Double carrying position transfer and separation frame feeding device and feeding method thereof

A technology of feeding device and frame, applied in the direction of surface coating device, conveyor, mechanical conveyor, etc., can solve the problems of small fixed position span, affecting the effect of gluing, low efficiency, etc., to avoid many electrical lines , Smooth gluing process, reasonable supporting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

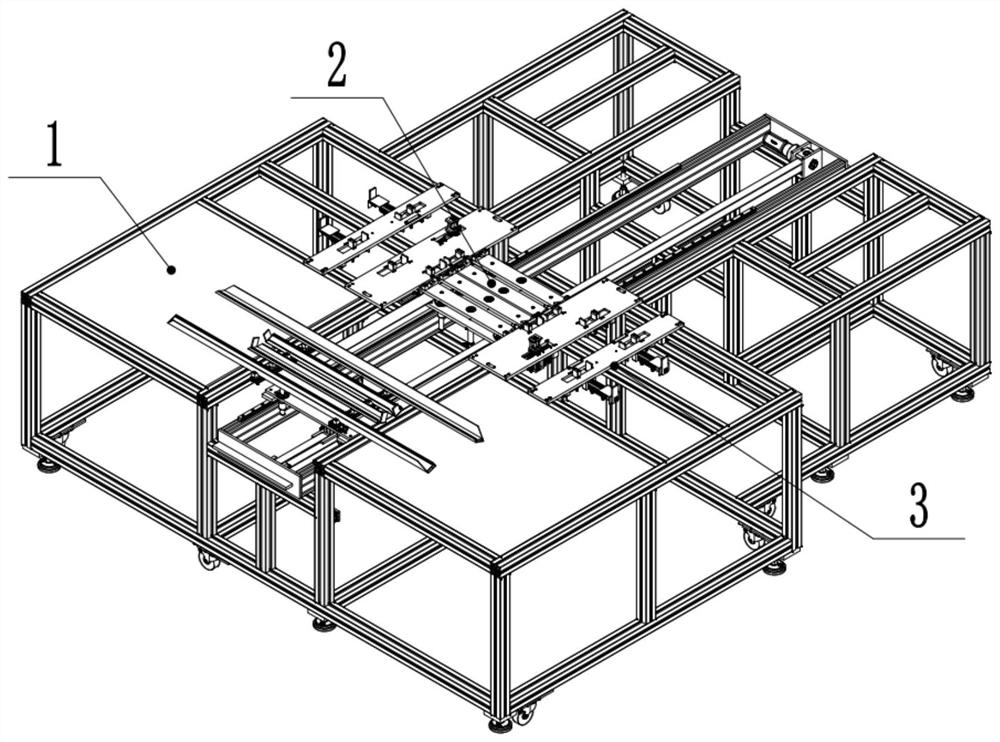

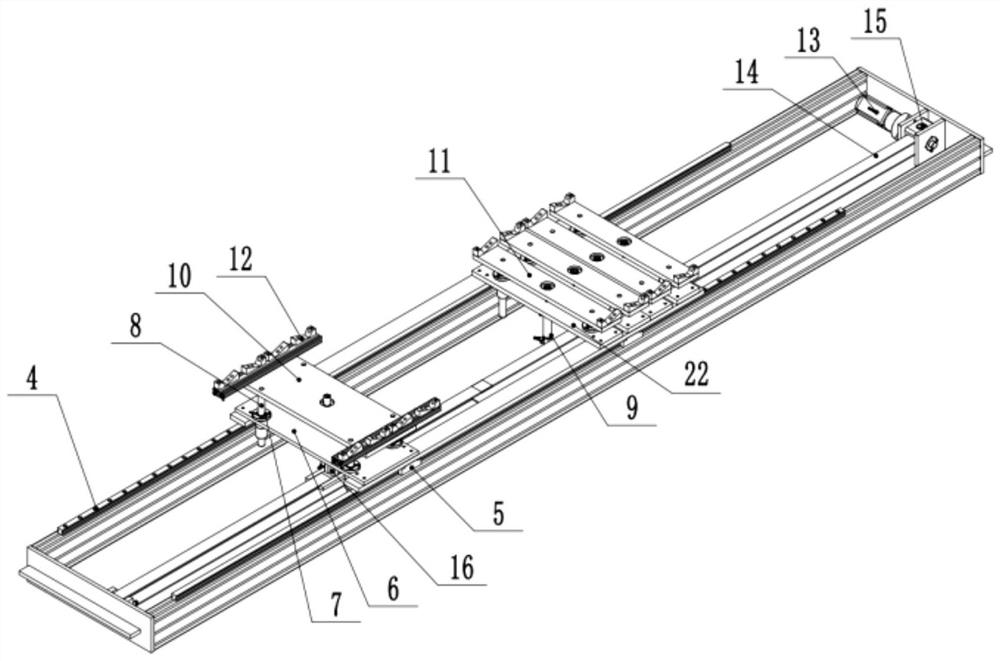

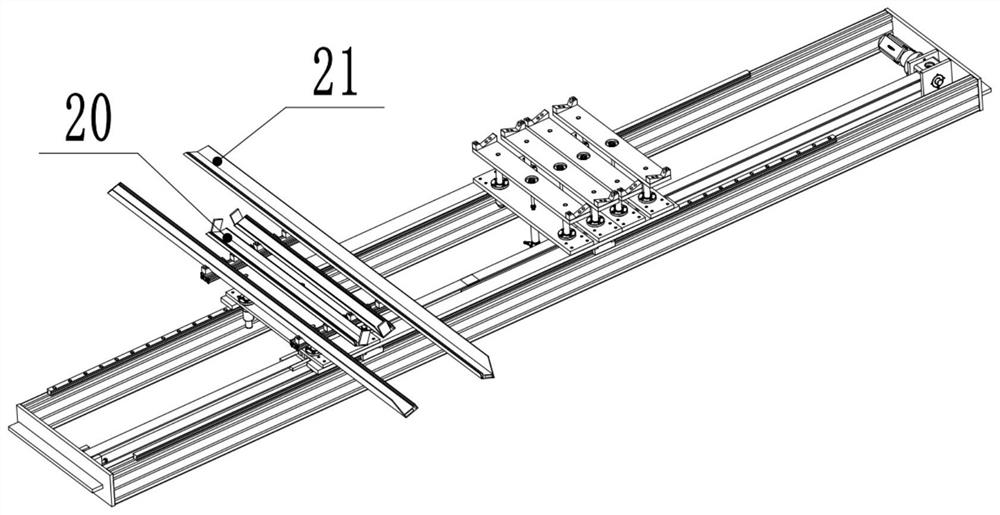

[0030] Such as figure 1 As shown, a double-carrying transfer and separation frame feeding device includes a frame 1, a double-carrying platform 2 and a gluing platform 3; The glue station and the loading and unloading station; such as figure 2 As shown, the double loading platform 2 includes a front loading base 6, a rear loading base 22, a lift cylinder 9, a front loading platform 10, a rear loading platform 11 and a V-shaped block 12; the front loading base 6 and The four rear loading bases 22 all form a sliding pair with the frame 1, and are driven by the driving mechanism to move synchronously along the arrangement direction of the loading feeding station, glue coating station and loading discharging station; the front loading base 6 and four rear bearing bases 22 are all fixed with a vertical lifting cylinder 9, the push rod of the lifting cylinder 9 on the front be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com