Column core concrete lift-up connecting device of steel pipe column

A technology of concrete roof and connecting device, applied in the direction of columns, piers, pillars, etc., can solve the problems of non-removal of the plug-in device, affecting the jacking pressure, easy to overflow, etc., to avoid concrete overflow, good pouring effect, and airtight effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

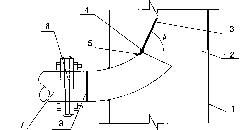

[0015] The basic structure of the steel pipe column core concrete jacking connection device in this embodiment is as follows: figure 1 As shown, the elbow 2 has a horizontal port and an upturned port, which extends into it from the lower part of the steel pipe column 1 at about 300 mm to 500 mm, and is sealed and welded. The higher side of the upturned port is equipped with a one-way valve cover 3 through the hinge 4, the angle between the section of the upturned port and the horizontal plane is 25° (between 20-30°), and the hinge 4 has a turning limit gear 5 , so that the maximum opening angle of the one-way valve cover is 90°, that is, the angle A with the horizontal plane is 65° (60-70° is acceptable), so that there is a certain inclination angle when pouring concrete, which is convenient for opening the one-way valve The smooth output of the cover 3 ensures sufficient jacking pressure, avoids the opening obstruction when the port is fully upward, and guarantees a reliable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com