Fixture for plating semiconductor lead frame and plating method thereof

A lead frame and semiconductor technology, applied to the surface coating liquid device, electrolysis process, electrolysis components, etc., can solve the problems of only waste copper treatment, consumption of deplating solution, serious environmental pollution, etc., and achieve economical operation The number of personnel and artificial physical strength, the effect of improving production efficiency and smooth and precise rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

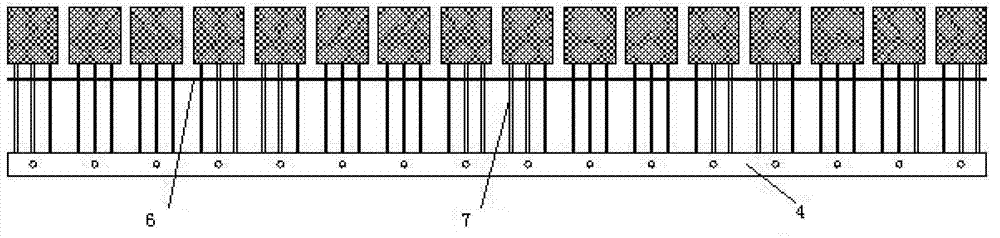

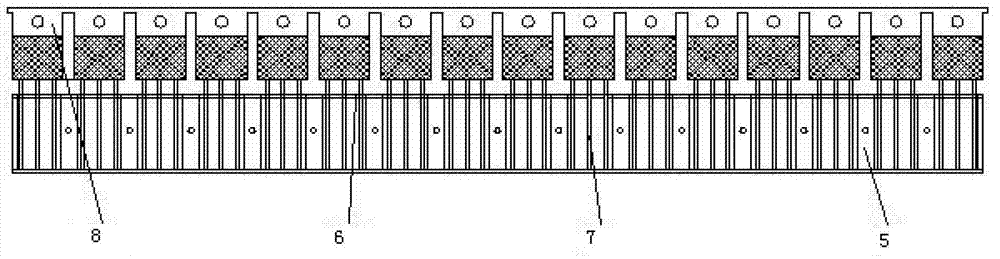

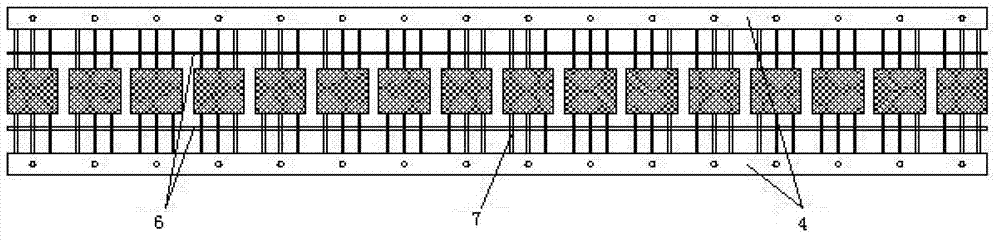

[0041] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

[0042] The jig for semiconductor lead frame electroplating includes a lower piece, an upper piece, and a shaft-torsion spring mechanism. The lower piece is a flat metal piece, and the jaw part of the lower piece is electrically connected to the clamped rib of the semiconductor lead frame. The upper piece is punched and bent. The shape and size of the rubber pad are the same as that of the jaw, and the front edge of the rubber pad is provided with a brush-like thin Brush, the fine brush is placed on the inner side of the clamped rib of the semiconductor lead frame, the rubber pad is silicone rubber, fluororubber or other acid-resistant rubber, the straight piece is followed by a curved surface, the curved surface is followed by a plane, and the rear end of the plane is a pressure handle , the rotating shaft-torsion spring mechanism includes a rotating shaft ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com