Terminal floating filter of separate rainwater drainage system

A drainage system and filtration device technology, which is applied in the direction of runoff/rainwater treatment, filtration treatment, water/sewage treatment, etc., can solve problems such as troublesome maintenance, harsh hydraulic conditions, and influence on sedimentation effect, so as to ensure the safety of drainage , Easy cleaning and maintenance, and the effect of improving the interception rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

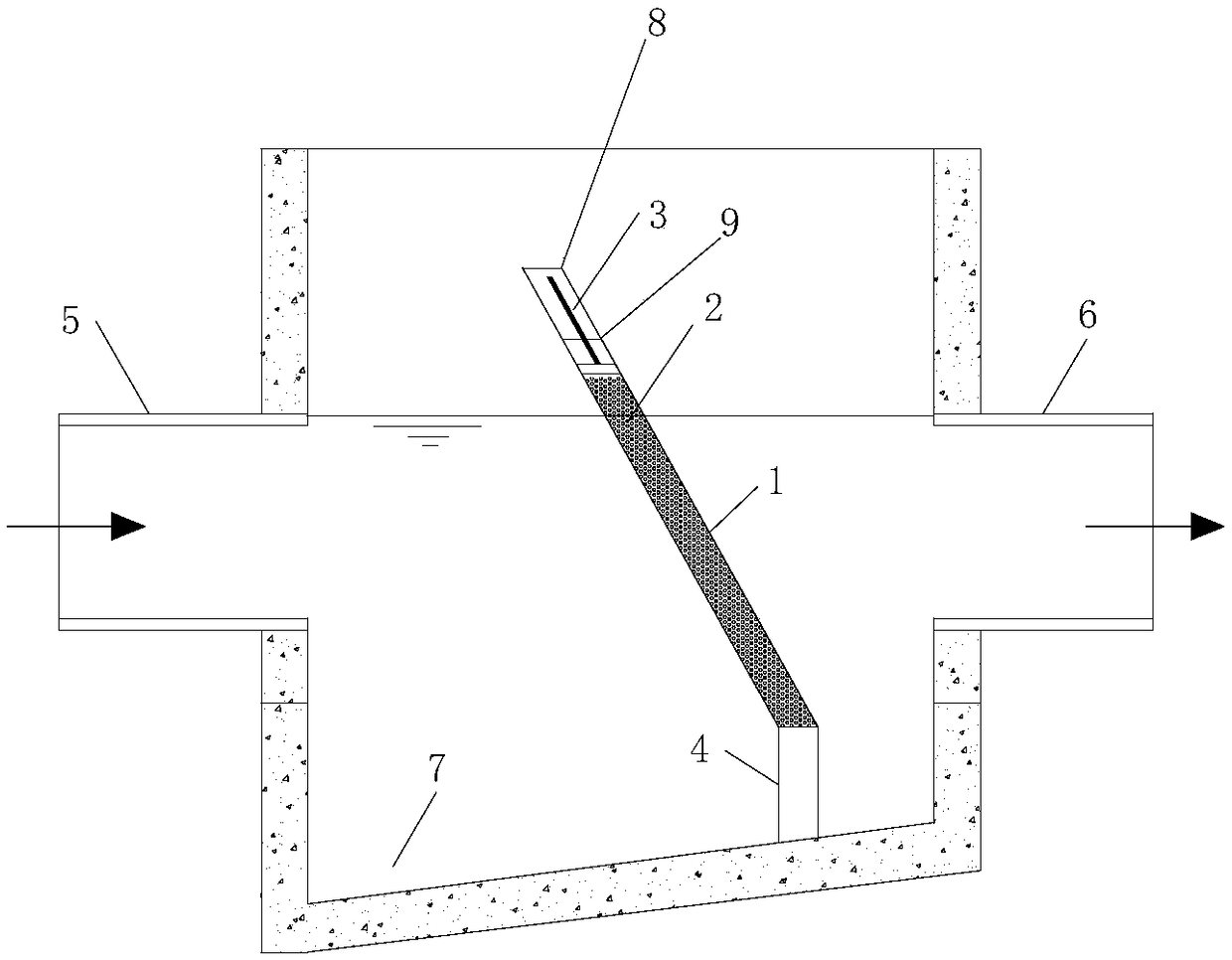

[0043] Such as figure 1 As shown, the floating filter device at the end of the divided rainwater drainage system in this embodiment includes a weir filter layer 8 composed of a stainless steel grid 1 , a suspended particle filter material 2 , and a telescopic pressure rod 3 , and a sedimentation zone 7 .

[0044] The stainless steel grid 1 is used as a container, including a front filter screen plate, a rear filter screen plate and two side plates.

[0045] The weir-type filter layer 8 is installed in the inspection well inclined to the side of the water inlet 5, and the water inlet 5 and the water outlet 6 are separated. The elevation of the weir top of the weir-type filter layer 8 can be adjusted. To ensure the outlet water quality of the device, it should be higher than the top elevation of the inlet pipe.

[0046] The weir-type filter layer 8 is installed on the buttress 4 at the bottom of the suspended shaft. Rainwater flows into the inspection well from the water inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com