Multi-row electrostatic spinning spray head

A technology of electrospinning and nozzle, which is applied in the direction of spinneret assemblies, textiles and papermaking, filament/thread forming, etc. It can solve the problems that affect the continuous operation of electrospinning, the difficulty of cleaning capillary, and the blockage of capillary. Difficult to clean, optimized arrangement and structure, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

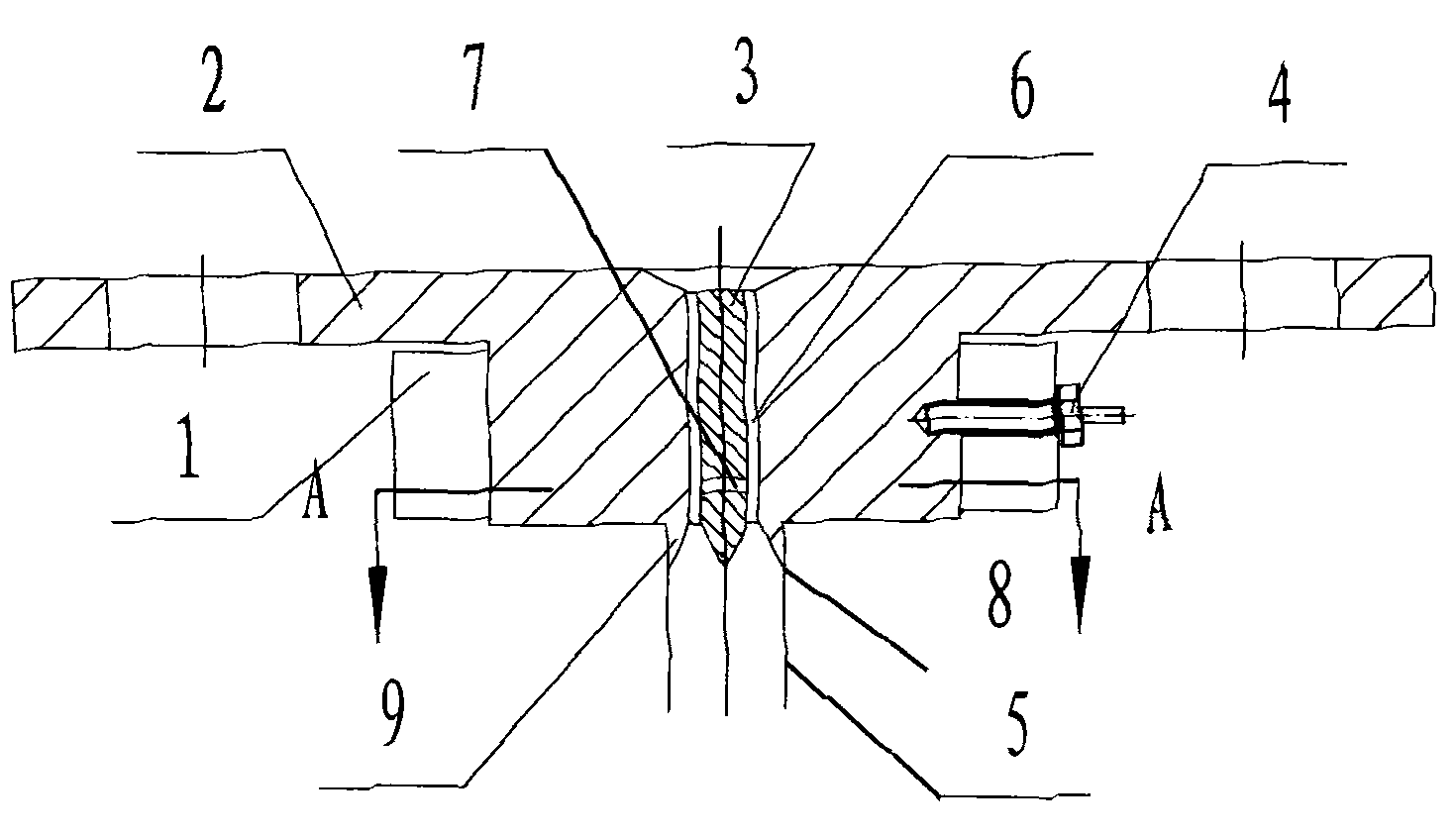

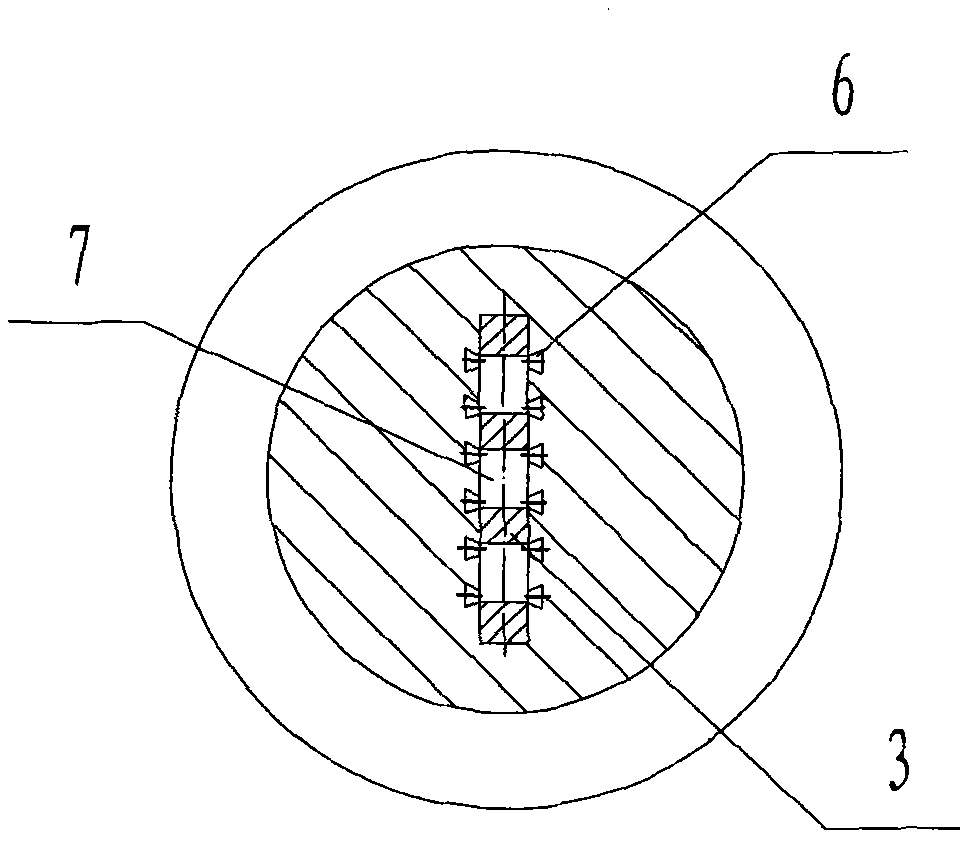

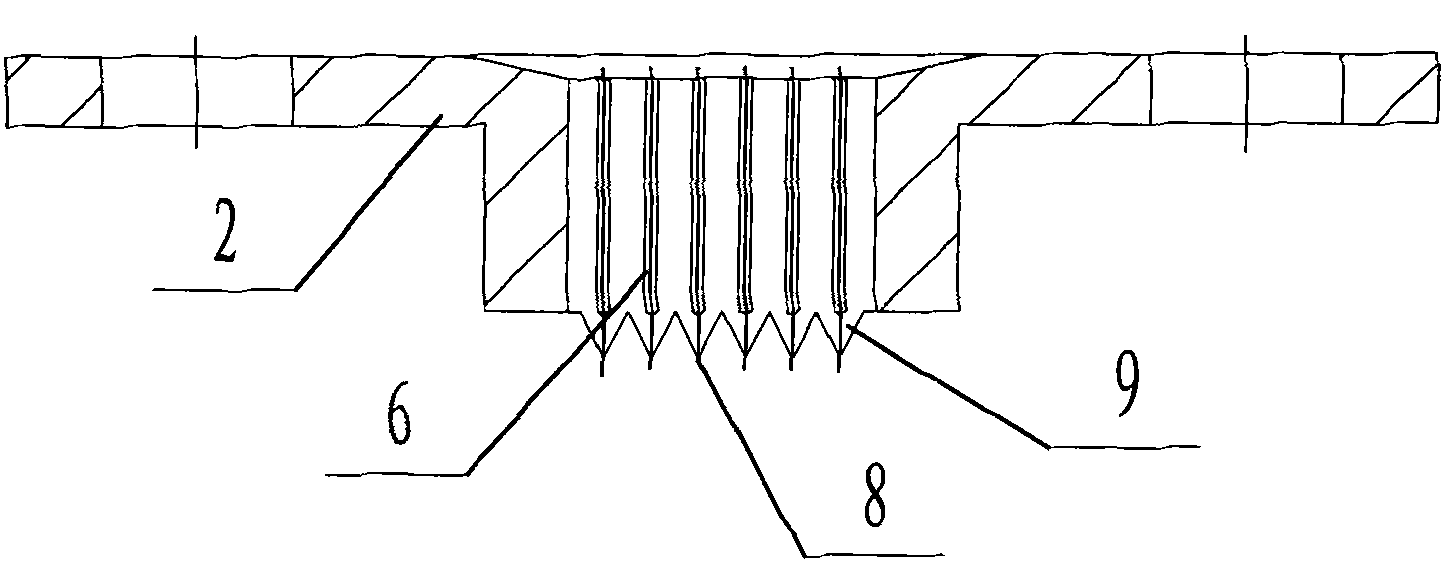

[0020] In the present invention, a multi-row electrospinning nozzle adopts such as figure 1 with figure 2 The schematic diagram of the device shown mainly includes a heating coil 1 for temperature control, a temperature sensor 4, a connecting piece 2, and a guide core 3 for guiding the flow of materials. The connecting piece 2 and the guide core 3 are connected by an interference fit . The connecting piece 2 is provided with a trapezoidal open flow channel 6 and a protrusion 9 for material drainage, and the protrusion 9 is provided with a spinning tip 8 which facilitates the formation of the jet stream 5 . The diversion core 3 is provided with a balance groove 7 for balancing the materials of each open channel 6, and has a protrusion 9 for drainage and a spinning tip 8 for forming a spinneret.

[0021] image 3 with Figure 4 Shown is a schematic diagram of the structure of the connector 2, Figure 5 with Figure 6 Shown is a schematic structural view of the guide core ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com