Preparation method for inorganic / organic multilayer composite separator

A multi-layer composite and diaphragm technology, applied in coating, metal material coating process, ion implantation plating, etc., can solve the problems of large functional limitation of diaphragm, high price, uneven powder dispersion, etc. The effect of improving liquid performance, improving cost performance, and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

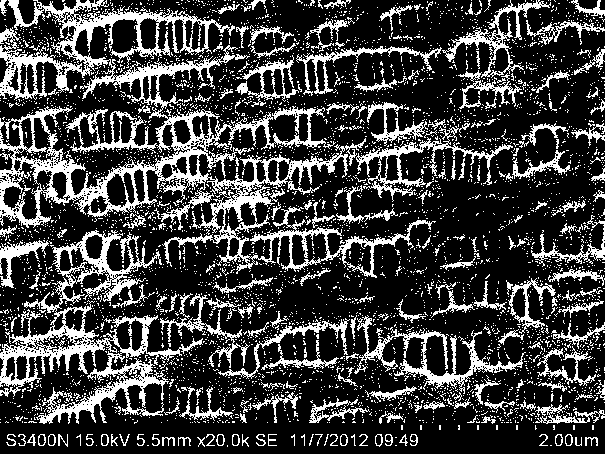

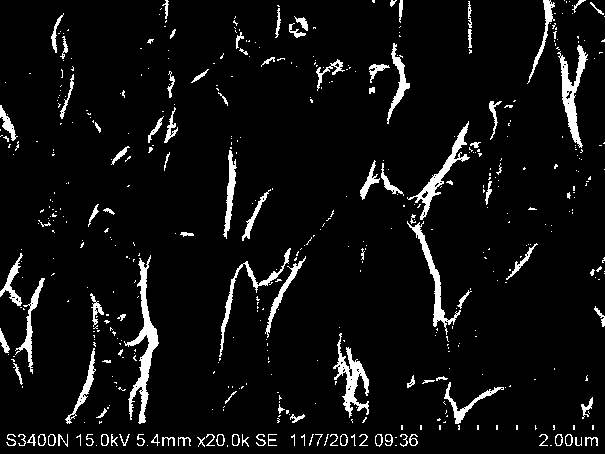

[0033] Soak the polyethylene diaphragm in n-hexane, ultrasonically oscillate for 15 minutes, then dry it in an oven at 80°C, cut the cleaned diaphragm into a square diaphragm of 45cm×50cm, and put it into the coating chamber of the radio frequency sputtering equipment , select the nickel target as the target material, first pump the coating chamber to 0.1Pa, then fill it with high-purity nitrogen, select the sputtering power as 5W, and the sputtering time as 5min, stop the equipment, take out the diaphragm, turn over and repeat the upper process , that is, a double-sided composite nickel nitride multilayer diaphragm is prepared. The result is better.

Embodiment 2

[0035] Soak the polypropylene diaphragm in acetone, ultrasonically oscillate for 15 minutes, and dry it in an oven at 80°C. Cut the cleaned diaphragm into a square diaphragm of 50cm×50cm, and put it into the coating chamber of the radio frequency sputtering equipment. Choose an aluminum target as the target material, pump the coating chamber to 1Pa first, and then fill it with high-purity oxygen. The sputtering power is 80W, and the sputtering time is 100min. After stopping the equipment, take out the diaphragm, turn it over and repeat the upper process. A double-sided composite alumina multilayer separator was obtained. The result is better.

Embodiment 3

[0037] Soak the polypropylene / polyethylene / polypropylene multilayer composite diaphragm in methanol, ultrasonically oscillate for 20 minutes, then dry it in an oven at 80°C, cut the cleaned diaphragm into a square diaphragm of 70cm×40cm, put it in In the coating chamber of the radio frequency sputtering equipment, cobalt target is selected as the target material. First, the pressure of the coating chamber is pumped to 0.4Pa, and then filled with high-purity oxygen. The sputtering power is selected as 40W, and the sputtering time is 70min. After stopping the equipment, Take out the diaphragm, turn it over and repeat the upper process to obtain a double-sided composite cobalt oxide multilayer diaphragm. The result is better.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com