Adaptable mandrel for spin forming

一种旋转成形、心轴的技术,应用在制造工具、成型工具、运输和包装等方向,能够解决降低成品材料性能等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will now be described in more detail with reference to the accompanying drawings, in which some, but not all embodiments of the invention are shown. In fact, the present invention can be implemented in many different ways and should not be limited by the embodiments given in this application; in addition, these embodiments are provided so that the disclosed content can meet the reasonable needs in the application. In the drawings, the same reference numerals designate the same components.

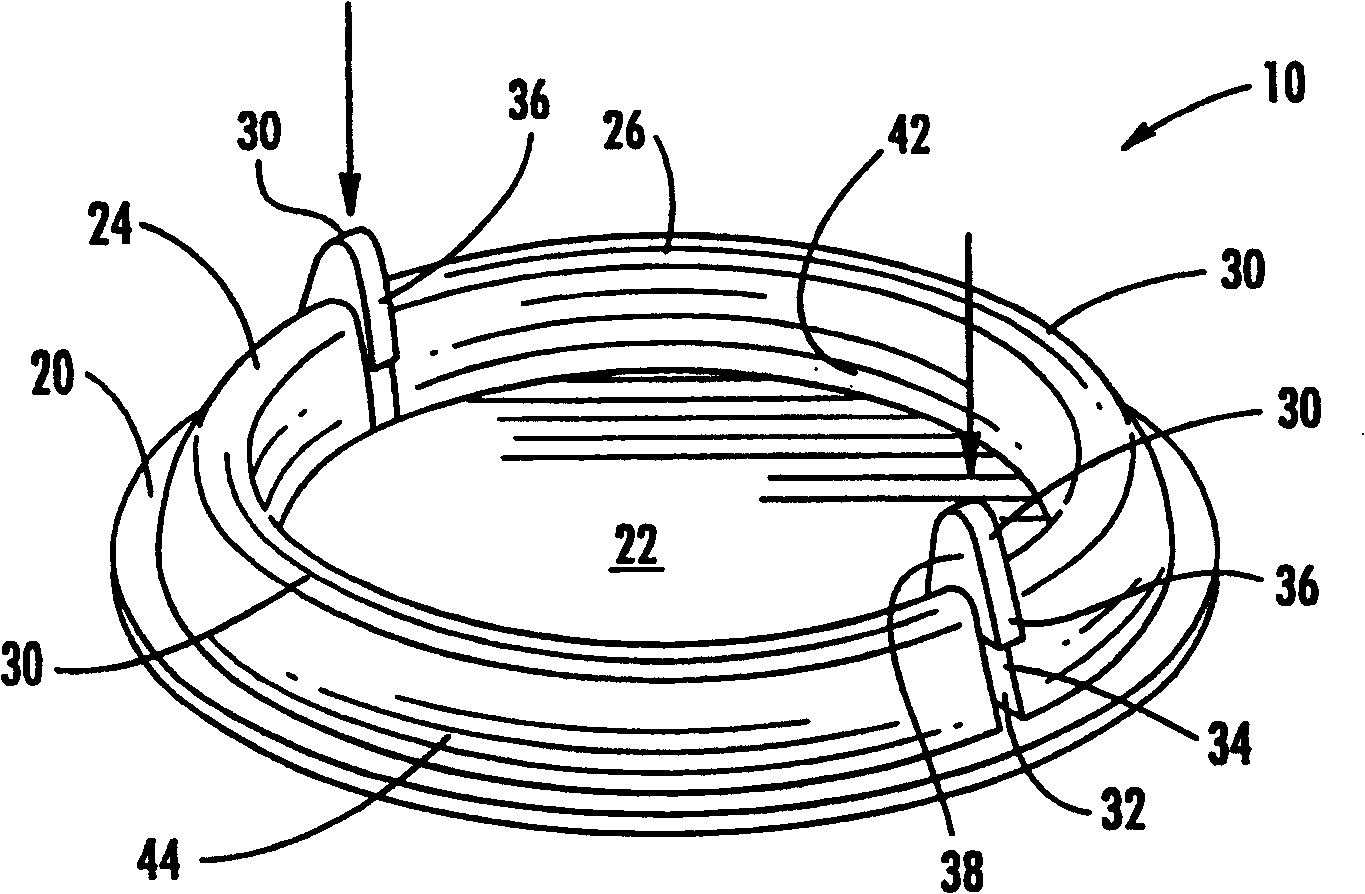

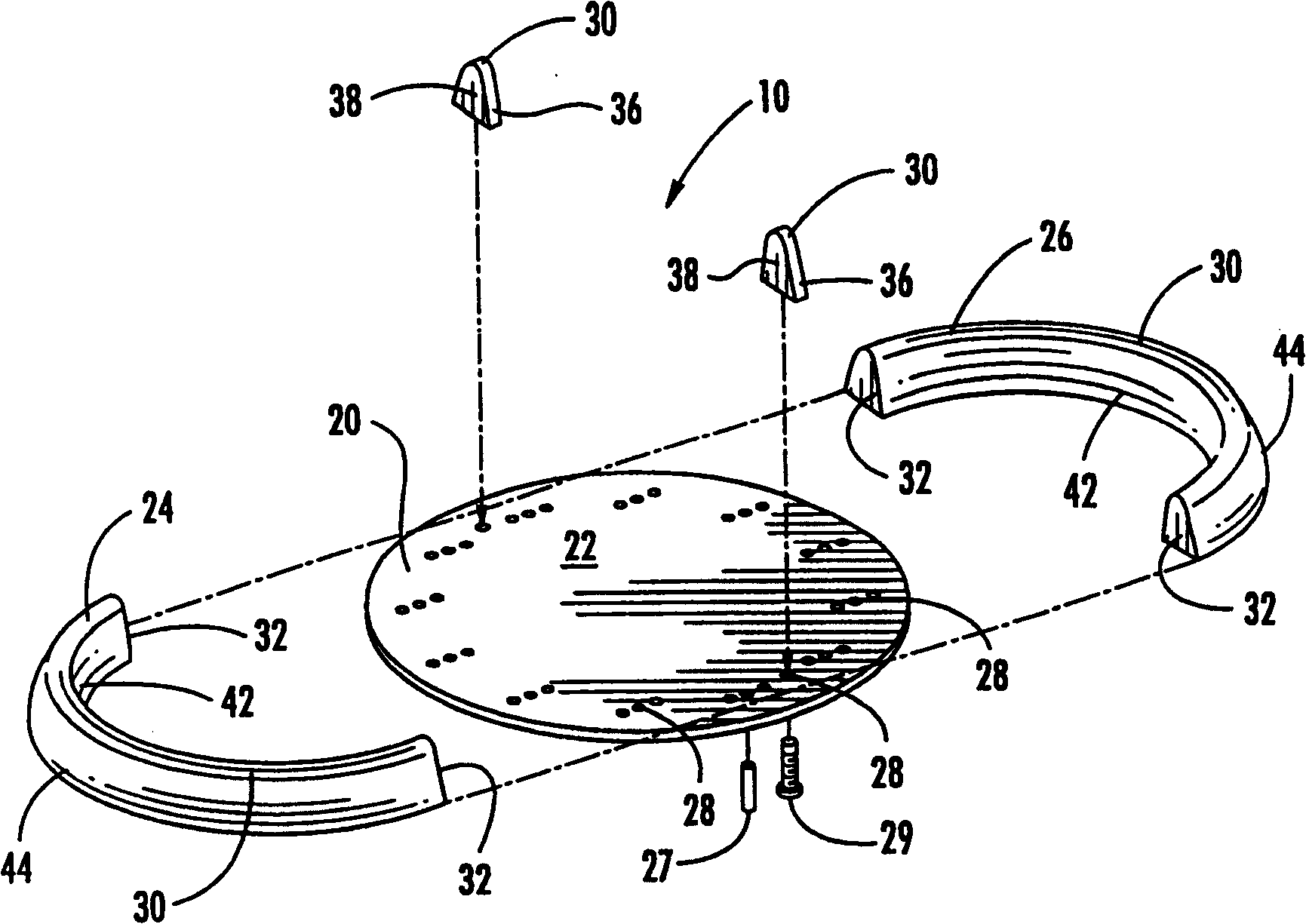

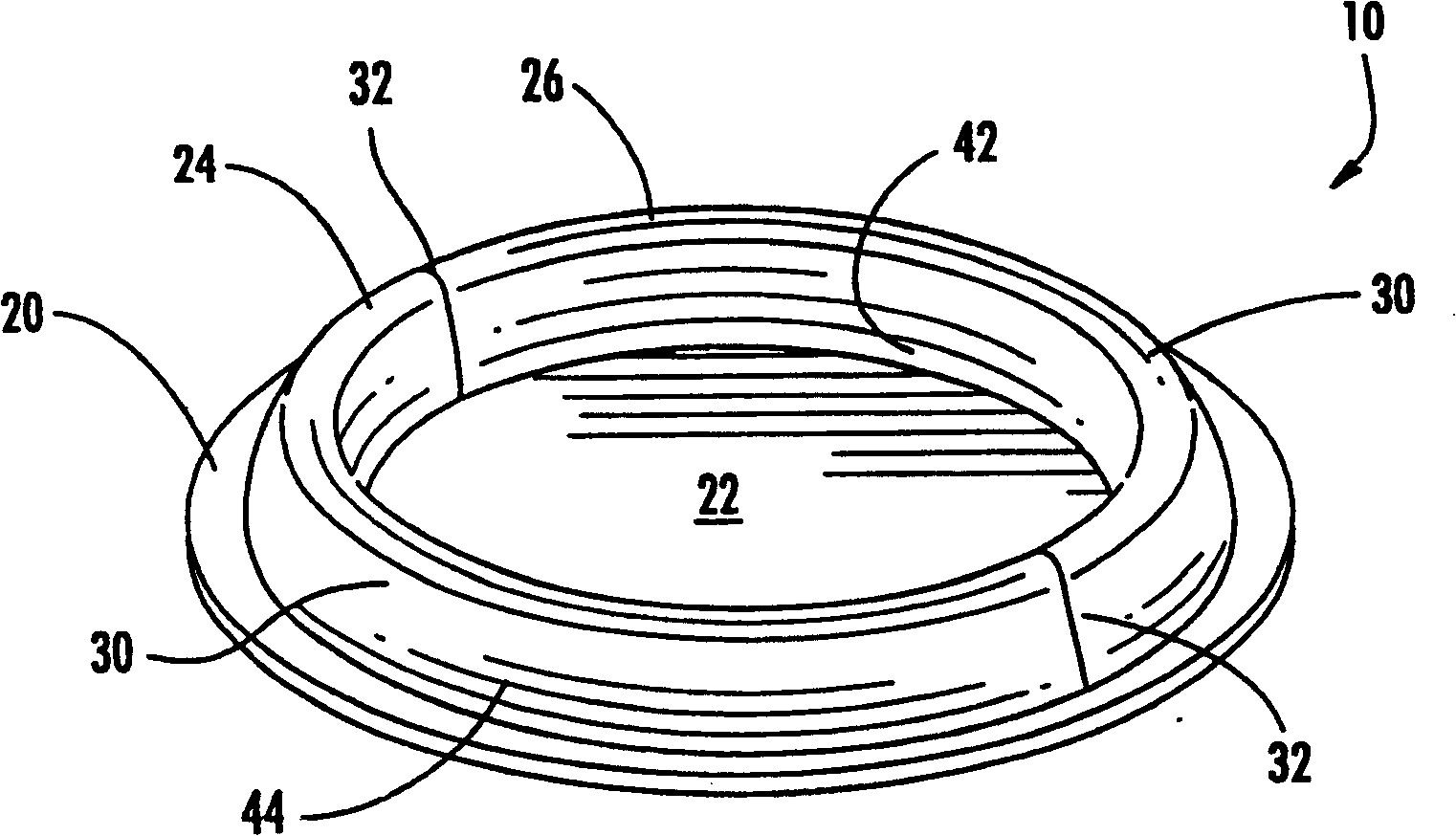

[0051] Figure 1-4 A mandrel 10 according to one embodiment of the invention is shown. Such as Figure 5 As shown, the mandrel 10 of the illustrated embodiment is used for rotational forming of an aircraft engine inlet lip skip 12 . The aircraft engine inlet lip cladding 12 is mounted on the leading edge of a jet engine 14 (eg, an aircraft engine) to direct air into or surround the jet engine 16 during normal operation. Aircraft engine inlet lip cladding 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com