Field emission electron source and preparation method of carbon nanotube graphene composite structure thereof

A graphene composite and field emission technology, applied in the manufacture of discharge tubes/lamps, components of discharge tubes/lamps, nanotechnology, etc., can solve problems such as poor electrical conductivity, low total emission current, and poor emission stability , to achieve the effects of improving emission capability and stability, high emission current density, and efficient and stable emission current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

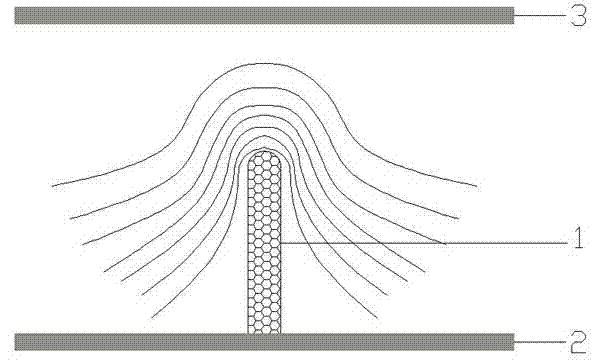

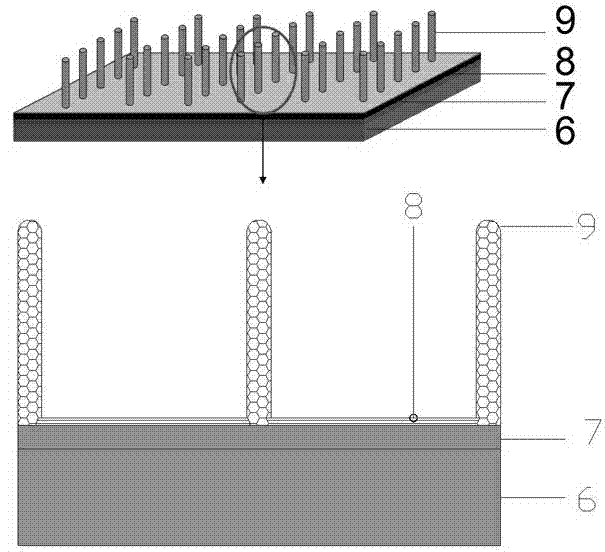

[0042] The present invention will be further described below in conjunction with the drawings and specific implementations.

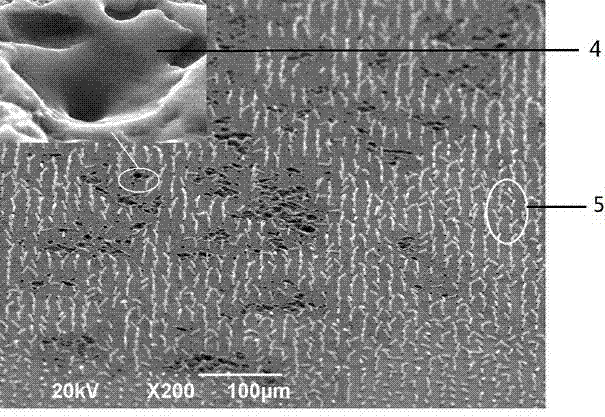

[0043] A field emission electron source with a carbon nanotube graphene composite structure, comprising a conductive substrate, a graphene film layer, and a carbon nanotube array oriented perpendicular to the graphene film layer, the graphene film layer being adhered to the conductive substrate One end of the carbon nanotubes in the carbon nanotube array is connected with the graphene film layer to form an integral structure. The diameter of the carbon nanotube is 1 nm-100 nm. The graphene film layer is a multilayer or a single layer. The conductive substrate is a metal substrate or other materials covered with metal electrodes.

[0044] Using carbon nanotube bundles with a diameter of 100nm~100μm as the emission unit, or a microcarbon nanotube with a width of 100nm~100μm, it is easy to achieve directional growth, can obtain a stable large emission current...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com