Roof gluing equipment and roof gluing method

A kind of equipment and gluing technology, applied in the direction of roofing, tools for roof engineering, devices for coating liquid on the surface, etc., can solve the problems affecting the bonding and installation quality or installation strength of solar panels, the length and thickness of the glue strips are not the same, Problems such as numbness and soreness of the operator's legs, to achieve the effect of improving the working efficiency of the glue, keeping the glue thickness uniform, and the glue pushing action stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

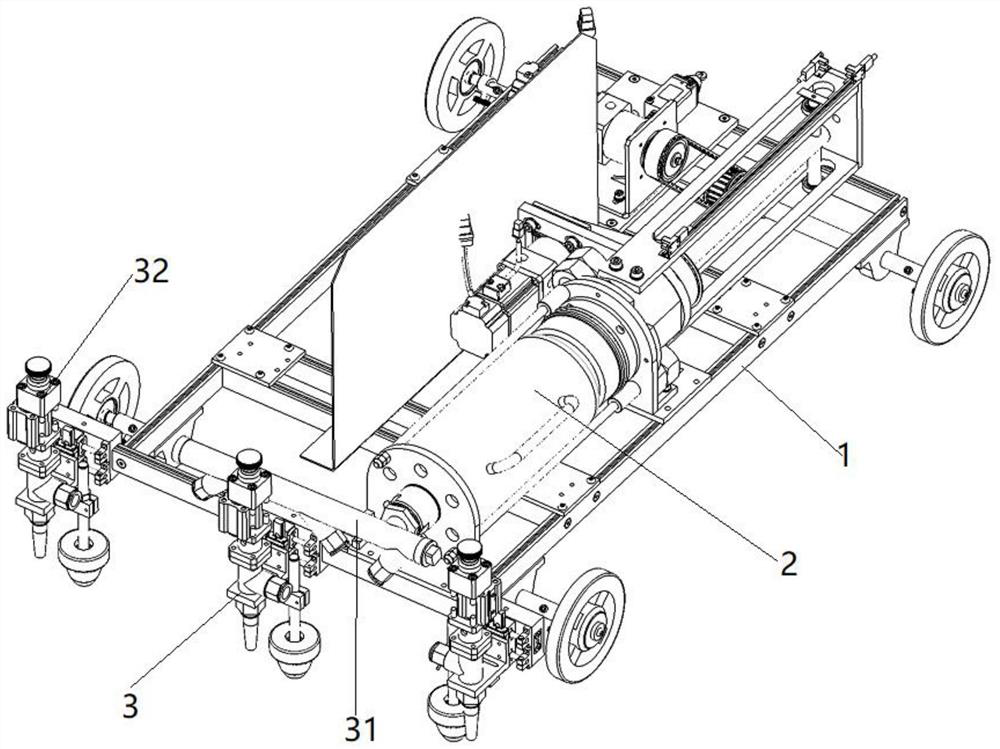

[0036] like Figure 1-Figure 4 As shown, a roof gluing equipment includes a traveling mechanism 1, a glue squeezing mechanism 2 and a gluing mechanism 3;

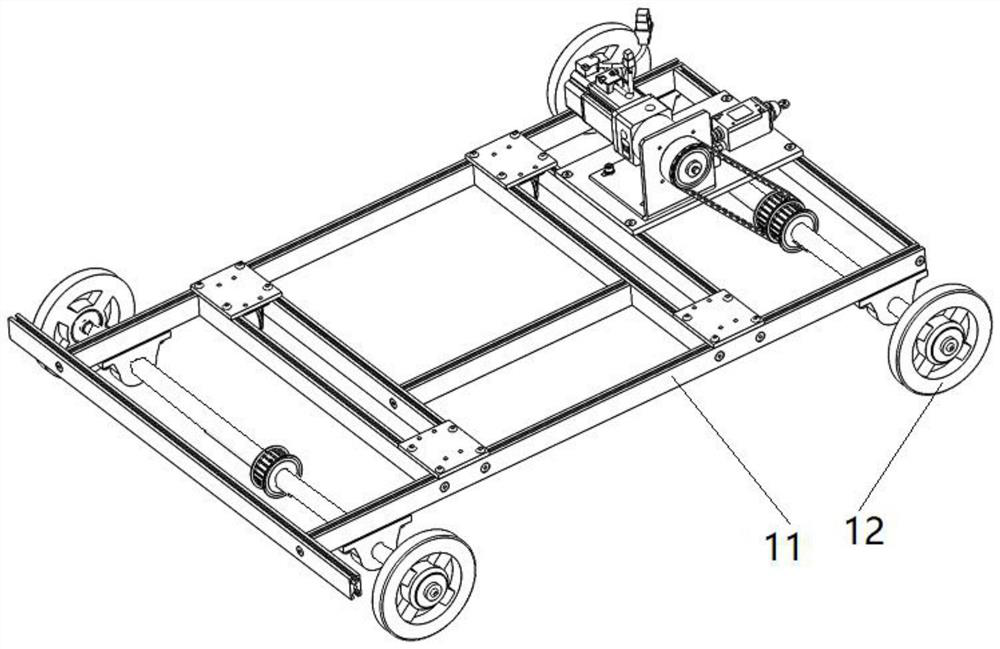

[0037] The running mechanism 1 comprises a vehicle frame 11 and road wheels 12 arranged on both sides of the vehicle frame 11. The vehicle frame 11 is provided with a gluing mechanism 2 along one end of its advancing direction, and the vehicle frame 11 is provided with a rubber extrusion mechanism 2. Link to each other with gluing mechanism 3;

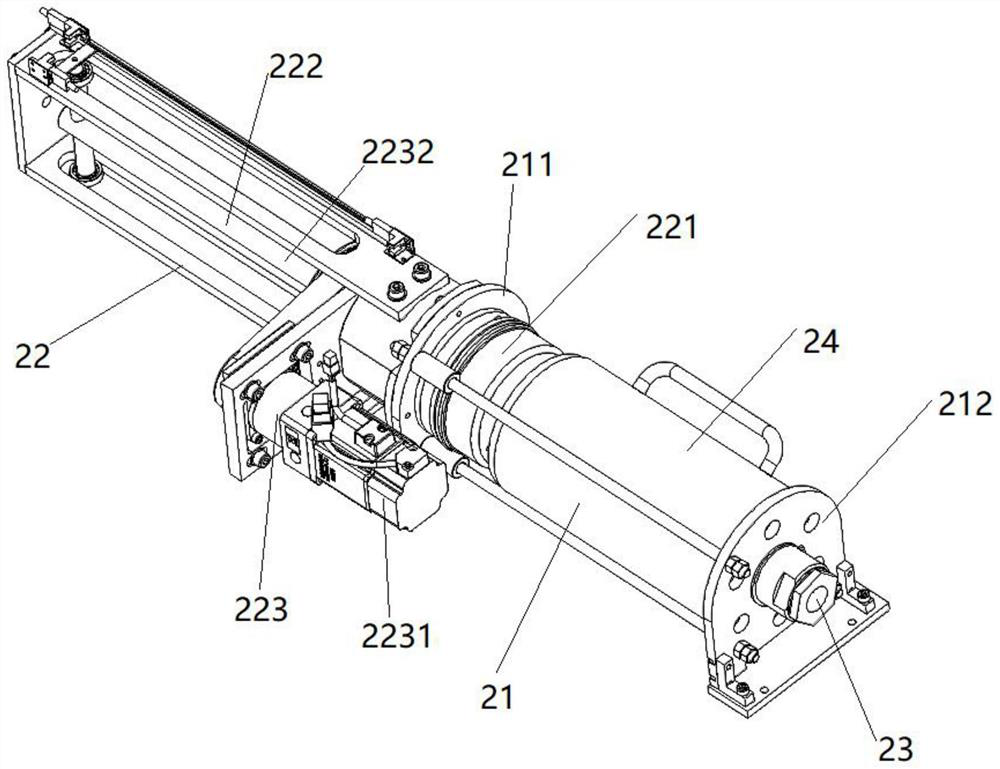

[0038] The rubber extruding mechanism 2 includes a rubber barrel clamping mechanism 21 and a rubber pushing mechanism 22. The rubber barrel clamping mechanism 21 includes a rear baffle 211 and a front baffle 212 arranged in sequence along the advancing direction of the vehicle frame 11, and the front baffle 212 is far away from the rear baffle. One end of the baffle 211 is provided with a glue outlet 23, and the side of the rear baffle 211 facing away from the front baffle 212 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com