A kind of aba-type colloidal particles with multiple properties on the surface and preparation method thereof

A technology of colloidal particles and properties, applied in the field of sub-micron scale material preparation, can solve problems such as the difficulty of colloidal particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

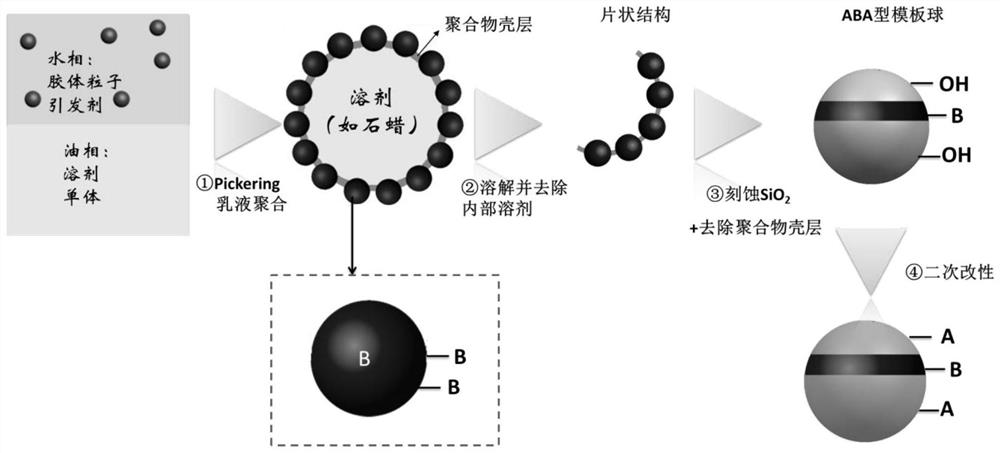

[0029] Embodiment 1—Preparation of ABA type multi-property silica colloidal particles

[0030] Prepare ABA type multi-property colloidal particles according to the following steps:

[0031] (1) Modification of colloidal particles: 1 g of silicon dioxide (SiO2) with a diameter of 400 nm 2 ) particles and ultrasonically dispersed in 40mL ethanol, adding 2g of γ-aminopropyltriethoxysilane ultrasonically dispersed until completely dissolved; the dispersion was placed in a 70°C water bath to reflux for 12h, centrifuged three times and vacuum-dried at room temperature to obtain Amino modified SiO 2 particles.

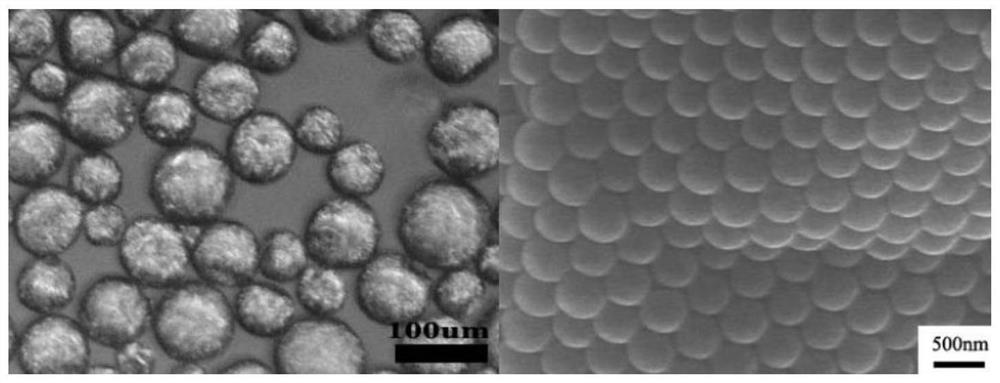

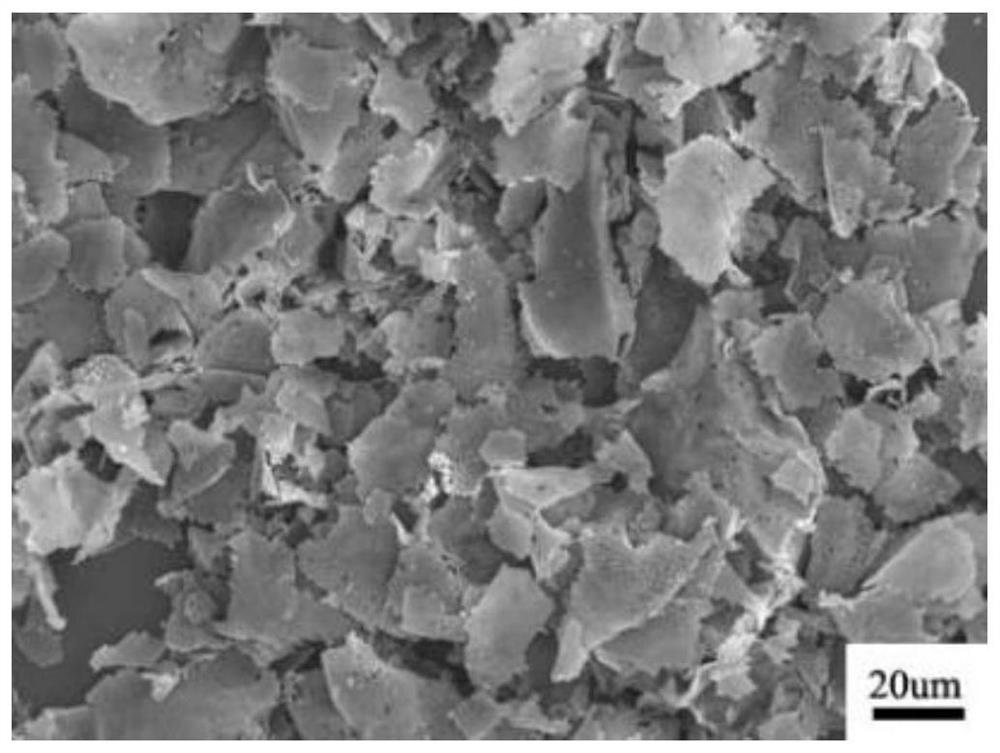

[0032] (2) Pickering emulsion polymerization: Weigh 0.05g of amino-modified SiO obtained in step (1) 2 Particles and 1mL of 0.1wt% potassium persulfate aqueous solution (mass percentage) were ultrasonically dispersed in 9g of distilled water to form an aqueous phase, weighed 0.2g of styrene and 0.8g of paraffin (52#, melting point 50-52°C) and mixed uniformly at 60°C To b...

Embodiment 2

[0035] Embodiment 2—Preparation of ABA type multi-property silica particles

[0036] Prepare ABA type multi-property silica particles according to the following steps:

[0037] (1) colloidal particle modification: the 1g diameter is 300nm silicon dioxide (SiO 2) particles and ultrasonic dispersion in 40ml of ethanol, adding 2g of isopropyl tris (dioctyl pyrophosphate acyloxy) titanate and ultrasonic dispersion until completely dissolved. The dispersion was condensed and refluxed in a water bath at 70 °C for 12 h, centrifuged three times and then dried in vacuum at room temperature to obtain acyloxy-modified SiO 2 particles.

[0038] (2) Pickering emulsion polymerization: Weigh 0.05g of the acyloxy-modified SiO obtained in step (1) 2 Particles and 1mL of 0.1% ammonium persulfate aqueous solution are ultrasonically dispersed in 7g of distilled water to form a water phase, weigh 0.4g of methyl methacrylate and 0.6g of paraffin (30#, melting point 30-32°C) and mix well to form ...

Embodiment 3

[0041] Embodiment 3—Preparation of ABA type multi-property titanium dioxide colloidal particles

[0042] Prepare ABA type multi-property colloidal particles according to the following steps:

[0043] (1) Modification of colloidal particles.: 1g of titanium dioxide (TiO2) with a diameter of 500nm 2 ) particles and ultrasonically dispersed in 40ml ethanol, adding 2g of γ-mercaptopropyltrimethoxysilane ultrasonically dispersed until completely dissolved; the dispersion was placed in a 70°C water bath to reflux for 12h, centrifuged three times and vacuum-dried at room temperature to obtain mercapto Modified TiO 2 particles.

[0044] (2) Pickering emulsion polymerization: Weigh 0.02g of thiol-modified TiO obtained in step (1) 2 Particles and 1 mL of 0.1% azodiisopropylimidazoline hydrochloride aqueous solution were ultrasonically dispersed in 9 g of distilled water to form an aqueous phase, and 0.12 g of methyl methacrylate, 0.08 g of styrene and 0.3 g of paraffin wax (25#, The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com