Gluing flattening equipment for wine box processing and processing method thereof

A technology of gluing and wine boxes, which is applied in box making operations, paper/cardboard containers, container manufacturing machinery, etc. Positioning, improving the efficiency of gluing, and improving the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

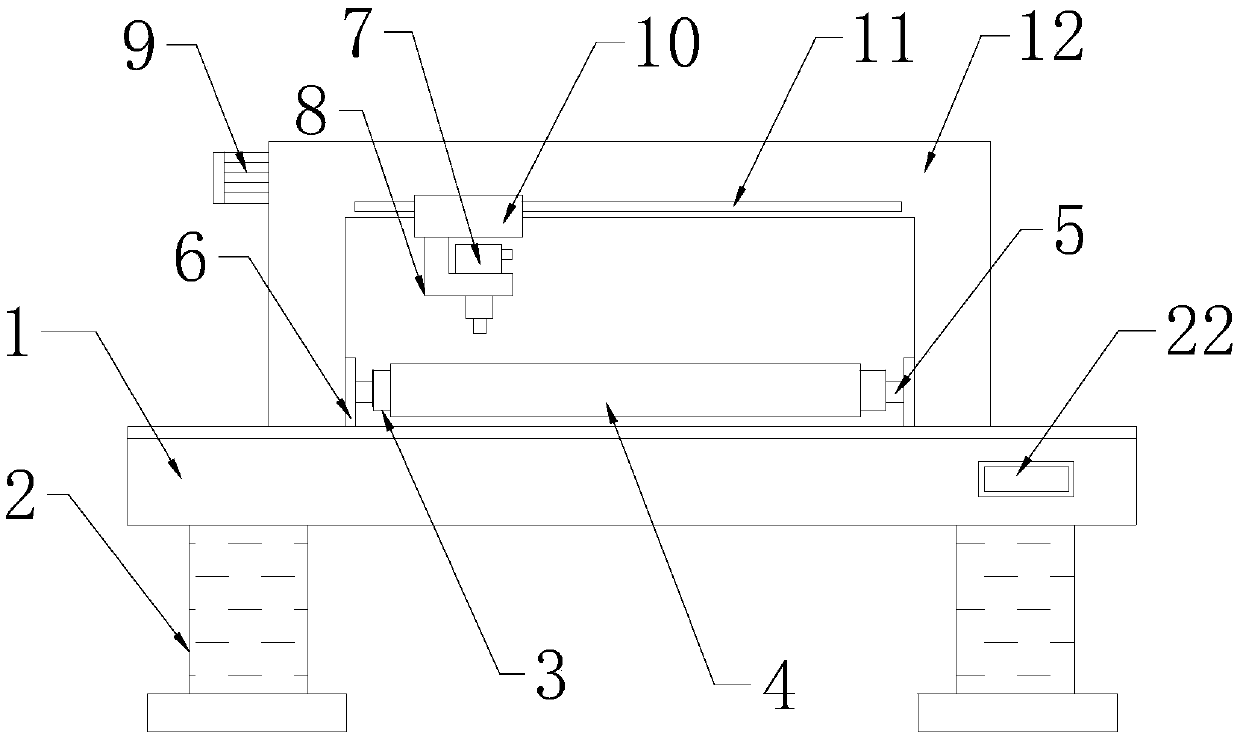

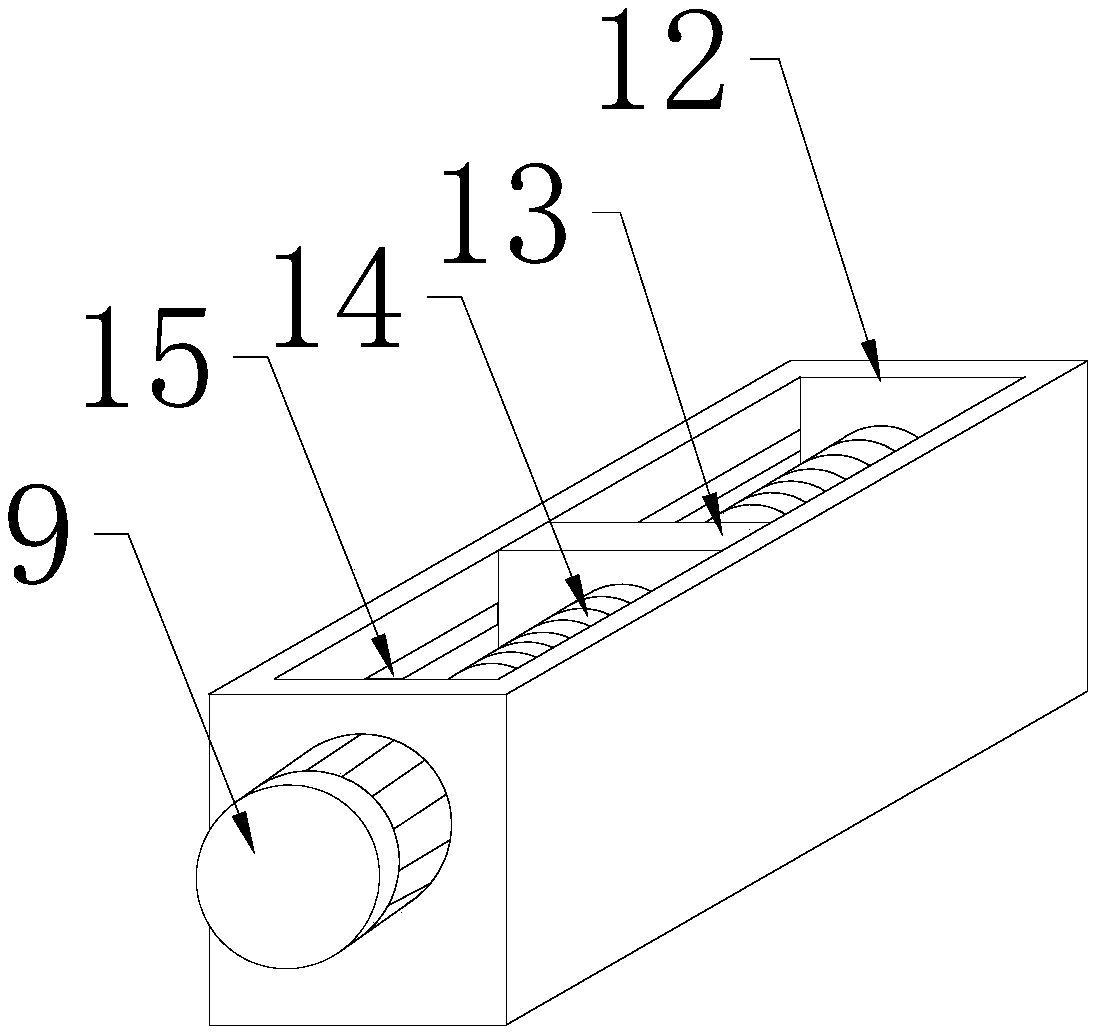

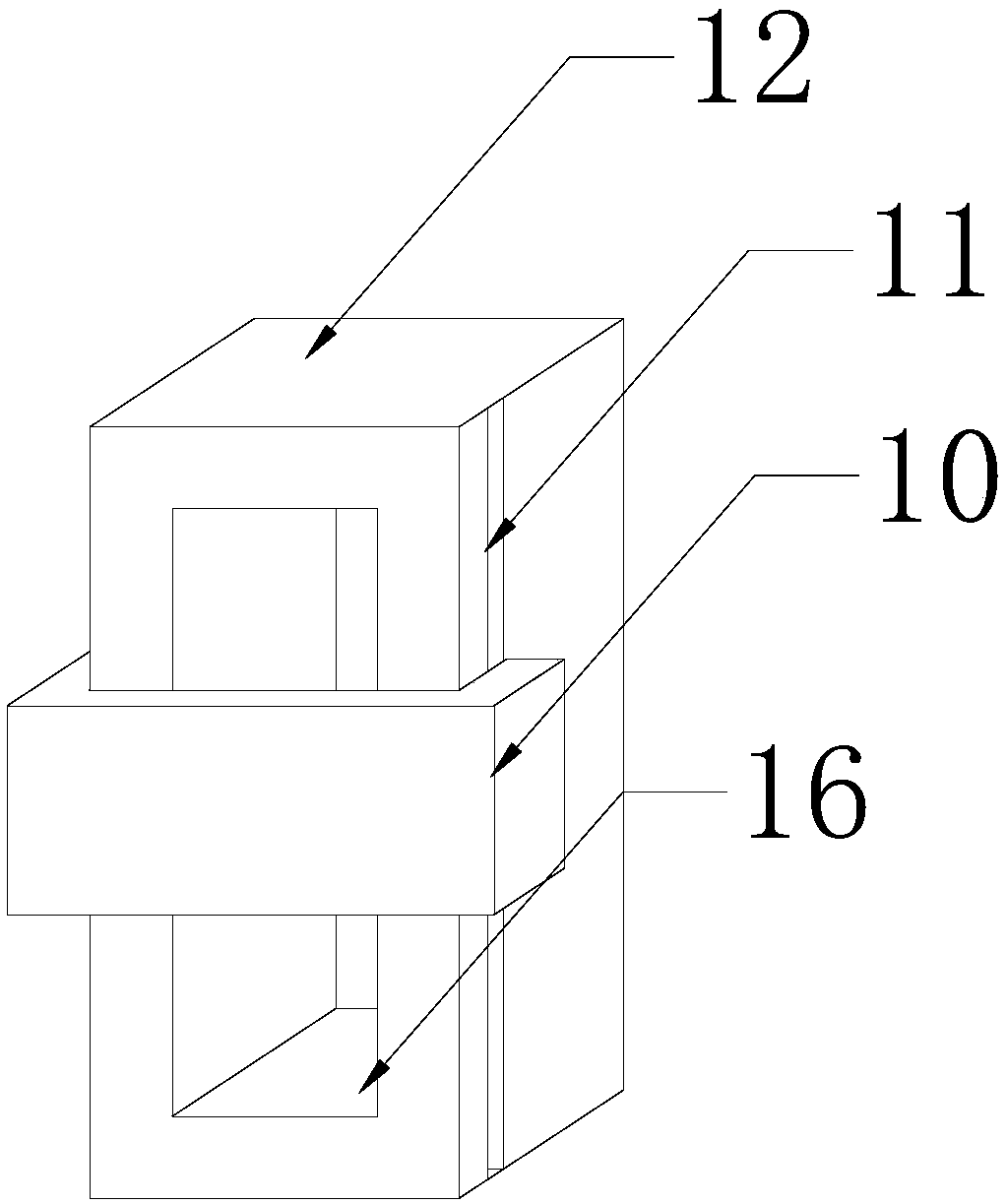

[0034] This embodiment includes an operating table 1, the top of the operating table 1 is clamped with a cover plate 18, and the top of the cover plate 18 is provided with through holes 17 all over the top, and a plurality of through holes 17 are opened on the top of the cover plate 18. When the box is placed, the through hole 17 can suck air, which is convenient for the wine box to be fixed on the cover plate 18. Several air pumps 20 are arranged inside the console 1, and the air pumps 20 provided can suck air, which is convenient for the wine box to be fixed on the cover plate 18. Place on the cover plate 18, the top of the cover plate 18 is fixedly connected with a support frame 12, both sides of the bottom of the support frame 12 are fixedly connected with a fixing mechanism 6, a roller 3 is arranged between the two fixing mechanisms 6, and a support frame 12 Both sides of the top are provided with a first chute 11, and the top of the support frame 12 is slidably connected ...

Embodiment 2

[0036] In the solution described in Embodiment 1 of this embodiment, a further embodiment is as follows: the bottom ends of several air pumps 20 are respectively fixed with connection seats 19 that are slidably connected to the console 1, and the two sides of the top ends of the connection seats 19 are Fastening bolts 21 are interspersed and threaded, and the provided air pump 20 can slide inside the console 1, which is convenient for the operator to adjust the position of the air pump 20 as required. The four corners of the bottom end of the console 1 are fixedly connected with supporting feet 2, and the bottom of the supporting feet 2 is fixedly connected with a backing plate, and the bottom end of the backing plate is fixedly connected with an anti-skid pad, and the backing plate and the anti-skid pad are provided, so that The device is placed more stably, which improves the stability when placed; the top of the support frame 12 is provided with a slot 16, and the groove wal...

Embodiment 3

[0040] The present embodiment is the method for using the gluing and flattening of the above-mentioned embodiment structure, and it comprises the following steps:

[0041] The first step is to place the wine box to be processed on the top of the cover plate 18, and at the same time, the operator starts the air pump 20 through the air pump switch on the switch panel 22, and at the same time takes the external magnet and places it on the top of the wine box. , the position of gluing needs to be placed in the direction along which the gluing mechanism 7 moves;

[0042] The second step is to adjust the length of the telescopic fixing frame 8, place the glue application mechanism 7 on the top of the wine box to be glued, and add glue to the inside of the glue barrel 702 through the liquid inlet pipe;

[0043] The third step is to start the servo motor 9 through the servo motor switch on the switch panel 22, and the servo motor 9 drives the movable plate 13 to move through the screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com