Scrape coating machine for edge banding

A technology of edge banding and scraping coater, which is applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems of high production cost, small contact area, long time consumption, etc., and achieves low production cost and glue coating. The effect of good quality and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

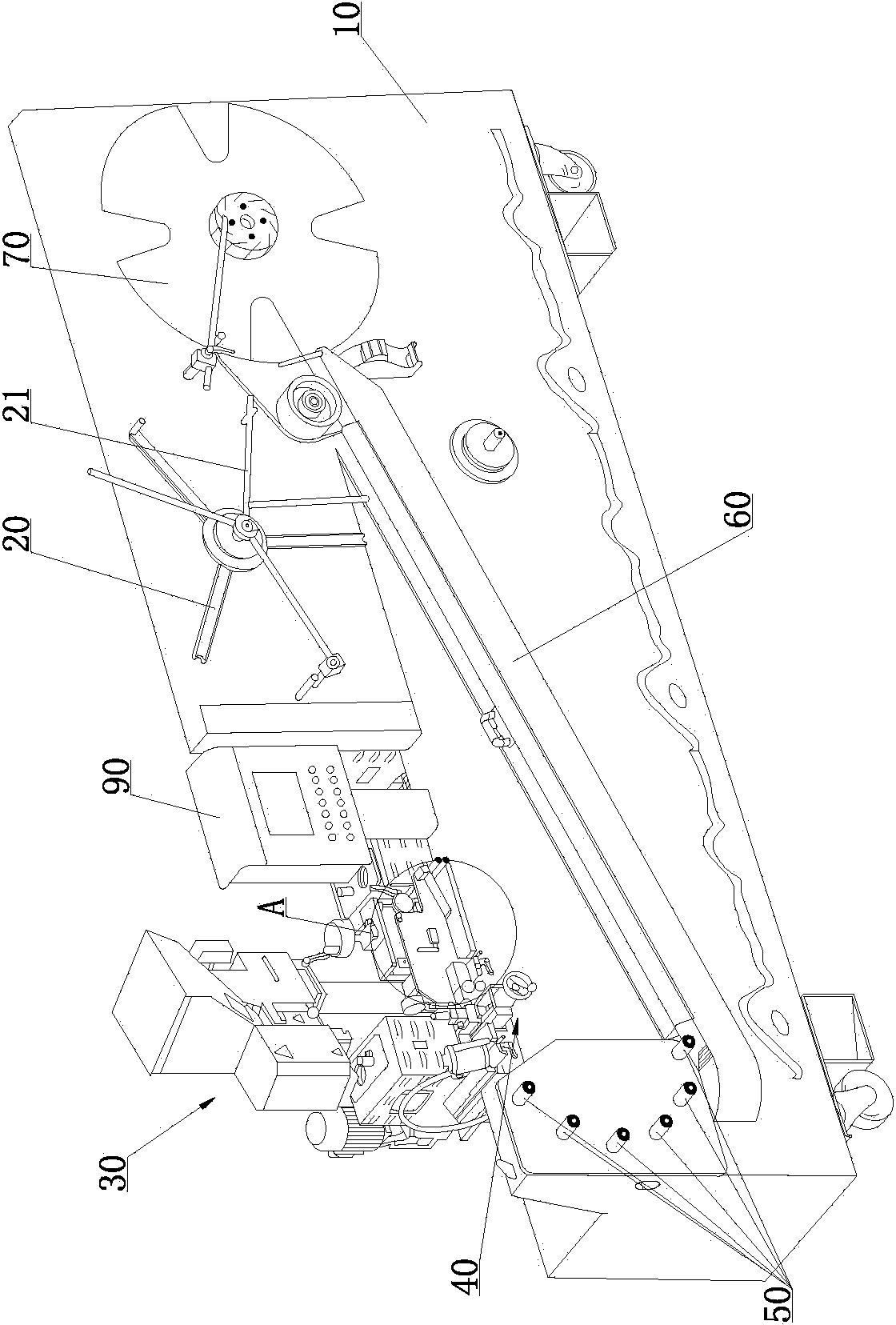

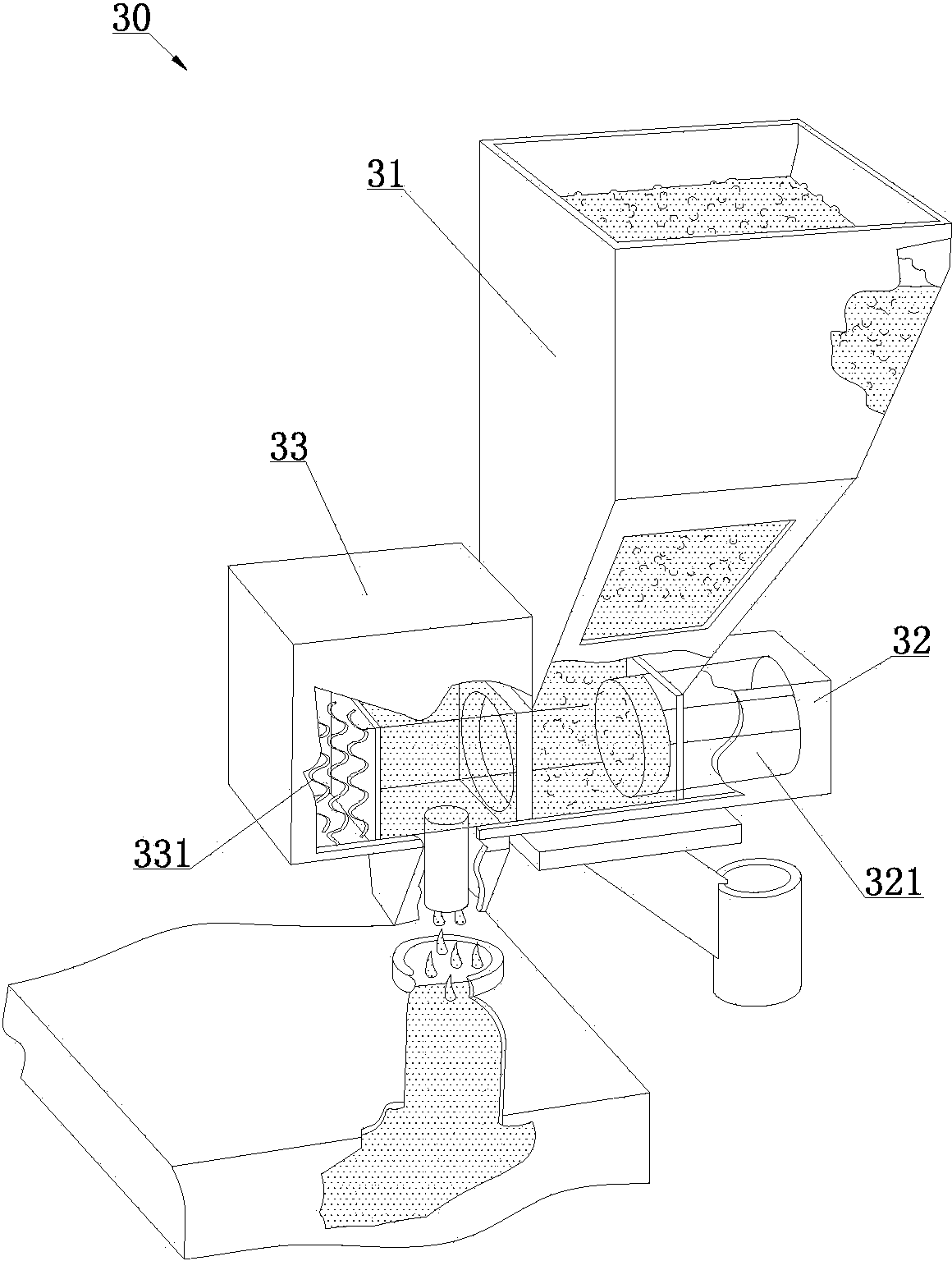

[0040] Such as Figure 1 to Figure 8 As shown, the edge strip glue applicator of the present invention includes a machine tool 10, and the machine tool 10 is provided with an unwinding reel 20, a glue melting device 30, a scraper coating device 40, an edge strip turning device, a cooling channel 60 and a winding Disc 70; Unwinding reel 20 is positioned above the front side of the machine tool 10, the glue melting device 30 is positioned at the rear side of the machine tool 10, the scraping device 40 is positioned at the front side of the machine tool 10 and is connected with the glue melting device 30, and the edge strip steering device is connected with the glue melting device 30. The output end of the squeegee coating device 40 is connected, that is, the edge banding after being glued by the squeegee coating device 40 will enter the edge banding turning device for bending and turning, and the cooling channel 60 is connected to the output end of the edge banding turning device...

Embodiment 2

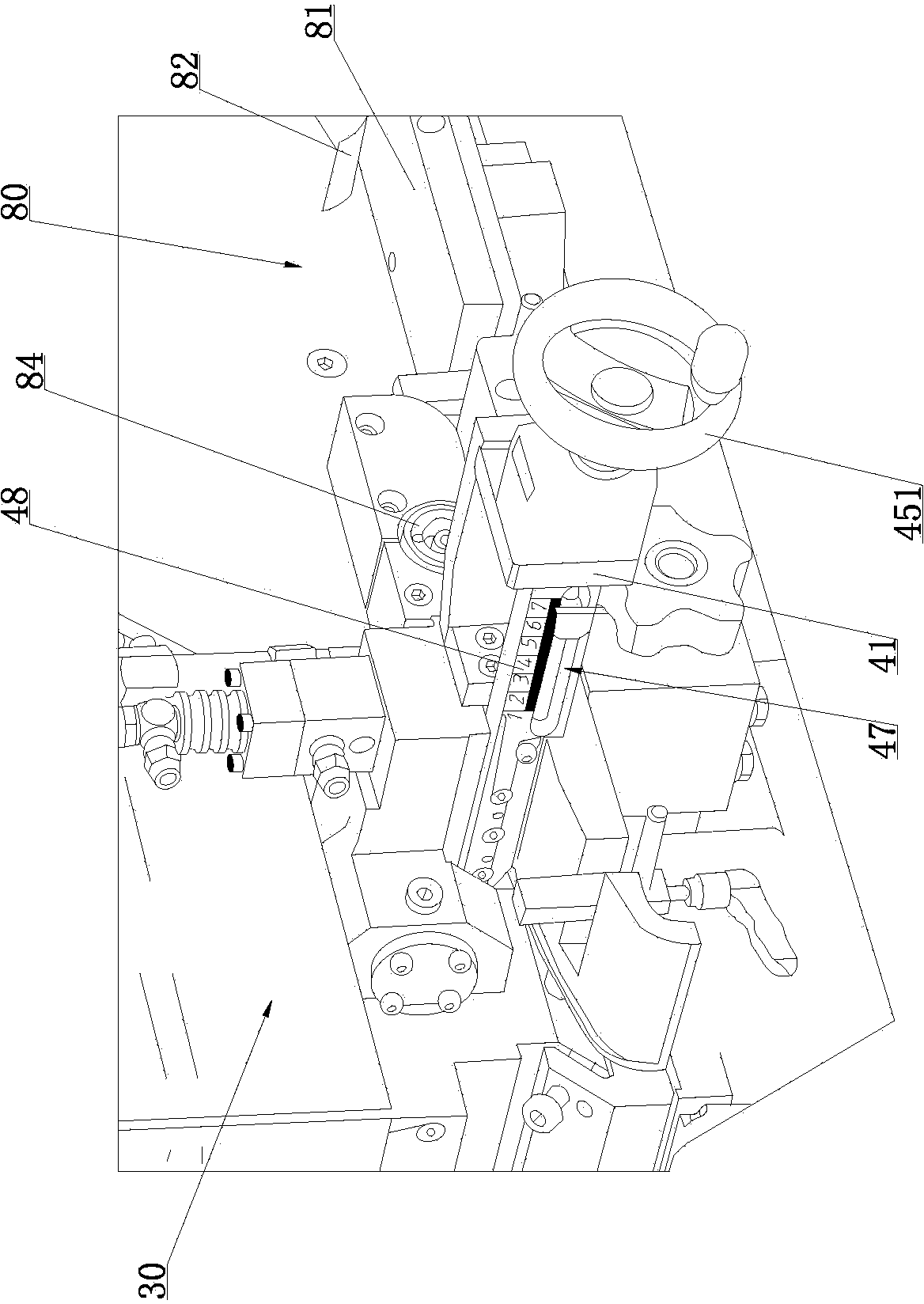

[0055] The difference between this embodiment and Embodiment 1 is that the shaft of the screw rod 45 is equipped with a scale indicator piece 46, and the side surface of the glue-coated positioning seat 41 is provided with an indicator piece moving groove 47, and the indicator piece moving groove 47 is provided with a moving groove 47. A scale line 48 is provided, and the scale indicator sheet 46 is positioned at the side of the scale display groove and points to the scale line 48, see Figure 4 with Figure 5 Specifically, when turning the hand wheel 451, the screw rod 45 drives the movable stopper 44 of the glue groove to move back and forth to adjust the glue width of the glue groove 43, wherein the value of the scale line 48 ranges from 10 to 70mm. When the rod 45 rotated, the scale indicating plate 46 installed on the shaft of the screw mandrel 45 moved with the screw mandrel 45, and the scale indicating plate 46 pointed to the corresponding scale line 48 values in the ...

Embodiment 3

[0058] The difference between this embodiment and Embodiment 1 is that the machine tool 10 is also provided with a transfer device 80, the transfer device 80 is located between the unwinding reel 20 and the scraper coating device 40, the transfer device 80 includes a positioning conveyor 81, and the positioning One end of the conveying path 81 close to the unwinding reel 20 is provided with an edge banding strip compression shrapnel 82, and the end of the positioning conveying path 81 close to the scraping device 40 is provided with a conveying wheel 83 and a pressing wheel 84, and the conveying wheel 83 is positioned at the pressing Below the wheel 84, see figure 2 with Figure 7 ; Concretely, after the edge banding strip is discharged through the unwinding reel 20, it passes through the positioning conveyor 81 of the conveying device 80 arranged between the unwinding reel 20 and the scraping device 40, and the compression shrapnel provided by the positioning conveyor 81 fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com