Intelligent glue gun

A glue gun, intelligent technology, applied in the direction of coating, coating liquid on the surface, etc., can solve the problems of affecting efficiency, waste of colloid materials, difficulty in finding a suitable gear, etc., and achieve the effect of uniform glue output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation, features and functions of a smart glue gun device according to the present invention will be described in detail below with reference to the accompanying drawings and preferred embodiments.

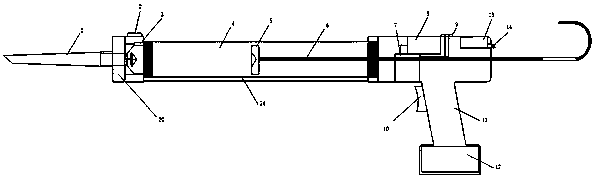

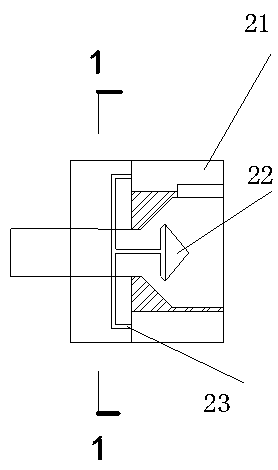

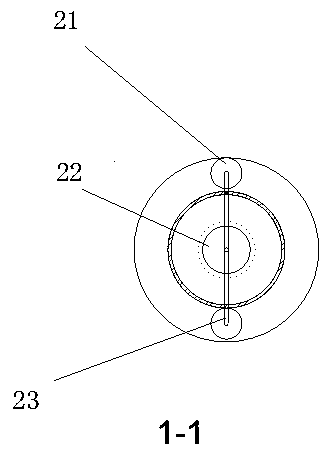

[0023] Such as Figure 1-3 As shown, a kind of intelligent glue gun of the present invention comprises gun mouth 1, infrared velocity detector 2, gun body 4, glue port opening controller 20, screw rod 6, switch 10, glue tank 24, wherein: gun mouth 1 is installed on The front end of the gun body 4, the glue tank 24 is installed in the middle of the gun body 4, the glue tank 24 is connected with the gun mouth 1 through the glue mouth opening controller 20, the gun handle 11 is installed at the rear lower part of the gun body 4, and the switch 10 is arranged on the gun handle 11 The front end of the gun body 4 is provided with an infrared speedometer 2, the pressure sensor 3 is located at the front end of the glue tank 24, the screw rod 6 passes through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com