Annular slit restrictor

A technology for annular gaps and restrictors, which is applied to bearings, bearing components, shafts and bearings, etc., can solve the problems of restrictors with complex structures, large space requirements, and easy blockage, and achieve compact structure, simple adjustment, and not easy to block Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

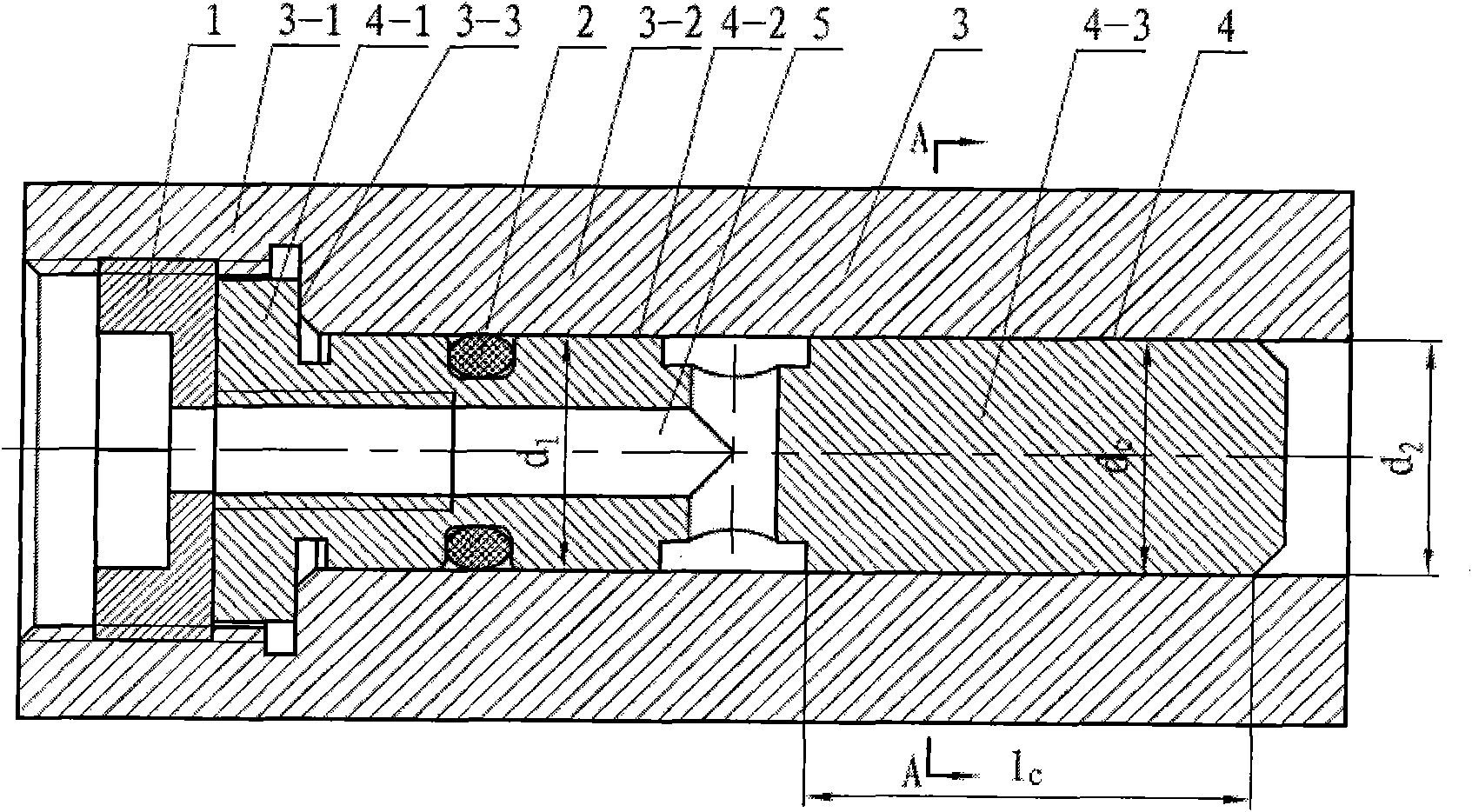

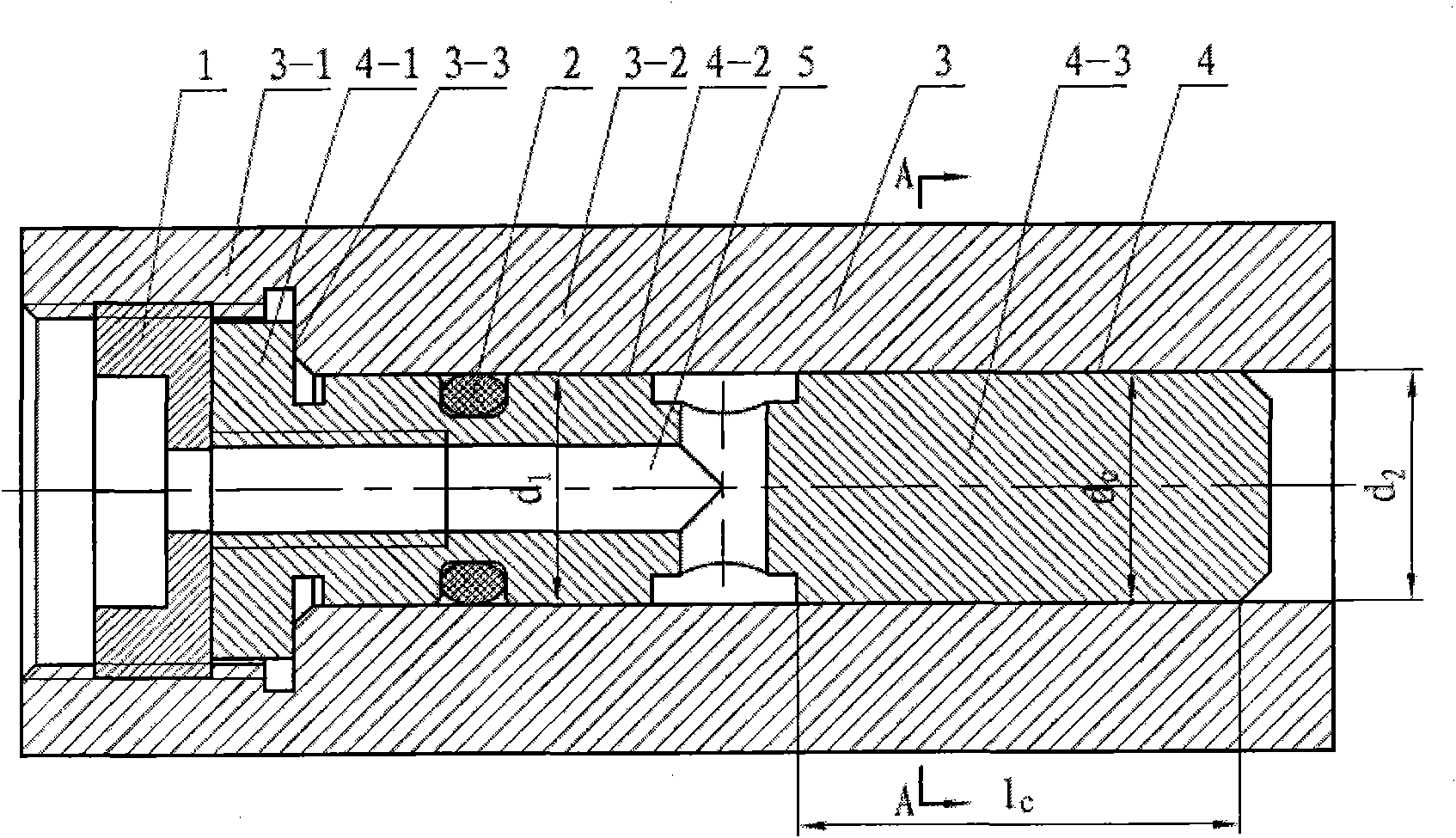

[0014] The structure and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

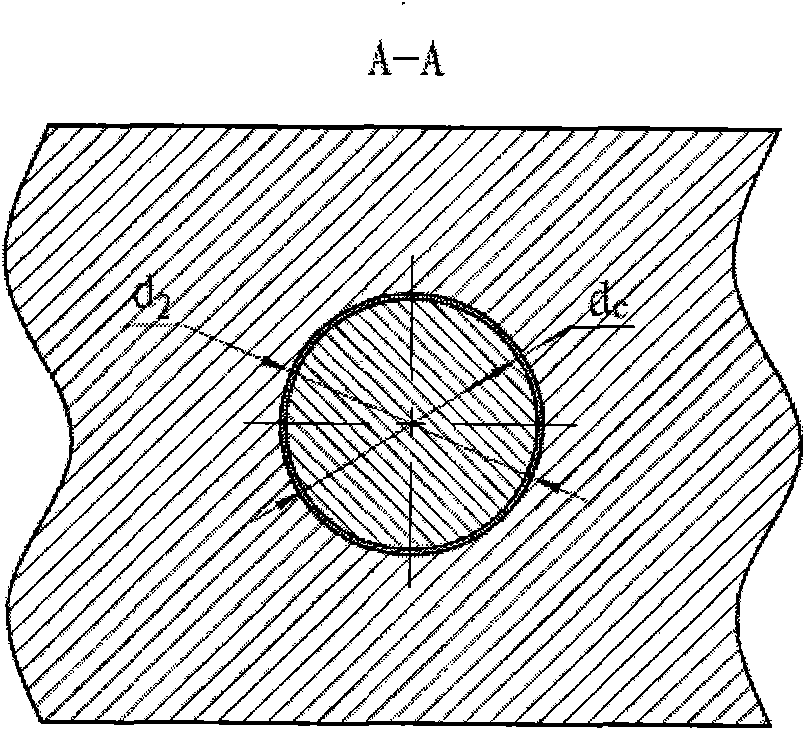

[0015] see figure 1 , the present invention includes a throttle installation body 3 and a throttle body 4 arranged in the throttle installation body 3, the throttle installation body 3 is composed of a stepped front cavity 3-1, a rear cavity 3- 2 and the hole shoulder 3-3, the diameter of the front cavity 3-1 is greater than the diameter d of the rear cavity 3-2 2 , the throttle body 4 is composed of a stepped front end 4-1, a middle part 4-2 and a rear end 4-3, the diameter of the front end 4-1 is greater than the diameter d of the middle part 4-2 1 and the diameter d of the rear end 4-3 c , the diameter d of the middle part 4-2 1 greater than the diameter d of the rear end 4-3 c , the front end 4-1 of the restrictor body 4 is axially positioned by the hole shoulder 3-3 of the restrictor mounting body 3, and fixed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com