Large-barrel dispenser servo glue discharging device

A dispensing machine and dispensing valve technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of insufficient glue output, high frequency of glue replacement, and small capacity of the vat, so as to facilitate maintenance and maintenance , Low frequency of rubber replacement, saving man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

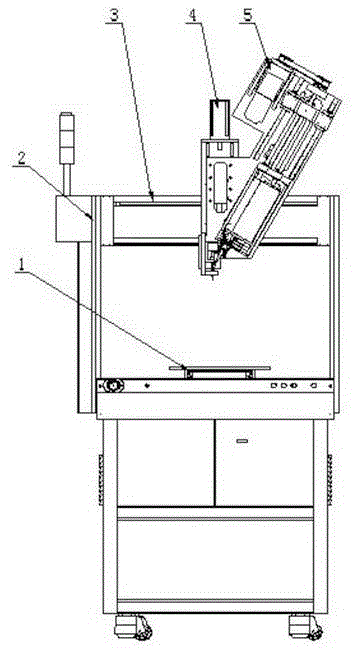

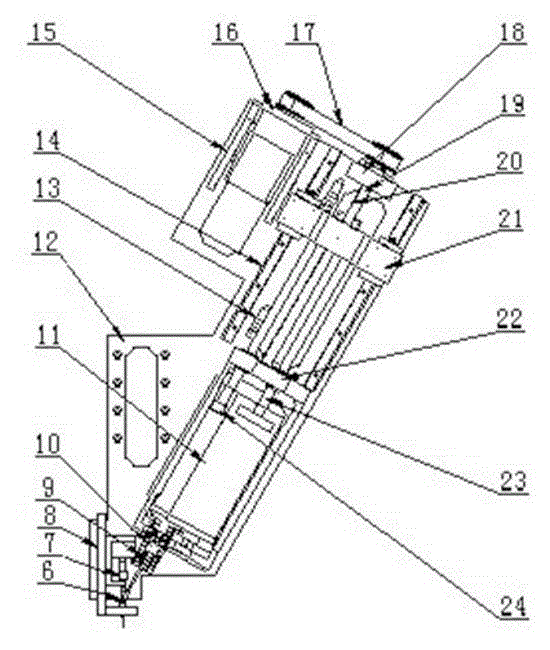

[0012] Such as figure 1 , figure 2 As shown, this specific embodiment adopts the following technical scheme: it includes a Y-axis workbench 1, a workbench 2, an X-axis guide rail 3, a Z-axis device 4 and a dispensing assembly device 5, and the lower end of the workbench 2 is provided with a Y-axis workbench. One side of table 1 and workbench 2 is provided with X-axis guide rail 3, Z-axis device 4 is slid on X-axis guide rail 3, dispensing assembly device 5 is installed on Z-axis device 4 by screws, wherein dispensing assembly device 5 Including Y-type dispensing valve 6, dispensing valve fixing seat 7, dispensing valve installation block 8, mixing tube bracket 9, mixing tube 10, glue bucket 11, bottom plate 12, sensor bracket 13, guide rail 14, motor bracket 15, Motor mounting plate 16, synchronous belt transmission device 17, screw mounting plate 18, guide post 19, screw rod 20, slider 21, rubber barrel fixing seat 22, large push rod 23, small push rod 24, dispensing valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com