Concrete vertical conveying descent control device

A technology of descending device and concrete, which is applied in the direction of construction, building structure, and building material processing, etc. It can solve the problems of affecting construction progress and construction quality, rapid wear, and increasing manufacturing and maintenance costs, so as to ensure construction accuracy and construction quality, long service life and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

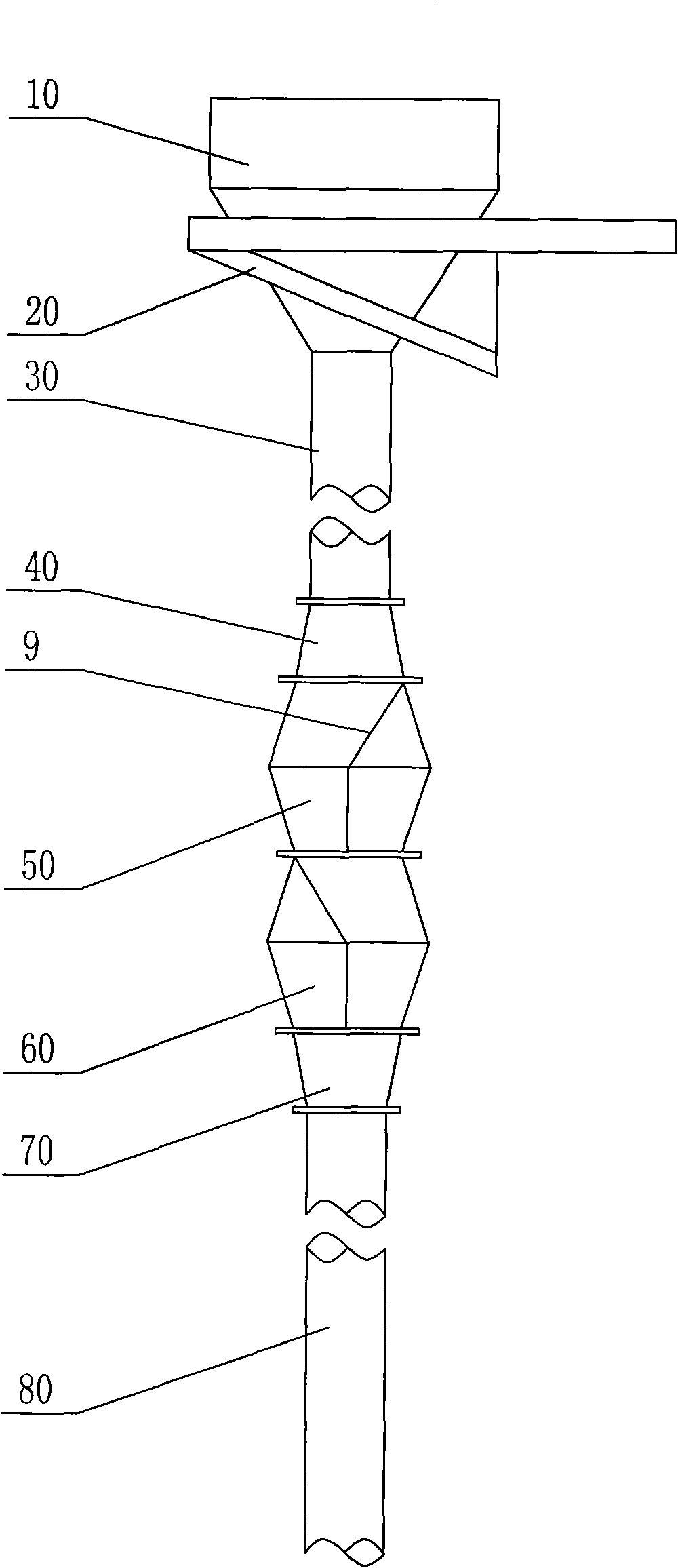

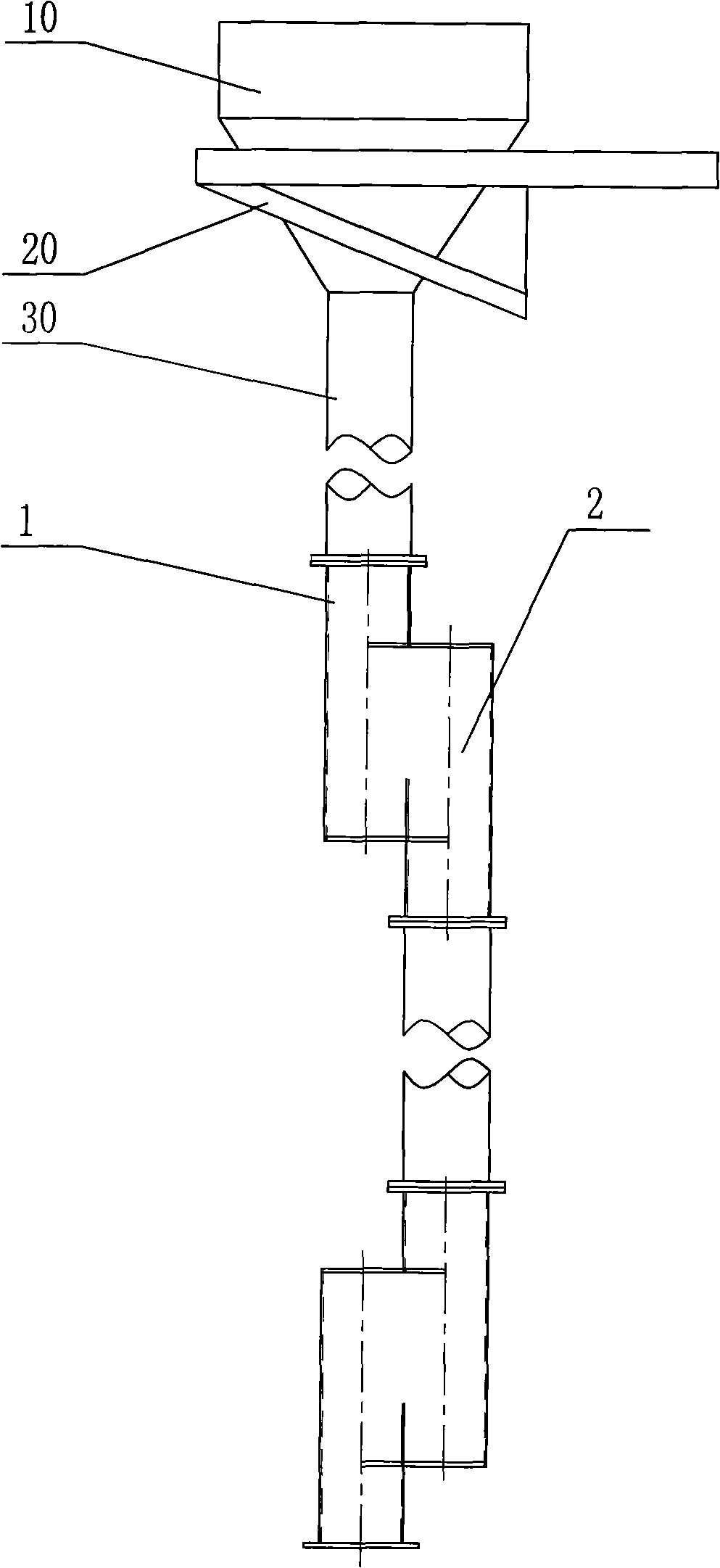

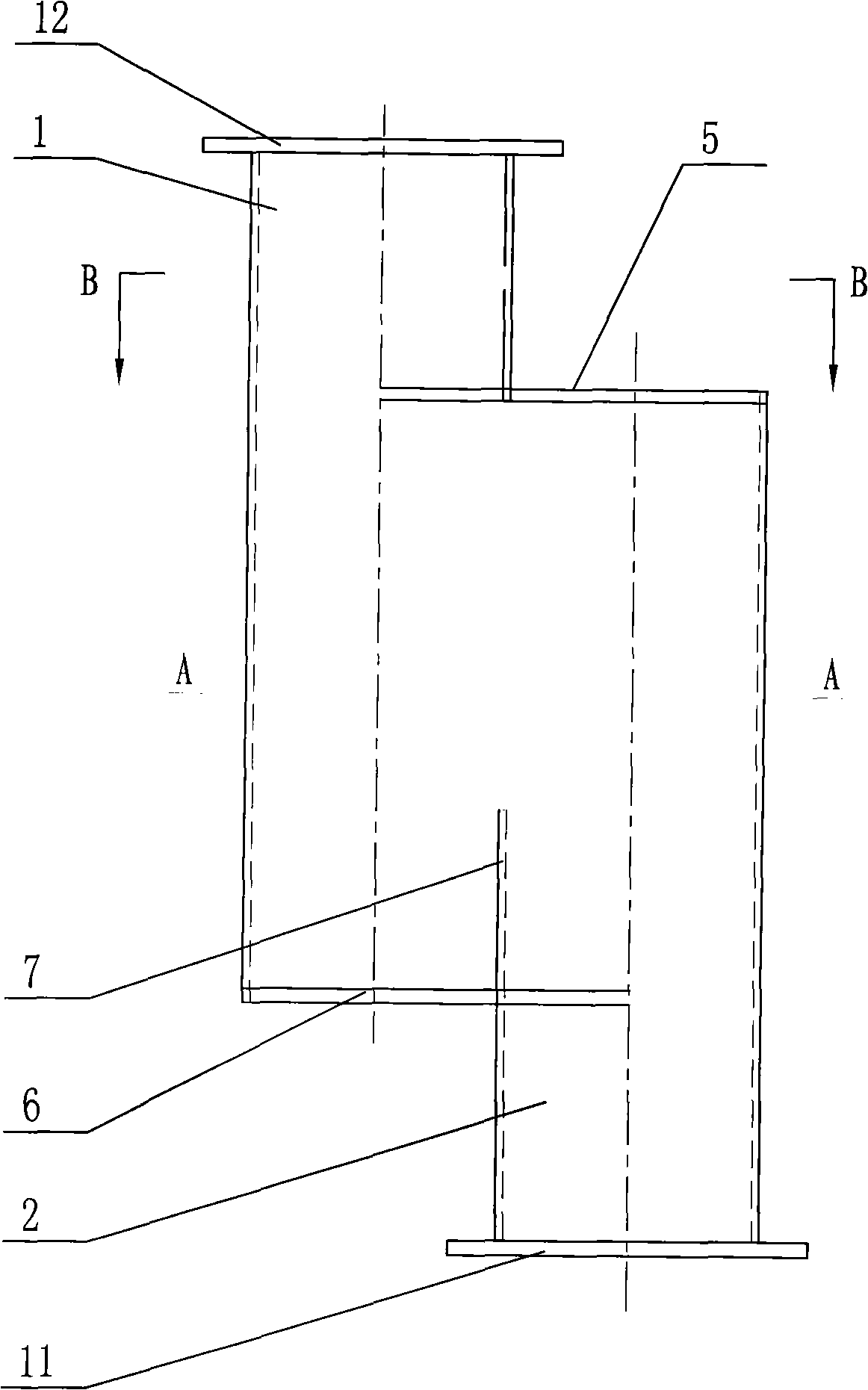

[0026] Such as Figure 3 ~ Figure 6 As shown, a concrete vertical conveying slow down device of the present invention includes a left round pipe 1 and a right round pipe 2, the centerlines of the left round pipe 1 and the right round pipe 2 are parallel, and the two are at a height of The direction is dislocated; the left round tube 1 and the right round tube 2 are provided with a certain length of arc-shaped incision; An arc-shaped incision with a certain distance from the end surface and an inverted L-shaped section; the incision on the right circular tube is an arc-shaped incision located on the left side of the center line, a certain distance from the upper end surface of the right circular tube, and an L-shaped cross-section incision. The cutout on the left round pipe 1 corresponds to the cutout on the right round pipe 2 in the length direction, and the two correspond on the front and rear sides, and the front connecting plate 3 and the rear connecting plate 4 made of re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com