Umbrella-shaped electrostatic spinning sprayer and electrostatic spinning method

An electrospinning, umbrella-shaped technology, applied in the field of umbrella-shaped electrospinning nozzles and electrospinning, can solve problems such as affecting production efficiency, increasing conveying speed, and being difficult to maintain, achieving continuous and large-scale production, and easy to solve problems. The effect of blocking and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

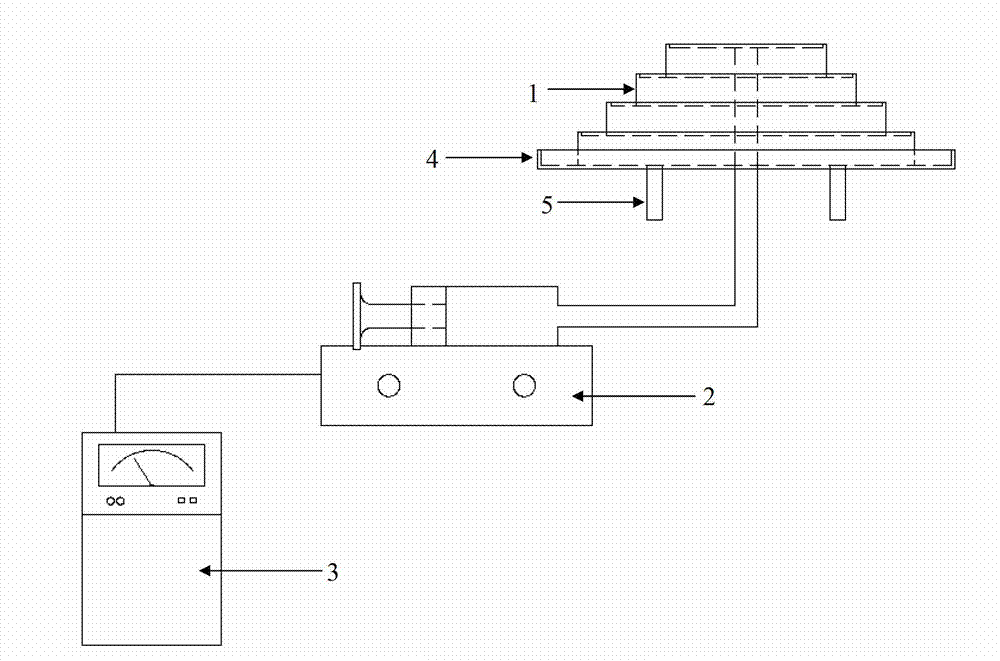

[0029] use figure 1 The new umbrella-shaped electrospinning nozzle shown is used for spinning. The solution is polyvinyl alcohol (PVA) aqueous solution with a mass concentration of 10%. The output end 2 of the solution propeller of the numerically controlled infusion device is placed in the middle of the umbrella-shaped spinneret 1. In the cylindrical hollow 8, the spinning solution will emerge from the top layer of the umbrella-shaped spinneret 1, forming a spinning solution layer with a uniform thickness and a certain curvature in all directions of each layer of copper plate. The distance between the receiving base fabric and the upper end of the umbrella-shaped spinneret 1 is kept at 20cm, the controller 3 is turned on, the voltage of the high-voltage generator is adjusted to 50kV, the base fabric moves at a speed of 0.01m / min, and the trolley carrying the spinneret does reciprocating motion. The diameters of the manufactured nanofibers are mostly distributed between 200~...

Embodiment 2

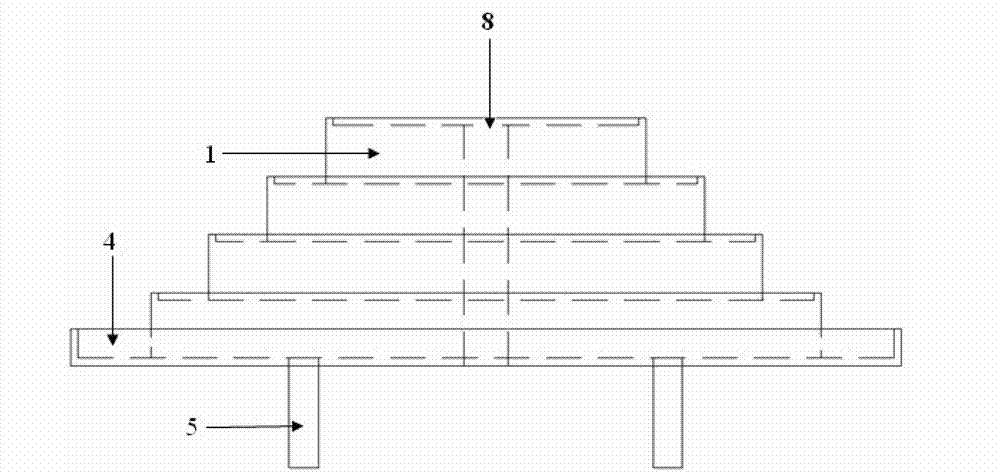

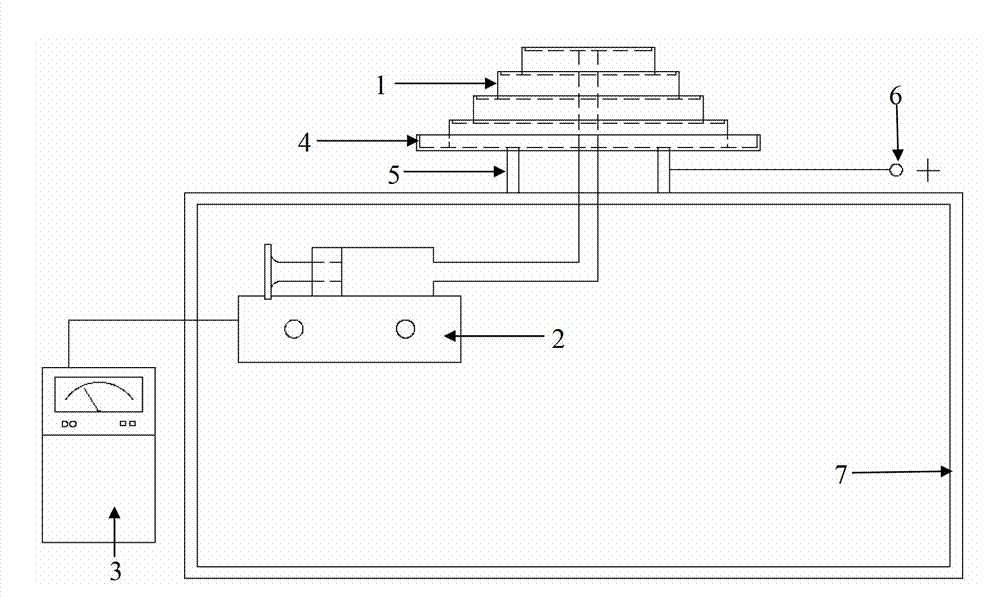

[0031] An umbrella-shaped electrospinning nozzle, including an umbrella-shaped spinneret 1, a numerically controlled infusion device and a solution collection tank 4, characterized in that the numerically controlled infusion device mainly includes a solution propeller 2 and a controller 3 There is a cylindrical hollow place 8 in the middle part of the umbrella spinneret 1, and the output end of the solution propeller 2 is inserted into the cylindrical hollow place 8 of the umbrella spinneret 1; the control Device 3 controls the flow rate and the flow rate of spinning solution, and continuously injects spinning solution into the top layer of the umbrella-shaped spinneret 1; the bottom of the umbrella-shaped spinneret 1 is placed with the solution collection tank 4; The spinneret 1 is provided with a terminal 6 connected with the high voltage positive electrode 5 . The axis of the described cylindrical hollow place 8 coincides with the central axis of the described umbrella spin...

Embodiment 3

[0033] An umbrella-shaped electrospinning nozzle, including an umbrella-shaped spinneret 1, a numerically controlled infusion device and a solution collection tank 4, characterized in that the numerically controlled infusion device mainly includes a solution propeller 2 and a controller 3 There is a cylindrical hollow place 8 in the middle part of the umbrella spinneret 1, and the output end of the solution propeller 2 is inserted into the cylindrical hollow place 8 of the umbrella spinneret 1; the control Device 3 controls the flow rate and the flow rate of spinning solution, and continuously injects spinning solution into the top layer of the umbrella-shaped spinneret 1; the bottom of the umbrella-shaped spinneret 1 is placed with the solution collection tank 4; The spinneret 1 is provided with a terminal 6 connected with the high voltage positive electrode 5 . The axis of the cylindrical hollow 8 coincides with the central axis of the umbrella spinneret 1 .

[0034] The el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com