Vertical hammer piece breaking mixing apparatus

The technology of a mixing device and a vertical hammer, which is applied in the field of chemical equipment, can solve the problems such as the inability of solid suspended matter to easily block the nozzle holes of a granulation nozzle, and achieve the effect of solving the problem that the holes are easily blocked and the work efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

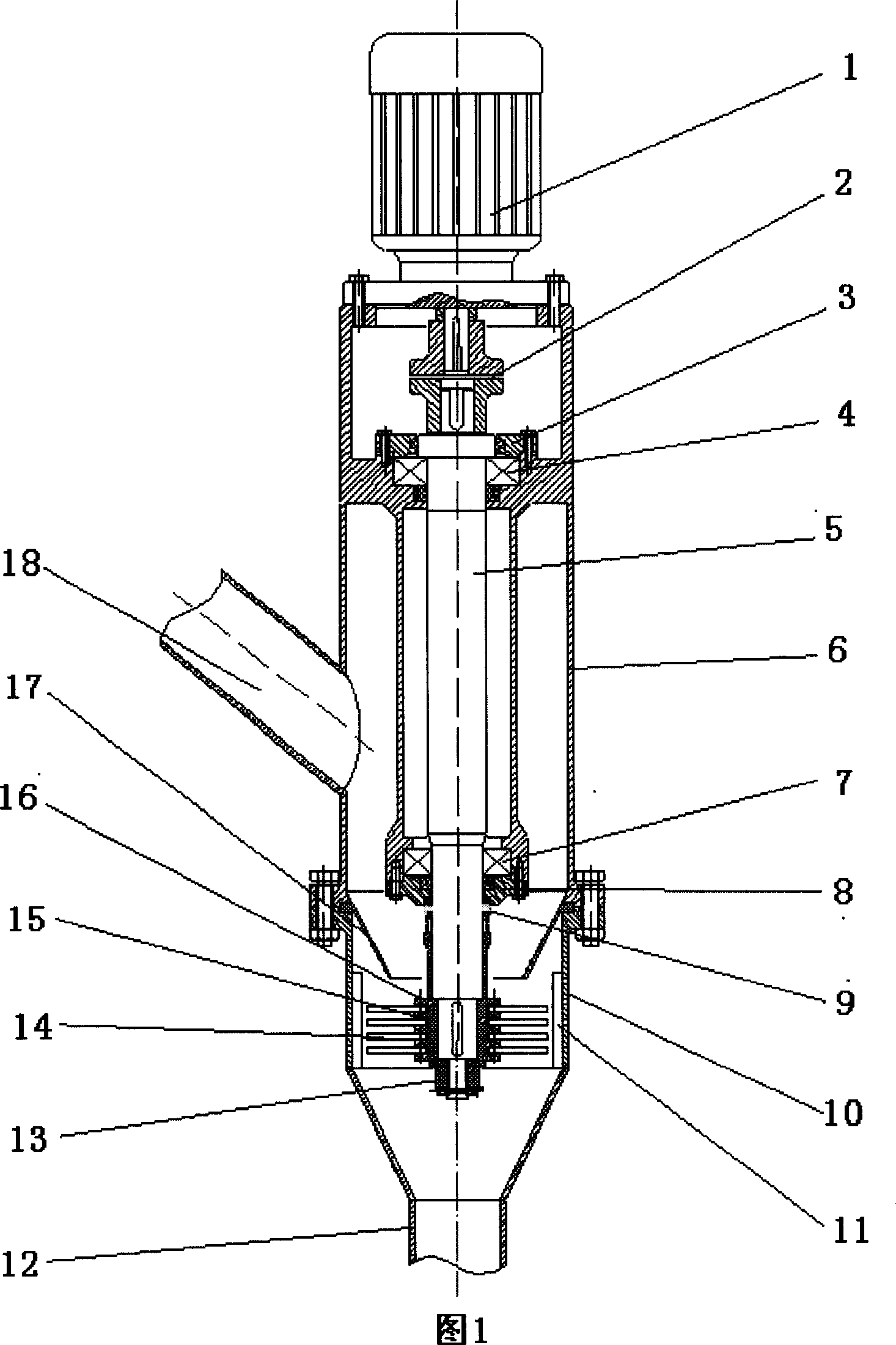

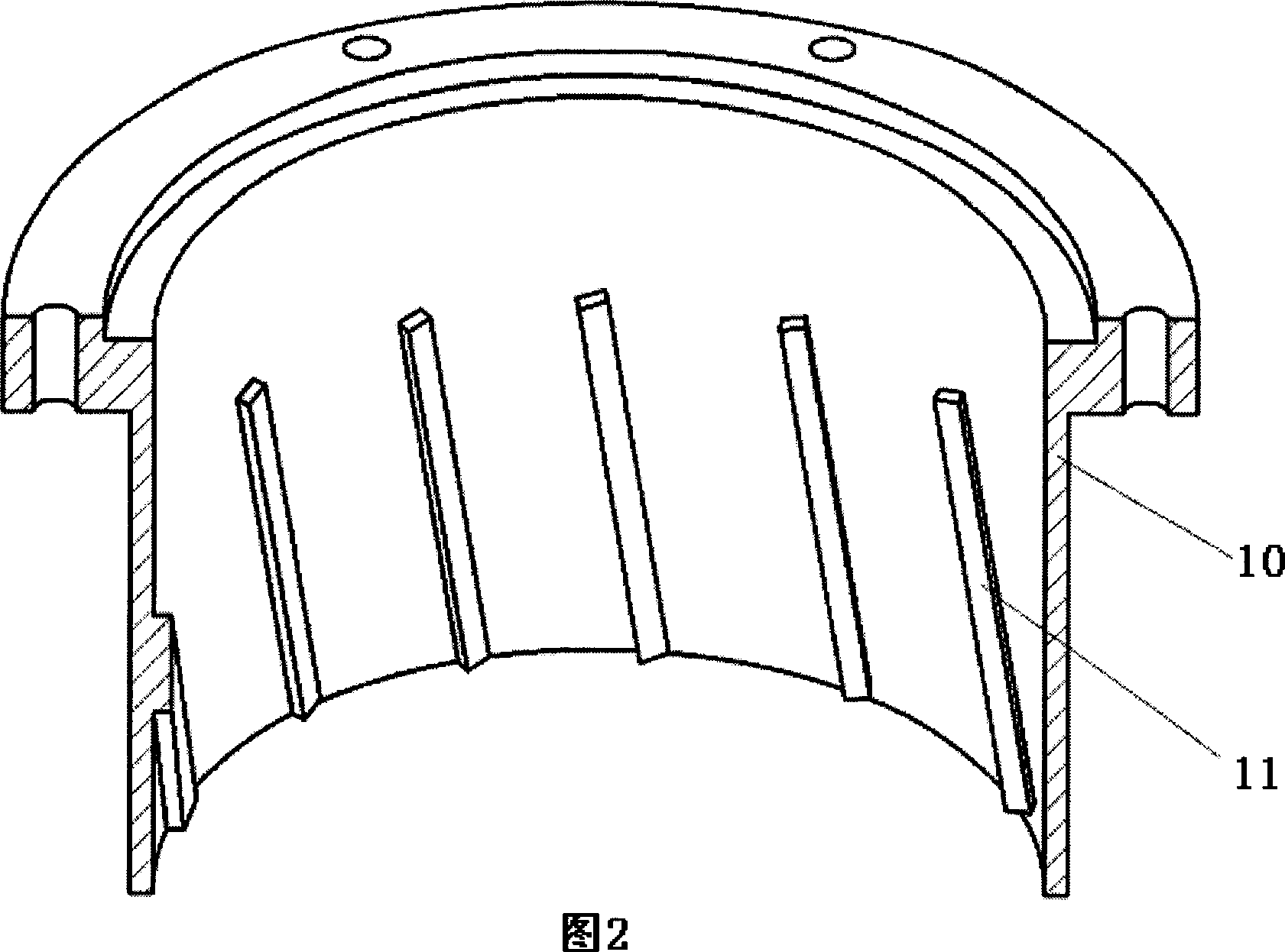

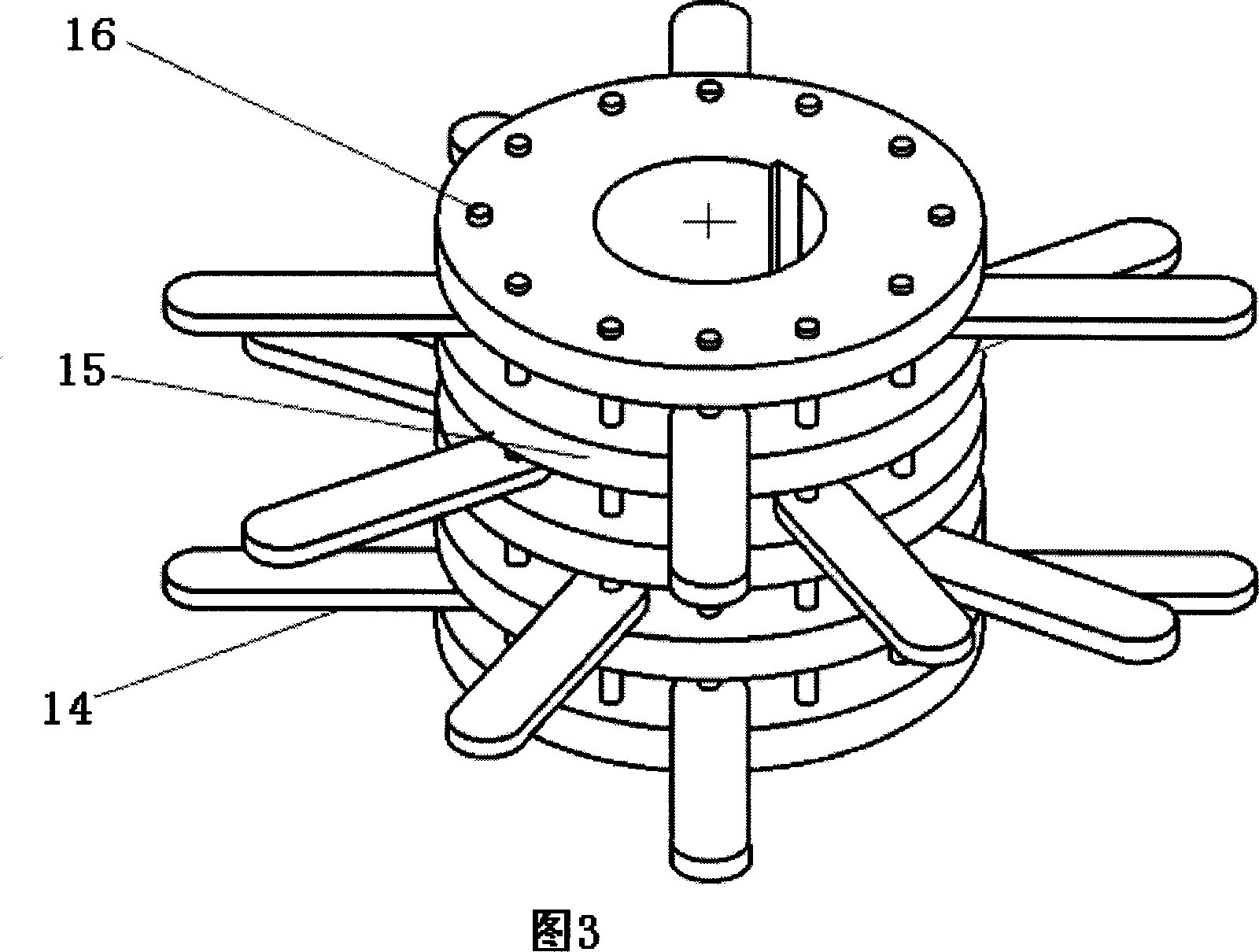

[0019] Fig. 1 is an embodiment of a vertical hammer crushing and mixing device provided by the present invention, which includes a housing 6, on which a feed pipe 18 communicating with the inner cavity of the housing 6 is installed, and the housing 6 is successively connected to the crushing chamber 10 and the discharge pipe 12 are fixedly connected, and a frustum-shaped guide cone bucket 17 with a large upper part and a smaller lower part is set at the junction of the housing 6 and the crushing chamber 10. A main shaft 5 is installed in the housing 6, and the main shaft 5 is connected to the main shaft through the coupling 2. The motor 1 installed on the top of the housing 6 is directly connected to the drive, and the upper and lower ends of the main shaft 5 are respectively provided with an upper bearing gland 3, an upper bearing 4, a lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com