Preparation method for epoxy resin binding agent diamond grinding tool with high polishing performance

An epoxy resin and diamond technology, applied in the direction of grinding/polishing equipment, metal processing equipment, abrasives, etc., can solve the problems of reducing the viscosity of the system and dissatisfaction with the casting of abrasive tools, so as to reduce the viscosity of the system, low epoxy resin content, The effect of increasing the curing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

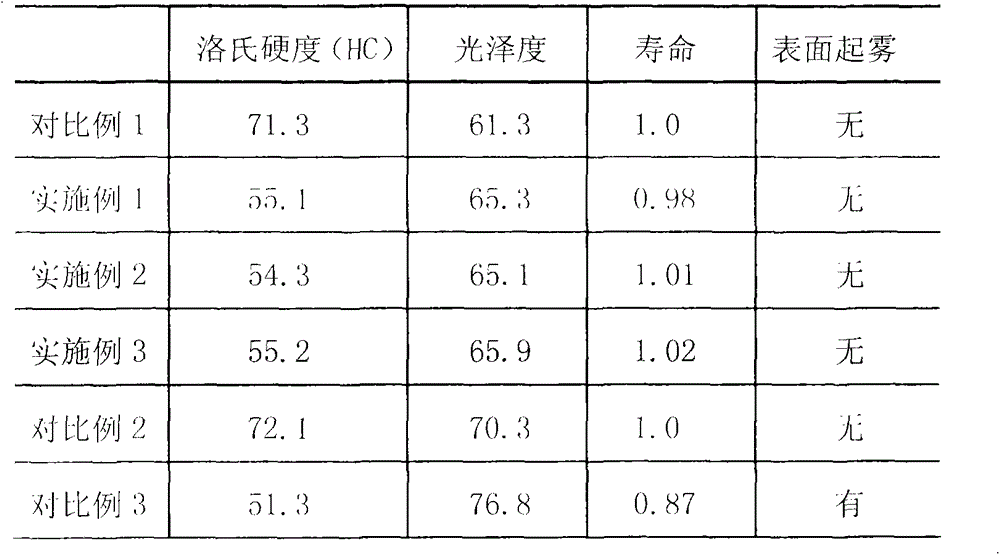

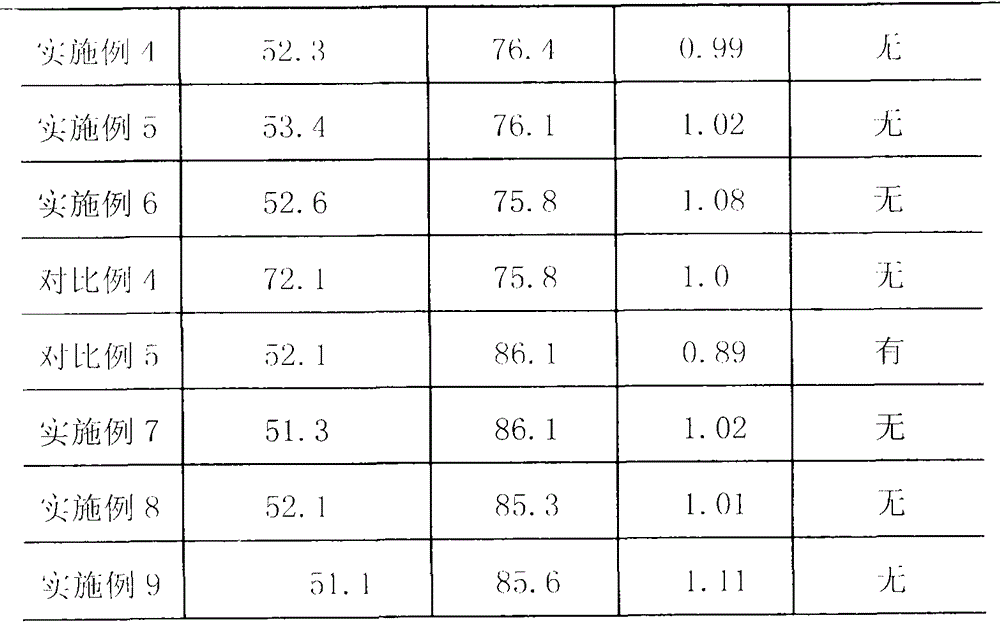

Examples

Embodiment 1

[0033] According to mass percentage, 13 parts of diamond micropowder with a particle size of 1000 mesh, 15 parts of rare earth polishing powder with a particle size of 1500 mesh, 5 parts of silicon carbide micropowder with a particle size of 1000 mesh, 2 parts of corundum with a particle size of 800 mesh, and hollow with a particle size of 1000 mesh 23.5 parts of glass microspheres, after the above powder is mechanically stirred, add 30 parts of epoxy resin (E~44, epoxy value 0.44), 6.5 parts of phenalkamine (PPA, commodity code T~31), 3-aminopropyl After stirring 5 parts of triethoxysilane into a uniform fluid, pour it into the plastic mold by pouring, and cover the top surface of the incompletely cured abrasive with a cotton cloth with the same size as the mold. After 12 hours of static curing, the mold was demoulded, and the abrasive tool was put into an oven at 90° C. for 6 hours, and the epoxy resin bonded diamond abrasive tool with high polishing performance of Example 1 ...

Embodiment 2

[0035] According to mass percentage, 5 parts of diamond micropowder with particle size number of 1000 mesh, 25 parts of rare earth polishing powder with particle size number of 5000 mesh, 10 parts of silicon carbide micropowder with particle size number of 1000 mesh, 15 parts of aluminum hydroxide with particle size number of 1000 mesh, and particle size number of 400 mesh 12 parts of glass fiber, after mechanical stirring, add 14 parts of epoxy resin (E~51, epoxy value 0.51), 3,4-epoxidized 6-methylcyclohexanecarboxylic acid epoxy resin (6201#) 8 parts, 9 parts of polyoxypropylene-based diamine, 2 parts of butanediol, after being stirred into a uniform fluid, inject it into the plastic mold by pouring, and cover the top surface of the incompletely cured abrasive tool with a cotton cloth of the same size as the mold , at a temperature of 85°C and a pressure of not less than 1500Pa for 20 hours of static curing and demoulding, and after the abrasive tool was put into a 90°C oven...

Embodiment 3

[0037] According to mass percentage, the particle size number is 13 parts of 1000 mesh diamond micropowder, the particle size number is 10 parts of rare earth polishing powder of 5000 mesh, the particle size number is 6 parts of silicon carbide micropowder of 1000 mesh, and the particle size number is 31 parts of talc powder of 1000 mesh. After mechanical stirring, Add 24 parts of epoxy resin (E~44, epoxy value 0.44), 5 parts of 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexyl carboxylate, 9 parts of polyoxypropylene diamine After mixing 2 parts of butanediol into a uniform fluid, pour it into the plastic mold by pouring, cover the top surface of the incompletely cured abrasive with a cotton cloth that is the same size as the mold, and place it at a temperature of 90°C and a pressure of not less than 1500Pa After standing and curing for 20 hours, the mold was demolded, and the abrasive tool was put into an oven at 90° C. for 7 hours and cured for 7 hours, and the epoxy resin bonde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com