Solar intermediate-temperate high-temperature selective absorbing coating with absorbing layers composed of boron-containing compounds and preparation method of solar intermediate-temperate high-temperature selective absorbing coating

A technology of absorbing coatings and boron compounds, applied in solar thermal power generation, chemical instruments and methods, coatings, etc., can solve problems such as unsuitable for large-scale industrial production, high energy consumption, high equipment requirements, and environmental pollution. Achieve the effects of fast film formation, low preparation cost and low emissivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

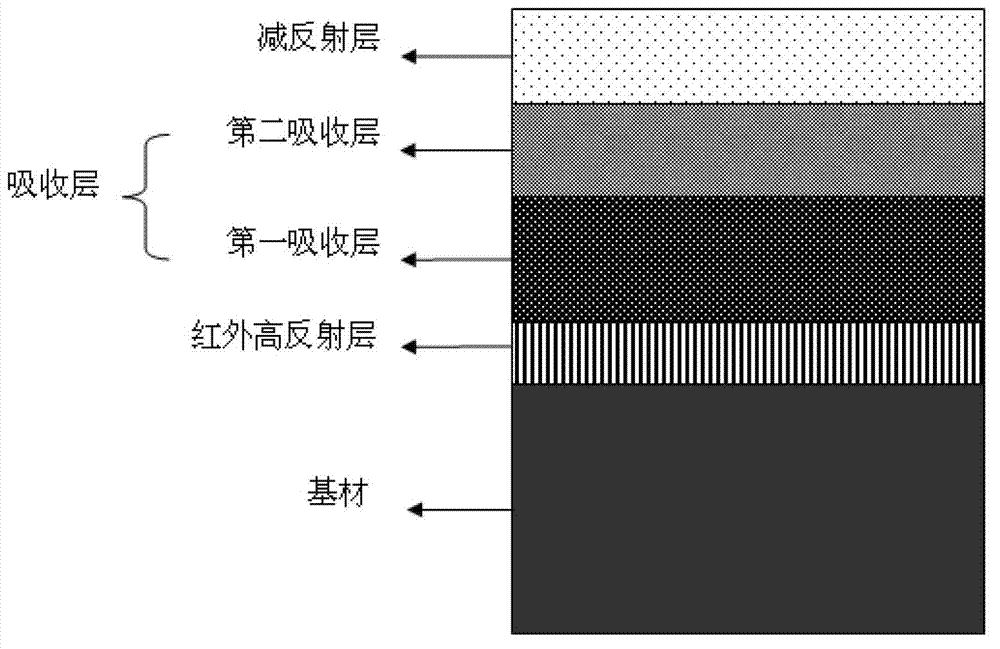

[0037] Coating structure reference figure 1 , the structure adopted from bottom to top is: substrate / copper / titanium monoboride / titanium nitride boride / titanium oxide, and the substrate is any one of aluminum, copper, stainless steel, alloy or glass. The infrared high reflective layer is copper, and copper powder is evaporated by electron beam; the first absorption layer is titanium boride (TiB, at this time, x and y are both 0), and titanium boride powder is evaporated by electron beam; the second absorption layer Titanium boride (TiBN 0.3 , at this time x'=0, y'=0.3), use electron beam to evaporate titanium boride powder, pass nitrogen gas into the evaporation process, and react to form titanium nitride boride; the anti-reflection layer is titanium oxide, which is oxidized by electron beam evaporation Titanium powder.

[0038] The thickness of the prepared film layer is as follows: the thickness of copper in the infrared high reflection layer is 50nm, the thickness of tita...

Embodiment 2

[0041] The substrate is any one of aluminum, copper, stainless steel, alloy or glass, and the coating structure is: substrate / molybdenum / molybdenum oxyboride / molybdenum oxyboride / zirconia, refer to figure 1. The infrared high reflective layer is molybdenum, which is prepared by multi-arc ion plating under argon with a molybdenum target; the first absorbing layer is molybdenum oxyboride (Mo 2 BO 0.4 , at this time x=0.4, y=0), prepared by multi-arc ion plating with molybdenum boride target and oxygen reaction; the second absorbing layer is molybdenum oxyboride (Mo 2 BO 0.8 , at this time x’=0.8, y’=0), prepared by multi-arc ion plating with molybdenum boride target and oxygen reaction; the oxygen flow rate of the second absorbing layer is greater than that of the first absorbing layer. The anti-reflection layer is zirconia, which is prepared by multi-arc ion plating with zirconium target and oxygen reaction.

[0042] The thickness of the prepared film layer is as follows: t...

Embodiment 3

[0045] Coating structure reference figure 1 , the structure adopted from bottom to top is: substrate / copper / titanium monoboride / titanium nitride boride / titanium oxide, and the substrate is any one of aluminum, copper, stainless steel, alloy or glass. The infrared high reflective layer is copper, which is DC sputtered with a copper target; the first absorption layer is titanium boride (TiB, at this time x and y are both 0), and a titanium boride target is used for DC sputtering under argon; The second absorber layer is titanium boride (TiBN 0.6 , at this time x’=0, y’=0.6), using a titanium boride target and nitrogen reactive sputtering; the anti-reflection layer is titanium oxide, titanium target and oxygen DC reactive sputtering.

[0046] The thickness of the prepared film layer is as follows: the thickness of copper in the infrared high reflection layer is 50nm, the thickness of titanium monoboride in the first absorption layer is 50nm, the thickness of titanium boride nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com