Gluing gun

A glue gun and hose technology, which is applied in the field of glue guns, can solve the problems of large glue output at the glue outlet, uneven glue lines, waste of glue, etc., to achieve reduced glue flow, neat and beautiful glue lines, easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

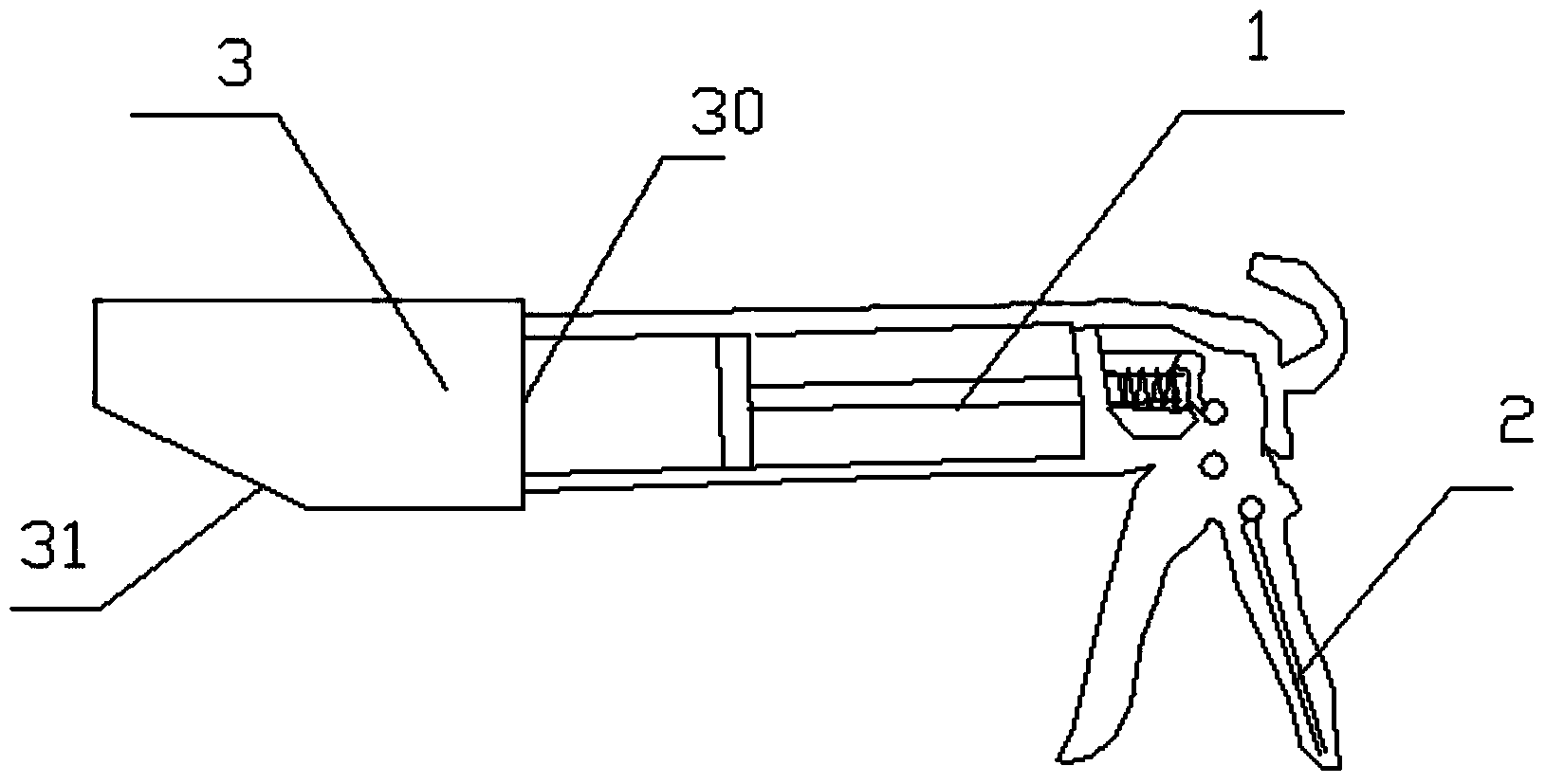

[0046] Such as figure 1 As shown, the present embodiment connects a glue pipe 3 on the body of a gun 1 of the existing glue gun. The glue outlet of the glue gun is connected, and the flat port 30 is used to connect the glue outlet of the existing glue gun and the glue pipe 3. The glue in the glue gun comes out from the glue outlet and enters the glue pipe 3, and the glue pipe 3 The other end is the bevel port 31, from which the glue is extruded. Since the port is changed to the bevel port 31, the flow rate of the glue is reduced, which is easy to control and saves glue. Even, the extruded glue line is neat and beautiful.

Embodiment 2

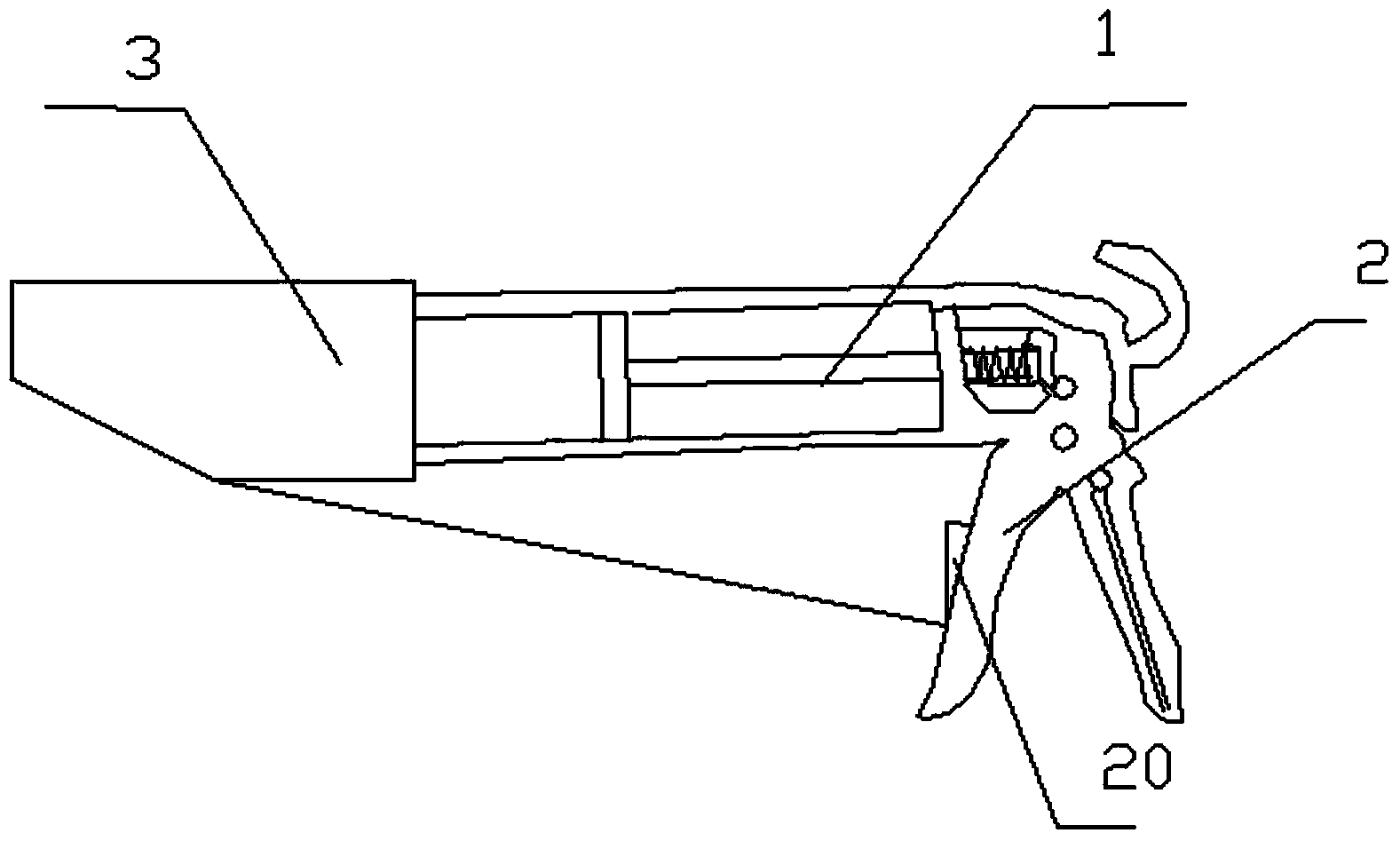

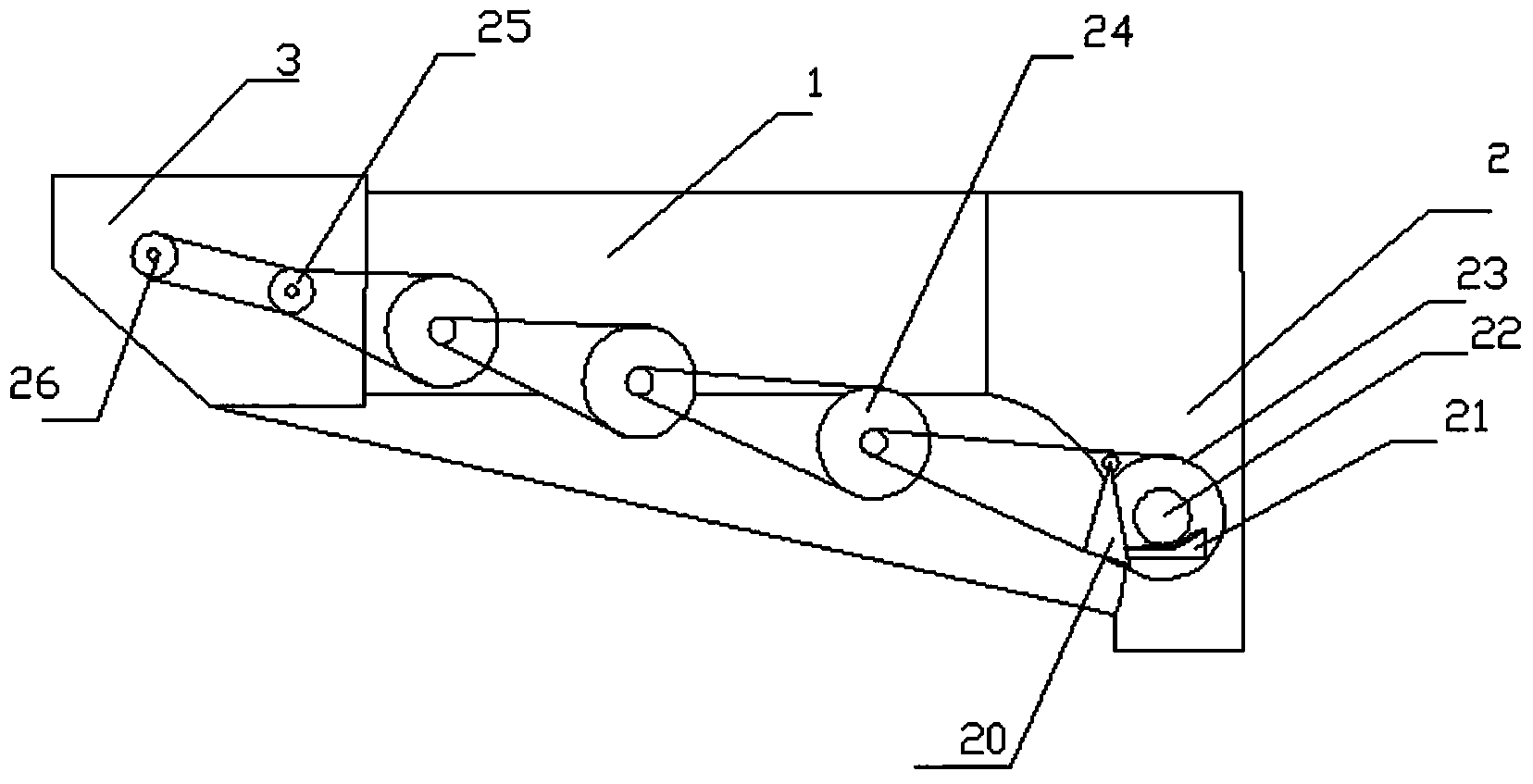

[0048] Such as figure 2 and image 3 As shown, the present embodiment includes a gun handle 2 and a gun body 1, and is characterized in that: it also includes a rubber hose 3, the rubber hose 3 is connected to the gun body 1, the two ends of the rubber hose 3 are open, and one end is a flat mouth 30, One end is a bevel port 31, and the plane port 30 is connected with the glue outlet of the gun body 1.

[0049] The rubber pipe 3 is provided with an agitator 26, the agitator 26 is connected to the switch 20 through a driving device, the switch 20 is connected with a rack 21, and the driving device includes a gear 22, a driving wheel 23, an intermediate wheel 24, a driven wheel 25 and Belt, rack 21 meshes with gear 22, gear 22 is fixed on the driving wheel 23, and the belt is sleeved on the driving wheel 23 and the intermediate wheel 24, the intermediate wheel 24 and the driven wheel 25, and the stirring shaft of the agitator 26 is fixed on On the driven wheel 25. The effect ...

Embodiment 3

[0051] Such as Figure 4 As shown, on the basis of any of the above-mentioned embodiments, the rubber pipe 3 in this embodiment includes an inner pipe 32 and an outer pipe 33 , and a noise-reducing material 34 is filled between the inner pipe 32 and the outer pipe 33 . The inner pipe 32 and the outer pipe 33 plus the noise-reducing material 34 can greatly reduce the noise generated during gluing, which is beneficial to the physical and mental health of the operating workers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com