Gas sensor of hydrogen semiconductor transducer, and preparation method

The technology of a gas sensor and its manufacturing method is applied in the direction of electrical components, electrical solid devices, circuits, etc., and can solve the problems of not being able to meet the needs of real-time monitoring of hydrogen leakage, poor selectivity and sensitivity, etc., and achieve good consistency and low price , good selective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Firstly, the tin dioxide micropowder is subjected to hot isostatic pressing, and the process is to dry the tin dioxide micropowder at 110°C for 18 hours, and then sinter at 1050°C for 4 hours.

[0034] Then carry out surface treatment to the Si single wafer of (100) plane, and its process is to use H to treat the Si single wafer of (100) plane 2 SO 4 +K 2 Cr 2 o 7 Soak in the lotion for 24 hours, and then use methanol, acetone, and ethanol as media to ultrasonically clean the soaked silicon wafers to obtain a clean silicon substrate.

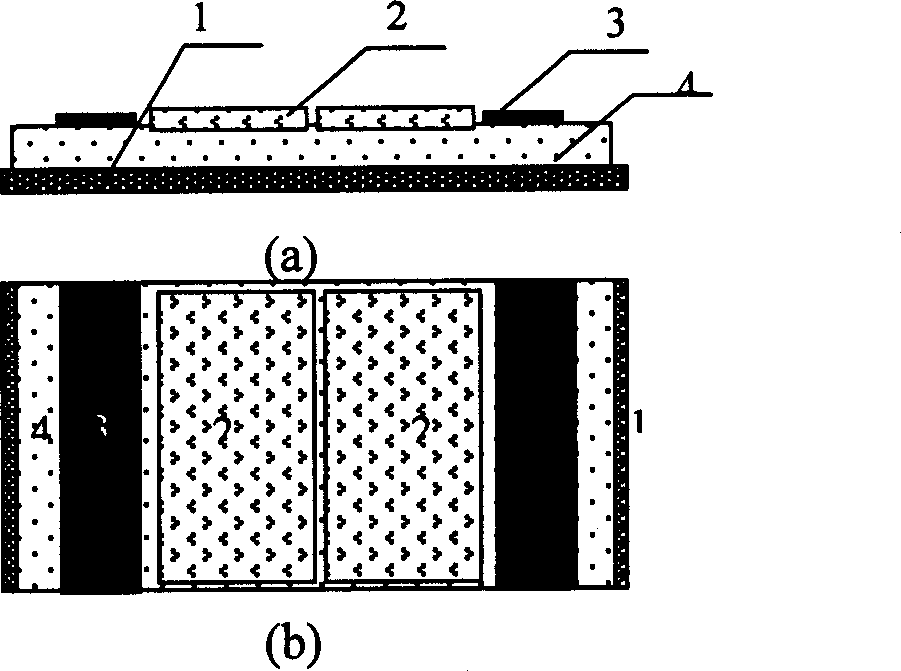

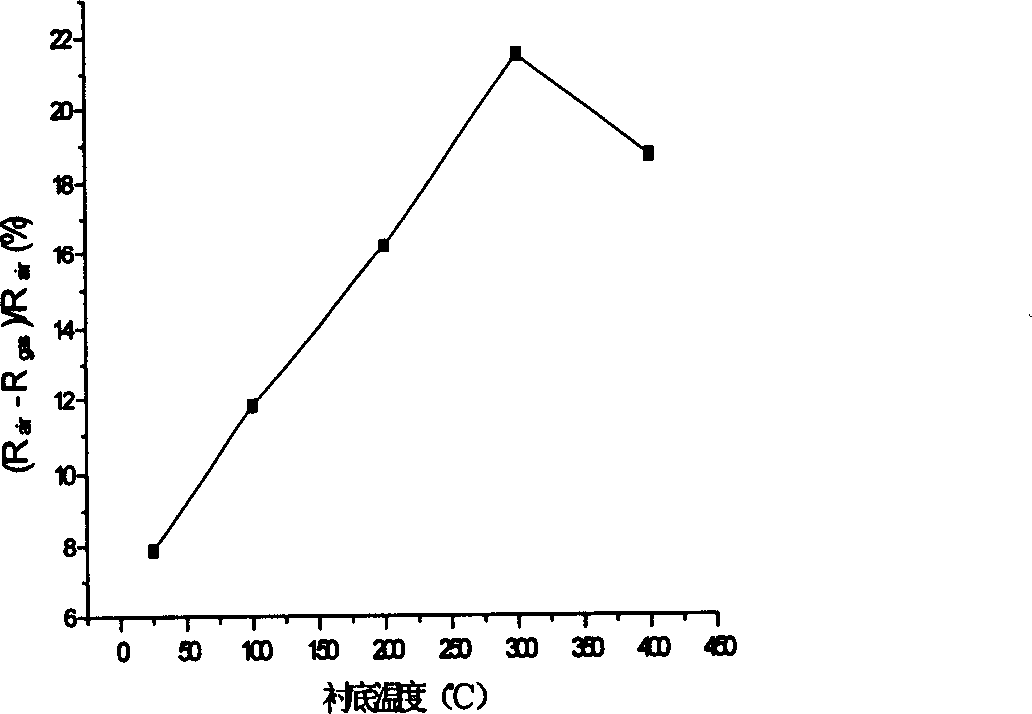

[0035] Then prepare a tin dioxide semiconductor thin film, and carry out radio frequency sputtering on a tin dioxide target with a sintered density of 90%. Sputtering parameters: sputtering power 65W; sputtering time 15 minutes; substrate temperature 25°C; P O2 / P Ar It is 1:4. The in-situ annealing process of the tin dioxide thin film is 400° C. for 6 hours. A Cu electrode was deposited on the prepared tin dioxide film, and then a...

Embodiment 2

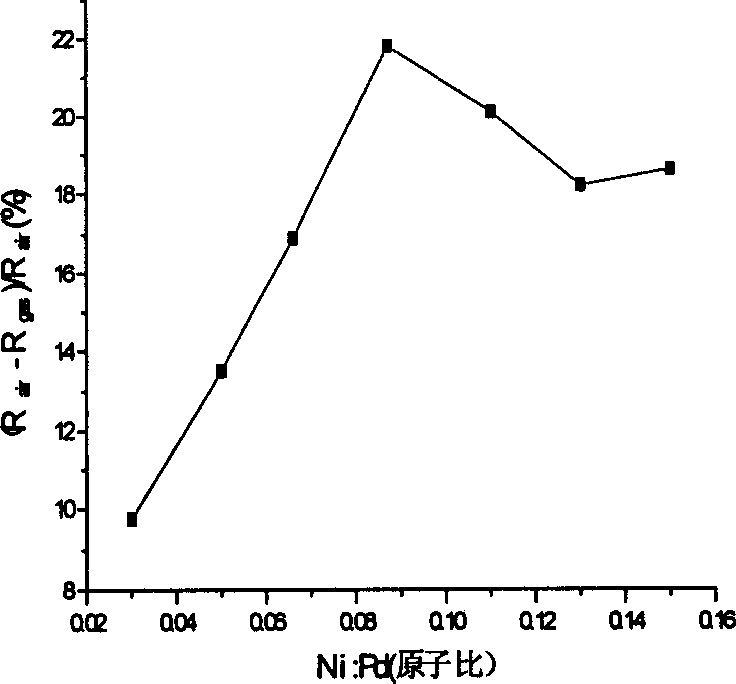

[0036] Embodiment 2: Except that the preparation process parameters of the tin dioxide thin film are different from that of Embodiment 1, the preparation methods adopted for each layer of Embodiment 2 are the same as those of Embodiment 1. The preparation process parameters of tin dioxide thin film are: sputtering power 98W; sputtering time 15 minutes; substrate temperature 400 ℃; P O2 / P Ar It is 1:4. The in-situ annealing process of the tin dioxide thin film is 700° C. for 6 hours. Cu electrodes were deposited on the prepared tin dioxide film. Ni:Pd=0.1 (atomic ratio) in the Pd-Ni alloy thin film, the thickness is 47nm, and it is annealed at 650° C. for 5.5 hours. It is proved by XRD and XPS tests that the tin dioxide film is an N-type semiconductor film with obvious (211) preferred orientation.

[0037]When the semiconductor sensor gas sensor in the present invention is actually used, that is, when detecting in an environment containing hydrogen, the hydrogen molecules ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com