Patents

Literature

61results about How to "Same material properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Etching-first and packaging-later manufacturing method for chip formal double-surface three-dimensional circuit and packaging structure of chip formal double-surface three-dimensional circuit

ActiveCN102723282ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesEtchingMetal substrate

The invention relates to an etching-first and packaging-later manufacturing method for a chip formal double-surface three-dimensional circuit and a packaging structure of the chip formal double-surface three-dimensional circuit. The method comprises the following steps of taking a metal substrate; pre-plating copper on the surface of the metal substrate; coating the surface of the metal substrate with green paint; removing a part of the green paint from the back surface of the metal substrate; electro-plating an inert metal circuit layer; electro-plating a metal circuit layer; coating the back surface of the metal substrate with the green paint; removing a part of the green paint from the back surface of the metal substrate; electro-plating the metal circuit layer; coating the back surface of the metal substrate with the green paint; removing a part of the green paint from the back surface of the metal substrate; coating a circuit screen board; pre-processing of metallization; removing the circuit screen board; electro-plating the metal circuit layer; coating the back surface of the metal substrate with the green paint; removing a part of the green paint from the front surface of the metal substrate; chemical-etching; electro-plating the metal circuit layer; coating bonding materials; installing a chip; bonding with metal wires; packaging; tapping at the back surface of the metal substrate; cleaning; implanting a metal ball; and cutting a finished product. The method disclosed by the invention has the beneficial effects that the manufacturing cost is lowered, the safety and the reliability of a packaging body are increased, the environment pollution is reduced, and the design and the manufacturing of a high-density circuit can be really realized.

Owner:JCET GROUP CO LTD

Normal chip single-faced three-dimensional circuit manufacture method by encapsulation prior to etching and normal chip single-faced three-dimensional circuit encapsulation structure

ActiveCN102723289ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesEtchingHigh density

The invention relates to a normal chip single-faced three-dimensional circuit manufacture method by encapsulation prior to etching. The method includes: taking a metal substrate; preplating copper to the metal substrate surface; coating with green paint; partially removing the green paint on the front of the metal substrate; electroplating inert a metal circuit layer; electroplating a metal circuit layer; coating with green paint; partially removing the green paint on the front of the metal substrate; electroplating a metal circuit layer; coating with green paint; partially removing the green paint on the front of the metal substrate; coating a circuit screen plate; performing metallization pretreatment; removing the circuit screen plate; electroplating metal circuit layer; coating bonding material; mounting a chip; performing metal circuit bonding; encapsulating; partially removing the green paint on the back of the metal substrate; performing chemical etching; electroplating a metal circuit layer; coating with green paint; reserving holes on the green paint; cleaning; attaching balls; and cutting finished products. The normal chip single-faced three-dimensional circuit manufacture method by encapsulation prior to etching has the advantages that manufacture cost is lowered, safety and reliability of encapsulation are enhanced, environmental pollution is reduced, and design and manufacture of high density circuit are really achieved.

Owner:JCET GROUP CO LTD

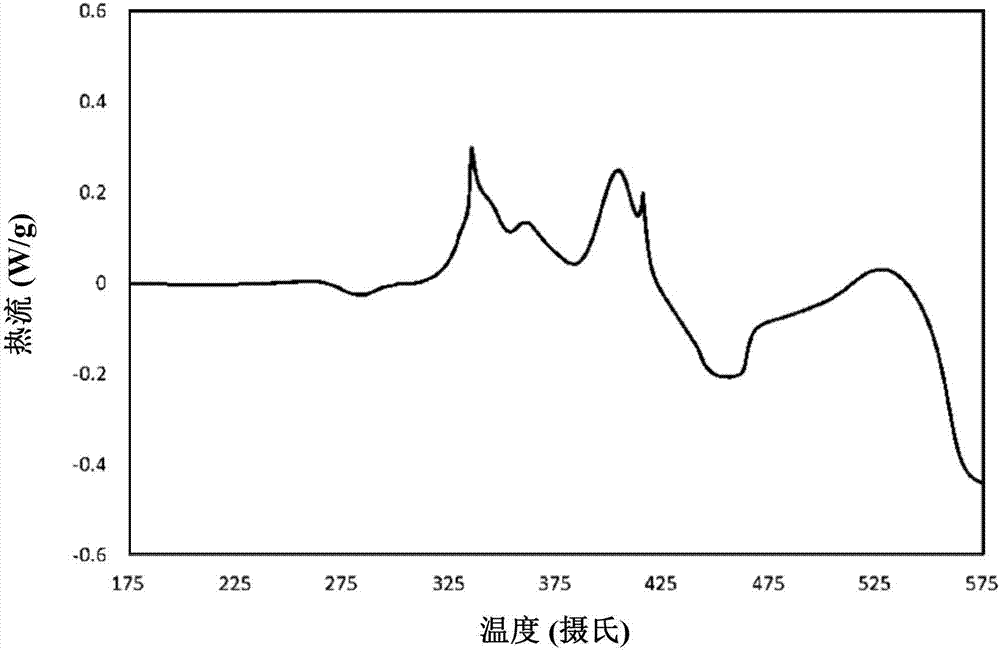

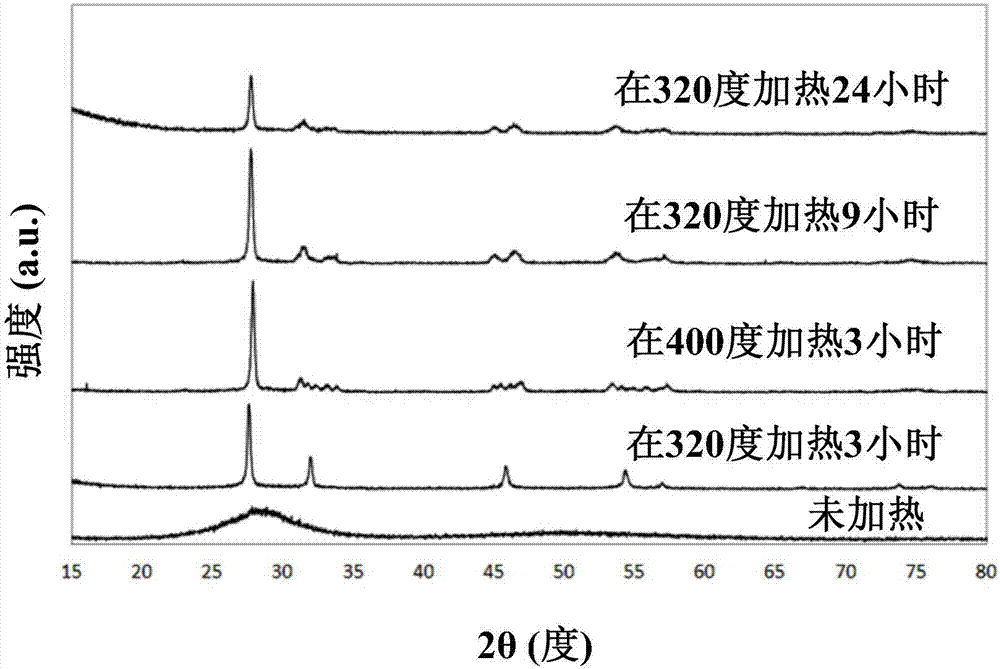

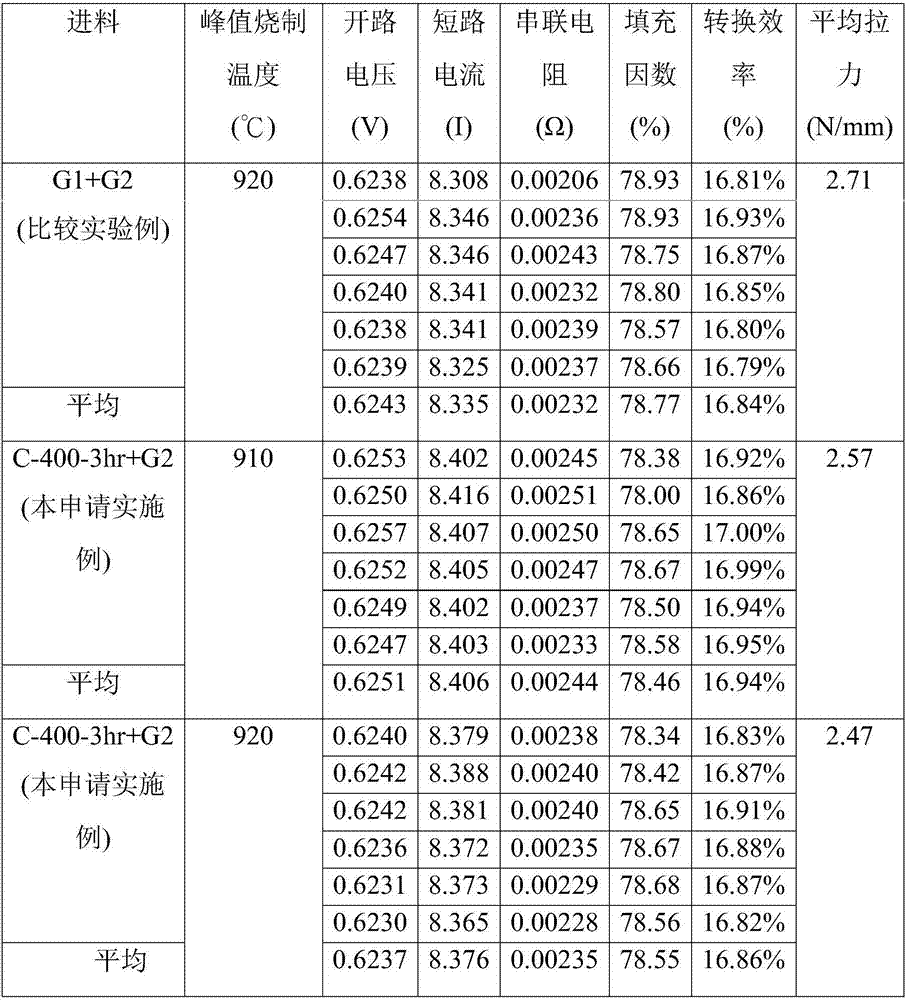

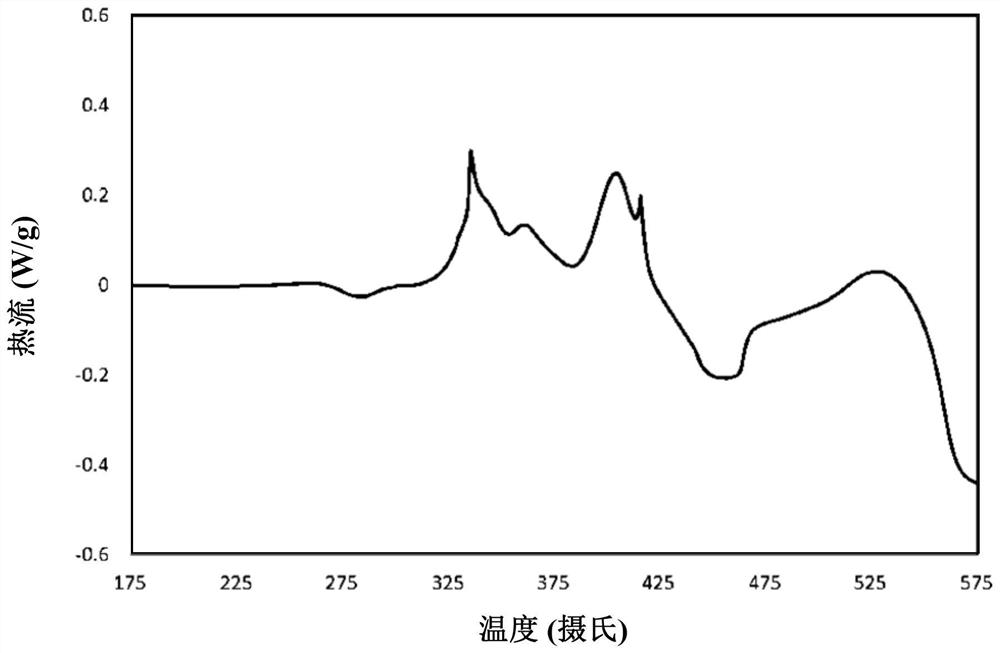

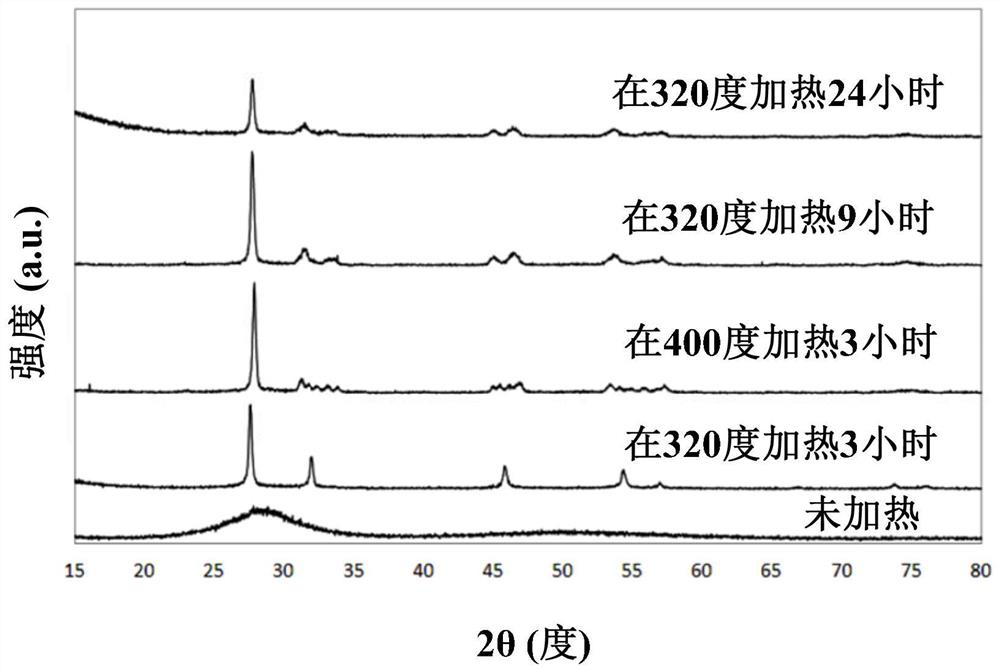

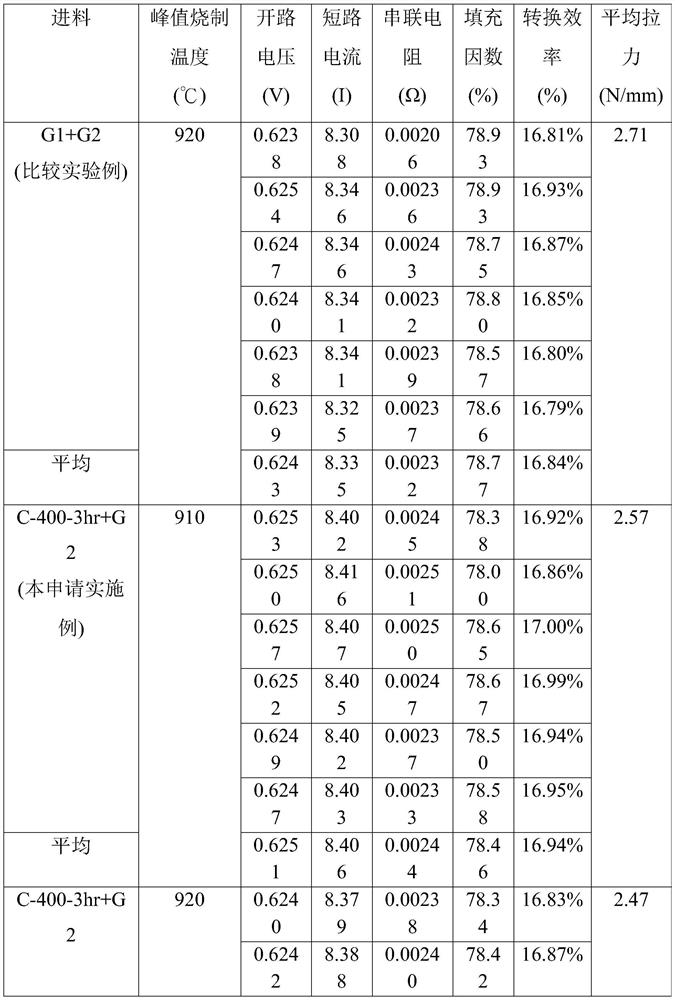

Crystalline oxides, preparation thereof and conductive pastes containing the same

ActiveCN107089798ASame electrical characteristicsDifferent electrical characteristicsNon-conductive material with dispersed conductive materialPhotovoltaic energy generationCrystalline oxideTe element

The present invention provides a novel crystalline oxide, a process for producing the crystalline oxides, a conductive paste comprising the crystalline oxides and an article comprising a substrate and an abovementioned conductive paste applied on the substrate. The present application can solve the problem that the content of the glass powder is too small to provide an appropriate pulling force and the reliability and durability of the solar cell are reduced. It is also possible to solve the problem that excessive glass powder will prevent the firing of the conductive paint and prevent the electrode from forming proper ohmic contact. During the firing of the conductive paint, the lead-tellurium-bismuth oxide crystals are heated and turned into liquid form, either alone or in combination with softened glass powder, providing appropriate corrosion and penetrating the anti-reflective layer on the front side of the solar cell, so that a good ohmic contact is formed between the conductive metal and the substrate and the conductive paint after firing forms a solar cell electrode having an appropriate physical property and excellent electrical conductivity.

Owner:GIGA SOLAR MATERIALS

First packaged and then etched packaging structure with single chip normally installed and base islands buried and preparation method of structure

ActiveCN102856283ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesSmall holeElectrical and Electronics engineering

The invention relates to a first packaged and then etched packaging structure with a single chip normally installed and base islands buried and a preparation method of the structure. The structure comprises base islands (1) and pins (2), wherein a chip (4) is arranged on the fronts of the base islands (1); the front face of the chip (4) and the front faces of the pins (2) are connected by metal wires (5); plastic package materials (6) are arranged in the surrounding regions of the base islands (1) and the pins (2) and outside the chip (4) and the metal wires (5); small holes (7) are formed on the surfaces of the plastic package materials (6) on the lower parts of the pins (2); the small holes (7) are communicated with the backs of the pins (2); metal balls (9) are arranged in the small holes (7); and the metal balls (9) are contacted with the backs of the pins (2). The packaging structure and the preparation method have the following beneficial effects that the preparation cost is reduced; the safety and reliability of the packaging body are improved; environmental pollution is reduced; and design and preparation of high-density circuits are truly achieved.

Owner:JCET GROUP CO LTD

Packaging-first and etching-later manufacturing method for chip formal double-surface three-dimensional circuit and packaging structure of chip formal double-surface three-dimensional circuit

ActiveCN102723287ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityEtching

The invention relates to a packaging-first and etching-later manufacturing method for a chip formal double-surface three-dimensional circuit. The method comprises the following technology steps of taking a metal substrate; pre-plating copper material on the surface of the metal substrate; carrying out the operation of pasting a photo-resisting film; removing a part of the photo-resisting film from the front surface of the metal substrate; electro-plating an inert metal circuit layer; electro-plating a metal circuit layer; packaging; carrying out the operation of pasting the photo-resisting film; tapping on the surface of plastic package material; electro-plating the metal circuit layer; coating bonding materials; installing a chip; bonding with metal wires; packaging; carrying out the operation of pasting the photo-resisting film; chemical-etching; electro-plating the metal circuit layer; packaging; tapping on the surface of plastic package material; digging a groove on the surface of the plastic package material; electro-plating the metal circuit layer; coating a circuit screen plate; pre-processing of metallization; removing the metal screen plate; electro-plating the metal circuit layer; packaging; tapping on the surface of plastic package material; cleaning; implanting a metal ball; and cutting a finished product. The method disclosed by the invention has the beneficial effects that the manufacturing cost is lowered, the safety and the reliability of a packaging body are increased, the environment pollution is reduced, and the design and the manufacturing of a high-density circuit can be really realized.

Owner:JCET GROUP CO LTD

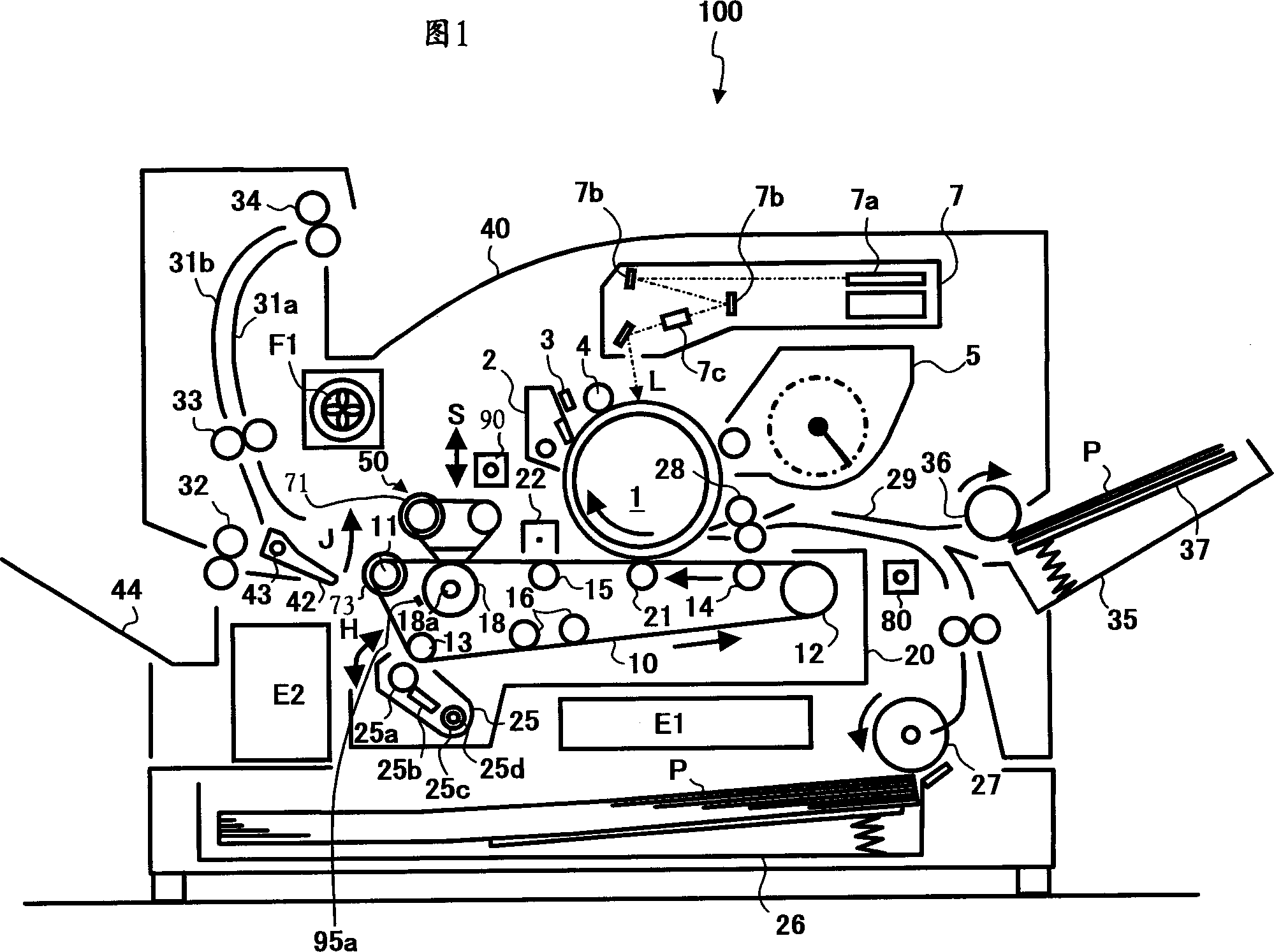

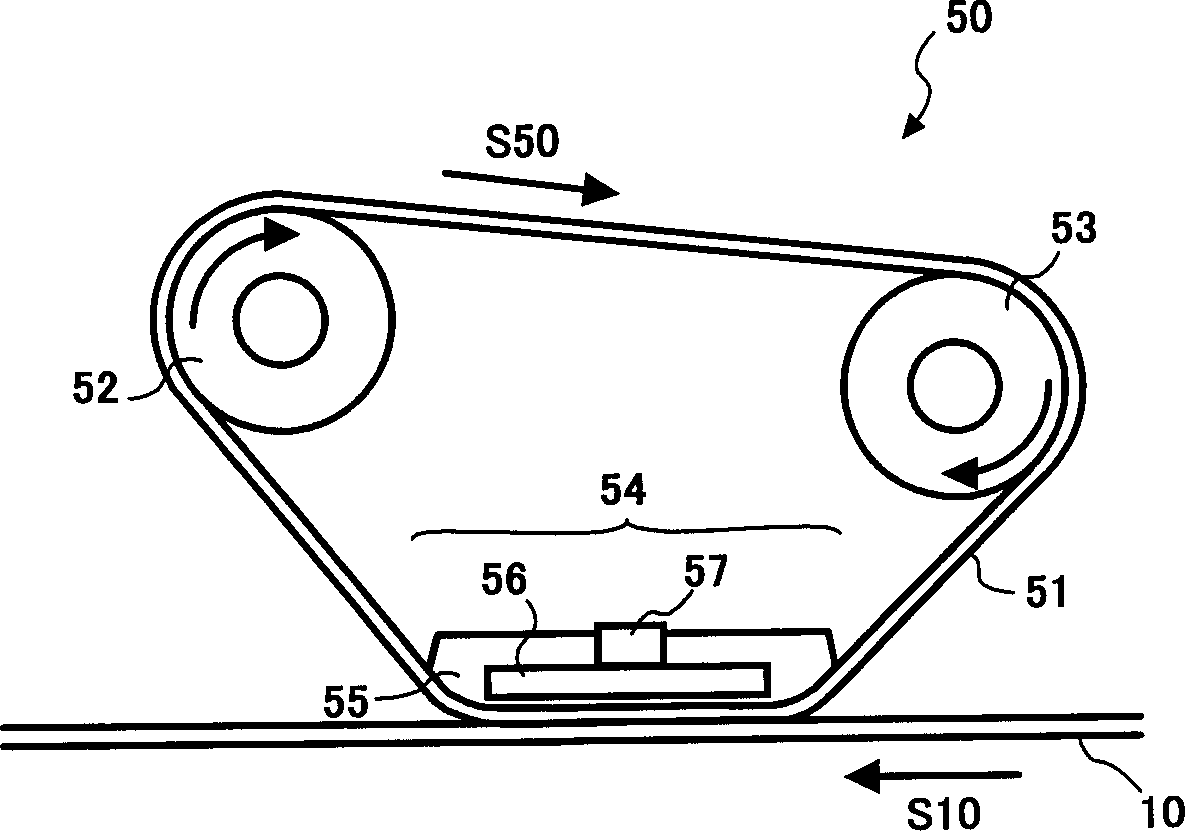

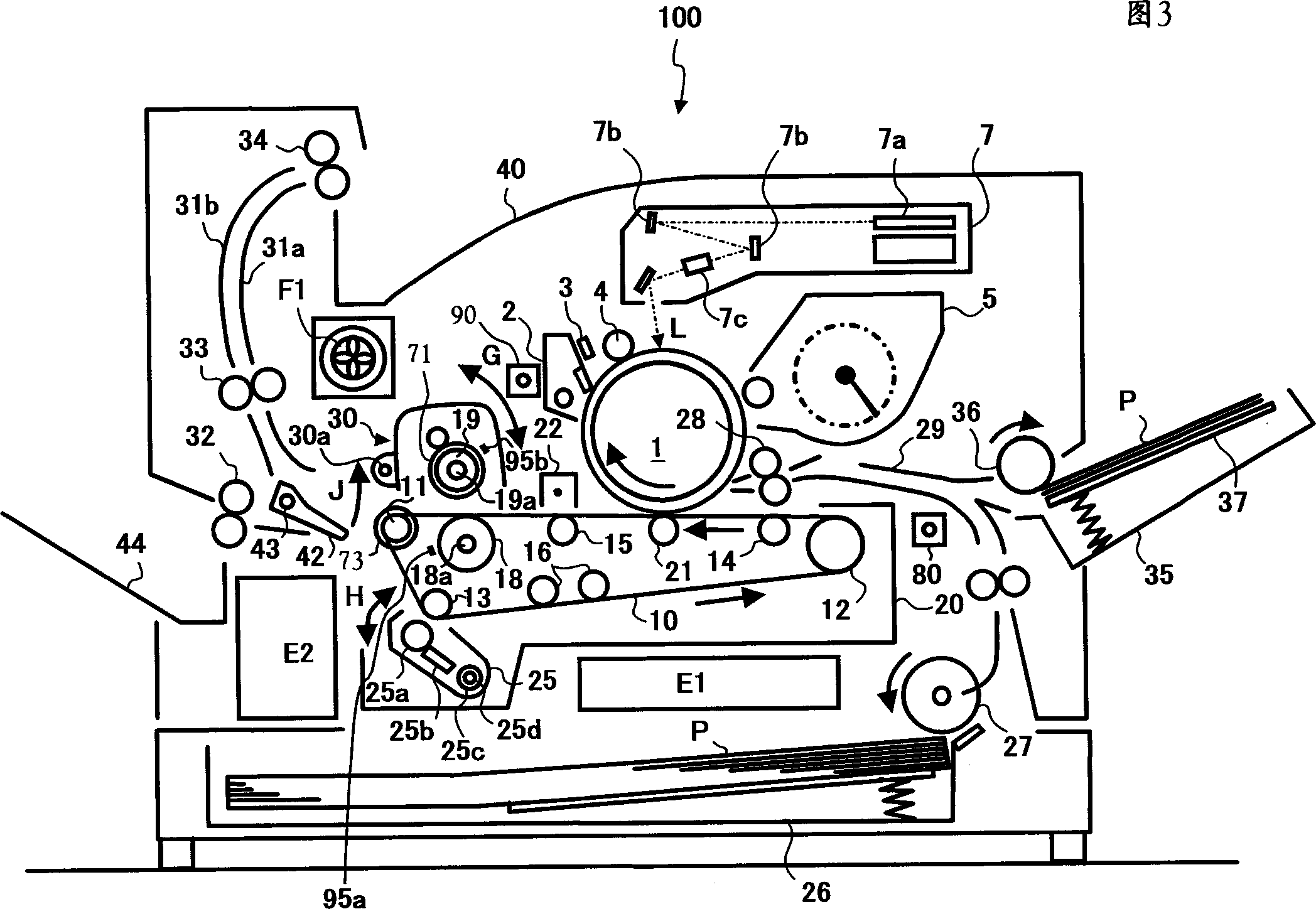

Image forming method and device

InactiveCN1347018ASame surface propertiesSame image qualityElectrographic process apparatusImage formationImage quality

Owner:RICOH KK

First etched and then packaged packaging structure with single chip reversedly installed and base islands buried as well as preparation method thereof

ActiveCN102856290ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densitySingle chip

The invention relates to a first etched and then packaged packaging structure with a single chip reversedly installed and base islands buried as well as a preparation method thereof. The packaging structure comprises base islands (1), pins (2) and a chip (3), wherein the chip is reversedly installed on the fronts of the base islands and the fronts of the pins; underfills (14) are arranged between the bottom of the chip and the fronts of the base islands and the pins; plastic package materials (4) are arranged in the peripheral regions of the base islands, the regions between the base islands and the pins, the regions between the pins, the regions on the upper parts of the base islands and the pins and the regions on the lower parts of the base islands and the pins and on the periphery of the chip; small holes (5) are arranged on the plastic package materials on the backs of the pins and are communicated with the backs of the pins; and metal balls (7) are arranged in the small holes and are contacted with the backs of the pins. The packaging structure and the preparation method have the following beneficial effects that the preparation cost is reduced; the safety and reliability of the packaging body are improved; environmental pollution is reduced; and design and preparation of high-density circuits are truly achieved.

Owner:JCET GROUP CO LTD

Multi-chip horizontal packaging, etching-after-packaging and pad exposed packaging structure and manufacturing method thereof

ActiveCN102856287ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityBiomedical engineering

The invention relates to a multi-chip horizontal packaging, etching-after-packaging and pad exposed packaging structure and a manufacturing method thereof. The structure comprises pads (1) and pins (2). A plurality of chips (4) are arranged on the right sides of the pads (1), and the right sides of the chips (4) and the pins (2) are connected through metal wires (5). Molding compounds (6) are packaged on the peripheries of the pads (1) and the pins (2) and outside the chips (4) and the metal wires (5). Holes (7) are opened on the surfaces of the molding compounds (6) on the lower portions of the pads (1) and the pins (2). Metal balls (9) are arranged in the holes (7) and contacted with the reverse sides of the pads (1) or the pins (2). The multi-chip horizontal packaging, etching-after-packaging and pad exposed packaging structure and the manufacturing method thereof have the advantages of reducing manufacturing costs, improving safety and reliability of packaging bodies, reducing environmental pollution, and being capable of designing and manufacturing high-density lines.

Owner:星科金朋半导体(江阴)有限公司

Multi-chip reversely-arranged etched-encapsulated base island-exposed encapsulating structure and manufacturing method thereof

ActiveCN102867802ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityAdhesive

The invention relates to a multi-chip reversely-arranged etched-encapsulated base island-exposed encapsulating structure and a manufacturing method thereof. The structure comprises a base island (1), a pin (2) and a plurality of chips (3), wherein the chips (3) are reversely arranged on the front faces of the base island (1) and the pin (2); bottom filling adhesives (14) are arranged between the bottoms of the chips (3) and the front faces of the base island (1) and the pin (2); plastic sealing materials (4) are enveloped in a region on the periphery of the base island (1), a region between the base island (1) and the pin (2) and a region between adjacent pins (2) and outside the chips (3); the surfaces of the plastic sealing materials (4) on the lower parts of the base island (1) and the pin (2) are provided with small holes (5); and metal balls (7) are arranged in the small holes (5). The multi-chip reversely-arranged etched-encapsulated base island exposing encapsulating structure has the beneficial effects that the manufacturing cost is lowered, the safety and the reliability of an encapsulating body are enhanced, environmental pollution is lowered, and design and manufacturing of a high-density circuit are realized truly.

Owner:JCET GROUP CO LTD

Multi-chip flip, etching-after-packaging and pad exposed packaging structure and manufacturing method thereof

ActiveCN102856284ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityBiomedical engineering

The invention relates to a multi-chip flip, etching-after-packaging and pad exposed packaging structure and a manufacturing method thereof. The structure comprises pads (1), pins (2) and a plurality of chips (3). The plurality of the chips (3) are arranged on the right sides of the pads (1) and the pins (2) in an inverted mode. Bottom filling glue (14) is arranged between the bottoms of the plurality of the chips (3) and the right sides of the pads (1) and the pins (2). Molding compounds (4) are packaged in areas on the peripheries of the pads (1), between the pads (1) and the pins (2), among the pins (2) and outside the plurality of the chips (3). Holes (5) are opened on the surfaces of the molding compounds (4) on the lower portions of pads (1) and the pins (2), and metal balls (7) are arranged in the holes (5). The multi-chip flip, etching-after-packaging and pad exposed packaging structure and the manufacturing method thereof have the advantages of reducing manufacturing costs, improving safety and reliability of packaging bodies, reducing environmental pollution, and being capable of designing and manufacturing high-density lines.

Owner:JCET GROUP CO LTD

Multi-chip reversely-arranged etched-encapsulated base island-buried encapsulating structure and manufacturing method thereof

ActiveCN102867791ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityAdhesive

The invention relates to a multi-chip reversely-arranged etched-encapsulated base island-buried encapsulating structure and a manufacturing method thereof. The structure comprises a base island (1), a pin (2) and a plurality of chips (3), wherein the chips (3) are reversely arranged on the front faces of the base island and the pin; bottom filling adhesives (14) are arranged between the bottoms of the chips and the front faces of the base island and the pin; plastic sealing materials (4) are enveloped in a region on the periphery of the base island, a region between the base island and the pin, a region between adjacent pins, regions on the upper parts of the base island and the pin, regions on the lower parts of the base island and the pin and the peripheries of the chips; the plastic sealing materials on the back face of the pin are provided with small holes (5); and metal balls (7) are arranged in the small holes (5), and are contacted with the back face of the pins. The multi-chip reversely-arranged etched-encapsulated base island-buried encapsulating structure has the beneficial effects that the manufacturing cost is lowered, the safety and the reliability of an encapsulating body are enhanced, environmental pollution is lowered, and design and manufacturing of a high-density circuit are realized truly.

Owner:JCET GROUP CO LTD

Single-side three-dimensional circuit chip upside-down-charging packaging-before-etching method and packaging structure thereof

ActiveCN102760668ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesPlastic packagingHigh density

The invention relates to a single-side three-dimensional circuit chip upside-down-charging packaging-before-etching method, which comprises the following process steps: taking a metal baseplate; pre-plating copper on the surface of the metal baseplate; pasting light resistant films; removing part of the light resistant films on the front surface of the metal baseplate; electroplating an inert metal circuit layer; electroplating a metal circuit layer; pasting light resistant films; removing part of the light resistant films on the front surface of the baseplate; electroplating a metal circuit layer; removing the light resistant films on the surface of the metal baseplate; encapsulating; processing before metallization; electroplating a metal circuit layer; removing the light resistant films on the surface of the metal baseplate; mounting a chip and filling the bottom of the chip; encapsulating; chemically etching; removing the light resistant films on the surface of the metal baseplate; electroplating a metal circuit layer; encapsulating; cutting holes in the surface of plastic packaging materials; washing; mounting balls; and cutting finished products. The method and the structure disclosed by the invention has the benefits that the manufacture cost is lowered, the safety and reliability of the packaged body are improved, and the environment pollution is reduced, so that design and manufacture of high-density circuits are realized actually.

Owner:JCET GROUP CO LTD

Packaging-first and etching-later manufacturing method for chip formal single-surface three-dimensional circuit and packaging structure of chip formal single-surface three-dimensional circuit

ActiveCN102723290ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityEtching

The invention relates to a packaging-first and etching-later manufacturing method for a chip formal single-surface three-dimensional circuit. The method comprises the following technology steps of taking a metal substrate; pre-plating copper material on the surface of the metal substrate; carrying out the operation of pasting a photo-resisting film; removing a part of the photo-resisting film from the front surface of the metal substrate; electro-plating an inert metal circuit layer; electro-plating a metal circuit layer; carrying out the operation of pasting a photo-resisting film; removing a part of the photo-resisting film from the front surface of the metal substrate; electro-plating the metal circuit layer; removing the photo-resisting film on the surface of the metal substrate; packaging; pre-processing of metallization; electro-plating the metal circuit layer; removing the photo-resisting film on the surface of the metal substrate; coating bonding materials; installing a chip; bonding with metal wires; packaging; carrying out the operation of pasting the photo-resisting film; removing a part of the photo-resisting film from the back surface of the metal substrate; chemical-etching; removing the photo-resisting film on the surface of the metal substrate; electro-plating the metal circuit layer; packaging; tapping on the surface of plastic package material; cleaning; implanting a metal ball; and cutting a finished product. The method disclosed by the invention has the beneficial effects that the manufacturing cost is lowered, the safety and the reliability of a packaging body are increased, the environment pollution is reduced, and the design and the manufacturing of a high-density circuit can be really realized.

Owner:JCET GROUP CO LTD

Single-chip flip, etching-after-packaging and pad exposed packaging structure and manufacturing method thereof

ActiveCN102856269ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesBiomedical engineeringHigh density

The invention relates to a single-chip flip, etching-after-packaging and pad exposed packaging structure and a manufacturing method thereof. The structure comprises pads (1), pins (2) and a chip (3). The chip (3) is arranged on the right sides of the pads (1) and the pins (2) in an inverted mode. Bottom filling glue (14) is arranged between the bottom of the chip (3) and the right sides of the pads (1) and the pins (2). Molding compounds (4) are packaged in areas on the peripheries of the pads (1), between the pads (1) and the pins (2), among the pins (2) and outside the chip (3). Holes (5) are opened on the surfaces of the molding compounds (4) on lower portions of the pads (1) and the pins (2), and metal balls (7) are arranged in the holes (5). The single-chip flip, etching-after-packaging and pad exposed packaging structure and the manufacturing method thereof have the advantages of reducing manufacturing costs, improving safety and reliability of packaging bodies, reducing environmental pollution, and being capable of designing and manufacturing high-density lines.

Owner:JCET GROUP CO LTD

Multi-chip flip-chip etching first packaging structure without base island and its manufacturing method

ActiveCN102856271BLow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityBiochemical engineering

The invention relates to a multi-chip flip, packaging-after-etching and non-pad packaging structure and a manufacturing method thereof. The structure comprises pins (1) and a plurality of chips (2). The plurality of the chips (2) are arranged on the right sides of the pins (1) in an inverted mode; bottom filling glue (13) is arranged between the bottoms of the chips (2) and the right sides of the pins (1); molding compounds (3) are packaged in areas on the peripheries of the pins (1), among the pins (1), on the upper portions and the lower portions of the pins (1) and outside the chips (2); holes (4) are opened on the surfaces of the molding compounds (3) on the lower portions of the pins (1), and communicated with the reverse sides of the pins (1); and metal balls (6) are arranged in the holes (4) and contacted with the reverse sides of the pins (1). The multi-chip flip, packaging-after-etching and non-pad packaging structure and the manufacturing method thereof have the advantages of reducing manufacturing costs, improving safety and reliability of packaging bodies, and being capable of designing and manufacturing high-density lines.

Owner:JCET GROUP CO LTD

First etched and then packaged packaging structure with single chip reversedly installed and base islands buried as well as preparation method thereof

ActiveCN102856290BLow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densitySingle chip

The invention relates to a first etched and then packaged packaging structure with a single chip reversedly installed and base islands buried as well as a preparation method thereof. The packaging structure comprises base islands (1), pins (2) and a chip (3), wherein the chip is reversedly installed on the fronts of the base islands and the fronts of the pins; underfills (14) are arranged between the bottom of the chip and the fronts of the base islands and the pins; plastic package materials (4) are arranged in the peripheral regions of the base islands, the regions between the base islands and the pins, the regions between the pins, the regions on the upper parts of the base islands and the pins and the regions on the lower parts of the base islands and the pins and on the periphery of the chip; small holes (5) are arranged on the plastic package materials on the backs of the pins and are communicated with the backs of the pins; and metal balls (7) are arranged in the small holes and are contacted with the backs of the pins. The packaging structure and the preparation method have the following beneficial effects that the preparation cost is reduced; the safety and reliability of the packaging body are improved; environmental pollution is reduced; and design and preparation of high-density circuits are truly achieved.

Owner:JCET GROUP CO LTD

Single-chip horizontal packaging, packaging-after-etching and pad-embedded packaging structure and manufacturing method thereof

ActiveCN102856294BLow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityEngineering

The invention relates to a single-chip horizontal packaging, packaging-after-etching and pad-embedded packaging structure and a manufacturing method thereof. The structure comprises pads (1) and pins (2). A chip (4) is arranged on the right sides of the pads (1), and the right side of the chip (4) and the right sides of the pins (2) are connected through metal wires (5). Molding compounds (6) are packaged on the peripheries of the pads (1) and the pins (2) and outside the chip (4) and the metal wires (5). Holes (7) are opened on surfaces of the molding compounds (6) on the lower portions of the pins (2) and communicated with the reverse sides of the pins (2). Metal balls (9) are arranged in the holes (7) and contacted with the reverse sides of the pins (2). The single-chip horizontal packaging, packaging-after-etching and pad-embedded packaging structure and the manufacturing method thereof have the advantages of reducing manufacturing costs, improving safety and reliability of packaging bodies, reducing environmental pollution, and being capable of designing and manufacturing high-density lines.

Owner:JCET GROUP CO LTD

Single-chip flip-chip first encapsulation and then etching base island embedded encapsulation structure and manufacturing method thereof

ActiveCN102856285BLow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesSpin-flipHigh density

The invention relates to a single-chip flip, etching-after-packaging and pad embedded packaging structure and a manufacturing method thereof. The structure comprises pads (1), pins (2) and a chip (3). The chip is arranged on the right sides of the pads and the pins in an inverted mode; bottom filling glue (14) is arranged between the bottom of the chip and the right sides of the pads and the pins; molding compounds (4) are packaged in areas on the peripheries of the pads, between the pads and the pins, among the pins, on the upper portions of the pads and the pins, on the lower portions of the pads and the pins and on the periphery of the chip; holes (5) are opened on the molding compounds on the reverse sides of the pins, and communicated with the reverse sides of the pins; and metal balls (7) are arranged in the holes and contacted with the reverse sides of the pins. The single-chip flip, etching-after-packaging and pad embedded packaging structure and the manufacturing method thereof have the advantages of reducing manufacturing costs, improving safety and reliability of packaging bodies, reducing environmental pollution, and being capable of designing and manufacturing high-density lines.

Owner:JCET GROUP CO LTD

Packaging-first and etching-later manufacturing method for chip formal double-surface three-dimensional circuit and packaging structure of chip formal double-surface three-dimensional circuit

ActiveCN102723286BLow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityEtching

Owner:JCET GROUP CO LTD

Multi-chip positive packaging structure for embedding basic island by first packaging and second etching, and manufacturing method for multi-chip positive packaging structure

ActiveCN102881670ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesEtchingHigh density

The invention relates to a multi-chip positive packaging structure for embedding a basic island by first packaging and second etching, and a manufacturing method for the multi-chip positive packaging structure. The multi-chip positive packaging structure comprises the basic island (1) and pins (2), wherein chips (4) are arranged on the front face of the basic island (1); the front faces of the chips (4) are connected with the front faces of the pins (2) through metal wires (5); plastic materials (6) wrap the surrounding regions of the basic island (1) and the pins (2) as well as the chips (4) and the metal wires (5); small holes (7) are formed in the surfaces of the plastic materials (6) on the lower parts of the pins (2) and are communicated with the back faces of the pins (2); and metal balls (9) are arranged in the small holes (7) and are in contact with the back faces of the pins (2). The multi-chip positive packaging structure has the advantages that the manufacturing cost is reduced, the safety and the reliability of a package body are improved, the environment pollution is reduced, and design and manufacturing of a high-density line can be really realized.

Owner:JCET GROUP CO LTD

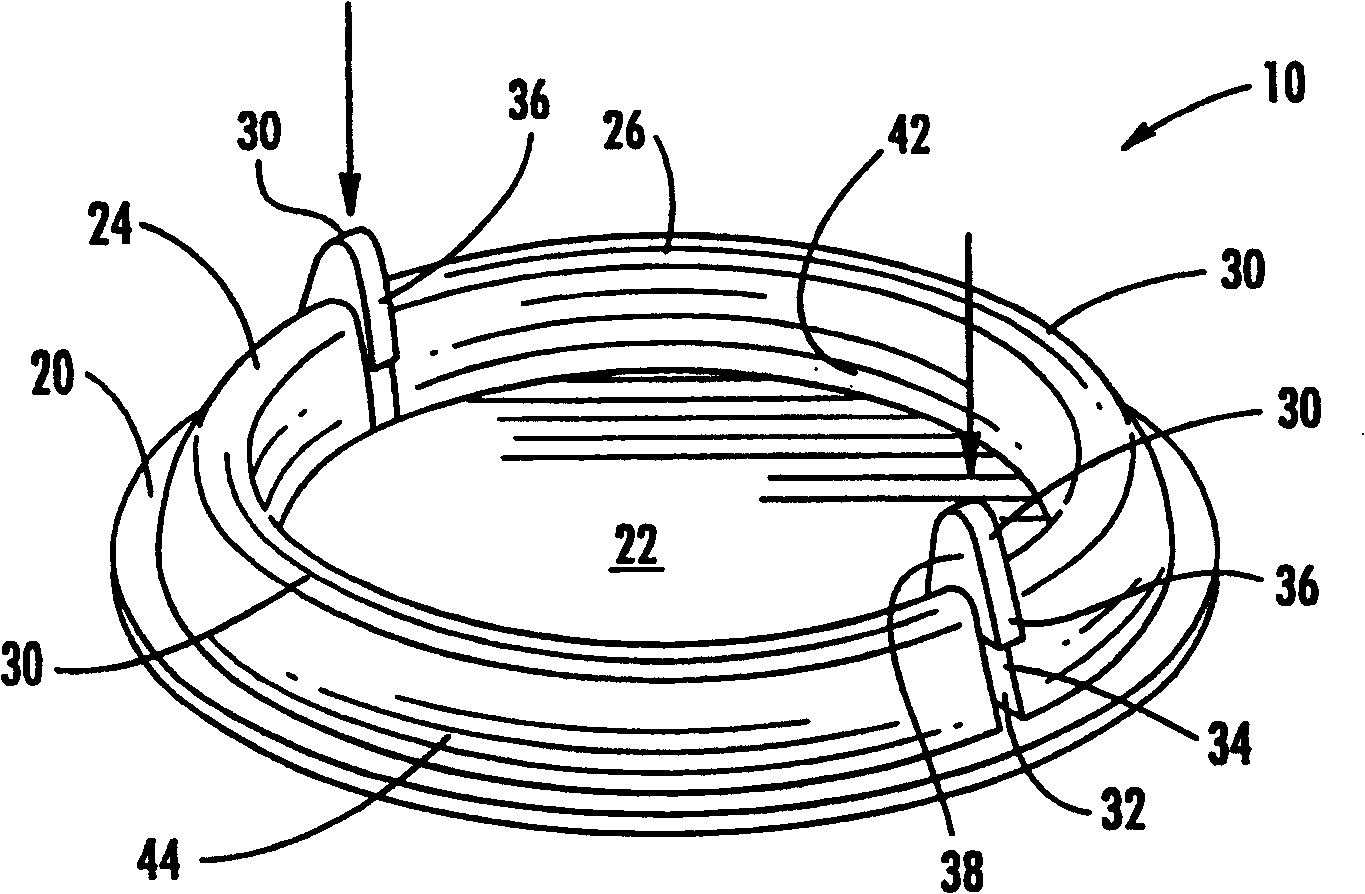

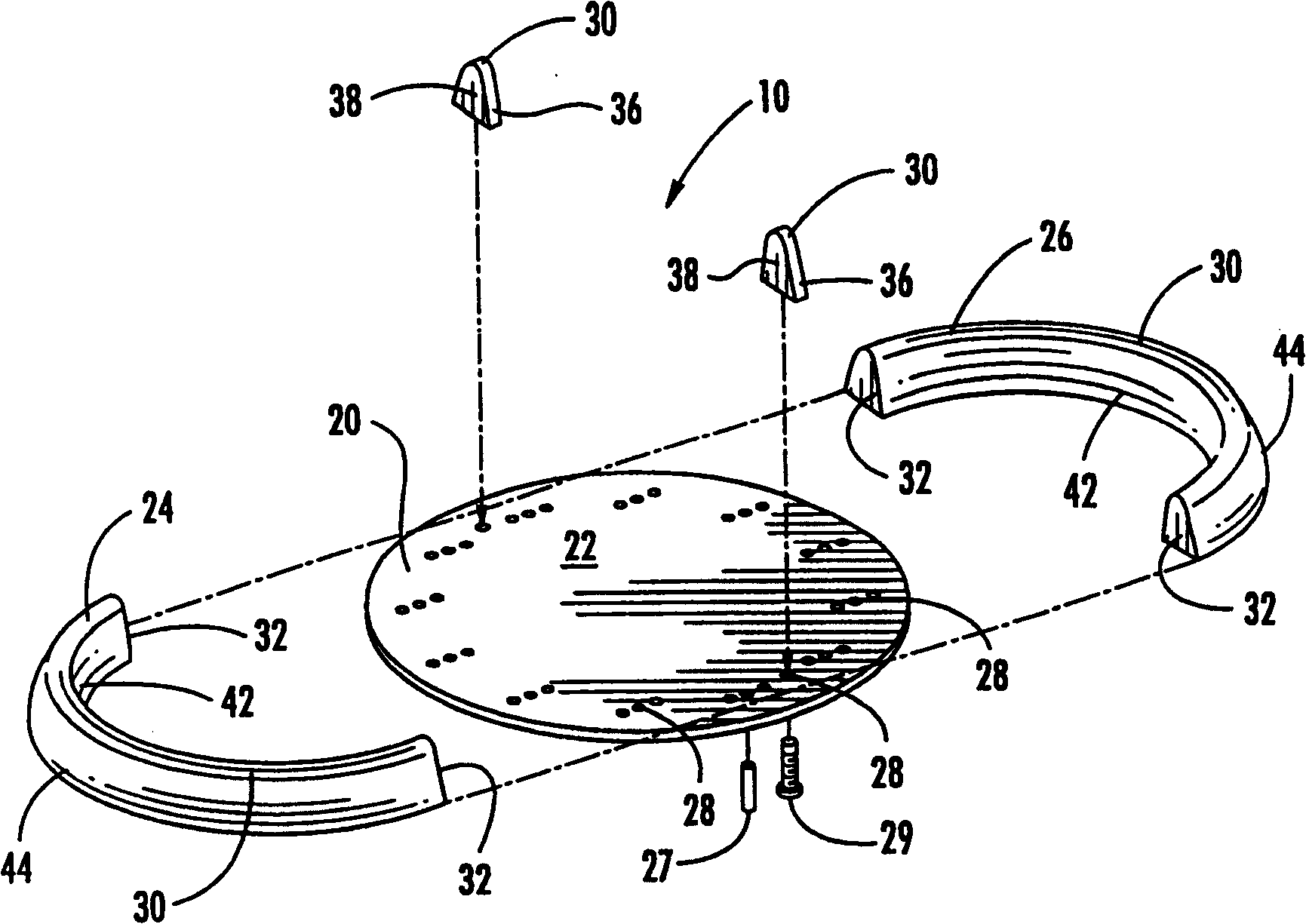

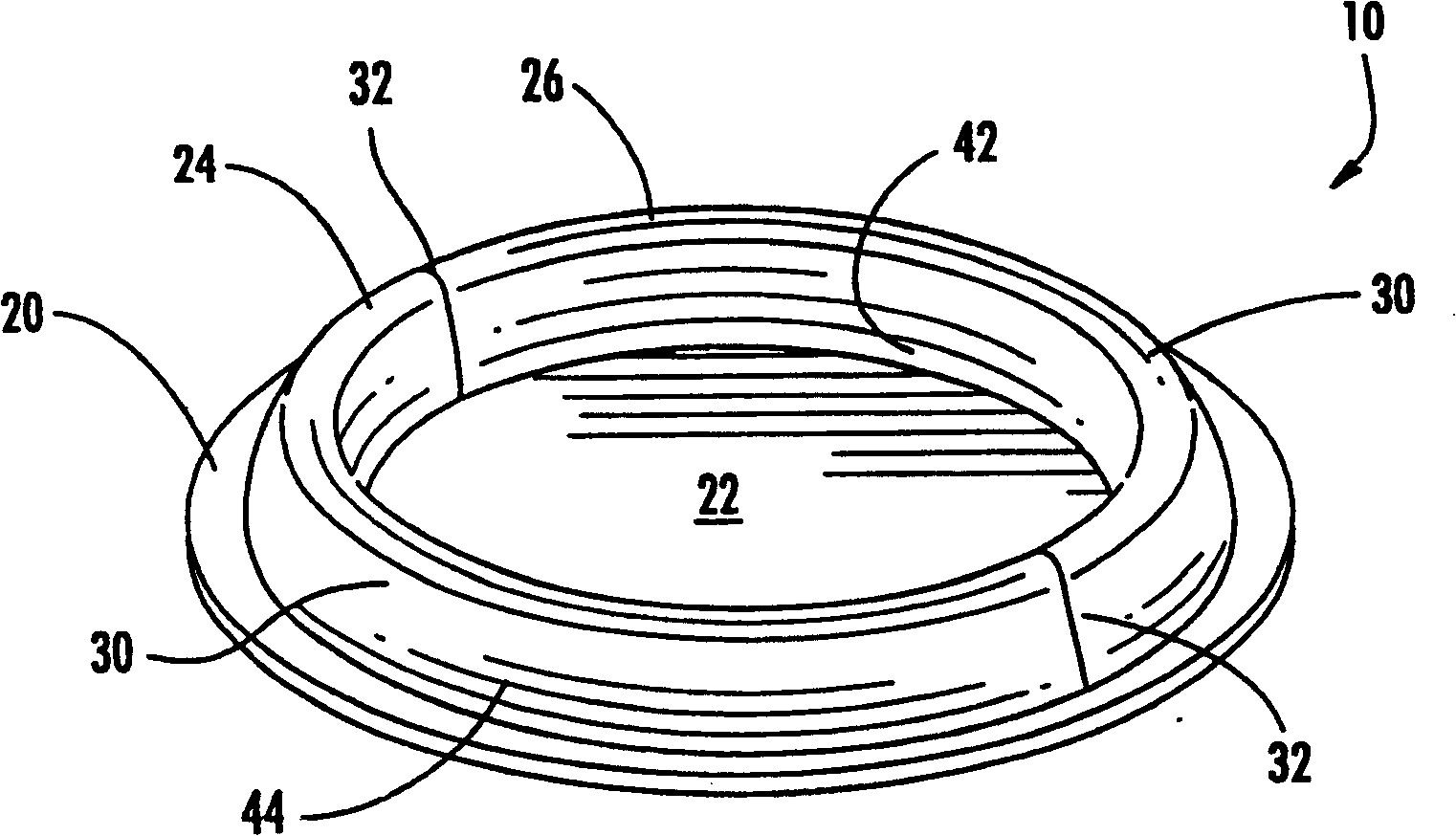

Adaptable mandrel for spin forming

The present invention provides a mandrel for rotational forming, the mandrel having a backing plate having a removably mounted mandrel portion and mandrel spacers, such that the mandrel is suitable for use in a variety of applications. kind of structure. Different configurations of mandrels may be used to provide different rotationally formed contoured surfaces upon which sheet metal or other rotationally formable material may be rotationally formed. The mandrel also has the ability to join individual metal sheets or multiple metal sheets into the desired rotationally formed product through friction stir welding or other suitable processing processes. The rotationally formed weld metal sheet may be trimmed to remove portions of the weld metal sheet, including the weld seams, that have significantly different material properties as a result of the welding process.

Owner:THE BOEING CO

Single-chip front-mount etch-before-package substrate-free packaging structure and manufacturing method thereof

ActiveCN102856293BLow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densitySingle chip

The invention relates to a first etched and then packaged packaging structure with a single chip normally installed and base islands buried as well as a preparation method thereof. The structure comprises base islands (1) and pins (2), wherein a chip (4) is arranged on the fronts of the base islands (1); the front of the chip (4) and the fronts of the pins (2) are connected by metal wires (5); plastic package materials (6) are arranged in the surrounding regions of the base islands (1) and the pins (2) and outside the chip (4) and the metal wires (5); small holes (7) are arranged on the surfaces of the plastic package materials (6) on the lower parts of the pins (2); the small holes (7) are communicated with the backs of the pins (2); metal balls (9) are arranged in the small holes (7); and the metal balls (9) are contacted with the backs of the pins (2). The packaging structure and the preparation method have the following beneficial effects that the preparation cost is reduced; the safety and reliability of the packaging body are improved; environmental pollution is reduced; and design and preparation of high-density circuits are truly achieved.

Owner:JCET GROUP CO LTD

Multi-chip flip-chip packaging first, then etching base island to expose packaging structure and manufacturing method thereof

ActiveCN102856284BLow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityBiochemical engineering

The invention relates to a multi-chip flip, etching-after-packaging and pad exposed packaging structure and a manufacturing method thereof. The structure comprises pads (1), pins (2) and a plurality of chips (3). The plurality of the chips (3) are arranged on the right sides of the pads (1) and the pins (2) in an inverted mode. Bottom filling glue (14) is arranged between the bottoms of the plurality of the chips (3) and the right sides of the pads (1) and the pins (2). Molding compounds (4) are packaged in areas on the peripheries of the pads (1), between the pads (1) and the pins (2), among the pins (2) and outside the plurality of the chips (3). Holes (5) are opened on the surfaces of the molding compounds (4) on the lower portions of pads (1) and the pins (2), and metal balls (7) are arranged in the holes (5). The multi-chip flip, etching-after-packaging and pad exposed packaging structure and the manufacturing method thereof have the advantages of reducing manufacturing costs, improving safety and reliability of packaging bodies, reducing environmental pollution, and being capable of designing and manufacturing high-density lines.

Owner:JCET GROUP CO LTD

First packaged and then etched packaging structure with single chip normally installed and base islands buried and preparation method of structure

ActiveCN102856283BLow costImprove the level ofSemiconductor/solid-state device detailsSolid-state devicesHigh densityEngineering

The invention relates to a first packaged and then etched packaging structure with a single chip normally installed and base islands buried and a preparation method of the structure. The structure comprises base islands (1) and pins (2), wherein a chip (4) is arranged on the fronts of the base islands (1); the front face of the chip (4) and the front faces of the pins (2) are connected by metal wires (5); plastic package materials (6) are arranged in the surrounding regions of the base islands (1) and the pins (2) and outside the chip (4) and the metal wires (5); small holes (7) are formed on the surfaces of the plastic package materials (6) on the lower parts of the pins (2); the small holes (7) are communicated with the backs of the pins (2); metal balls (9) are arranged in the small holes (7); and the metal balls (9) are contacted with the backs of the pins (2). The packaging structure and the preparation method have the following beneficial effects that the preparation cost is reduced; the safety and reliability of the packaging body are improved; environmental pollution is reduced; and design and preparation of high-density circuits are truly achieved.

Owner:JCET GROUP CO LTD

Multi-chip positive packaging structure for embedding basic island by first packaging and second etching, and manufacturing method for multi-chip positive packaging structure

ActiveCN102881670BLow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesEtchingHigh density

The invention relates to a multi-chip positive packaging structure for embedding a basic island by first packaging and second etching, and a manufacturing method for the multi-chip positive packaging structure. The multi-chip positive packaging structure comprises the basic island (1) and pins (2), wherein chips (4) are arranged on the front face of the basic island (1); the front faces of the chips (4) are connected with the front faces of the pins (2) through metal wires (5); plastic materials (6) wrap the surrounding regions of the basic island (1) and the pins (2) as well as the chips (4) and the metal wires (5); small holes (7) are formed in the surfaces of the plastic materials (6) on the lower parts of the pins (2) and are communicated with the back faces of the pins (2); and metal balls (9) are arranged in the small holes (7) and are in contact with the back faces of the pins (2). The multi-chip positive packaging structure has the advantages that the manufacturing cost is reduced, the safety and the reliability of a package body are improved, the environment pollution is reduced, and design and manufacturing of a high-density line can be really realized.

Owner:JCET GROUP CO LTD

Multi-chip front-mount packaging structure with etching first and packaging without base island and its manufacturing method

ActiveCN102856291BLow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityEngineering

The invention relates to a first etched and then packaged packaging structure with multiple chips normally installed and base islands buried as well as a preparation method thereof. The structure comprises base islands (1) and pins (2), wherein chips (4) are arranged on the fronts of the base islands (1); the fronts of the chips (4) and the fronts of the pins (2) are connected by metal wires (5); plastic package materials (6) are arranged in the surrounding regions of the base islands (1) and the pins (2) and outside the chips (4) and the metal wires (5); small holes (7) are arranged on the surfaces of the plastic package materials (6) on the lower parts of the pins (2); the small holes (7) are communicated with the backs of the pins (2); metal balls (9) are arranged in the small holes (7); and the metal balls (9) are contacted with the backs of the pins (2). The packaging structure and the preparation method have the following beneficial effects that the preparation cost is reduced; the safety and reliability of the packaging body are improved; environmental pollution is reduced; and design and preparation of high-density circuits are truly achieved.

Owner:JCET GROUP CO LTD

Oxide crystal, its preparation method and conductive paint containing oxide crystal

ActiveCN107089798BSame electrical characteristicsDifferent electrical characteristicsNon-conductive material with dispersed conductive materialPhotovoltaic energy generationSolar cellChemistry

The present application discloses a novel oxide crystal, a preparation method of the oxide crystal, a conductive paint containing the oxide crystal, and an object including a substrate and the conductive paint applied to the substrate. The present application can solve the problem that the content of glass powder is too small to provide proper pulling force and reduce the reliability and durability of solar cells. It can also solve the problem that too much glass powder will hinder the firing of the conductive paint, so that the electrodes cannot form proper ohmic contact. During the conductive paint firing process, lead-tellurium-bismuth-oxide crystals are heated to liquid form, acting alone or in combination with softened glass powder, to provide proper corrosion and penetrate the anti-reflection layer on the front side of the solar cell , so that a good ohmic contact is formed between the conductive metal and the substrate, so that the fired conductive paint forms a solar cell electrode with appropriate physical properties and excellent conductivity.

Owner:GIGA SOLAR MATERIALS

First etched and then packaged packaging structure with single chip reversedly installed and base islands exposed and preparation method of structure

ActiveCN102856289ALow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityEngineering

The invention relates to a first etched and then packaged packaging structure with a single chip reversedly installed and base islands exposed and a preparation method of the structure. The structure comprises base islands (1), pins (2) and a chip (3), wherein the chip (3) is reversedly installed on the front faces of the base islands (1) and the pins (2); underfills (14) are arranged among the bottom of the chip (3), the fronts of the base islands (1) and the pins (2); plastic package materials (4) are arranged in the peripheral regions of the base islands (1), the regions between the base islands (1) and the pins (2) and the regions between the pins (2) and outside the chip (3); small holes (5) are formed on the surfaces of the plastic package materials (4) on the lower parts of the base islands (1) and the pins (2); and metal balls (7) are arranged in the small holes (5). The packaging structure and the preparation method have the following beneficial effects that the preparation cost is reduced; the safety and reliability of the packaging body are improved; environmental pollution is reduced; and design and preparation of high-density circuits are truly achieved.

Owner:JCET GROUP CO LTD

First packaged and then etched packaging structure with multiple chips reversedly installed and base islands buried and preparation method of structure

ActiveCN102856267BLow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesHigh densityEngineering

Owner:江阴芯智联电子科技有限公司

Manufacture method of flip chip single-faced three-dimensional circuit manufactured by encapsulation prior to etching and flip chip single-faced three-dimensional circuit encapsulation structure

ActiveCN102723288BLow costImprove securitySemiconductor/solid-state device detailsSolid-state devicesEtchingHigh density

The invention relates to a flip chip single-faced three-dimensional circuit manufacture method by encapsulation prior to etching. The method includes: taking a metal substrate; preplating copper to the metal substrate surface; coating with green paint; partially removing the green paint on the front of the metal substrate; electroplating an inert metal circuit layer; electroplating a metal circuit layer; coating with green paint; partially removing the green paint on the front of the metal substrate; electroplating metal circuit layer; coating with green paint; partially removing the green paint on the front of the metal substrate; coating a circuit screen plate; performing metallization pretreatment; removing the circuit screen plate; electroplating a metal circuit layer; mounting a chip and filling the bottom of the chip; encapsulating; partially removing the green paint on the back of the metal substrate; performing chemical etching; electroplating a metal circuit layer; coating with green paint; reserving holes on the green paint; cleaning; attaching balls; and cutting finished products. The flip chip single-faced three-dimensional circuit manufacture method by encapsulation prior to etching has the advantages that manufacture cost is lowered, safety and reliability of encapsulation are enhanced, environmental pollution is reduced, and design and manufacture of high density circuit are really achieved.

Owner:JCET GROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com