Preparation method of low-residual-stress copper film

A residual stress and copper thin film technology, applied in the field of metal thin film preparation, can solve the problems of complex copper thin film preparation process, lack of residual stress, and high requirements for experimental equipment, achieving excellent and simple test methods, easy preparation methods, and easy requirements. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

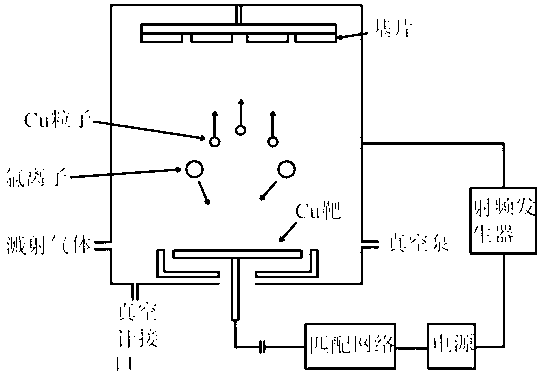

[0035] In terms of specific implementation, the preparation method comprises the following steps:

[0036] 1. Pretreat the substrate;

[0037] 2. Place the pretreated substrate in the magnetron sputtering chamber;

[0038] 3. Vacuumize the magnetron sputtering chamber;

[0039] 4. Inject high-purity argon gas into the magnetron sputtering chamber;

[0040] 5. Adjust the radio frequency sputtering power and air pressure, sputter the magnetron sputtering target, and form a copper film on the substrate;

[0041] 6. After the magnetron sputtering chamber is cooled, take out the copper thin film sample for residual stress test.

[0042] The sputtering target in the sputtering chamber of the present invention adopts a copper target, the target base distance is 100 mm, the diameter is 55 mm, the thickness is 5 mm, and the purity of the copper material is 99.99%.

[0043] For step 1, the substrate can be a silicon (Si) substrate with a resistivity of 3~5Ω.cm, a thickness of 525±20...

Embodiment 1

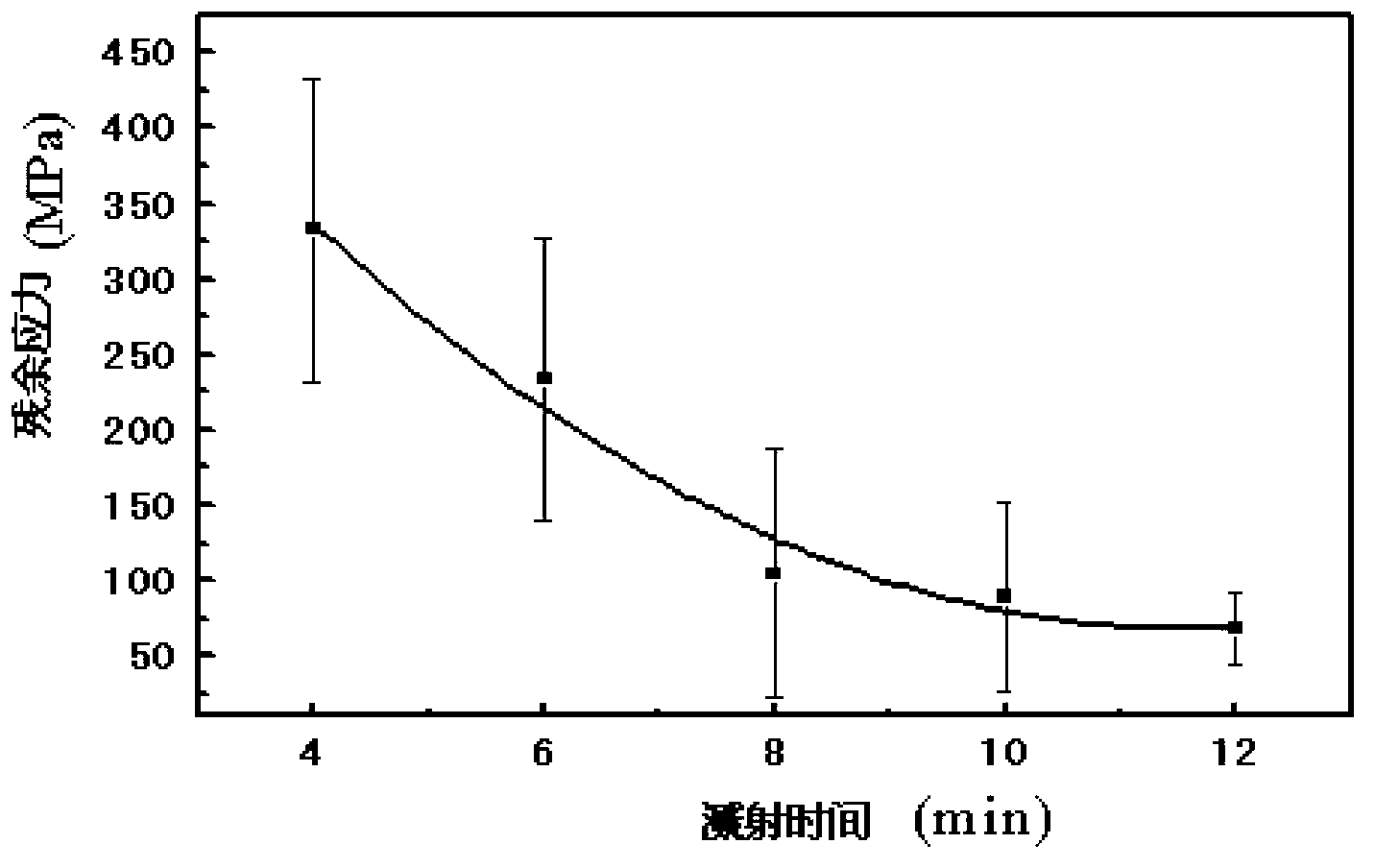

[0048] In this example, the selection of materials and process parameters for preparing the copper film is as follows: the temperature of the substrate is selected as 25 ° C; the selection of the substrate: Si single crystal substrate, the radio frequency power is 100W, and the frequency is 13.56MHz; the magnetron sputtering equipment used The high-purity silicon target size is 2×2cm 2 ; Target base distance is 100mm. The background vacuum is pumped to 4.0×10 by mechanical pump and molecular pump -4 Pa, the working pressure after the Ar gas is introduced is 0.7Pa, and the sputtering time is 4min.

[0049] The residual stress of the Cu film prepared on the QX-500-2 / D ultra-high vacuum multi-target magnetron sputtering coating equipment using the above materials and process parameters combined with the preparation method of the present invention is 332.33 MPa.

Embodiment 2

[0051] The materials and process parameters for preparing the copper film in this example are basically the same as in Example 1, except that the sputtering time is changed to 6min. The residual stress of the Cu film prepared on the ultra-high vacuum multi-target magnetron sputtering coating equipment is 233.33MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com