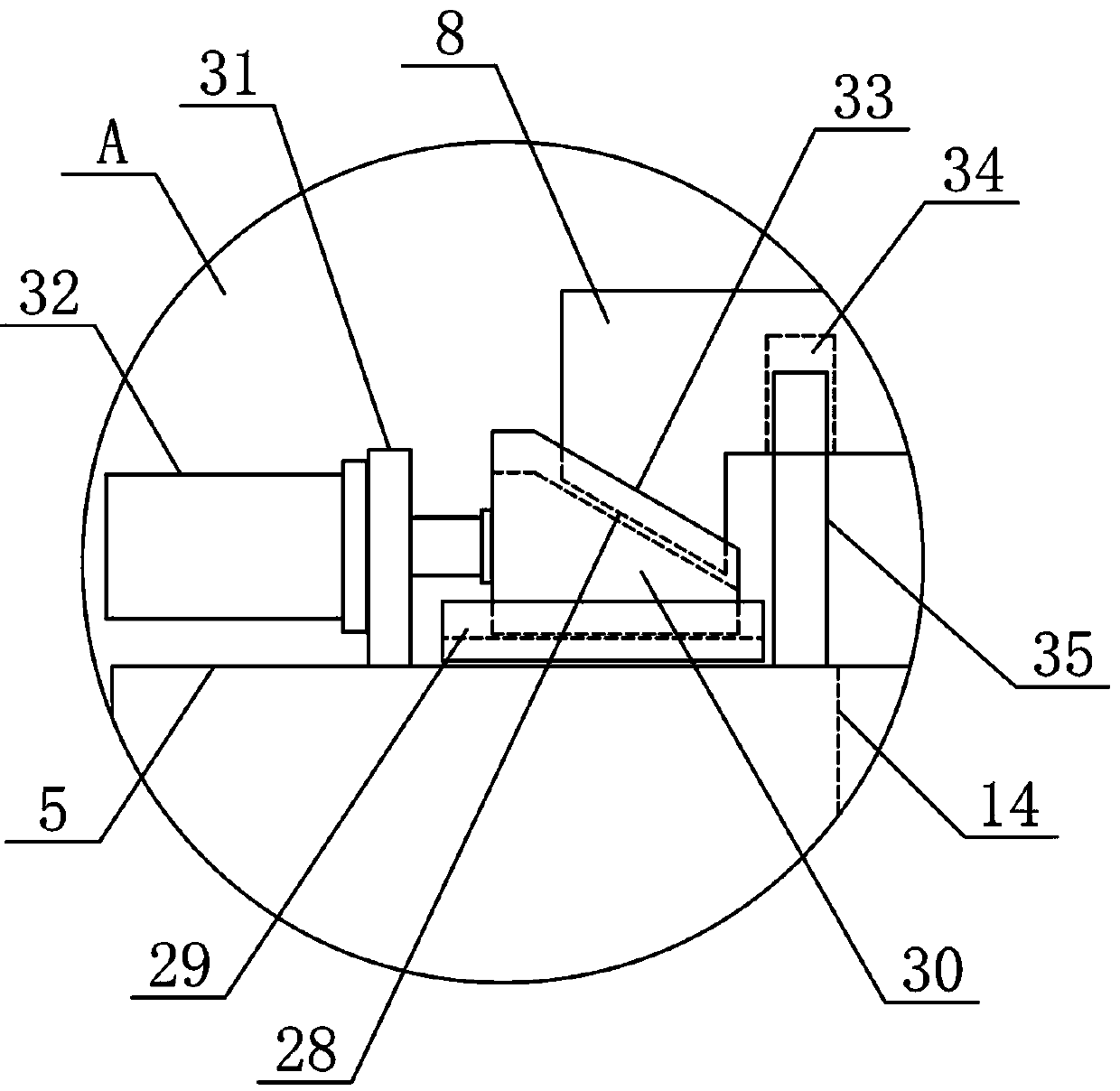

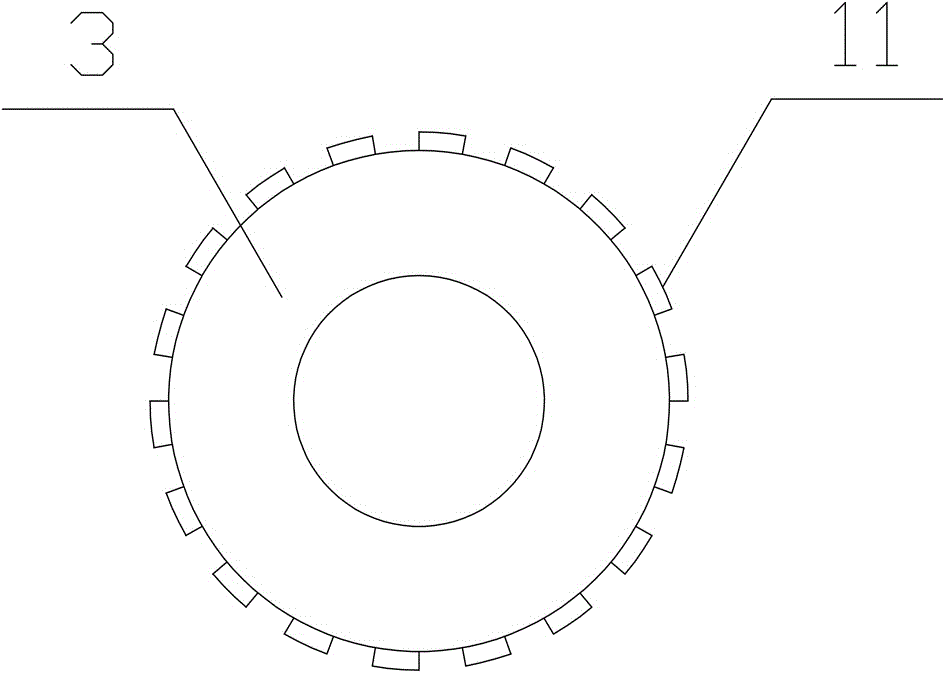

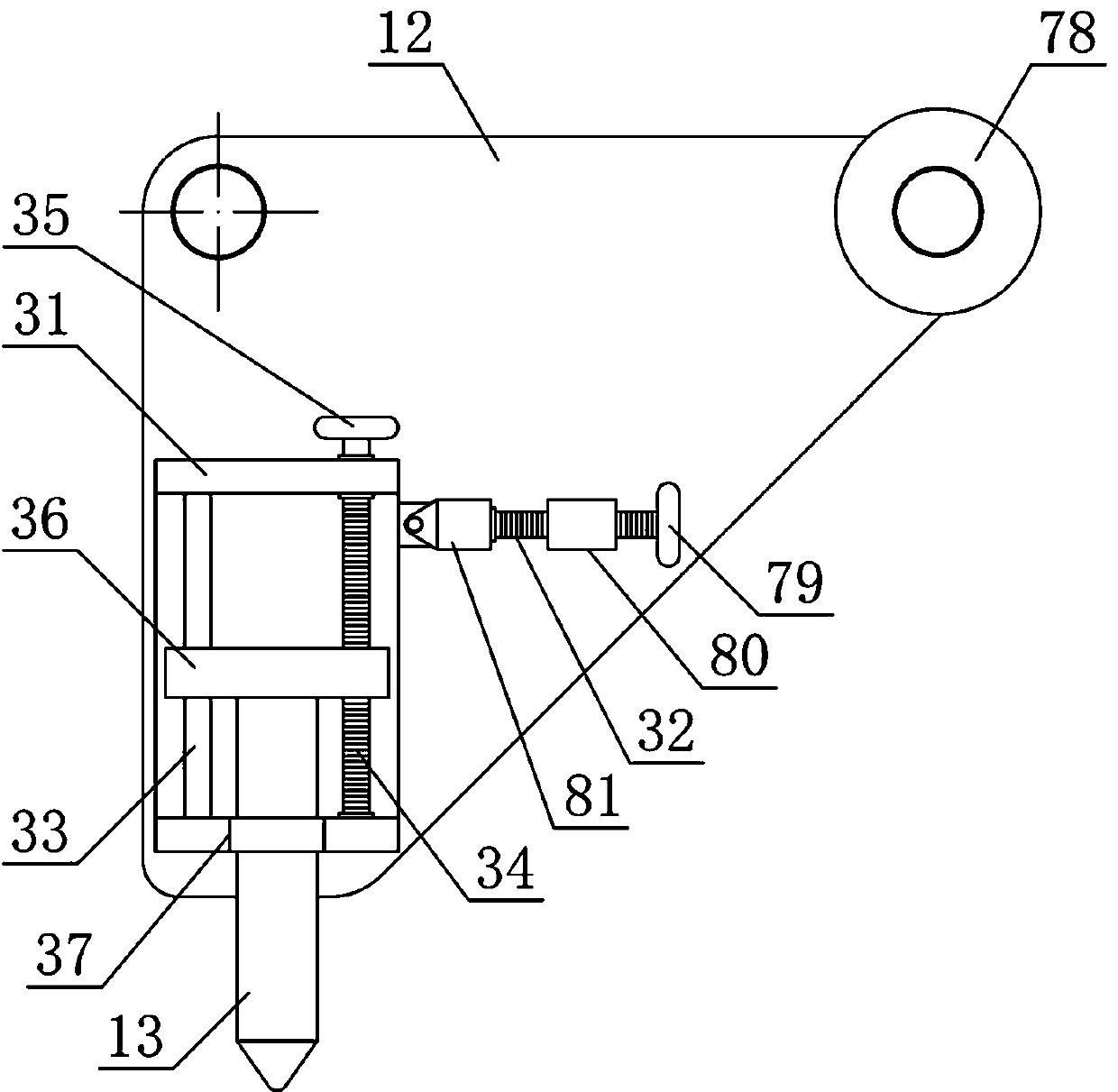

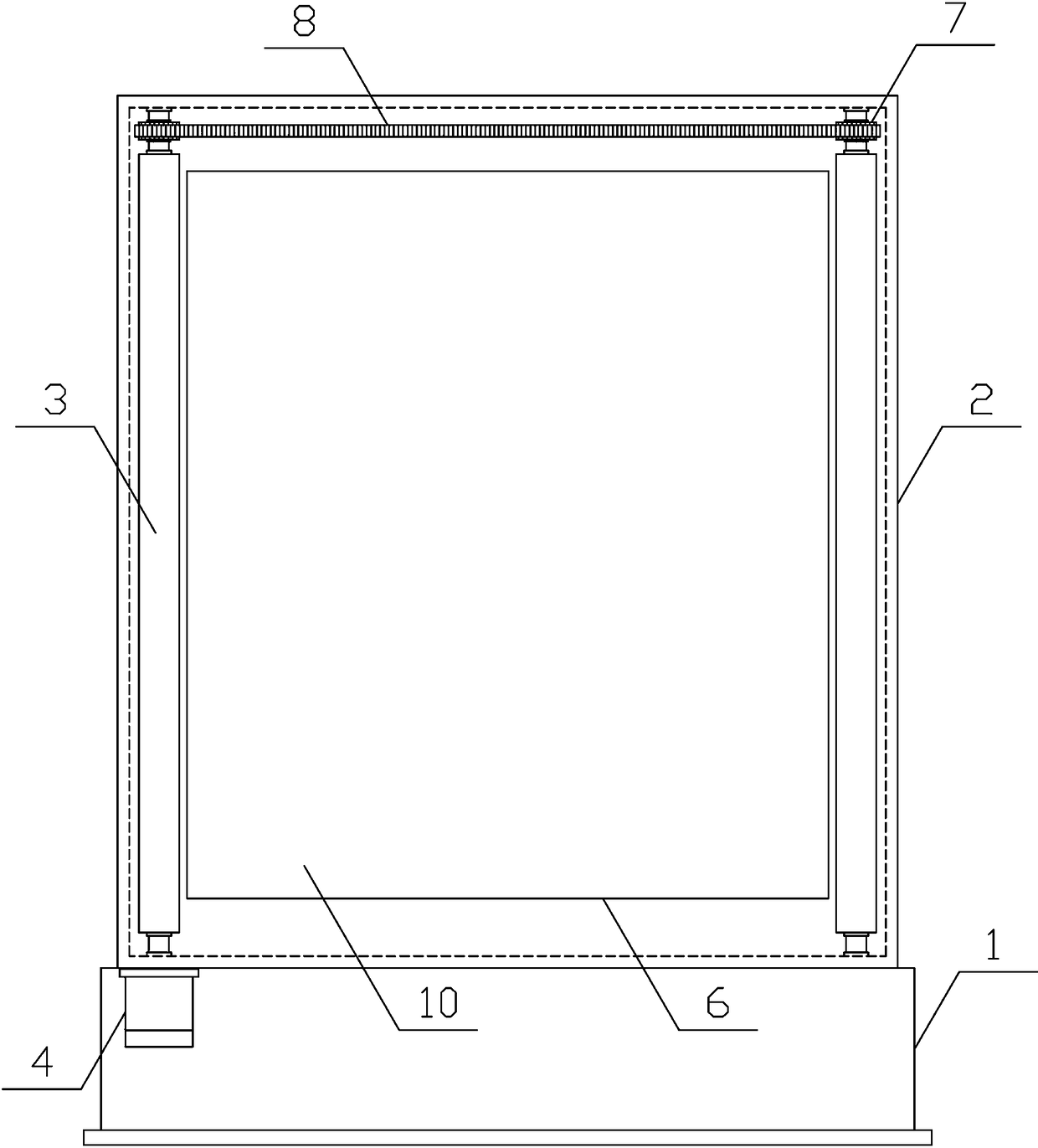

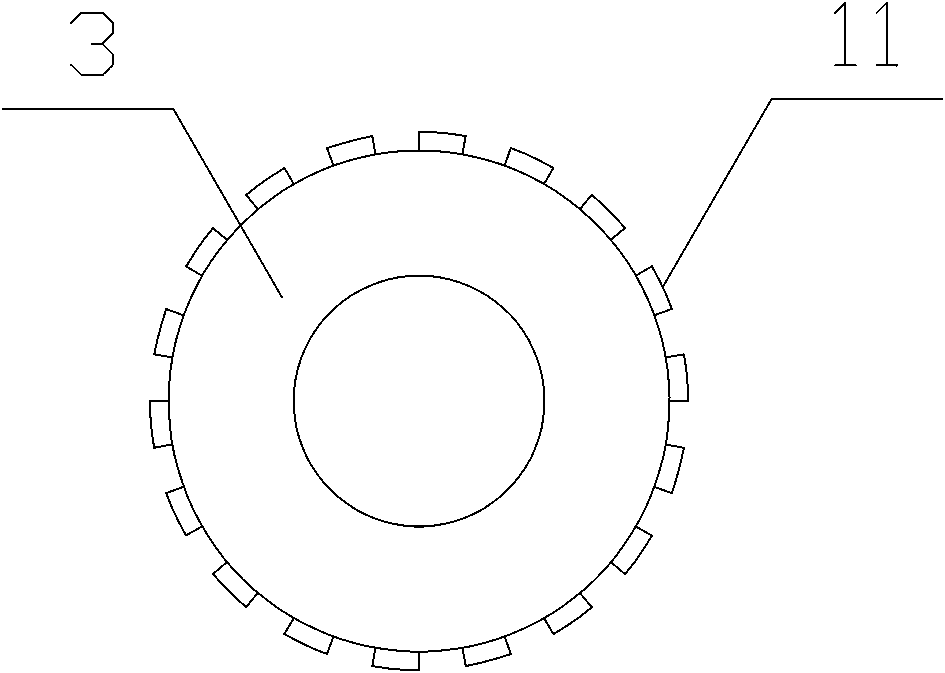

Grooving device for camber surface of inner side of shaft sleeve workpiece

ActiveCN110560706AEfficient and convenient clamping and fixingClamping and fixing is stable and accurateAutomatic control devicesFeeding apparatusMachiningAutomation

The invention discloses a grooving device for a camber surface of the inner side of a shaft sleeve workpiece and belongs to the field of machinery equipment for machining the workpiece. According to the grooving device, a workpiece clamping mechanism is arranged at a machining bracket positioned at one side of a translational grooving mechanism; a translational guide plate is horizontally and slidably arranged on a guide support; a push plate bevel is arranged at the lower side of the end part of a translational pressing plate; the translational pressing plate is slidably arranged at a tool bit bracket; a grooving rotary plate is arranged at the tool bit bracket, positioned along the underside of the end of the push plate bevel, of the translational pressing plate; a machining rotary platerotates along bearing plate rotating wheels; the machining rotary plate positioned at the outer side of a clamping main gear is provided with a plurality of clamping auxiliary gears; a rotary gear ofa driving bracket is engaged with a rotary rack of the machining rotary plate; and a converting bracket is horizontally arranged at one side of a lifting bracket. The grooving device is reasonable instructural design, can be used for efficiently and conveniently clamping and fixing the shaft sleeve workpiece and realizing stable and accurate rotation, thereby realizing automatic grooving machining of the camber surface of the inner side of the shaft sleeve workpiece, achieving a high machining automation degree and meeting the use demands of machining of the workpiece.

Owner:常熟市万顺轴承有限公司

Automatic arranging mechanism for punched and sheared workpieces

ActiveCN110479847AHigh degree of processing automationSmooth and smooth separation and finishingMetal-working feeding devicesPositioning devicesFixed bearingPunching

The invention discloses an automatic arranging mechanism for punched and sheared workpieces and belongs to the field of workpiece processing mechanical devices. A plate feeding guide roller and a plate discharging guide roller are separately, horizontally and rotationally connected to the two sides of an arranging bracket; a guide rotating plate is rotationally arranged in an arranging rotating hole; a punching and shearing die plate is horizontally and fixedly arranged on the upper side of the arranging bracket; a punching and shearing die head matched with a punching and shearing pressure hole is fixedly arranged in the middle of the lower side of a lifting punching plate; translation guide rods are arranged on a reciprocating guide plate in the horizontal direction in a sliding manner;an output end of a plate pushing cylinder is fixedly connected with one side of the reciprocating guide plate; a lower pressure plate is fixedly arranged on the upper side of a fixed bearing plate atthe lower end of one side of the reciprocating guide plate in a horizontal laminating manner; and an upper pressure plate is arranged on the lower side of one end of a rotating pressure plate. The automatic arranging mechanism is reasonable in structural design, can conveniently, efficiently and continuously perform punching and shearing processing to produce workpieces, and annular workpieces formed through synchronous punching and shearing processing are stably and smoothly separated and arranged, so that the workpiece processing automatic degree is improved, and the processing and using requirements are met.

Owner:乳山吾星纤维有限公司

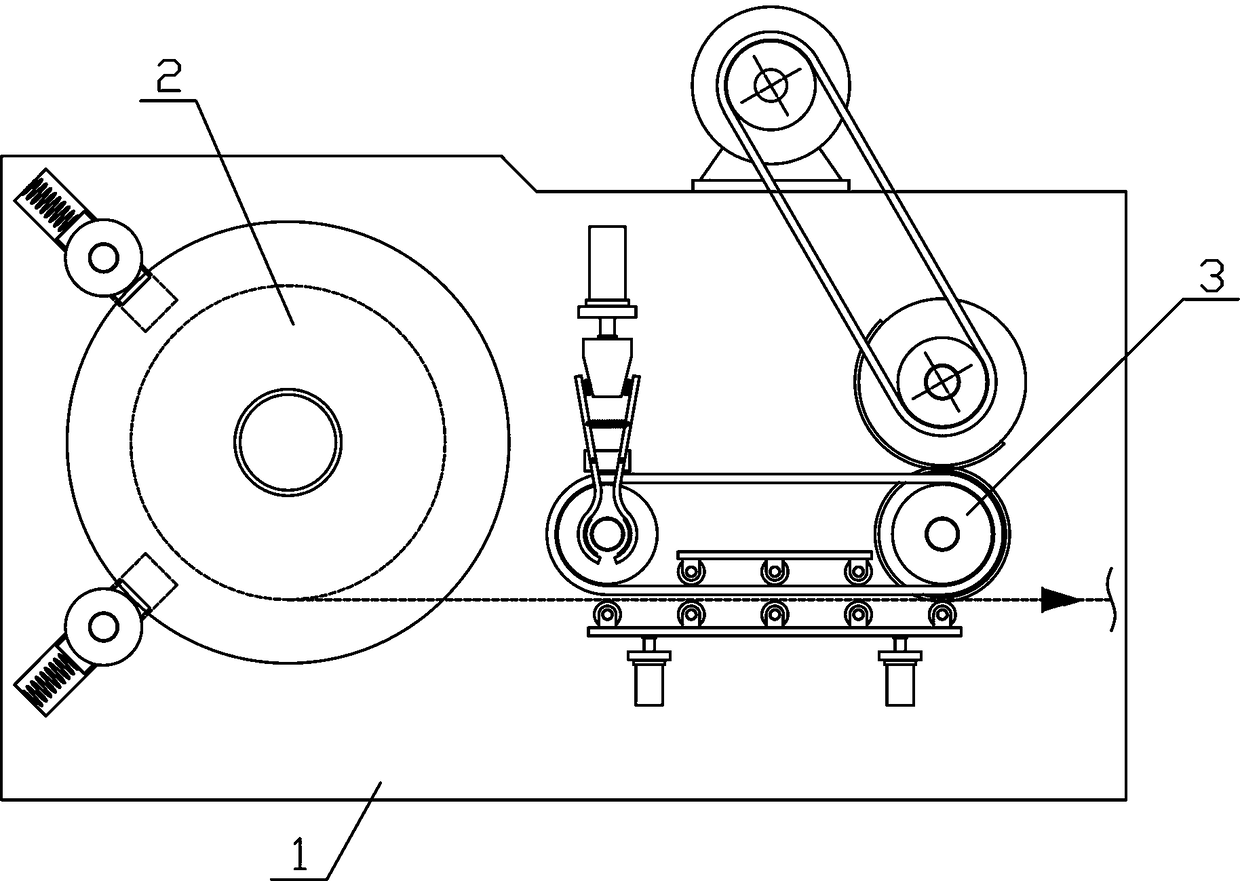

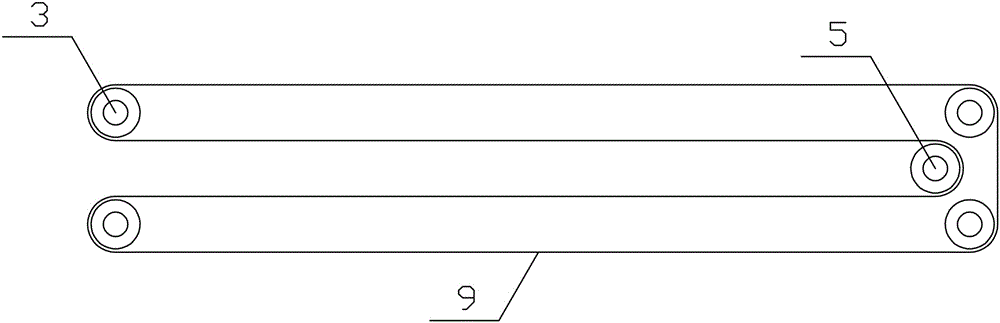

Intermittent feeding mechanism for yarn

InactiveCN109230820ARealize automatic intermittent feeding and conveyingAvoid looseFilament handlingYarnEngineering

The invention discloses an intermittent feeding mechanism for yarn and belongs to the field of mechanical equipment for yarn conveying processing. A yarn reel of the mechanism horizontally sleeves a yarn release rotation roller, a damping press wheel is vertically and rotatably connected to one side of a press cylinder guide block, and a damping compression spring is obliquely arranged between a press cylinder guide block and a feeding support; a yarn pulling conveying belt is horizontally arranged at one side of the feeding support, a yarn pulling gear and an intermittent gear are alternatively meshed with each other, and the output end of a yarn pulling motor is in transmission connection with the intermittent gear through a yarn pulling belt; multiple yarn bearing press rollers are rotatably connected to the upper side of a yarn bearing lifting plate of the output end of a yarn bearing air cylinder in the horizontal direction in sequence, multiple press belt rotation rollers are rotatably and horizontally connected to the lower side of a press belt fixing plate in the horizontal direction in sequence, and a roller clamping mechanism is vertically arranged at one side of an auxiliary yarn pull rotation roller. The intermittent feeding mechanism for the yarn is reasonable in structural design, the yarn can be efficiently and conveniently drafted and conveyed segment by segmentand can be automatically, stably and intermittently fed, and the demands of processing and application are met.

Owner:桐乡市澳得利纤维股份有限公司

Key structure

ActiveCN105551866ALower the altitudeApproach steadilyElectric switchesTactile feedbackKey pressingEngineering

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

Cutting machining device for spherical-surface workpieces

ActiveCN110586962ARealize automatic transferSmooth rotationAutomatic control devicesFeeding apparatusMechanical equipmentTransfer mechanism

The invention discloses a cutting machining device for spherical-surface workpieces, and belongs to the field of workpiece machining mechanical equipment. The cutting machining device comprises a machining conveying support, a horizontal moving and cutting mechanism, a clamping and lifting mechanism, a turning and transferring mechanism and a workpiece conveying mechanism, wherein the horizontal moving and cutting mechanism is horizontally and fixedly arranged on one side above the machining conveying support, the clamping and lifting mechanism is vertically arranged at the position, on one side of the horizontal moving and cutting mechanism, of the machining conveying support, the turning and transferring mechanism is vertically arranged at the position, on one side below the clamping andlifting mechanism, of the machining conveying support, and the workpiece conveying mechanism is horizontally arranged at the position, on one side of the turning and transferring mechanism, of the machining conveying support in a mode of being adjacent to the turning and transferring mechanism. The cutting machining device has the advantages that the structural design is reasonable, the spherical-surface workpieces can be efficiently and stably cut and machined one by one, moreover, automatic transferring feeding and pushing of the spherical-surface workpieces can be achieved, the machining automation degree is high, and the workpiece machining and use requirements are met.

Owner:昆山勖盟工业科技有限公司

Sheet conveying and grooving device

InactiveCN108608073AMeet the needs of groovingReasonable structural designWood mortising machinesMetal working apparatusEngineeringMaterials processing

The invention discloses a sheet conveying and grooving device, and belongs to the field of building material processing machinery and equipment. According to the sheet conveying and grooving device, alifting support is horizontally arranged on the lower side of a conveying support, a plurality of material conveying rotating rollers are sequentially and uniformly arranged on the lifting support inthe horizontal direction, a plurality of material bearing rotating rollers are sequentially and vertically arranged on a material bearing support in the horizontal direction, a plurality of materialpressing rotating rollers are sequentially and vertically arranged on a material pressing support in the horizontal direction, an upper fixing rotating shaft and a lower fixing rotating shaft are sequentially and horizontally connected to a fixing support in a rotating mode from top to bottom, a grooving rotating disc is vertically arranged at one end of the upper fixing rotating shaft, a groovinginclined plane is arranged on one side of the grooving rotating disc, and a grooving pressing rod is arranged on a reciprocating support in a sliding mode in the horizontal direction. According to the sheet conveying and grooving device, the structural design is reasonable, sheets can be stably and accurately conveyed in a translation mode according to requirements, the side edges of the sheets can be continuously subjected to grooving processing in the sheet conveying process, the processing automation degree of the sheets can be improved, and the requirement for processing and using can bemet.

Owner:嘉兴汉羿文化传播有限公司

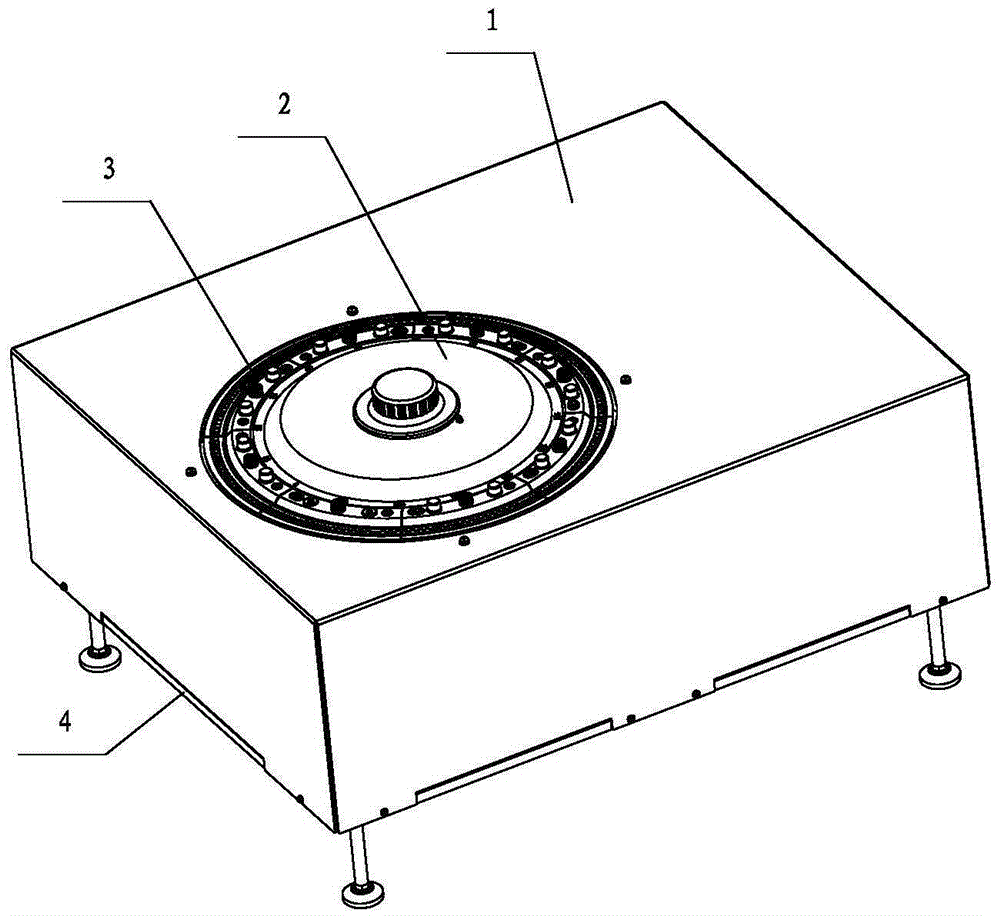

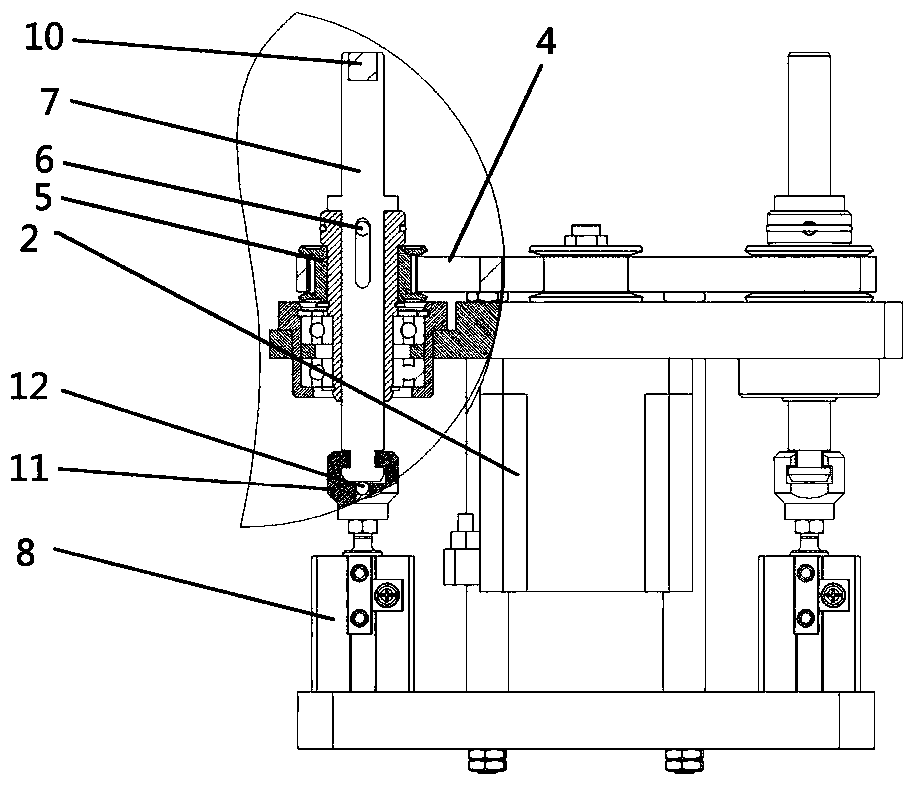

Cuvette light transmittance tester

ActiveCN105334194AThe results of biochemical analysis are accurateReduce varianceTransmissivity measurementsCuvetteElectricity

The invention discloses a cuvette light transmittance tester. The tester comprises a pedestal, and a reaction disc, a reaction tank, a driving device, a luminescence device, a photoelectric receiver and a shell cover which are arranged on the pedestal; the reaction disc is in rotating connection with the pedestal through the driving device, and the edge of the reaction disc is circumferentially connected with a plurality of cuvette couplings forming a ring; the reaction tank is circumferentially provided with a ring of annular grooves with upward openings, and the cuvette couplings are positioned in the annular grooves; the luminescence device is positioned in the reaction tank, light beams emitted by the luminescence device go through the cuvette couplings and are received by the photoelectric receiver, and the photoelectric receiver is electrically connected with the data analyzer of the tester through a lead; and the edge of the shell cover is connected with the edge of the pedestal, and the cuvette couplings are positioned in the perforated position of the top surface of the shell cover. The cuvette light transmittance tester adopting the above structure reduces differences in cuvettes, couplings and batches, so the biochemical analysis result using the cuvettes is accurate.

Owner:宁波美康盛德生物科技有限公司 +1

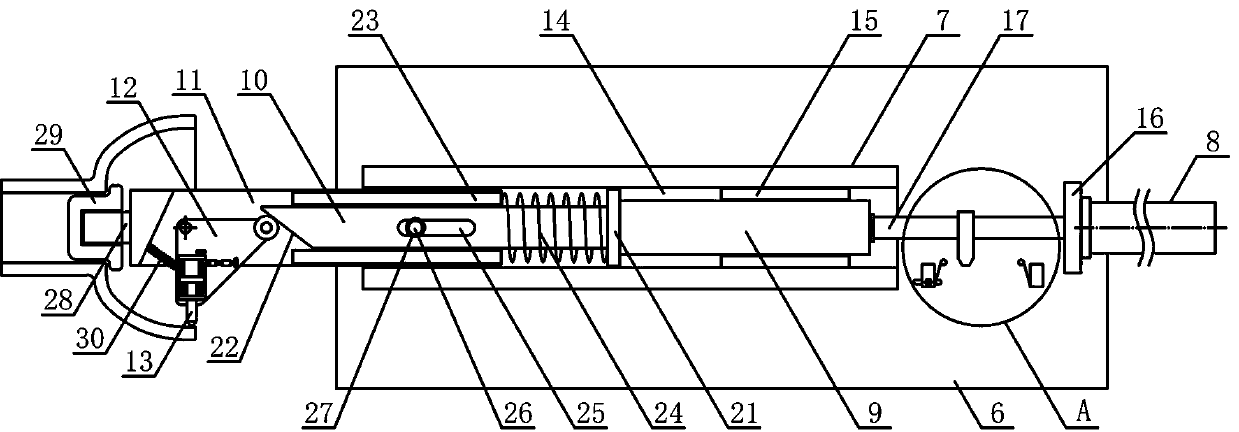

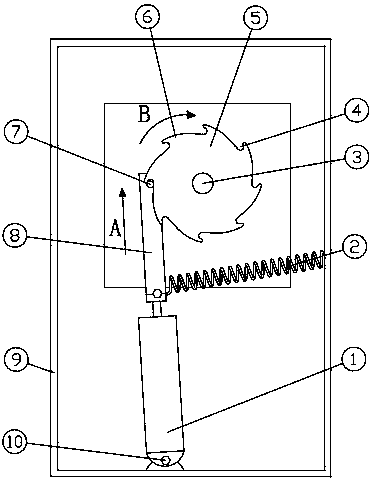

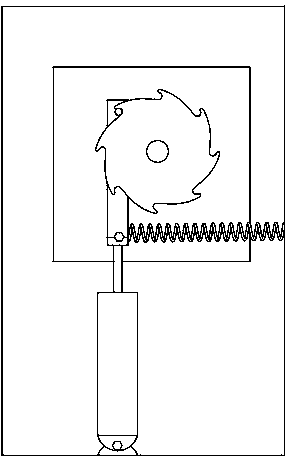

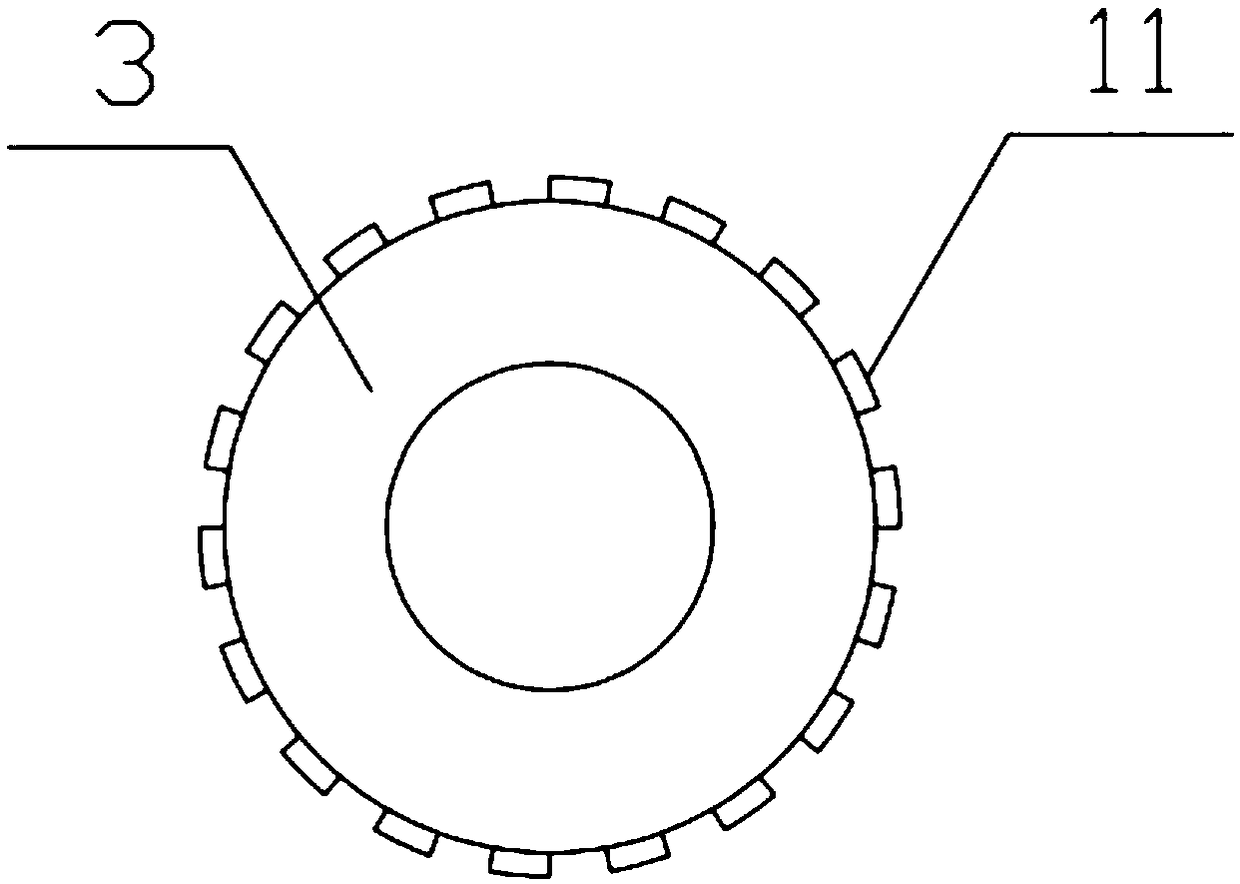

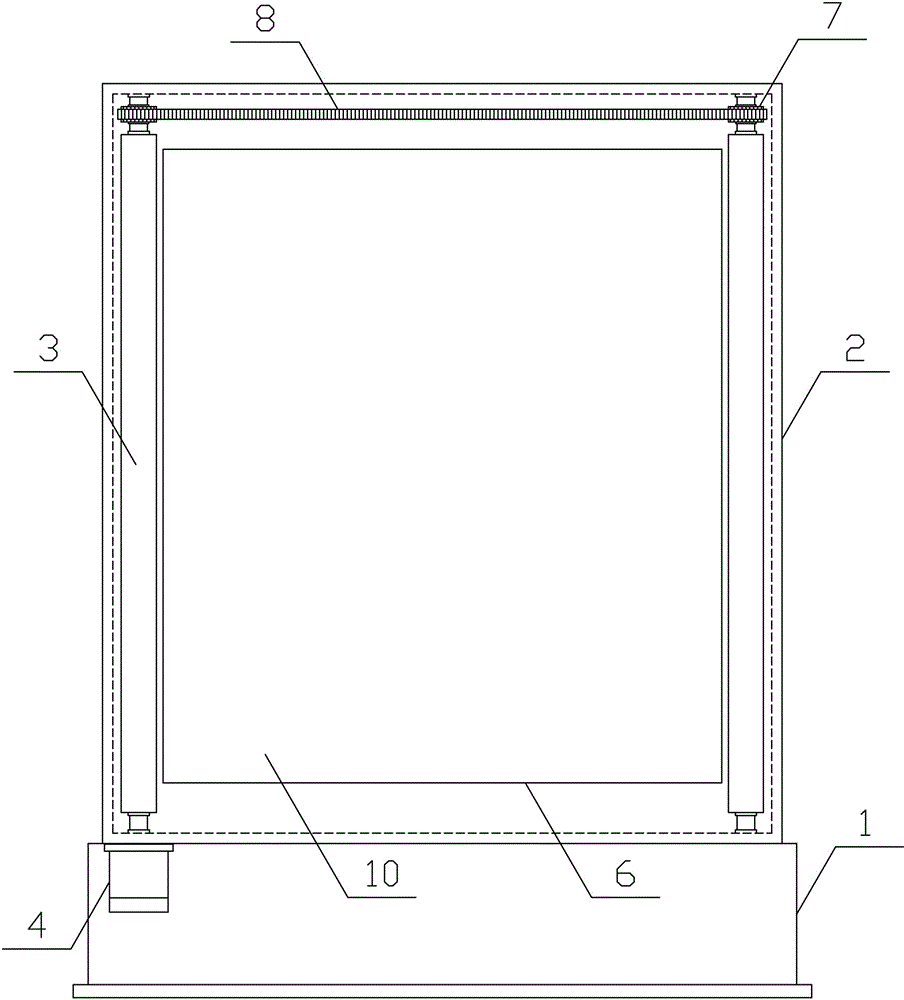

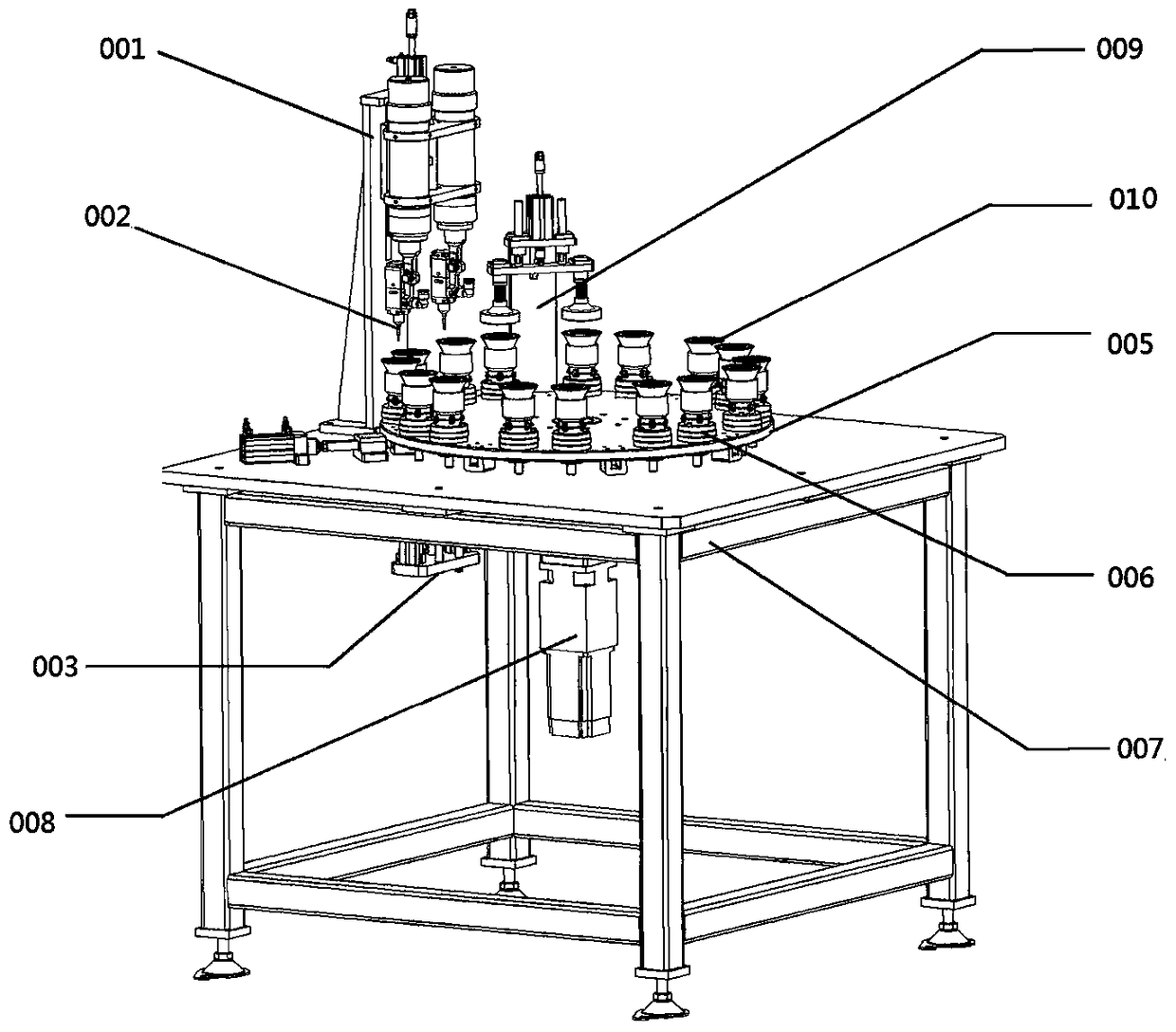

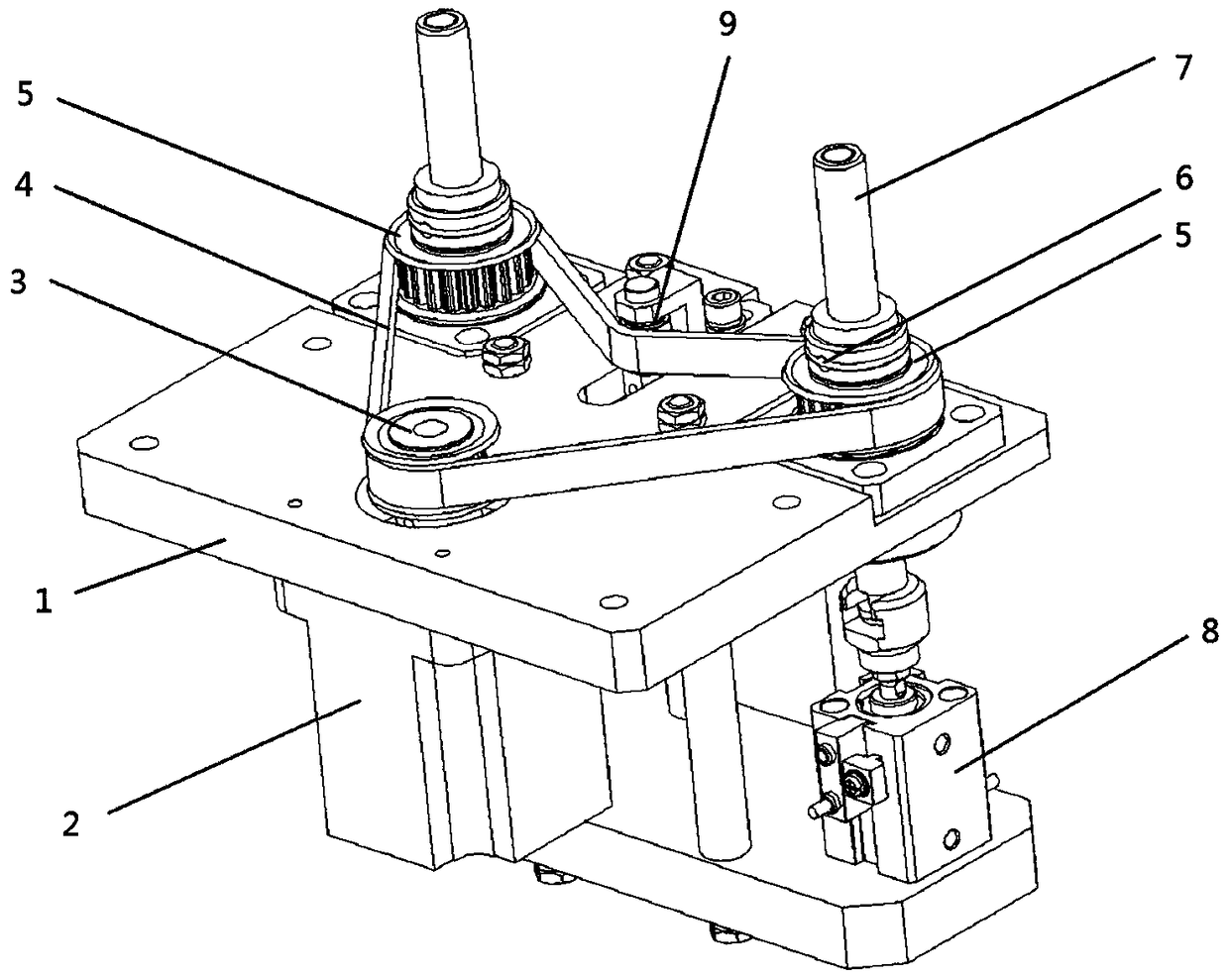

Driving platform of multi-station combination drilling machine

InactiveCN104354013AStable and precise rotationSimple structureFeeding apparatusLarge fixed membersRatchetEngineering

The invention relates to a driving platform of a multi-station combination drilling machine. The driving platform comprises a pedestal, a rotating platform and a driving mechanism, wherein the rotating platform is mounted at the upper end of the pedestal; the driving mechanism is connected with the rotating platform and drives the rotating platform to move; the driving mechanism comprises a ratchet wheel, a connecting shaft, a push block, an air cylinder and a tension spring; the push block is mounted at the front end of a mandrel of the air cylinder; a top block is arranged at the front end of the push block; the ratchet wheel is connected with the rotating platform through the connecting shaft; a plurality of unidirectional ratchets are arranged on the ratchet wheel; bayonets are arranged between the unidirectional ratchets and the ratchet wheel; the top block can be clamped in the bayonets; the tension spring is transversely mounted on the push block; the other end of the tension spring is connected with the pedestal. The driving platform disclosed by the invention is stable and accurate in rotation, simple in structure, and low in production cost.

Owner:PINGHU PINYAO MACHINERY AUTOMATION CO LTD

Flax roll transferring and end cropping mechanism

InactiveCN108823955ASmooth transfer transferImprove efficiencySevering textilesFibre feedersEngineeringMechanical equipment

The invention discloses a flax roll transferring and end cropping mechanism, and belongs to the field of textile processing mechanical equipment. According to the flax roll transferring and end cropping mechanism, the transferring mechanism is arranged in the middle of a fixed support, a cropping mechanism is arranged at the position, on the lower side of one end of the transferring mechanism, ofthe fixed support, the middle of a rotary circular truncated cone is vertically and rotationally connected with a transferring rotary shaft, and a roll clamping mechanism is vertically arranged on oneside of a rotary disc in the radial direction of the rotary disc. An impurity suction fan housing is horizontally arranged on the upper side of a lifting support, the two sides of a translation guideplate are slidingly arranged on cutting guide rods on the two sides of the impurity suction fan housing respectively, adjusting guide plates are slidingly arranged on the two sides of adjusting guiderods, impurity cutting supports are vertically arranged on the upper sides of the adjusting guide plates, and a lifting cutter is horizontally and fixedly arranged on one side of an impurity cuttingconnecting plate. The flax roll transferring and end cropping mechanism is reasonable in structural design, a flax roll can be stably clamped and transferred, the end of the flax roll can be cropped efficiently and accurately, the automation degree of flax roll processing is improved, and the need of flax roll processing use is met.

Owner:戴杰

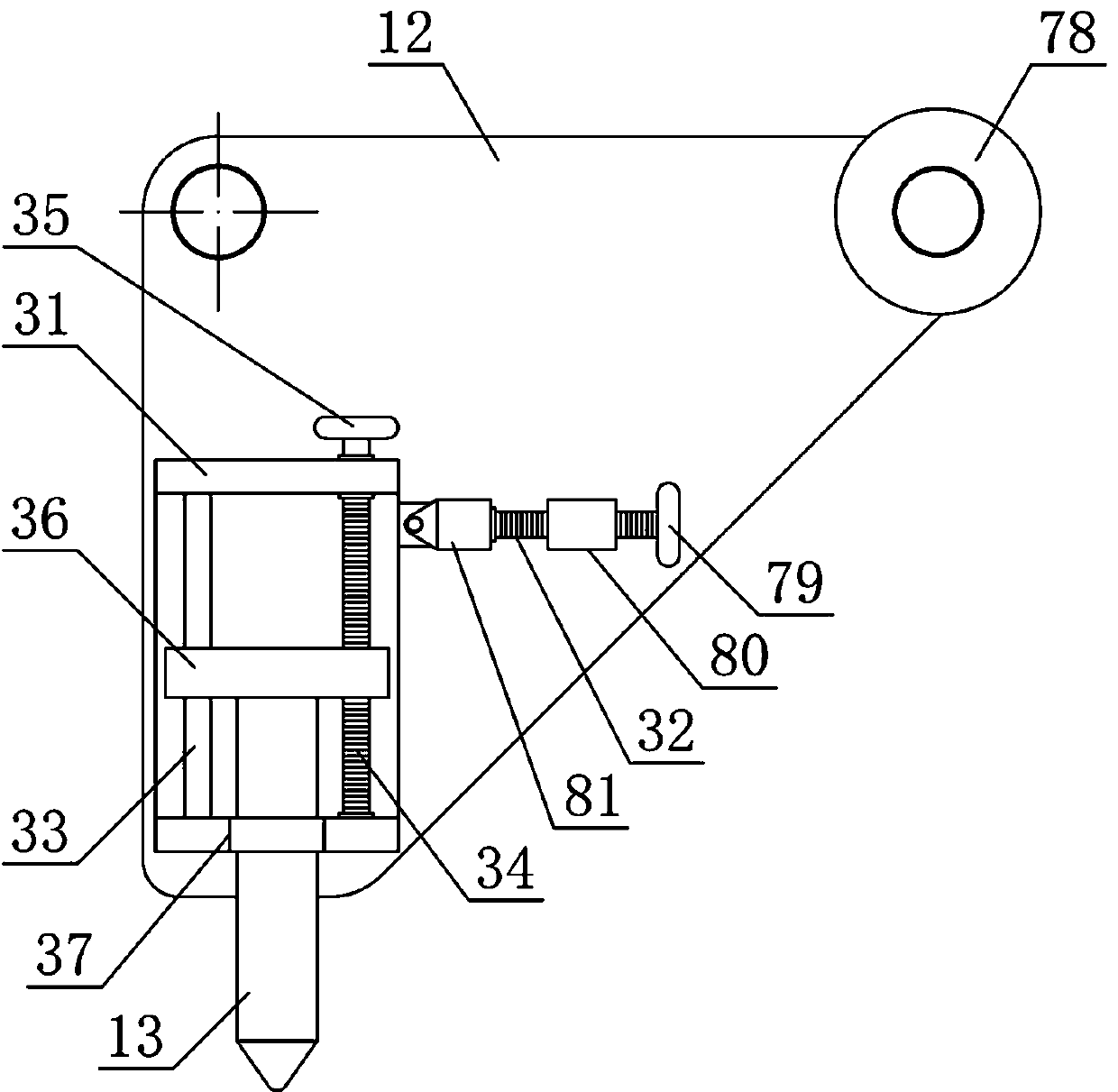

Cylindrical battery testing platform

ActiveCN105973153AGuaranteed helical scanGuaranteed accuracyUsing optical meansHelical scanMeasuring instrument

A cylindrical battery testing platform comprises a linear reciprocating device, a rotating platform and testing benches. The linear reciprocating device is connected with a first servo motor. The testing benches are connected with the movably part of the linear reciprocating device. The testing benches are arranged at two sides of the rotating platform. The rotating platform is provided with rotating shafts which are used for supporting and rotating a battery. The rotating shafts are parallelly arranged in the motion direction of the linear reciprocating device. A to-be-tested area is formed between adjacent rotating shafts. The testing benches are provided with laser length measuring instruments. An included angle between laser transmitting direction of each laser length measuring instrument and the rotation direction of the rotating shaft is 5-90 DEG. The linear reciprocating device realizes spiral laser scanning in a plane through arranging the to-be-tested area which performs rotation relative to the transmitting direction of the laser length measuring instrument and cooperating with linear reciprocation of the laser length measuring instrument relative to the to-be-tested area, thereby realizing online automatic testing.

Owner:万克能源科技有限公司

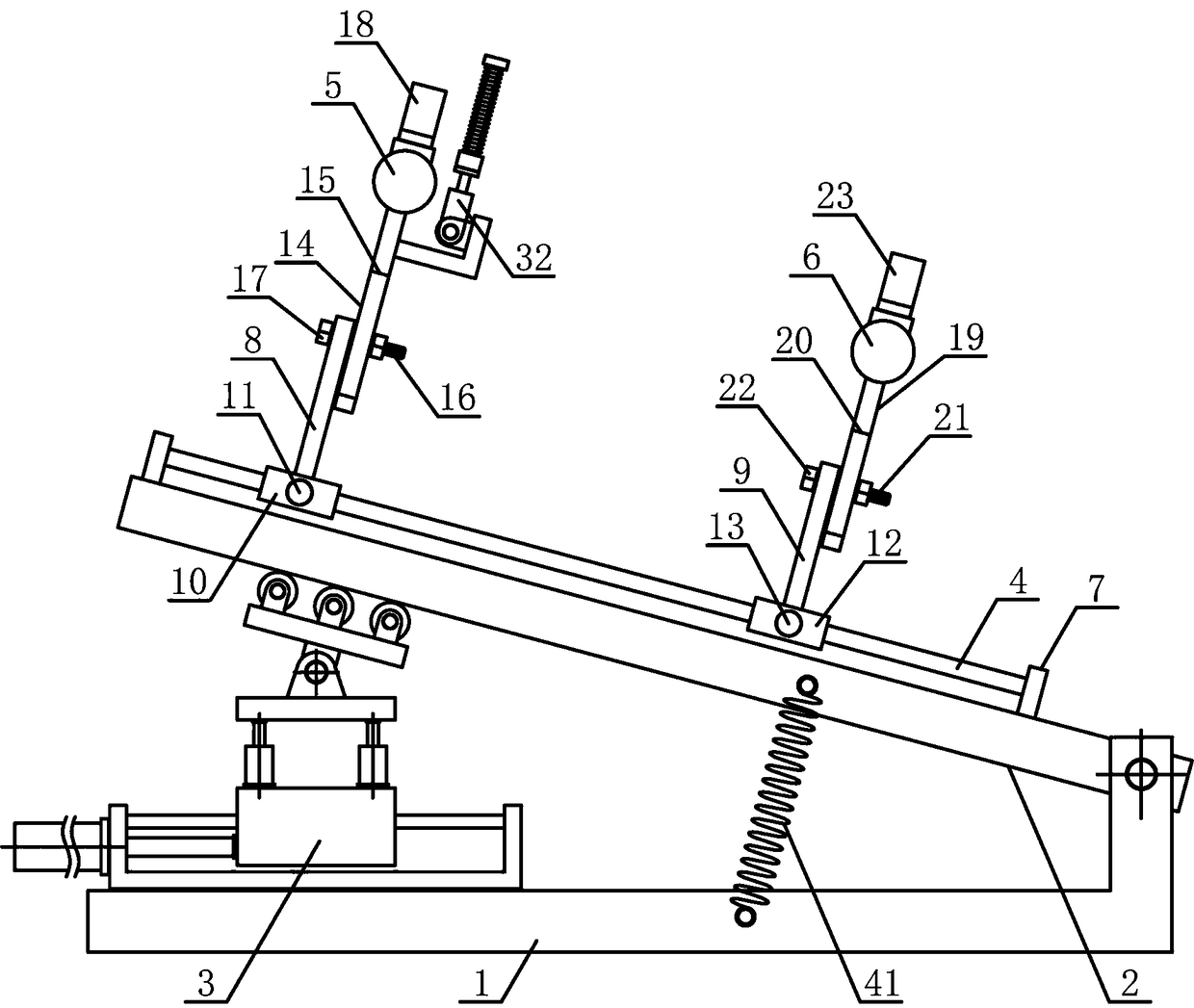

Placement bracket for bicycle frame installation

InactiveCN109397210AStable and precise rotationImprove stabilityWork benchesMetal-working hand toolsVehicle frameMechanical equipment

The invention discloses a placement bracket for bicycle frame installation, and belongs to the field of bicycle frame production auxiliary mechanical equipment. A placement rotating plate is obliquelyarranged on the upper side of a fixing support seat. A push plate mechanism is fixedly arranged on the fixing support seat on one side of the lower portion of the placement rotating plate horizontally. The placement rotating plate is horizontally and fixedly provided with a front support plate and a rear support plate in sequence from top to bottom. The upper side of the front support plate is provided with a front adjusting plate. A front placement bar is arranged on the upper side of the front adjusting plate. A front placement clamp with a U-shaped structure is fixedly arranged on the upper side of the front placement bar. The upper side of the rear support plate is provided with a rear adjusting plate. A rear placement bar is arranged on the upper side of the rear adjusting plate. A rear placement clamp with the U-shaped structure is fixedly arranged on the upper side of the rear placement bar. The placement bracket for the bicycle frame installation has the reasonable structure and design, and the placement bracket can be adjusted conveniently and smoothly according to the dimension and specification of a bicycle frame and the needs of installation and use, so that the secureplacement and the working position adjustment of the bicycle frame are achieved, the efficiency and quality of the frame installation are improved, and the needs of machining and use are met.

Owner:ZHEJIANG YONGFU VEHICLE IND CO LTD

Decorative panel stacking equipment

ActiveCN114104749AEfficient and stable rotationStable and precise rotationPackage recyclingConveyorsCircular discEngineering

The invention discloses decorative panel stacking equipment, and belongs to the field of decorative panel processing mechanical equipment. A panel stacking mechanism and a panel lifting mechanism are sequentially arranged on the upper side of a panel stacking base from top to bottom, panel centering mechanisms are horizontally and symmetrically arranged on the two sides of the panel lifting mechanism, and a plurality of panel conveying guide wheels are sequentially and rotationally connected to panel conveying bearing plates on the two sides of the panel stacking base; stacking limiting baffles are vertically arranged on the two sides of the upper portion of the panel stacking base correspondingly, stacking supporting swing plates are fixedly arranged on the two sides of the bearing plate reciprocating rotating shaft correspondingly, and a push plate swing connecting rod is arranged between the lifting reciprocating push plate and the push plate rotating disc. And a panel centering push rod and a reciprocating translation push rod are horizontally and slidably arranged on the stacking supporting vertical plates on the two sides of the lifting reciprocating push plate from top to bottom respectively. The decoration panel stacking device is reasonable in structural design, decoration panels can be efficiently, stably and orderly stacked one by one, the stacking efficiency and quality of the decoration panels are improved, and the requirements of production and use are met.

Owner:ZHEJIANG MINGTAO IND

Full-view three-dimensional reconstruction shooting system

InactiveCN111323990AEfficient collectionAcquisition is effectively completedCamera body detailsPhotographyComputer graphics (images)Engineering

The invention discloses a full-view three-dimensional reconstruction shooting system, which comprises a shooting device and a PC, wherein the shooting device comprises a shooting shed, a central object placing table and a shooting assembly; a plurality of lamp banks are arranged in the shooting shed; and the shooting assembly comprises a shooting track, an electric sliding base, a shooting supportand a camera. The system is simple in structure and reasonable in design, is used for efficient and stable collection of 3D materials, good in shadowless effect during material collection, capable ofeffectively completing full-view collection of materials, high in collection efficiency and good in quality, and facilitates quickly completing the three-dimensional reconstruction of the materials.Moreover, when the object is rotated or the camera is rotated, the rotation is stable and accurate, the shooting effect and the material collection quality can be effectively ensured, the camera can be fixed and moved and can be increased and decreased according to requirements, and the purchase cost is reduced under the condition of ensuring the shooting efficiency. Meanwhile, the central objectplacing table can be lifted, so that the center of the object is convenient to adjust, and the collection quality is improved.

Owner:SHANGHAI SUOBEI INFORMATION TECH CO LTD

Working method of print cloth advertisement displaying mechanism

InactiveCN108630117AImprove efficiencyQuality improvementIdentification meansPulp and paper industryTextile

Owner:曹丹丹

Fixture for plating semiconductor lead frame and plating method thereof

InactiveCN102936745BSave anode materialSave plating materialLiquid surface applicatorsElectrolysis componentsSprocketEngineering

The invention discloses a fixture for plating a semiconductor lead frame and a plating method thereof. Only a clamp port of a lower piece of the fixture is electrically connected with a to-be-clamped rib of the semiconductor lead frame, and other parts are electrically insulated. The plating method includes the steps that when the lead frame is a unilateral rib, only the fixture with the clamp port with the same shape with a side rib is used for fixing the side rib for plating; when the lead frame is only provided with a middle rib, only the fixture with the clamp port with the same shape with the middle rib is used for fixing the middle rib for plating; and if the lead frame is a bilateral rib, one side rib is coated with an insulation paste, and the fixture is used for clamping the other side rib for the plating. A side rib glue spreader comprises a horizontally annularly circular chain sprocket drive mechanism, a feeding bracket, a blanking retaining board, a glue spreading mechanism, an air knife, a drying groove and a hot wind cover. The fixture has the advantages that the side rib or the middle rib can be prevented from being plated by a tin coating, materials are saved, and the side rib and the middle rib can be recovered directly; and the operation is convenient, the process is reliable, production and labor costs can be reduced, production efficiency can be improved, and a deplating process of the plating fixture can be omitted.

Owner:SHENZHEN ALLMERIT TECH

A cylindrical battery testing platform

ActiveCN105973153BStable and precise rotationGuaranteed helical scanUsing optical meansHelical scanElectric machine

A cylindrical battery testing platform comprises a linear reciprocating device, a rotating platform and testing benches. The linear reciprocating device is connected with a first servo motor. The testing benches are connected with the movably part of the linear reciprocating device. The testing benches are arranged at two sides of the rotating platform. The rotating platform is provided with rotating shafts which are used for supporting and rotating a battery. The rotating shafts are parallelly arranged in the motion direction of the linear reciprocating device. A to-be-tested area is formed between adjacent rotating shafts. The testing benches are provided with laser length measuring instruments. An included angle between laser transmitting direction of each laser length measuring instrument and the rotation direction of the rotating shaft is 5-90 DEG. The linear reciprocating device realizes spiral laser scanning in a plane through arranging the to-be-tested area which performs rotation relative to the transmitting direction of the laser length measuring instrument and cooperating with linear reciprocation of the laser length measuring instrument relative to the to-be-tested area, thereby realizing online automatic testing.

Owner:万克能源科技有限公司

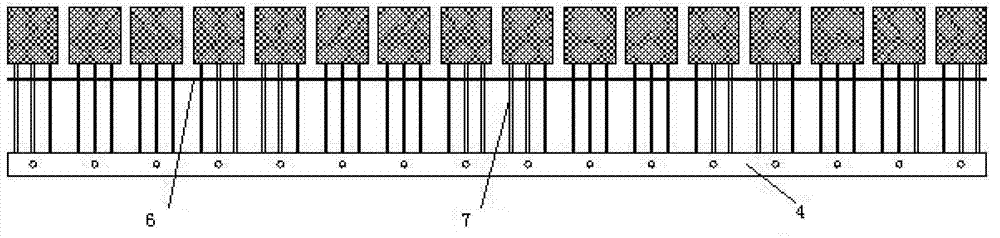

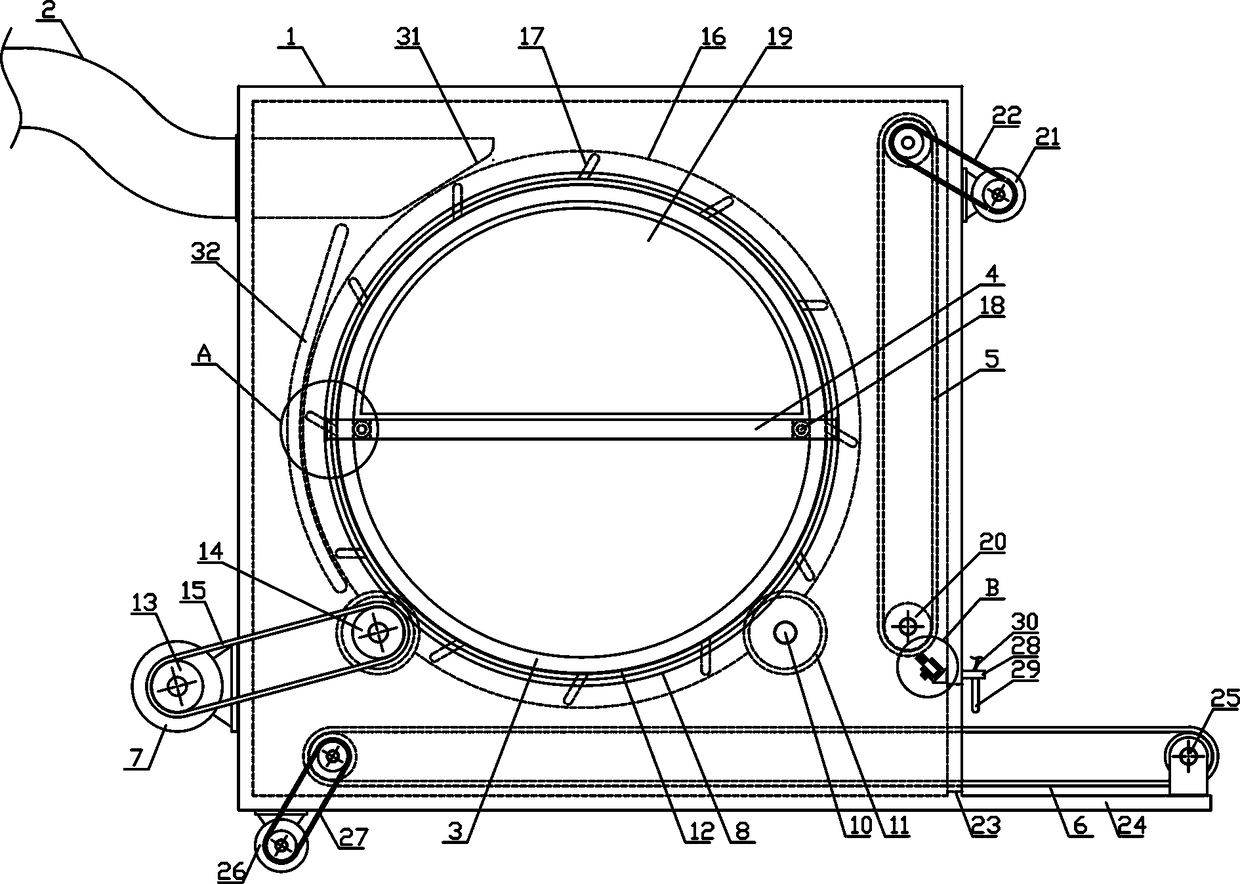

Spray painting cloth advertisement display mechanism

ActiveCN105931577AImprove efficiencyQuality improvementIdentification meansMotor driveMechanical equipment

The invention discloses a spray painting cloth advertisement display mechanism and belongs to the field of advertisement display mechanical equipment. The spray painting cloth advertisement display mechanism comprises a fixed bracket, a display show window, display cloth rollers, a rotary motor and a cloth guide roller, wherein the display show window is vertically arranged on the fixed bracket; a display window is arranged at one side of the display show window; the four display cloth rollers are vertically, uniformly and rotatably connected into the display show window; rotary chain wheels are horizontally arranged at the upper ends of the four display cloth rollers respectively; the four rotary chain wheels are in transmission connection by adopting a conveying chain; the rotary motor drives the display cloth rollers; the cloth guide roller is vertically arranged at one side between the two display cloth rollers at one end of the display show window; the cloth guide roller is vertically and rotatably connected to the display show window; spray painting cloth is wound on the four display cloth rollers and the cloth guide roller. The spray painting cloth advertisement display mechanism is reasonable in structural design, can be used for rapidly, efficiently and stably carrying out rotary display on the spray painting cloth printed with advertisements; the quantity of the advertisements displayed by the spray painting cloth can be increased, and the requirements of advertisement display are met.

Owner:广州开萝广告标识有限公司

A kind of led lamp base dispensing machine

ActiveCN104492657BGlue stableDispensing effect is easy to controlLiquid surface applicatorsCoatingsElectric machineryEngineering

The invention relates to the technical field of automatic LED lamp production equipment and in particular relates to an LED lamp cap dispenser. The LED lamp cap dispenser comprises a dispensing assembly, a dispensing needle, a dispensing rack, a rotary driving assembly, a base mounting disc, a lamp cap positioning seat and a mounting disc motor, wherein the base mounting disc is rotationally arranged on the dispensing rack; the mounting disc motor is arranged on the dispensing rack and can drive the base mounting disc to rotate; the lamp cap positioning seat is rotationally arranged on the base mounting disc; and the rotary driving assembly can drive the lamp cap positioning seat to rotate. According to the LED lamp cap dispenser disclosed by the invention, the lamp cap positioning seat is driven to rotate, rotation of the LED lamp cap on the automatic production line is realized, the dispensing needle is stationary in the dispensing process, stable dispensing in the operation of the dispensing assembly is promoted, the problem that the dispensing needle is vibrated and collided is solved, and the dispensing effect is easy to control.

Owner:佛山市顺德区格律诗自动化科技有限公司

Dust removing and material conveying mechanism for woolen materials

InactiveCN108842187AReasonable structural designPrevent proliferationAnimal fibre deburring machinesEngineeringMechanical engineering

The invention discloses a dust removing and material conveying mechanism for woolen materials, and belongs to the field of textile processing machinery equipment. According to the dust removing and material conveying mechanism for woolen materials disclosed by the invention, a dust removing rotary cage is horizontally arranged in a dust removing cover shell, spacing baffles adopting an arc-shapedstructure are respectively arranged at the outer ends of the two sides of the dust removing rotary cage, a plurality of material guiding connection plates are sequentially, horizontally and uniformlyarranged on the outer side of the dust removing rotary cage, a dust collecting baffle is horizontally arranged at the middle part of the dust removing rotary cage, dust suction wind pipes are symmetrically arranged on two sides of the dust removing cover shell, and the dust suction wind pipes communicate with the dust removing rotary cage on the upper side of the dust collecting baffle; a materialcharging guiding pipe horizontally penetrates through the upper side of the dust removing cover shell; the upper side and the lower side of a material discharging guiding belt are respectively connected to material discharging rotary rollers on the upper side and the lower side of the dust removing cover shell in a winding manner; and the two sides of the material conveying guiding belt are respectively connected to material conveying rotary rollers on the upper side of the dust removing cover shell and a material conveying bearing plate in a winding manner. The dust removing and material conveying mechanism disclosed by the invention is reasonable in structural design, dust removing processing can be efficiently and conveniently performed on the woolen materials, the woolen materials after dust removing processing can be smoothly conveyed, and processing and using requirements can be met.

Owner:于星杰

key structure

ActiveCN104201029BLower the altitudeApproach steadilyElectric switchesTactile feedbackKey pressingSuction force

The invention relates to a key structure. The key structure comprises a base, a keycap, a lifting mechanism and a magnetic part; the keycap can move vertically relative to the base through the lifting mechanism; the lifting mechanism comprises a support; one lateral side portion of the support comprises a magnetic portion; the lateral side portion is in abutting joint with the base through a sharp edge; the magnetic portion extends outward from the lateral side portion; the support is flexibly connected with the keycap through an opposite lateral side portion; the magnetic part is arranged on the base corresponding to the magnetic portion; the magnetic suction force is produced between the magnetic part and the magnetic portion; when the keycap is pressed by the external force, the support rotates relative to the base through the sharp edge to enable the magnetic portion to be far away from the magnetic part and the keycap to be close to the base; when the external force is released, the support is driven by the magnetic suction force to rotate relative to the base through the sharp edge to enable the keycap to be far away from the base; the base can be provided with a magnetic part, wherein the magnetic suction force can be applied to the other magnetic portion of the support to drive the lateral side portion to be in abutting joint with the base.

Owner:DARFON ELECTRONICS (SUZHOU) CO LTD +1

Using method of spherical workpiece cutting machining device

InactiveCN111531227AAccurate and efficient reciprocating translational movementHigh degree of processing automationAutomatic control devicesFeeding apparatusMechanical equipmentMaterial transfer

The invention discloses a using method of a spherical workpiece cutting machining device, and belongs to the field of workpiece machining mechanical equipment. The spherical workpiece cutting machining device comprises a machining material conveying support, a translation cutting mechanism, a material clamping lifting mechanism, a turnover material transferring mechanism and a workpiece conveyingmechanism; the translation cutting mechanism is horizontally and fixedly arranged on one side above the machining material conveying support, the material clamping lifting mechanism is vertically arranged on the machining material conveying support on one side of the translation cutting mechanism, the turnover material transferring mechanism is vertically arranged on the machining material conveying support on one side below the material clamping lifting mechanism, and the workpiece conveying mechanism is horizontally and adjacently arranged on the machining material conveying support on one side of the turnover material transferring mechanism. The spherical workpiece cutting machining device is reasonable in structural design, capable of efficiently and stably cutting spherical workpiecesone by one, capable of achieving automatic transferring, feeding and returning of the spherical workpieces, high in machining automation degree and capable of meeting the requirements for workpiece machining and use.

Owner:黄明珠

A cloth purging and impurity removal mechanism

InactiveCN106555324BImprove efficiencyQuality improvementMechanical cleaningPressure cleaningMotor driveMechanical equipment

Owner:盐城市纺织染整产业园实业开发有限公司

A spray-painted cloth advertising display mechanism

ActiveCN105931577BImprove efficiencyQuality improvementIdentification meansMotor driveMechanical equipment

Owner:广州开萝广告标识有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com