Intelligent tunnel lining trolley

A lining trolley, intelligent technology, applied in the direction of tunnel lining, tunnel, shaft lining, etc., can solve the problems of low efficiency, waste of clean water and release agent, increase of labor costs, etc., and achieve the effect of stable placement and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

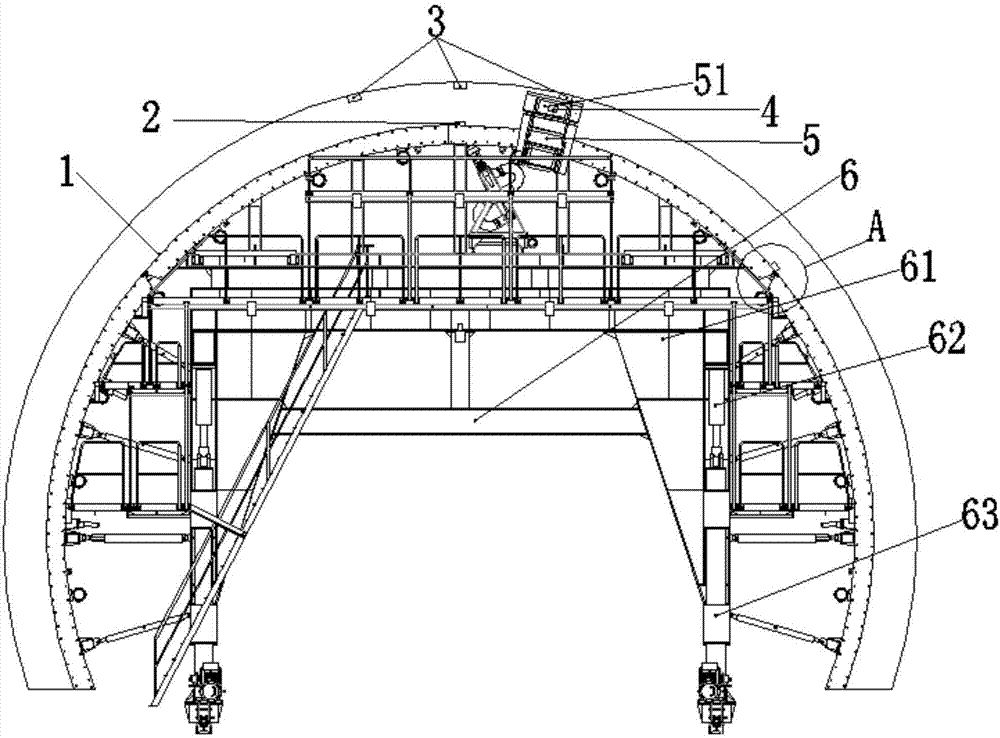

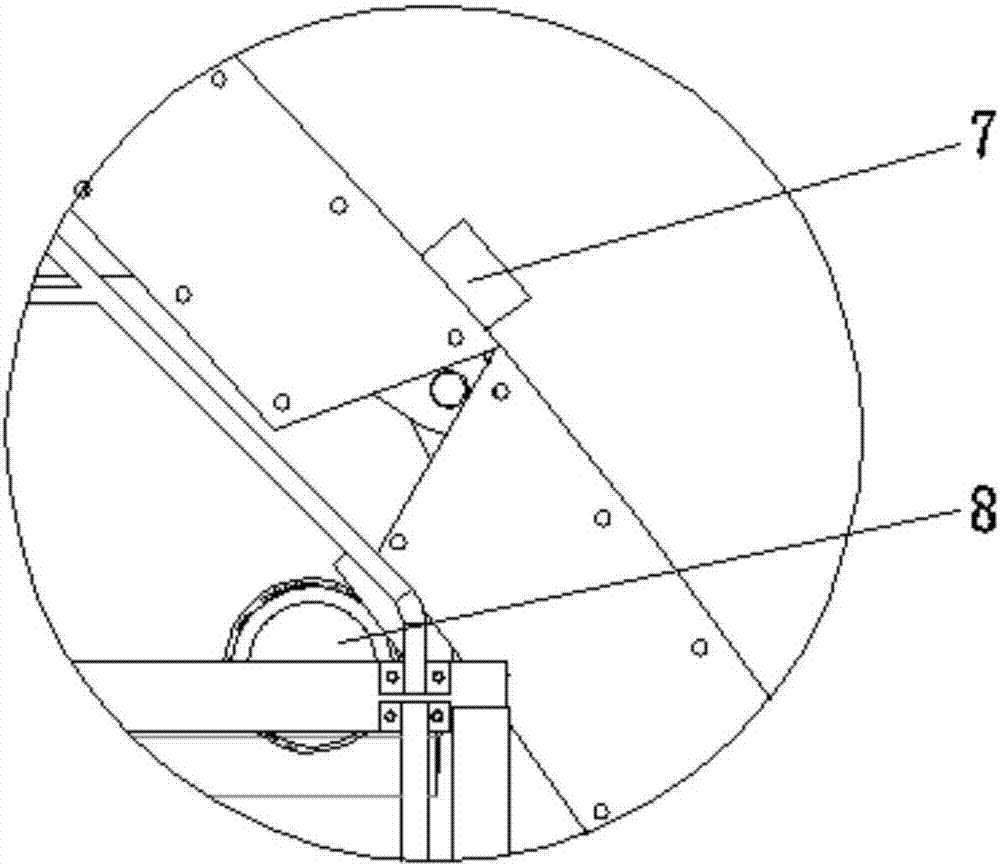

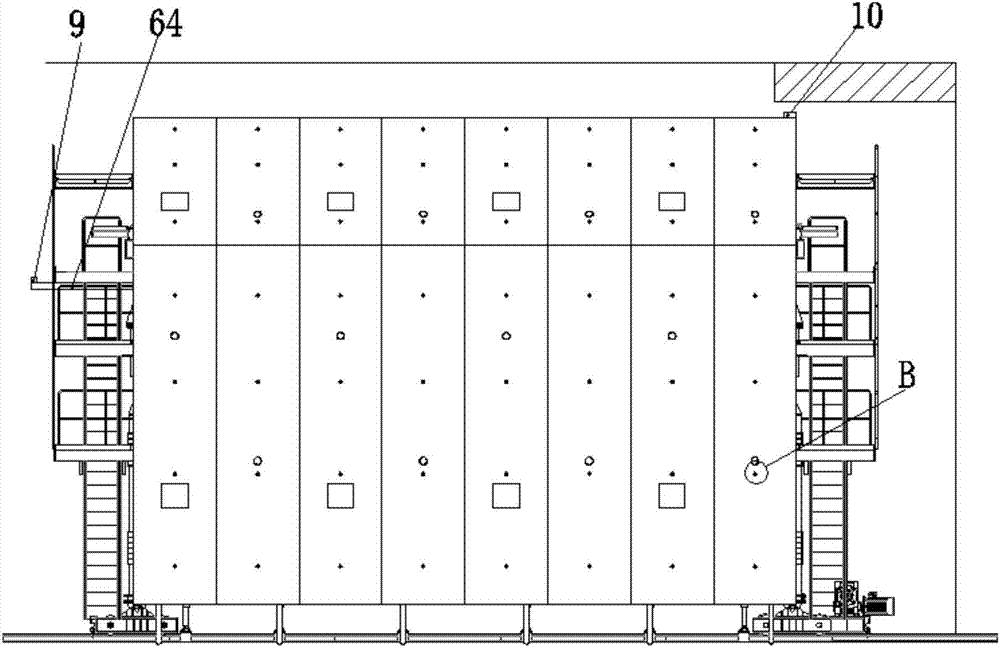

[0102] see Figure 1 to Figure 27 , an intelligent tunnel lining trolley according to an embodiment of the present invention, comprising a gate-shaped main steel frame 6, a concrete pouring information monitoring system, a terminal formwork 5, a formwork cleaning and surface lubrication system, an automatic walking device and a layered window-by-window Pouring and cleaning system.

[0103] The door-shaped main steel frame 6 in this embodiment includes a connection base 63, a plurality of lifting devices 62 and a plurality of main steel frame bodies 61, and the connection base 63 includes two main beams 632 and a plurality of support columns 631, The two main beams 632 are slidably connected to a plurality of support columns 631, the main steel frame body 61 is detachably connected to the main beams 632, and the lifting device 62 is connected to the support columns 631 Above, the main steel frame body 61 is connected to the lifting device 62 .

[0104] The lifting device 62 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com