Air purifier

An air purifier and vibration generator technology, applied in the field of air purification, can solve the problems of affecting the filtration effect, frequent replacement of the filter element, short filter life, etc., and achieve the effect of reducing human intervention and improving the collection and storage effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

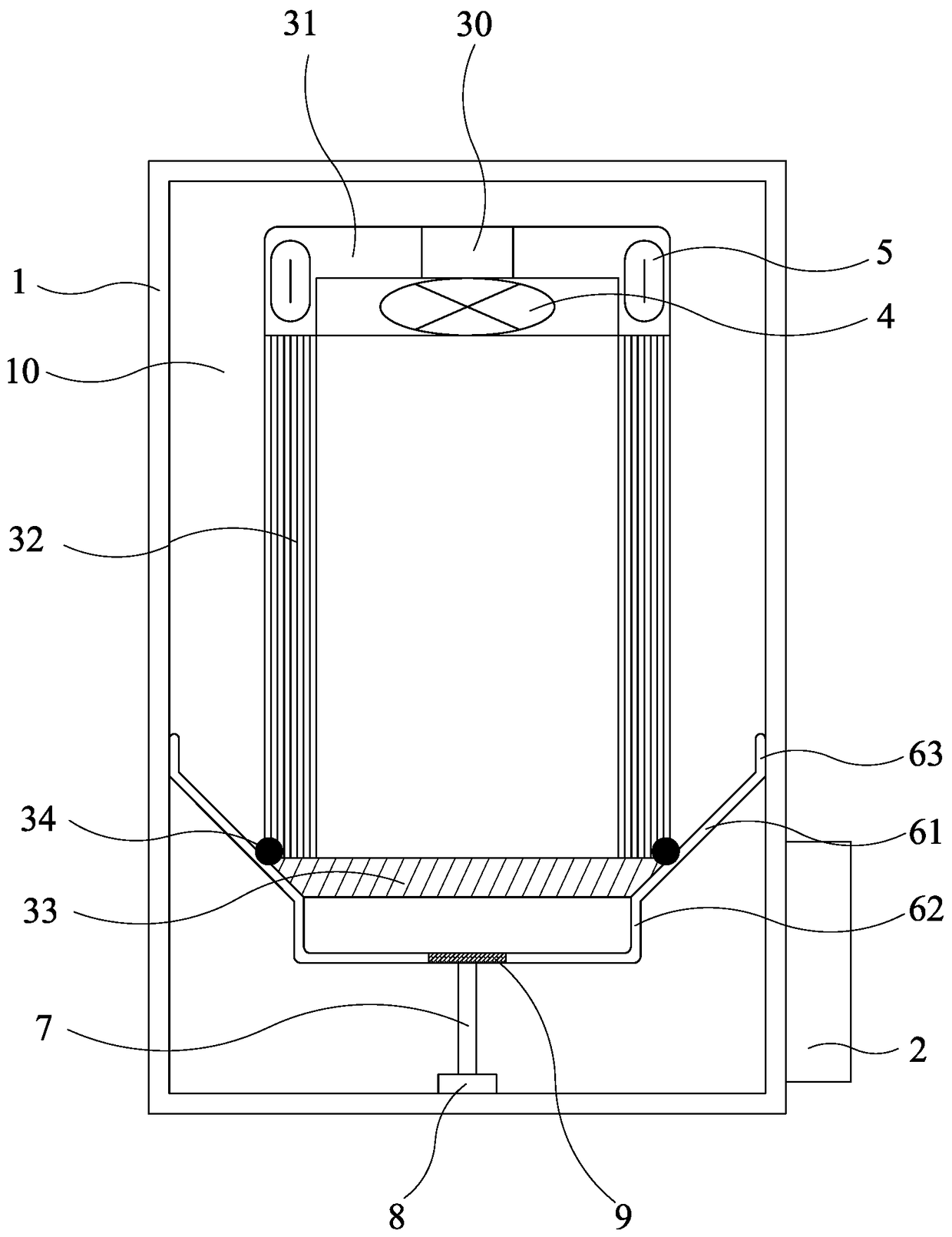

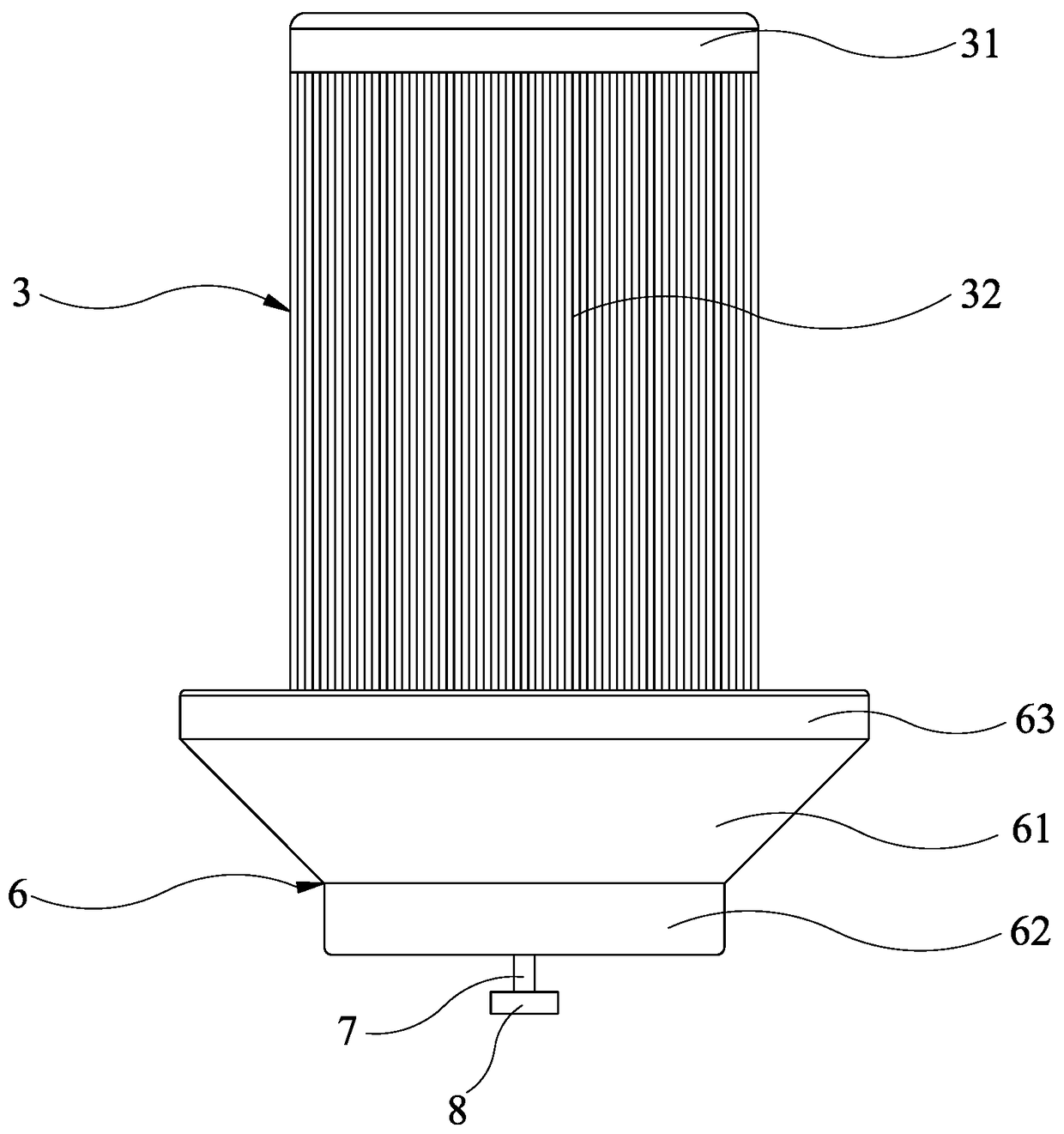

[0026] Such as figure 1 and figure 2 As shown, an air cleaner includes a casing 1, a filter assembly, an ash collection assembly and a control panel 2, wherein the filter assembly and the ash collection assembly are installed inside the casing 1, and the control panel 2 is installed on the casing 1.

[0027] The casing 1 is hollowed out so that air can enter and exit the casing 1, and an accommodating space 10 for installing the filter assembly and the ash collection assembly is provided inside.

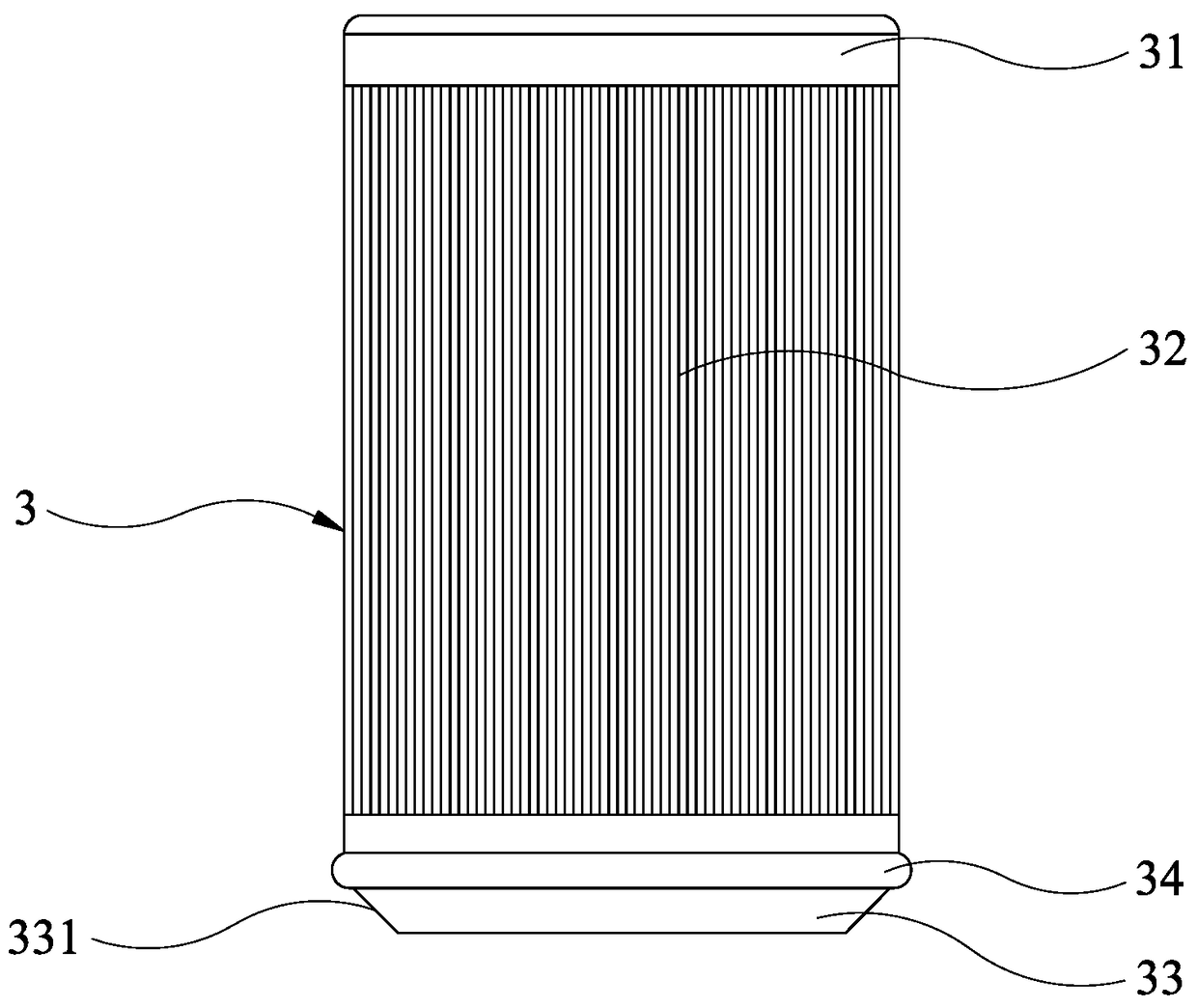

[0028] The filter assembly includes a filter cartridge 3 , a vortex fan 4 and a vibration generator 5 . The upper end of the filter cartridge 3 is provided with an air outlet 30, the diameter of the filter cartridge 3 ranges from 130-400mm, and the height ranges from 200-550mm. The vortex fan 4 is installed on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com