Patents

Literature

63results about How to "Improve membrane quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid crystal orientation agent, liquid crystal orientation film, manufacturing method of liquid crystal orientation film, and liquid crystal display element

InactiveCN103666486AImprove yieldUniform coatingLiquid crystal compositionsNon-linear opticsDiacetone alcoholDiethylene glycol diethyl ether

The invention relates to a liquid crystal orientation agent, a liquid crystal orientation film, a manufacturing method of the liquid crystal orientation film, and a liquid crystal display element. The liquid crystal orientation agent has good printing performance with respect to a substrate and good continuous printing performance and prevents swelling of printing plates. The liquid crystal orientation agent contains at last one polymer (A) selected from the group formed by polyamide acid, polyimide, polyamide acid ester and polysiloxane, a first solvent containing more than one of N-ethyl-2-pyrrolidone, 1,3-dimethyl-2-imidazolone, 3-methoxy-N, N-dimethylpropionamide and so on, and a second solvent containing more than one of propylene glycol diacetate, diethylene glycol diethyl ether, diisoamyl ether diacetone alcohol and so on.

Owner:JSR CORPORATIOON

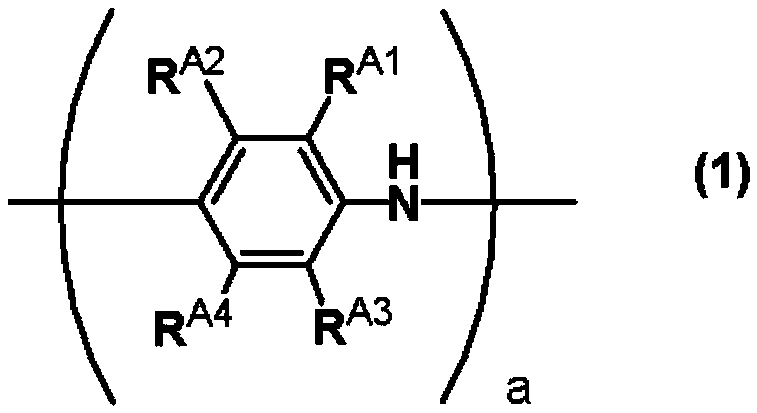

Liquid crystal alignment agent, liquid crystal alignment film and liquid crystal display element

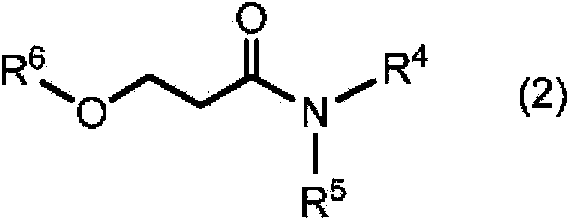

ActiveCN103627406AImprove yieldUniform coatingLiquid crystal compositionsNon-linear opticsCrystallographyCarbon number

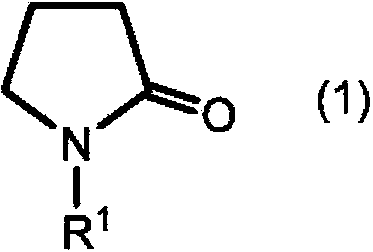

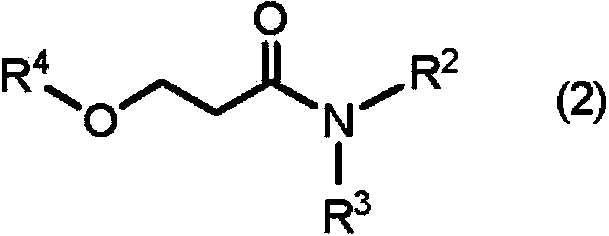

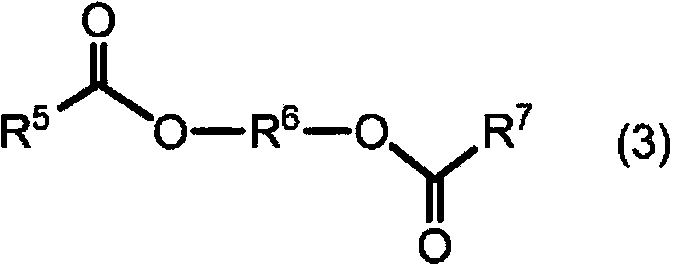

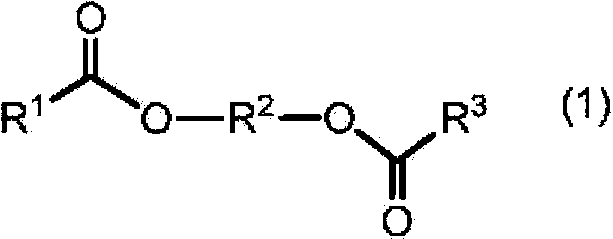

The present invention relates to a liquid crystal alignment agent, liquid crystal alignment film and liquid crystal display element. The present invention provides a liquid crystal alignment agent that not only is a good coating property on the substrate, but is difficult to swelling the printing plate and is excellent in continuous printing. The liquid crystal alignment agent of the present invention comprises: at least one polymer (A) that selected from a group that comprises a polyamic acid, a polyimide, a polyamic acid ester and a polyorganosiloxane. In addition, the liquid crystal alignment agent comprises a solvent of compound (p1) that represented in the following formula (1) (Formula (1), R1 and R3 are respectively a straight-chain or a branched 1-alkyl having a carbon number from 1 to 3, and R2 is a straight-chain or branched 2-alkyl having a carbon number from 2 to 5.).

Owner:JSR CORPORATIOON

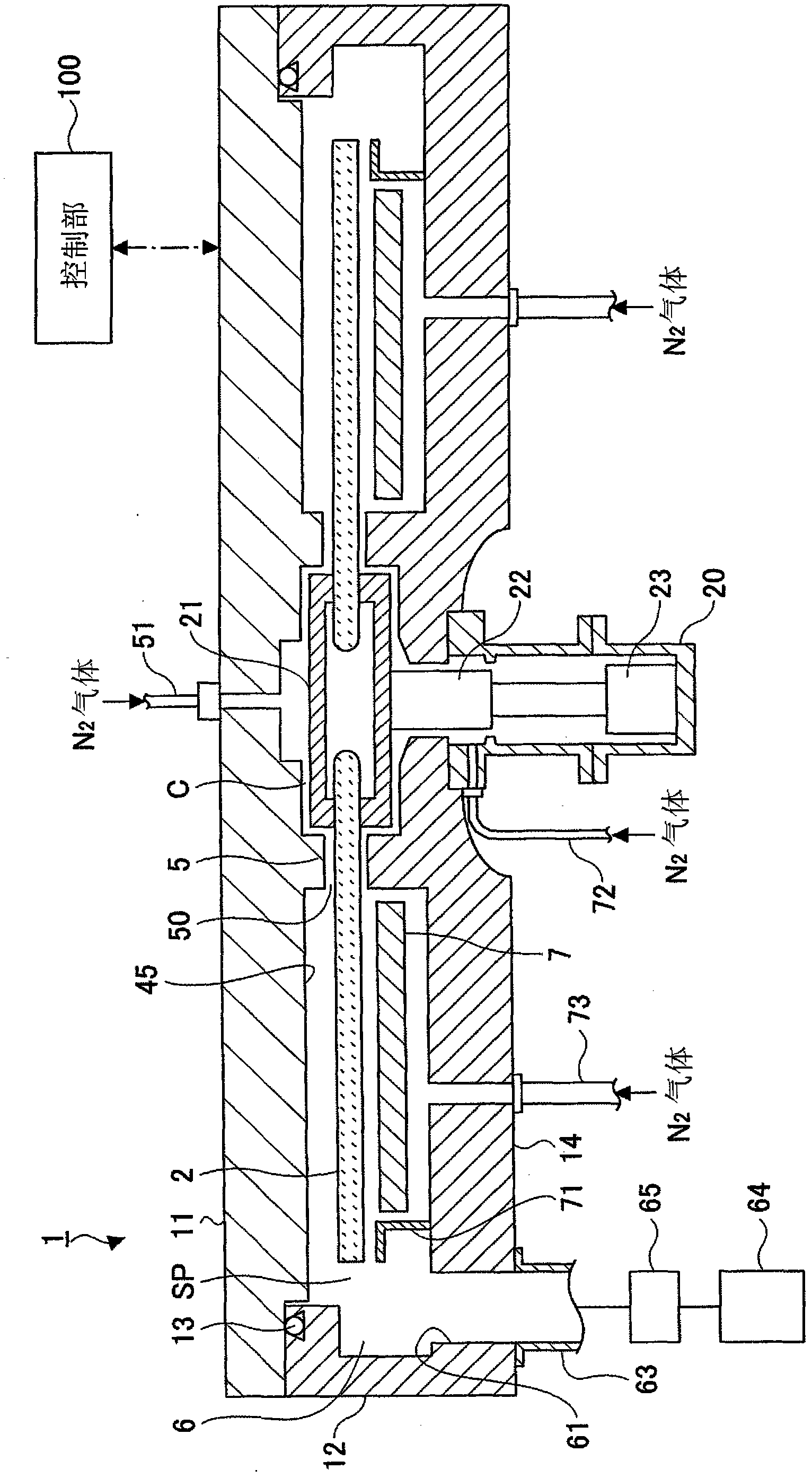

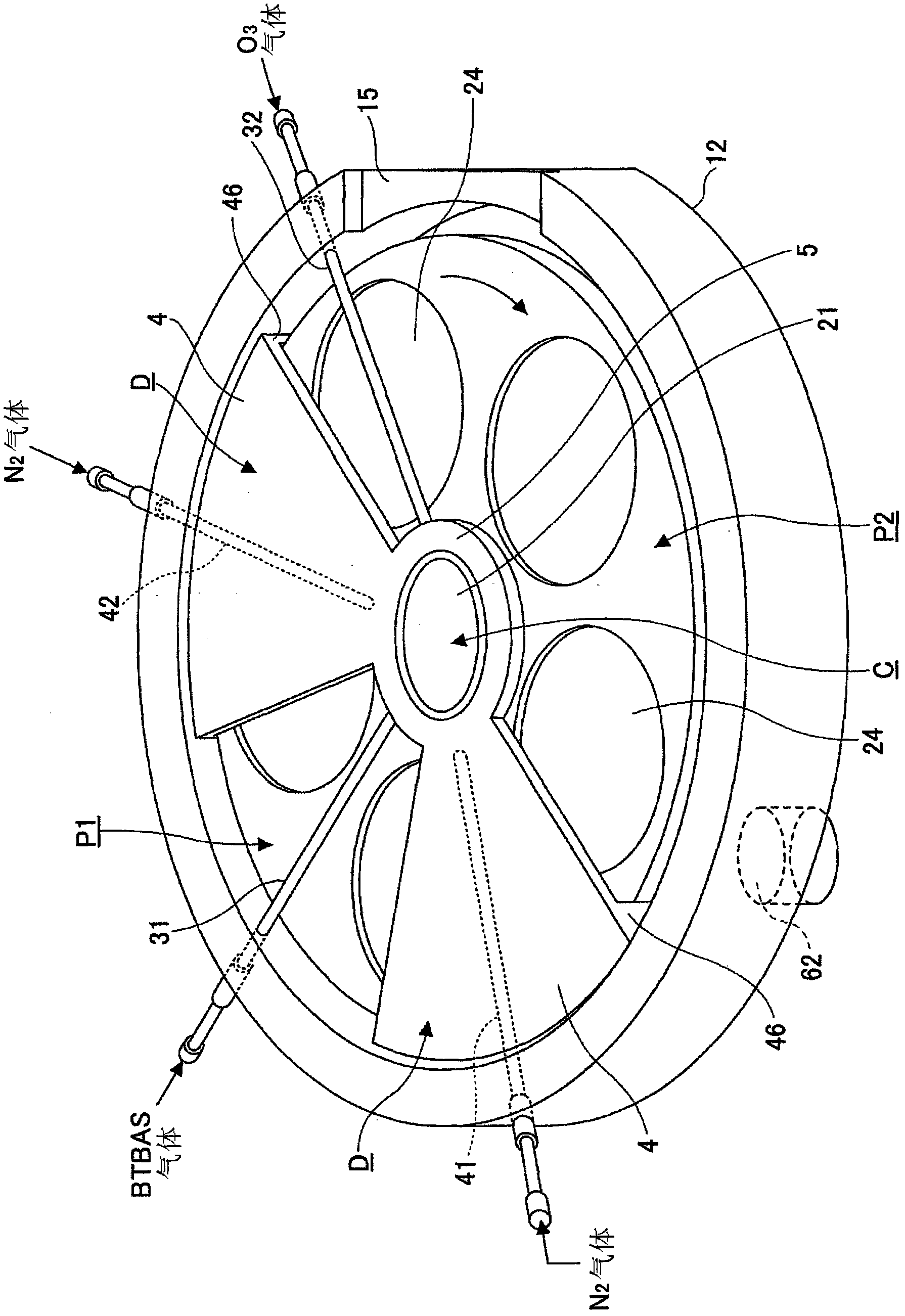

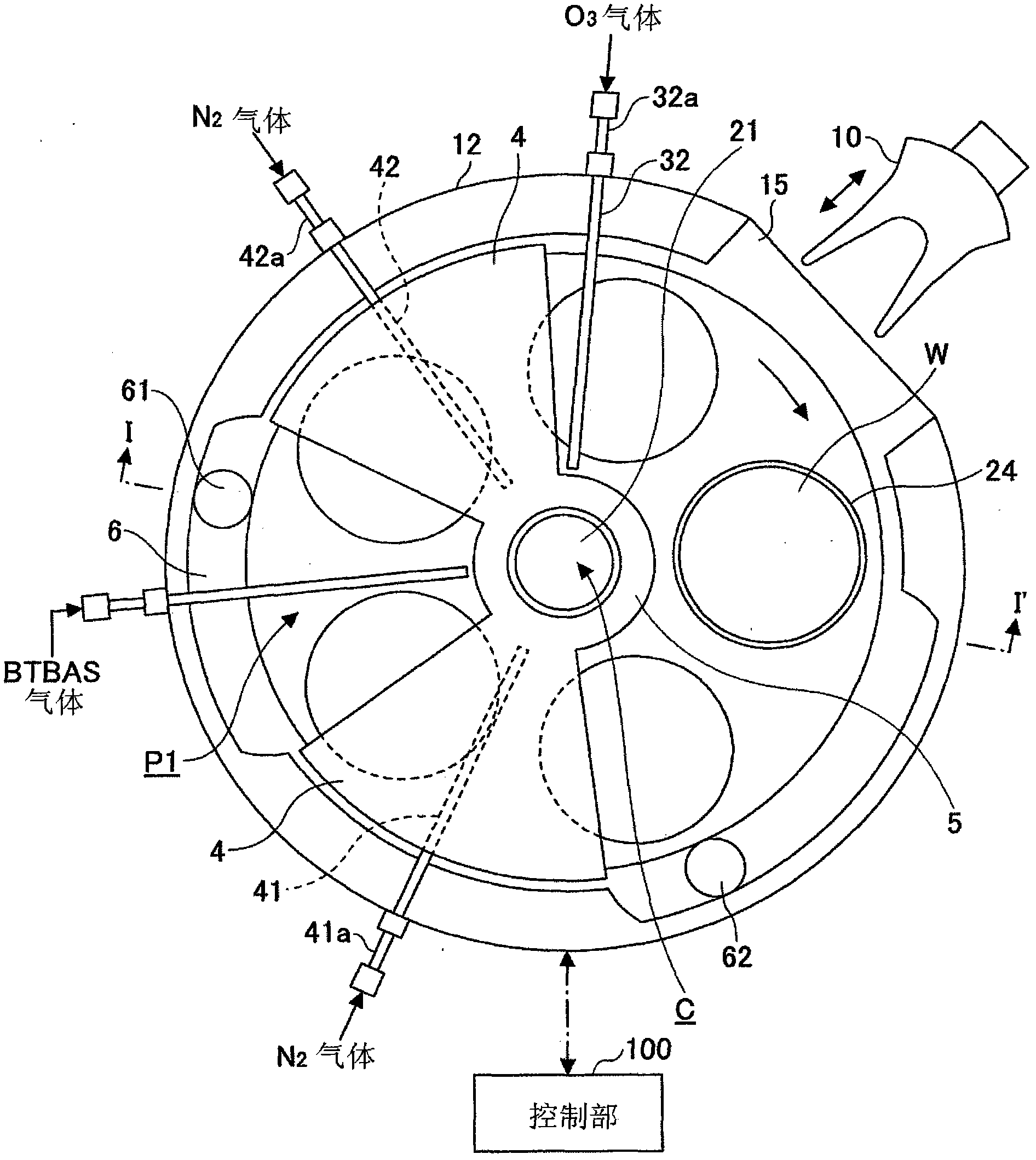

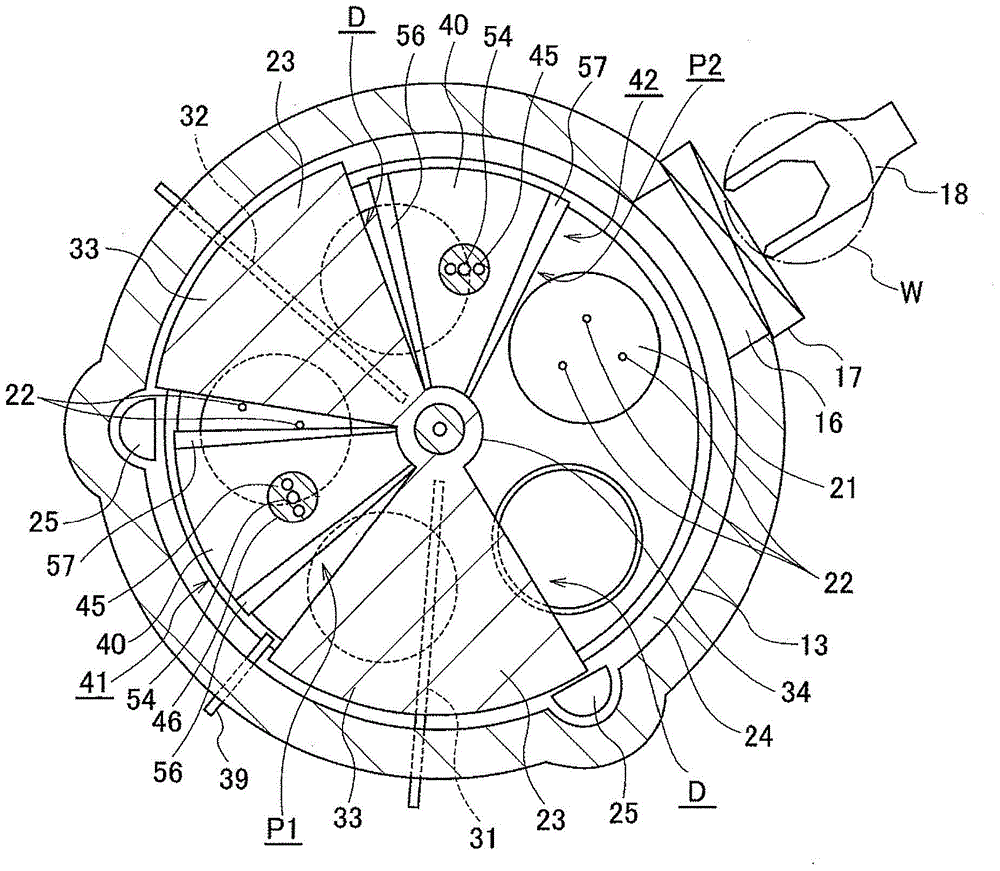

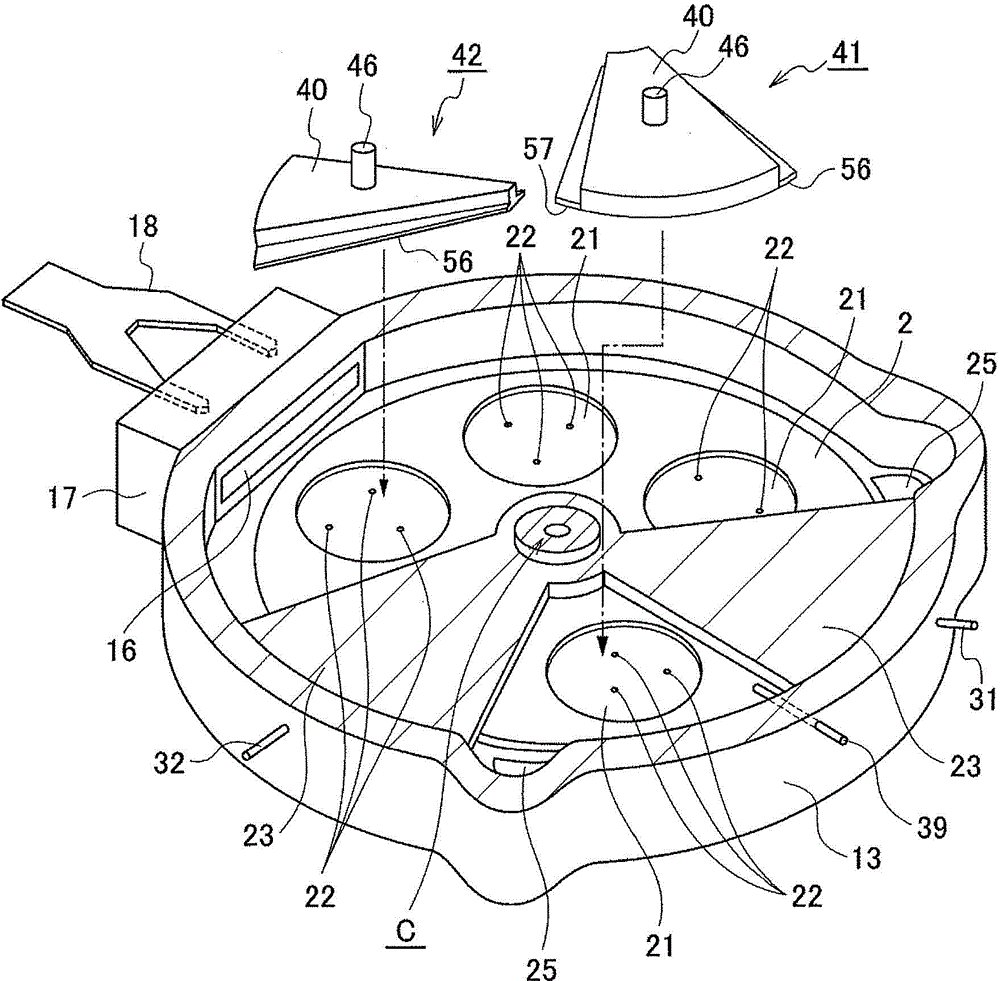

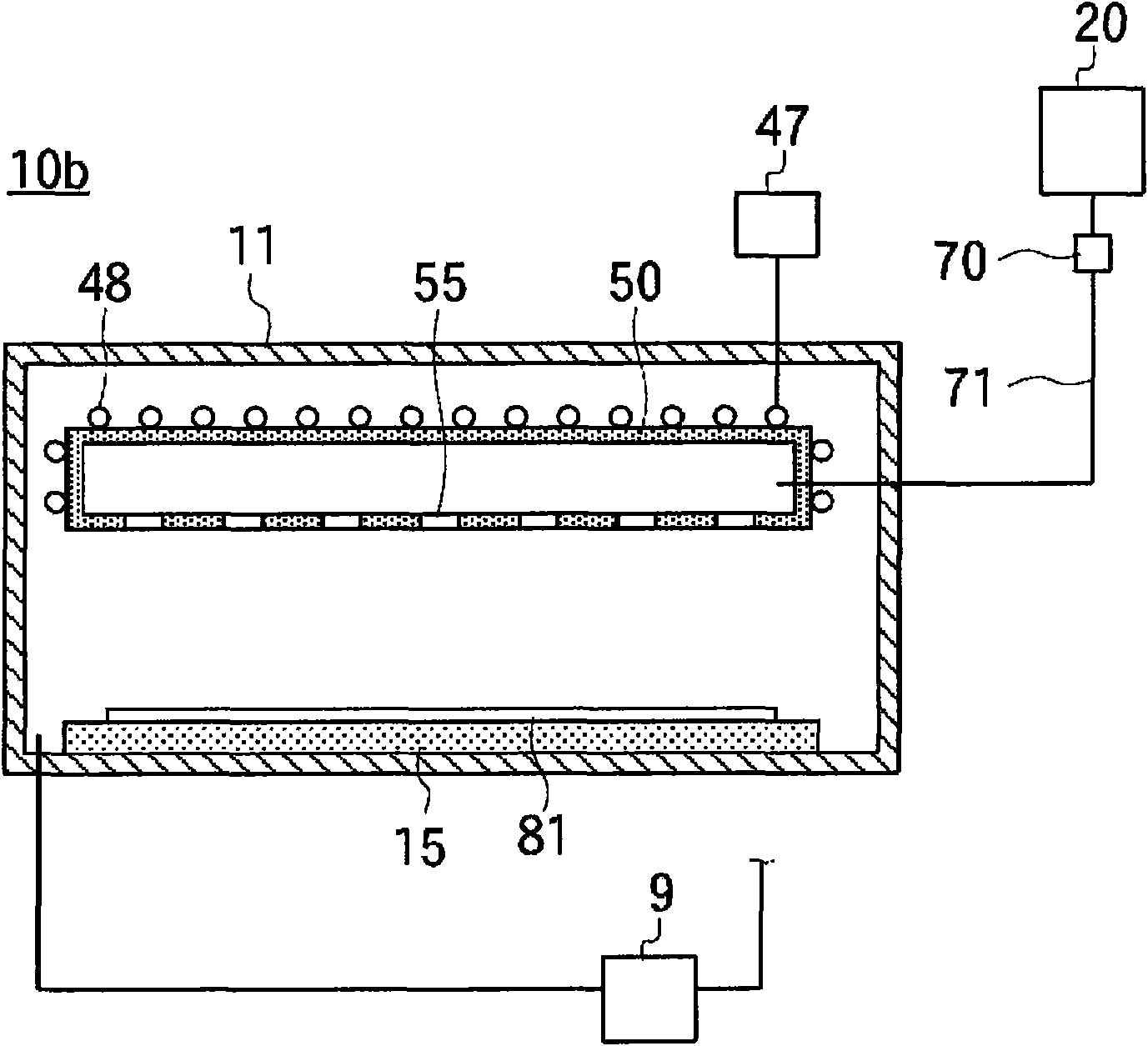

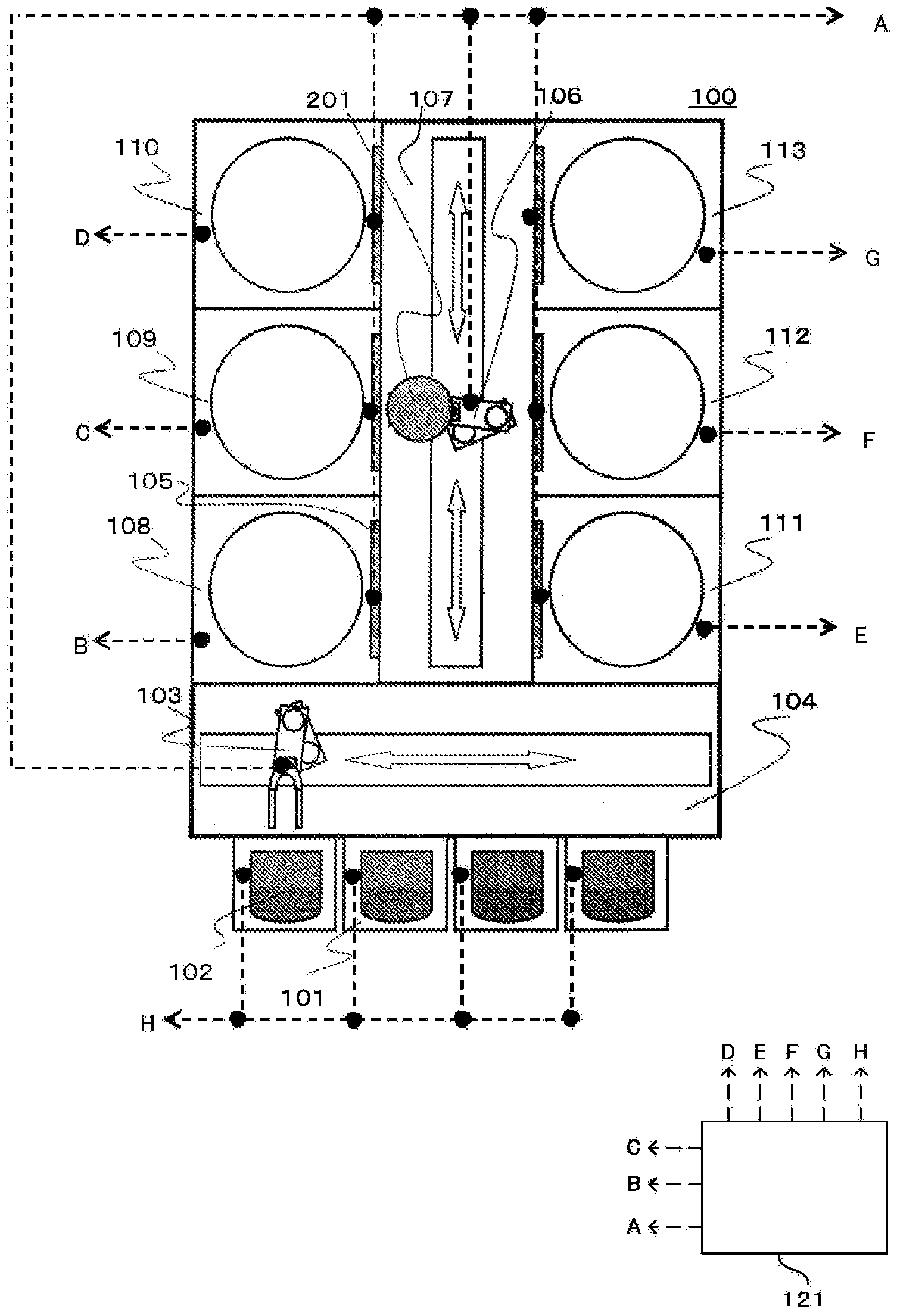

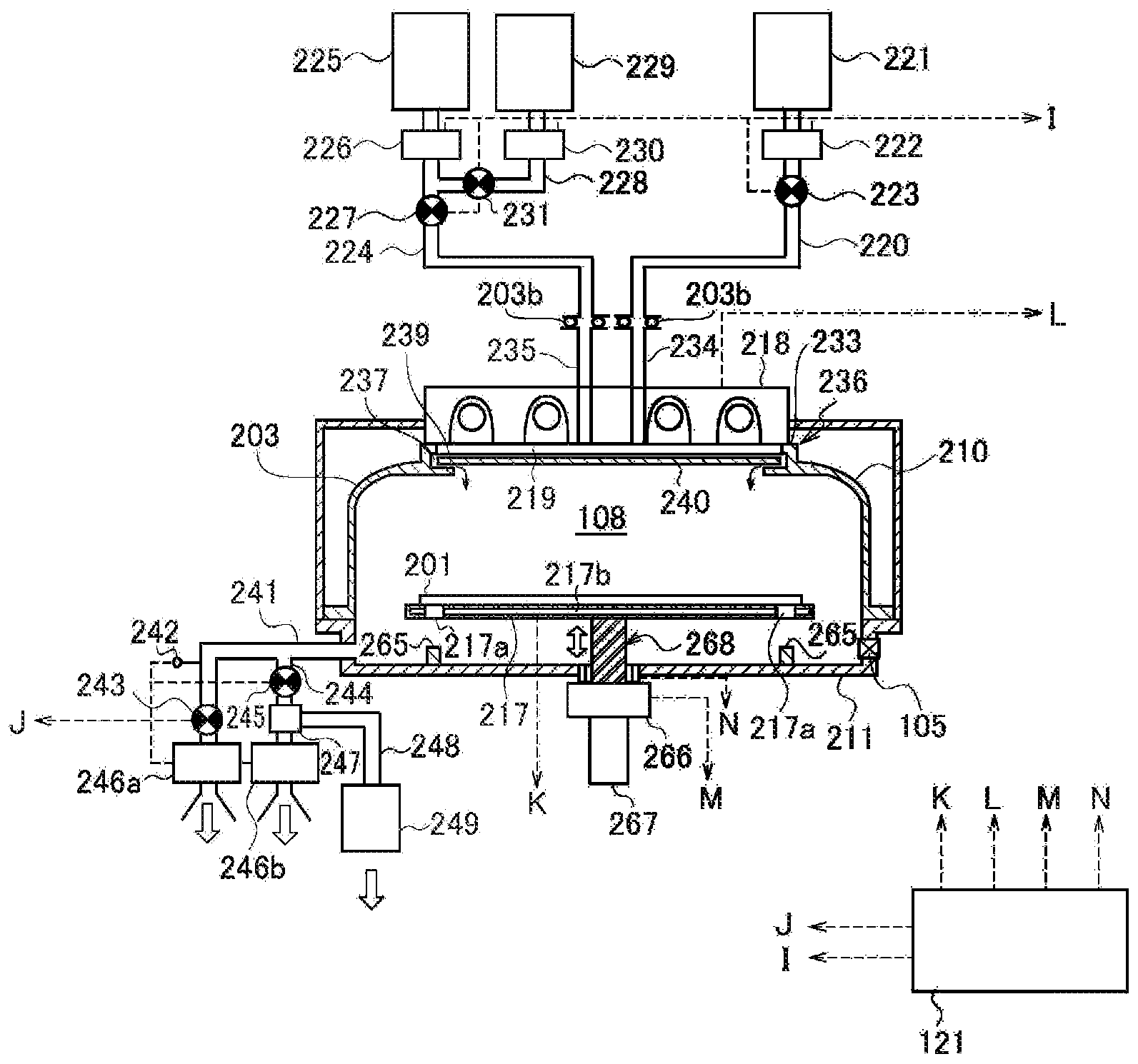

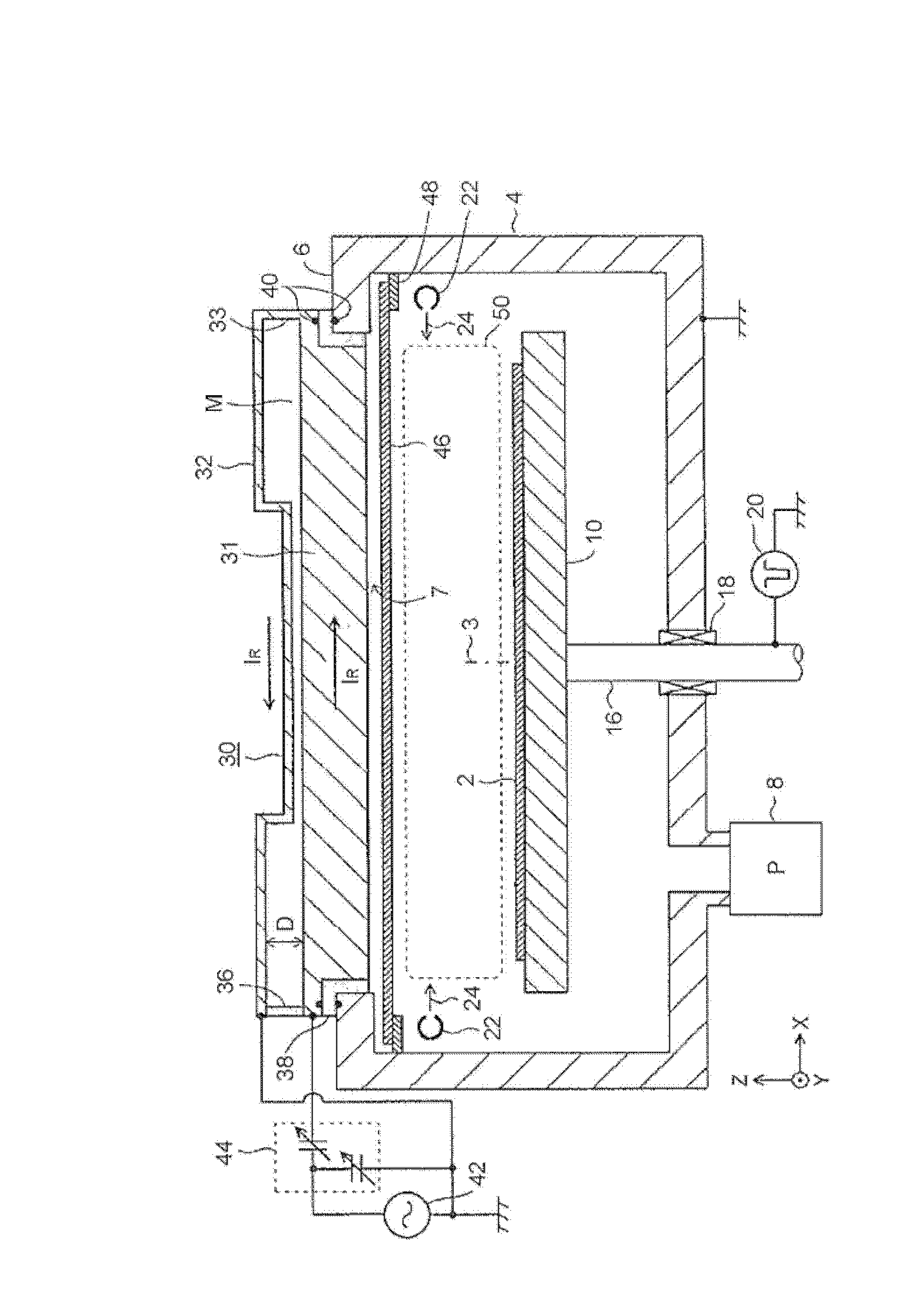

Film deposition apparatus

ActiveCN102134709AExtended processing timeIncrease speedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingChemical reactionProcess engineering

A film deposition apparatus has a vacuum chamber in which a turntable placing plural substrates is rotated, the plural substrates come into contact with plural reaction gases supplied to plural process areas and thin films are deposited on surfaces of the plural substrates, and has plural reaction gas supplying portions for supplying the plural processing gases, a separation gas supplying portion for supplying a separation gas and an evacuation mechanism for ejecting the plural processing gases and the separation gas, wherein the plural process areas includes a first process area for causing a first reaction gas to adsorb on the surfaces of the plural substrates, and a second process area, having an area larger than the first process area, for causing the first reaction gas having adsorbed the surfaces of the plural substrates and a second reaction gas to react, and depositing the films on the surfaces of the plural substrates.

Owner:TOKYO ELECTRON LTD

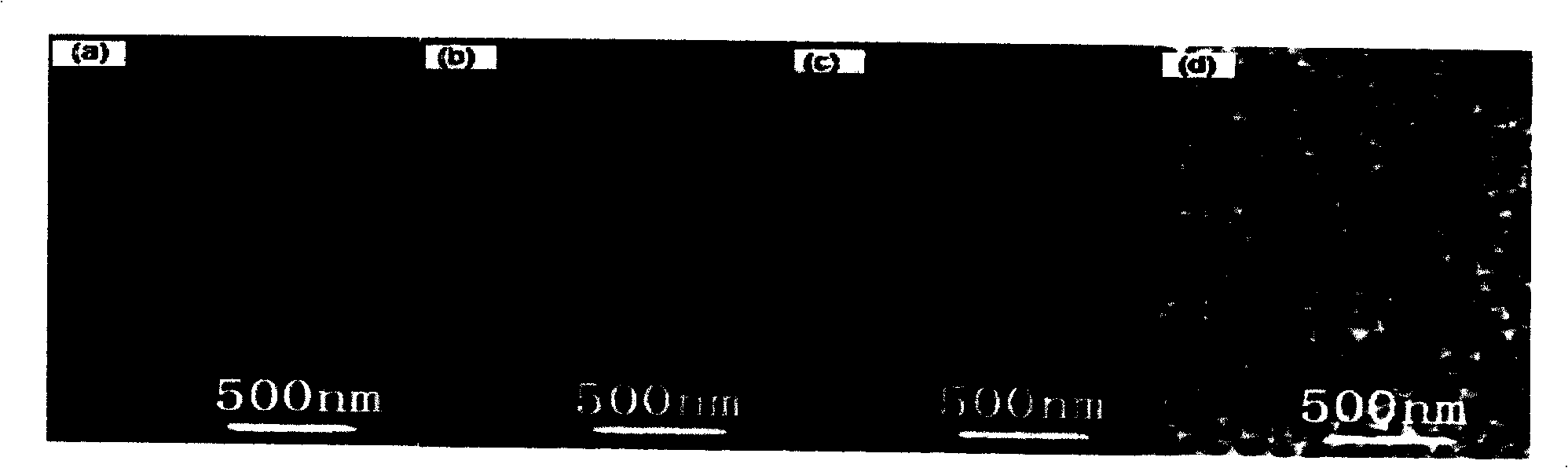

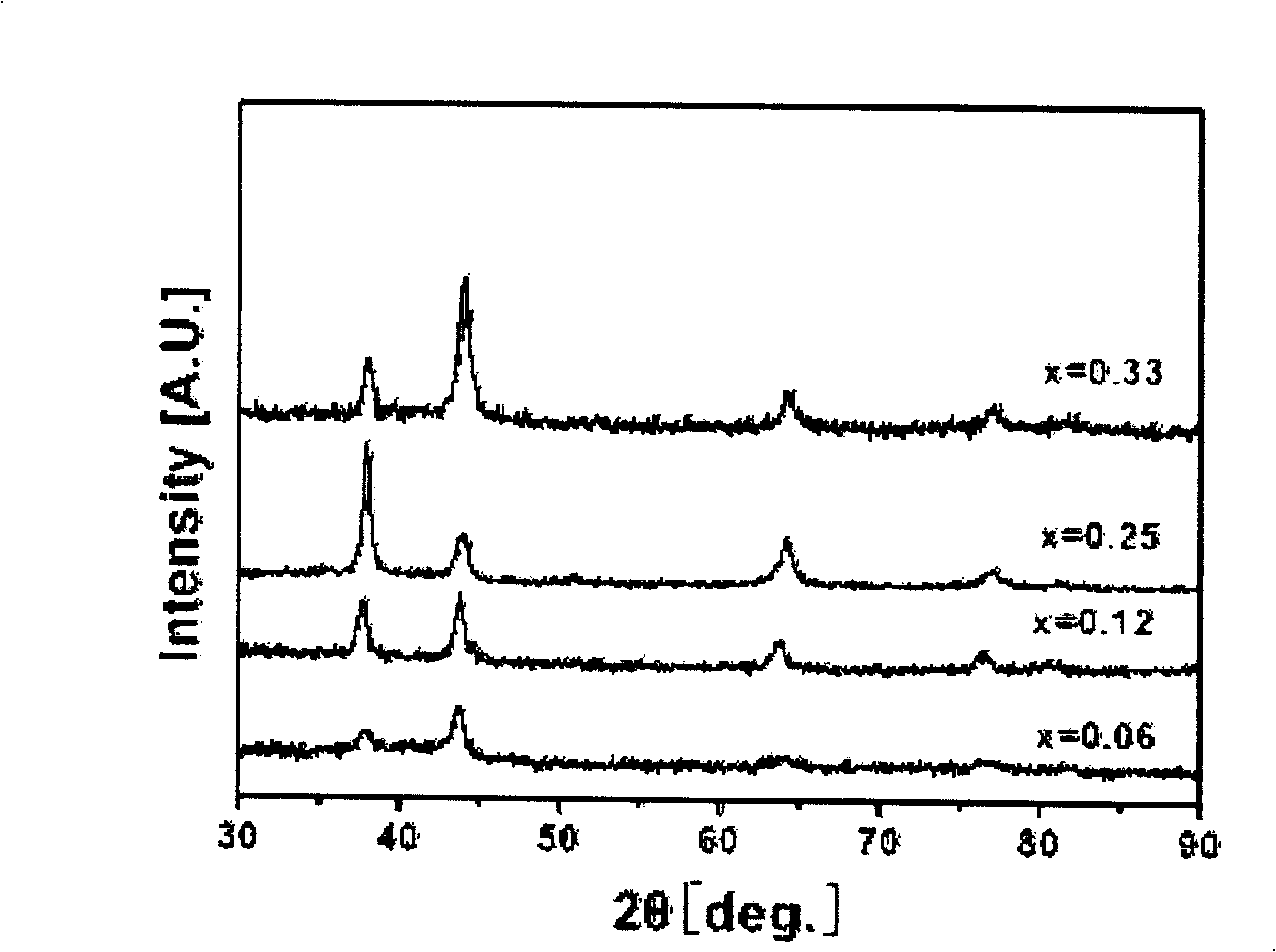

Molybdenum base nitride composite ganoine thin film and preparation thereof

InactiveCN101244644AReduce the temperatureNo holesLayered productsVacuum evaporation coatingMo elementArea ratio

The invention discloses a Mo-based nitride composite hard film and a preparation method, wherein the substrate is coated with nanometer composite hard film that is made of Mo-based metal nitride or nonmetal nitride, the crystallized size of the film is 5-40nm, the thickness of the film is 1-5Mum, the molar percentage between the Mo element and the substitution element in the film is 50 to 94% : 6 to 50%; the preparation method is that: (a) the target material (made of Mo and the substitution) and the substrate are respectively arranged on the cathode and sample table in vacuum room of magnetic control sputtering equipment, the area ratio of the Mo and the substitution in the target material is 1 to 8 : 8 to 1, the distance between the target material and the substrate is 40-80mm; (b) after the vacuum degree in the vacuum room is less than or equal to 8 x 10-4pa and substrate temperature reaches 300 to 500 DEG C, the vacuum room is made to be in the atmosphere of argon and nitrogen mixed gas and 30-130 minutes sputtering is made so as to prepare the Mo-based nitride composite hard film. The invention can widely be used for material protection and can improve abradability and durability of material obviously.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

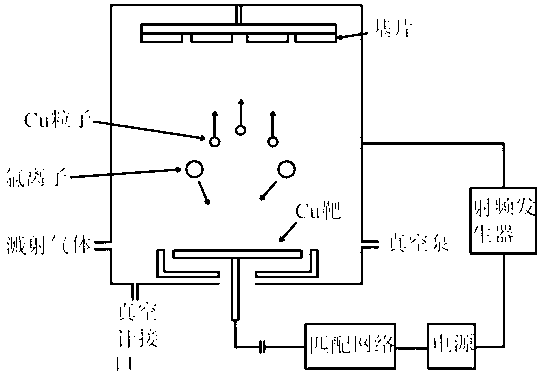

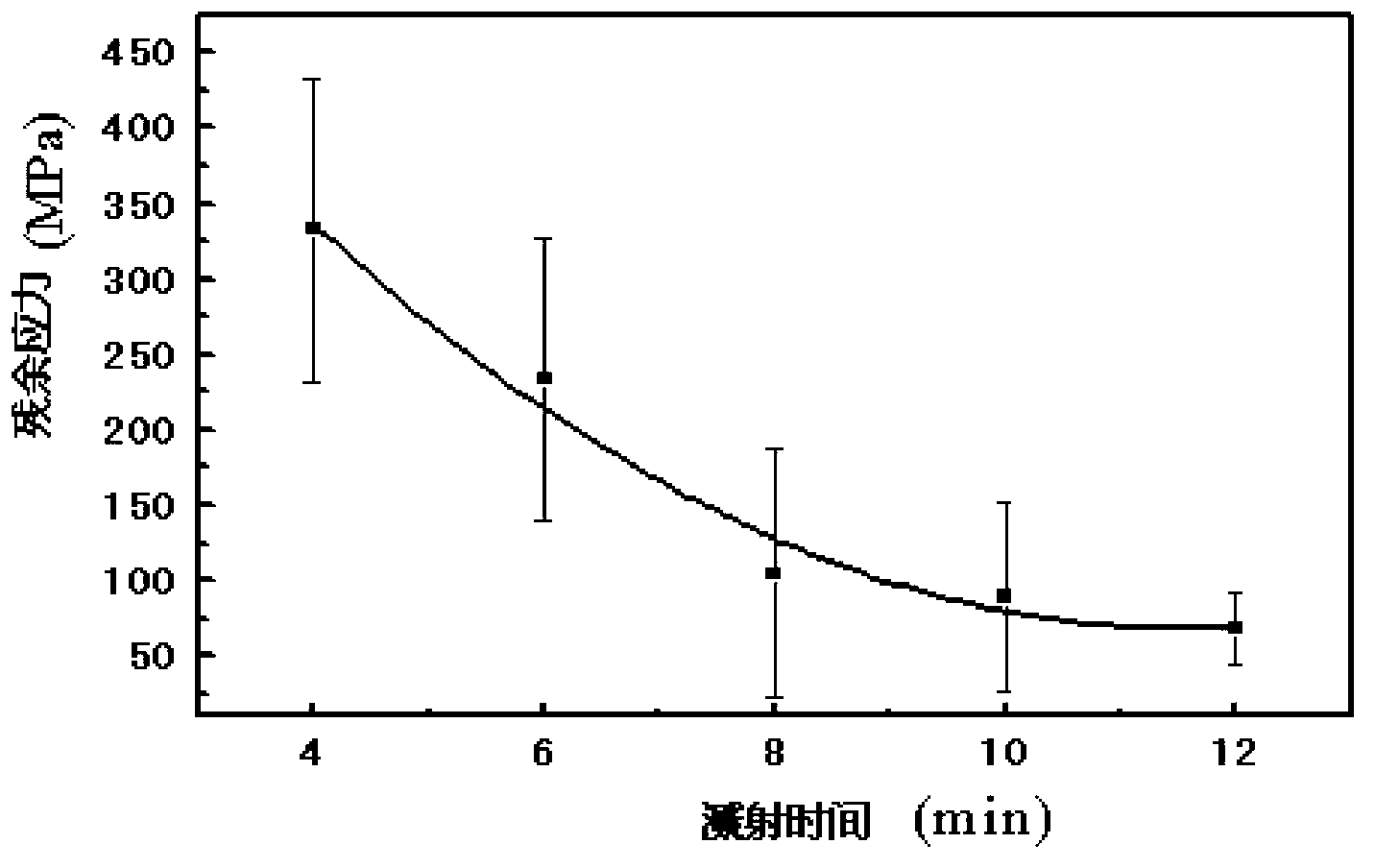

Preparation method of low-residual-stress copper film

InactiveCN102851645AImprove membrane qualityImprove performanceVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringRadio frequency sputtering

The invention relates to preparation technology of a metal film, and discloses a new simple and convenient preparation method of a copper film. The invention effectively controls the magnitude of residual stress generated in the preparation process, thereby implementing preparation of the low-residual-stress copper film material. The method is applied to a magnetron sputtering coating device, and adopts radio-frequency magnetron sputtering to prepare the copper film. The magnetron sputtering coating device is provided with a magnetron sputtering chamber, and a magnetron sputtering target is arranged in the magnetron sputtering chamber. The method comprises the following steps: a. pretreating a substrate; b. putting the pretreated substrate in the magnetron sputtering chamber; c. vacuumizing the magnetron sputtering chamber; d. introducing high-purity argon into the magnetron sputtering chamber; e. regulating the radio-frequency sputtering power and gas pressure, and sputtering the magnetron sputtering target to form the copper film on the substrate; and f. after cooling the magnetron sputtering chamber, taking out the copper film sample, and carrying out residual stress testing.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

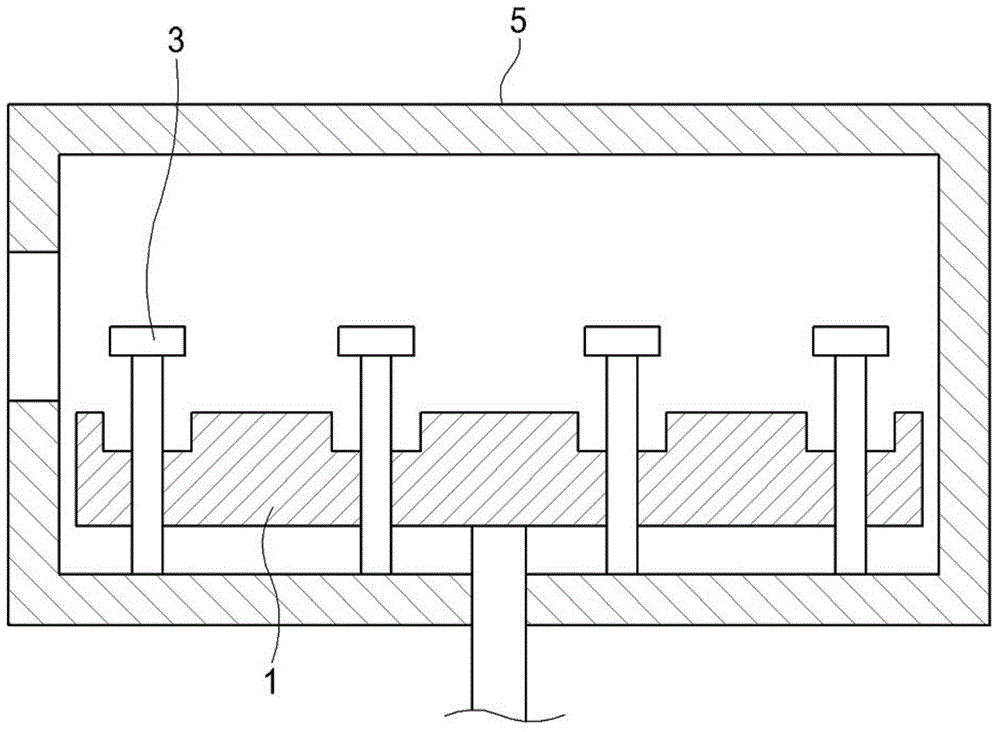

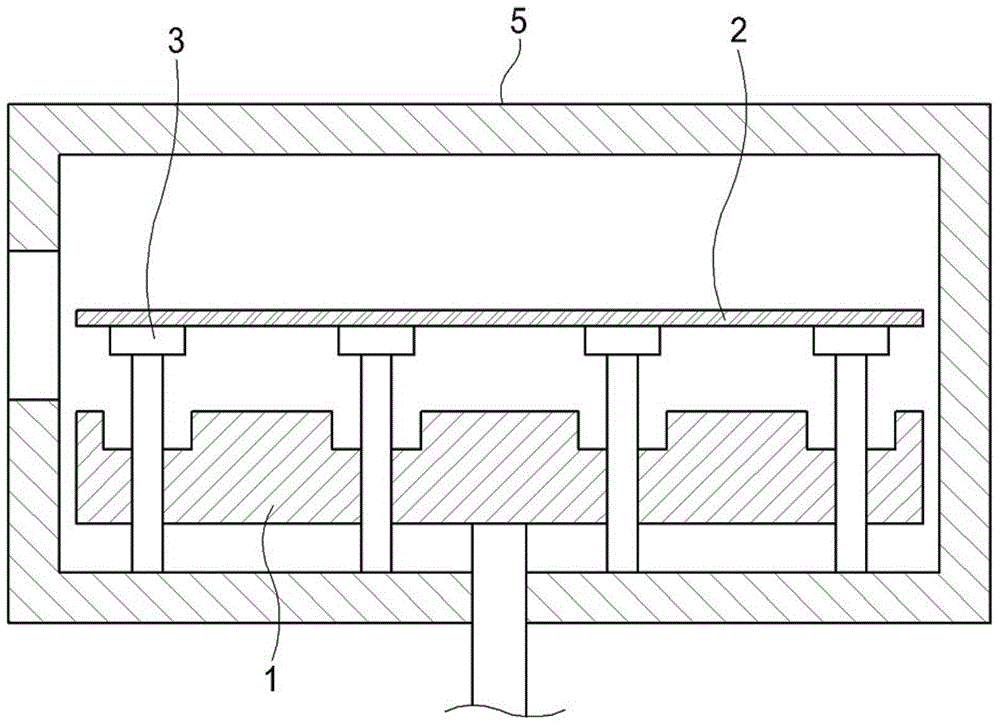

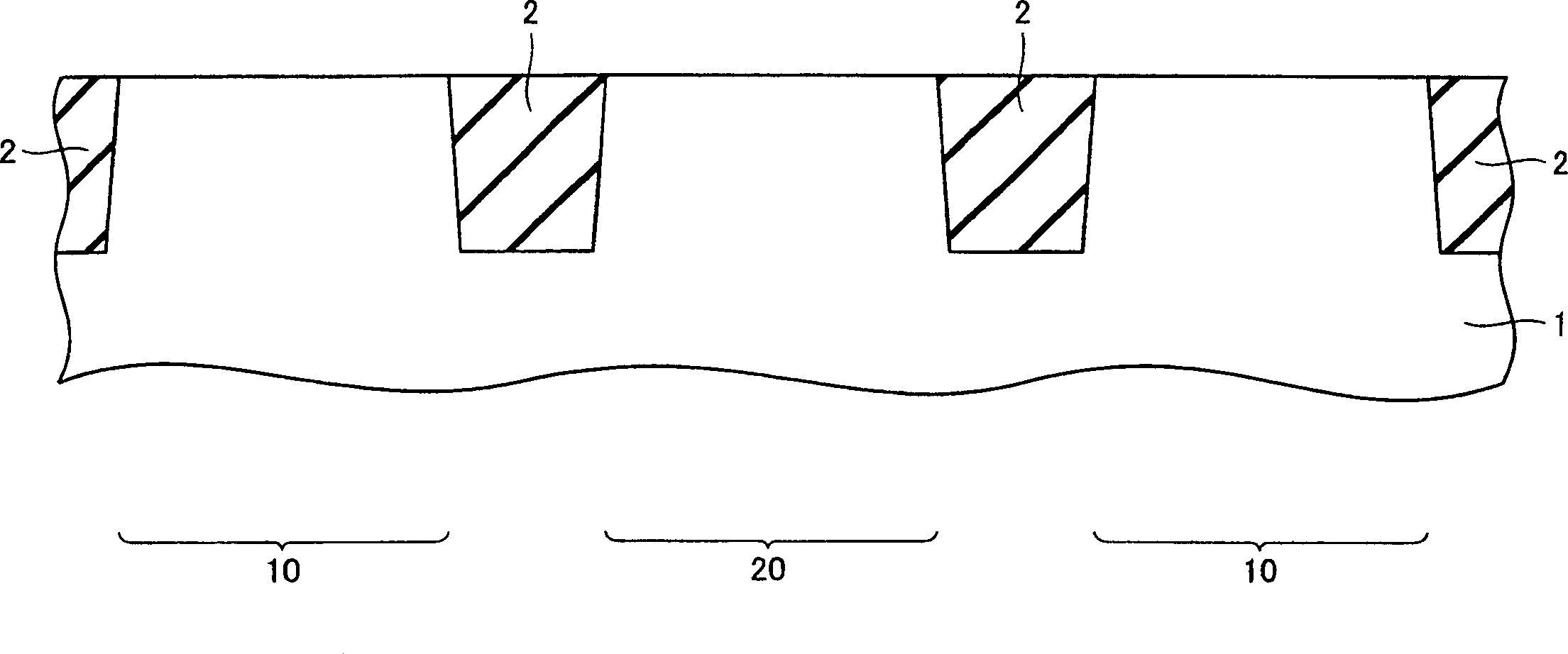

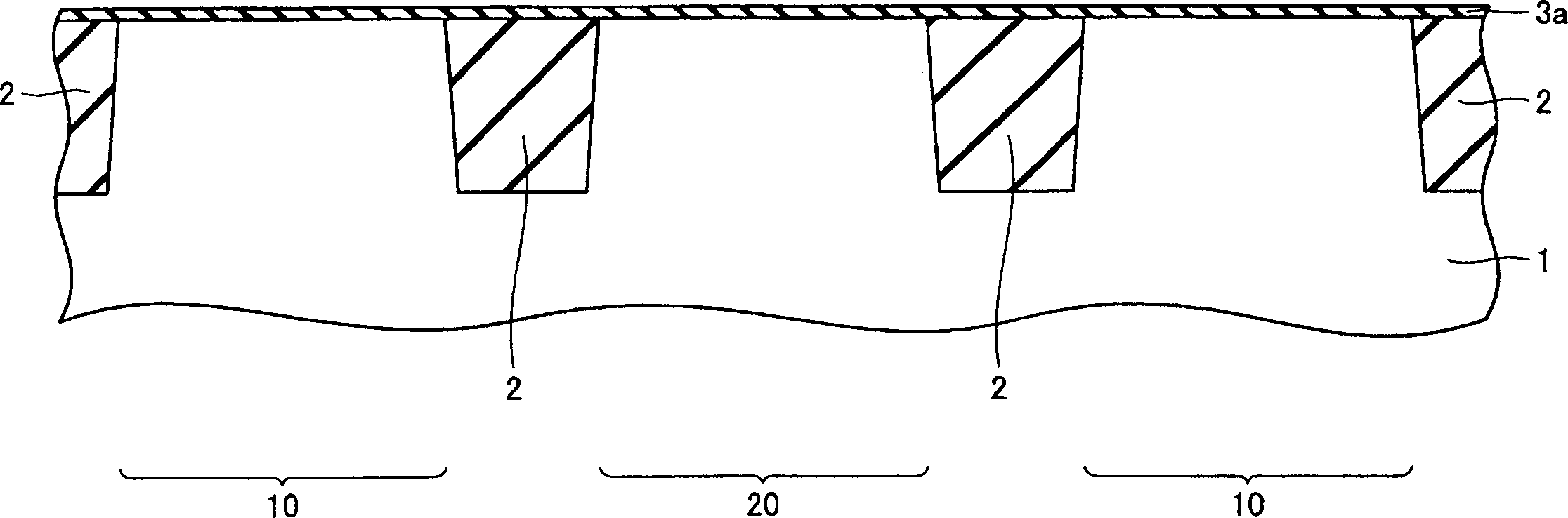

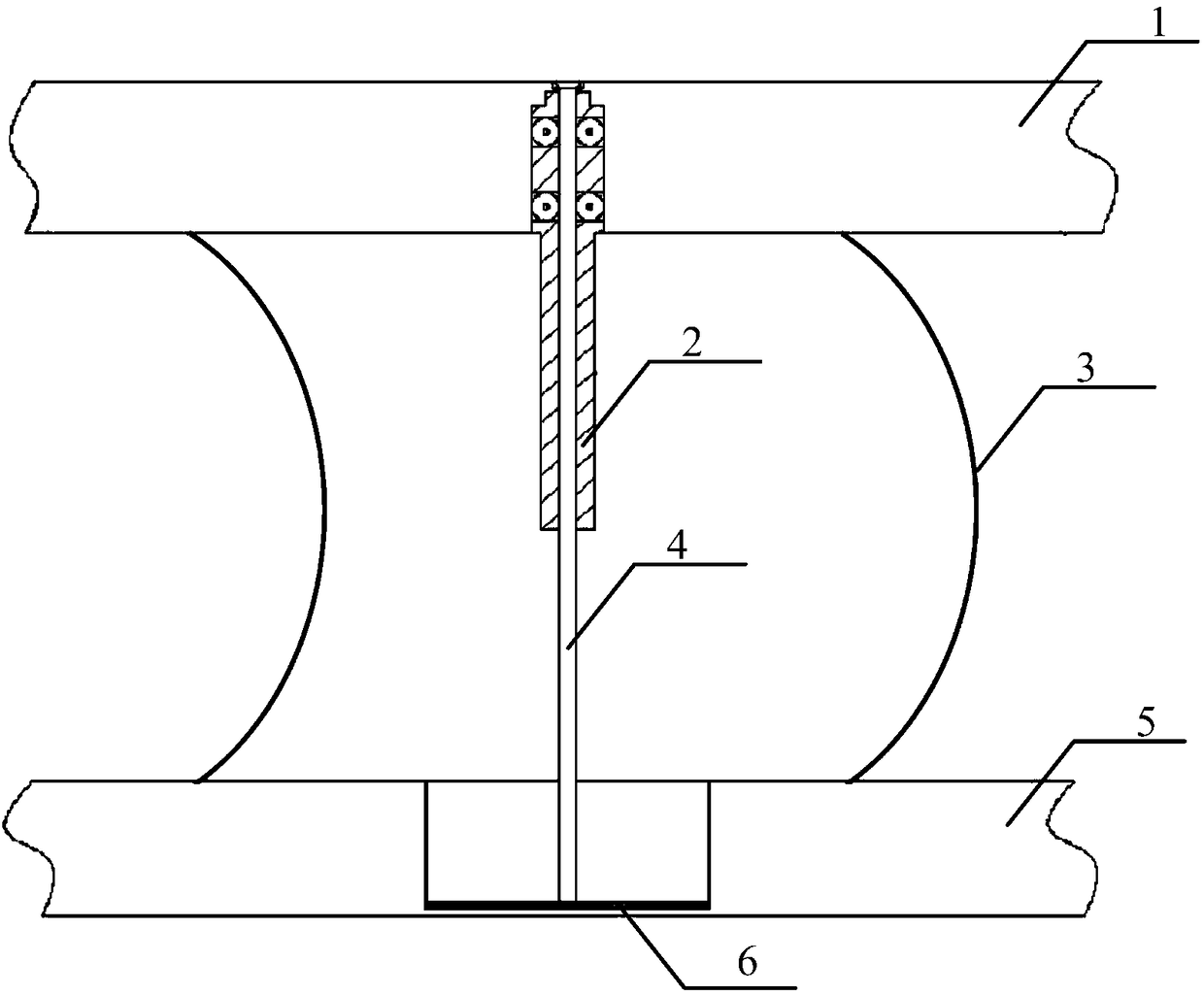

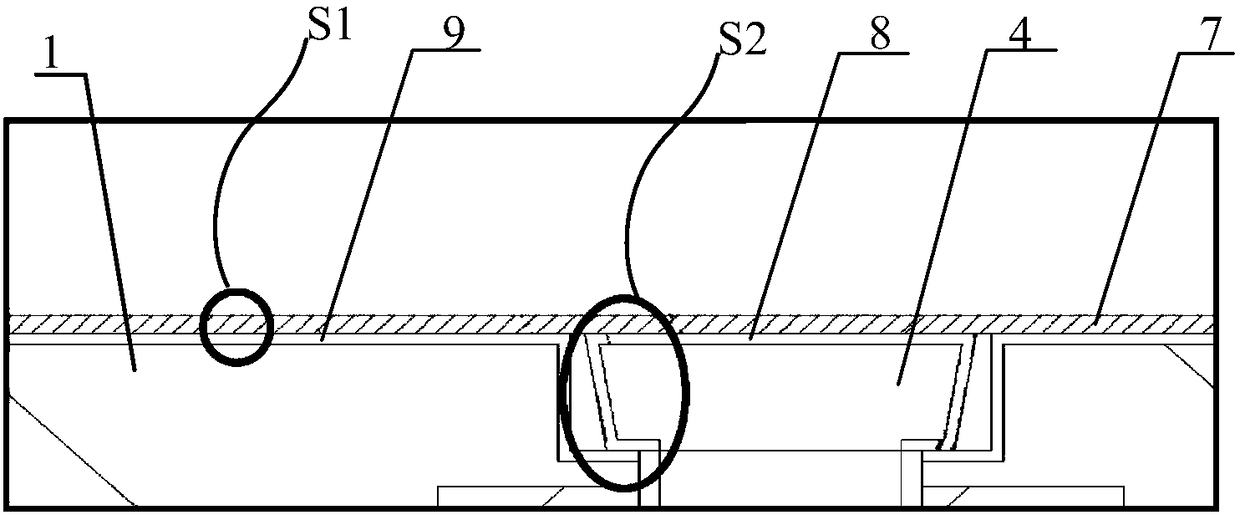

Substrate elevation pin and substrate processing device

ActiveCN104900571AReduce temperature differenceImprove membrane qualitySemiconductor/solid-state device manufacturingConveyor partsEngineering

Owner:沈境植

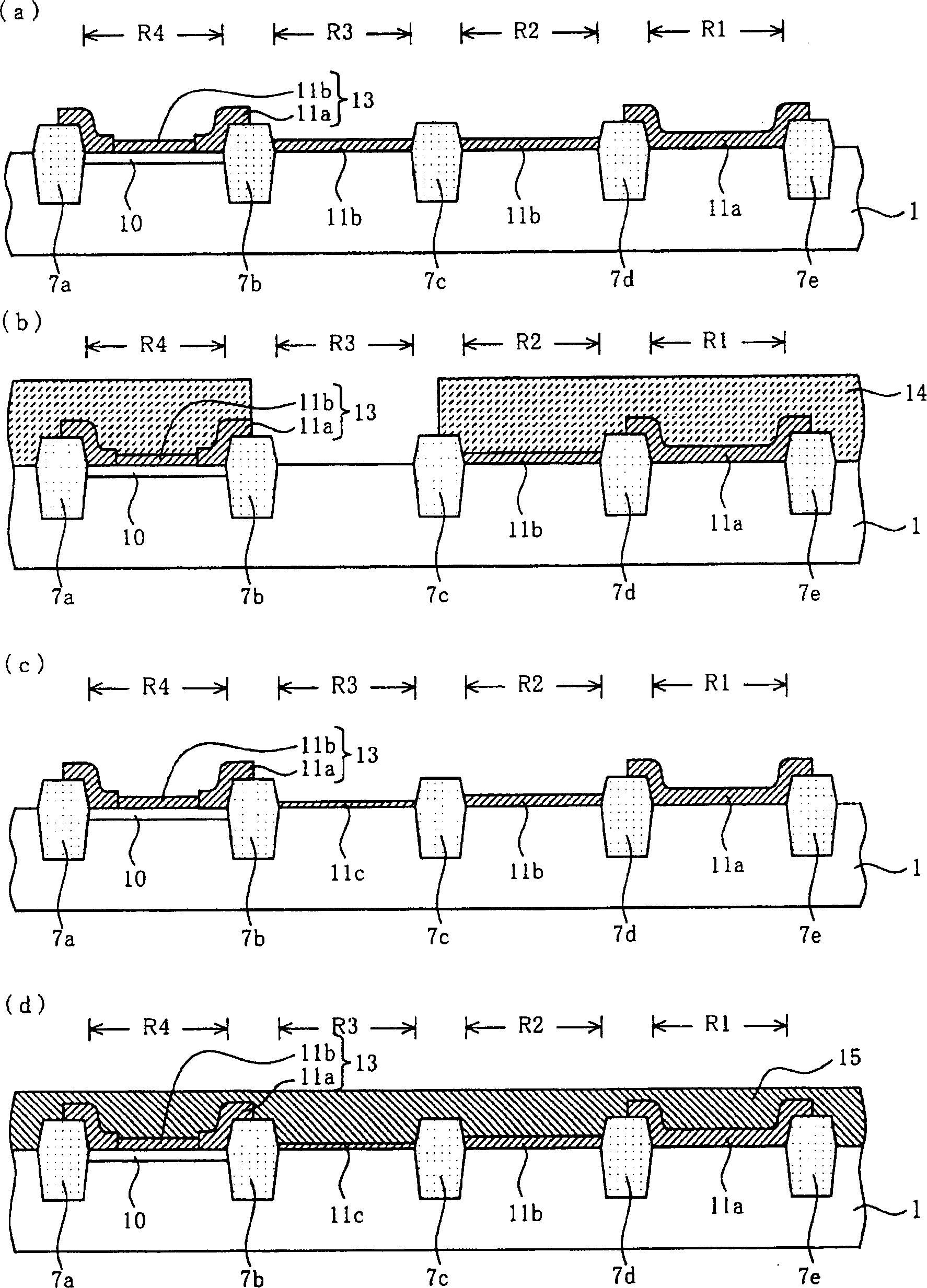

Silicon crystallization method

InactiveCN101445958AImprove membrane qualityVarious characteristics improvedPolycrystalline material growthSemiconductor/solid-state device manufacturingAmorphous siliconThermal treatment

The present invention provides a silicon crystallization method for manufacturing polysilicon with excellent crystallization characteristic. The silicon crystallization method of the invention is characterized in that including (a) a step of allocating metallic catalyst on amorphous silicon, (b) a step of thermal treatment with a first thermal treatment temperature, and (c) a step of thermal treatment with a second thermal treatment temperature, wherein the first thermal treatment temperature is less than the second thermal treatment temperature.

Owner:TERASEMICON CO LTD

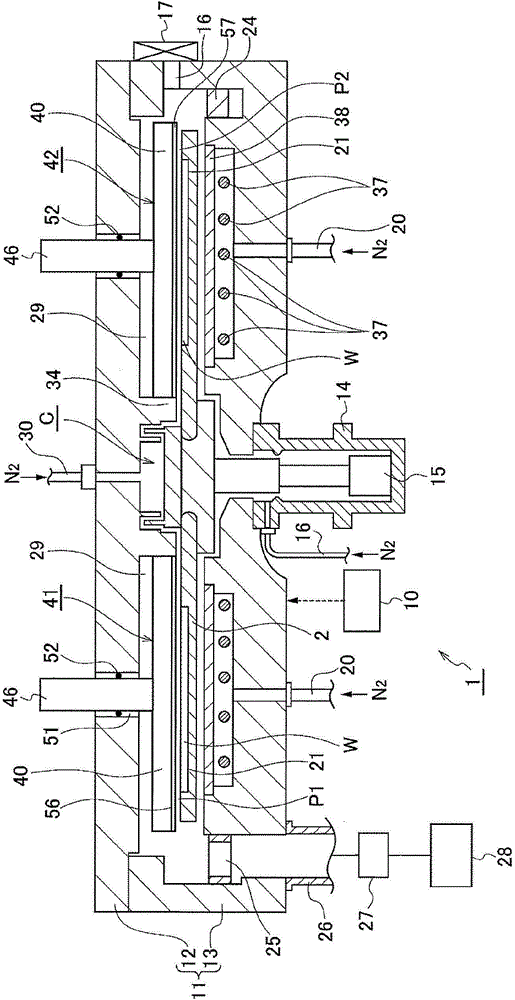

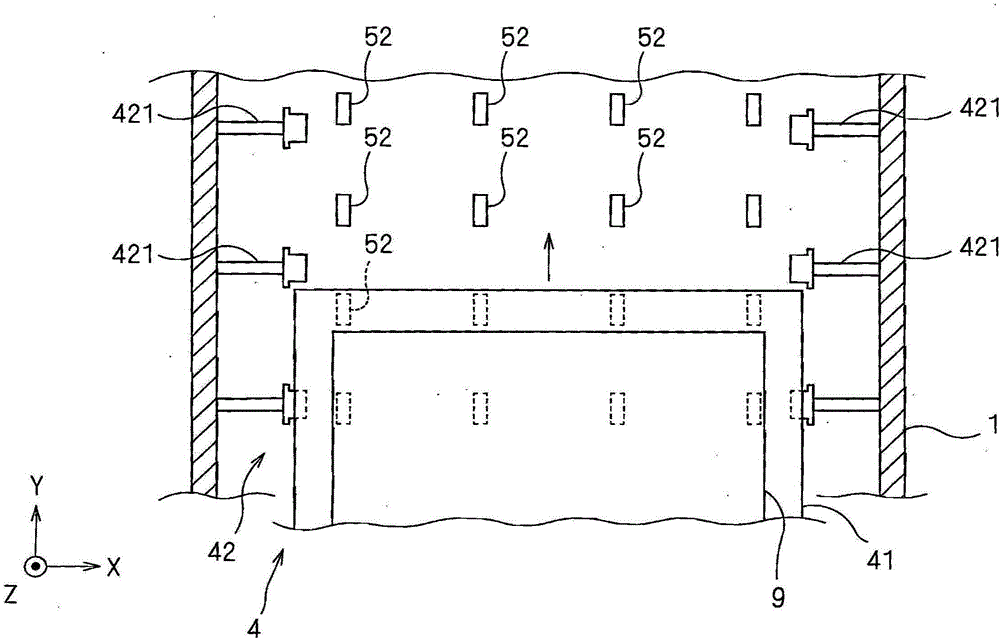

Film deposition apparatus

ActiveCN104805416AFast film formationImprove membrane qualityChemical vapor deposition coatingGas-discharge lampDecomposition

A film deposition apparatus includes a vacuum chamber, and a turntable having a substrate receiving area provided in the vacuum chamber. A heating unit is provided to heat the turntable so as to heat the substrate up to 600 degrees C. or higher. A process gas supply part is provided to supply a process gas having a decomposition temperature of 520 degrees C. or lower under 1 atmospheric pressure or lower, to the substrate. A gas shower head is provided in the process gas supply part and has a plurality of gas discharge holes provided in an opposed part facing a passing area of the substrate placed on the turntable. A cooling mechanism is provided in the process gas supply part and is configured to cool the opposed part in the gas shower head up to a temperature lower than the decomposition temperature of the process gas.

Owner:TOKYO ELECTRON LTD

Plasma treatment apparatus

InactiveCN102833937APlasma density distribution improvedImproved uniformity of plasma density distributionElectric discharge tubesSemiconductor/solid-state device manufacturingElectrical conductorPotential difference

Owner:NISSIN ELECTRIC CO LTD

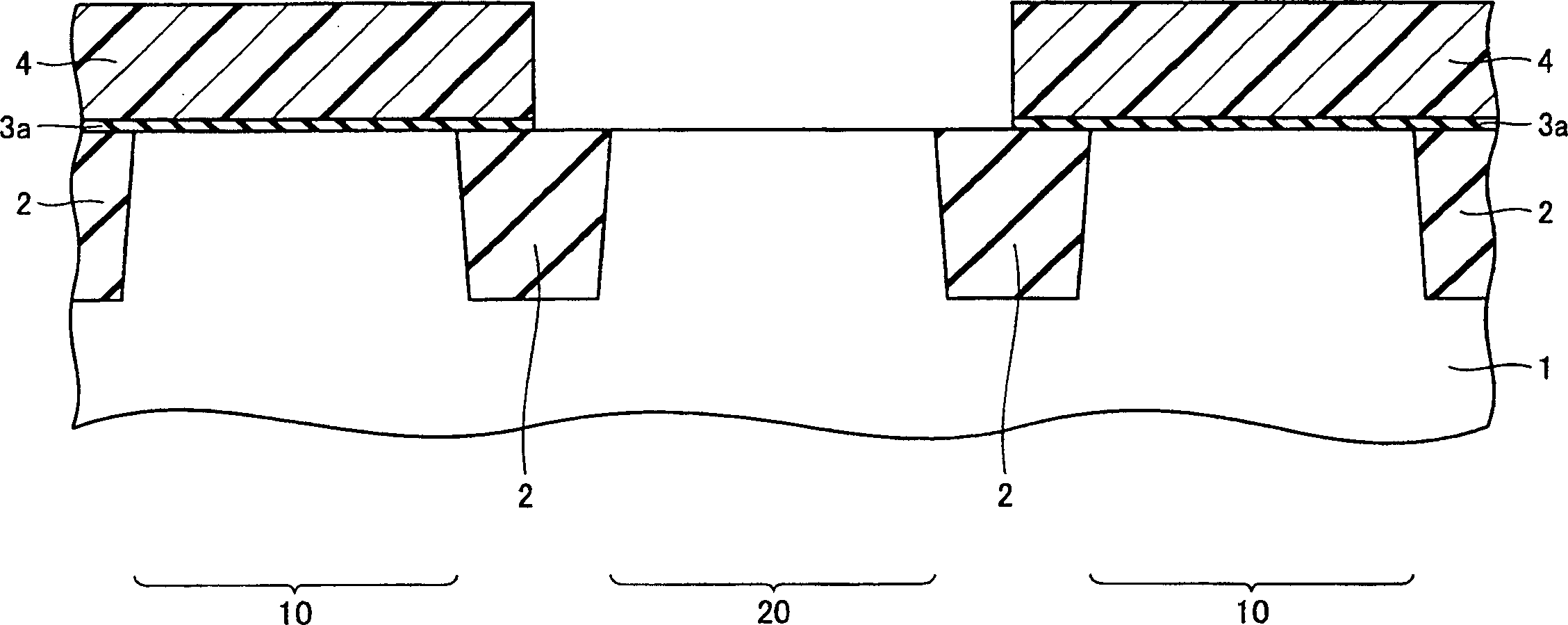

Method for depositing insulating film on recessed portion having high aspect ratio

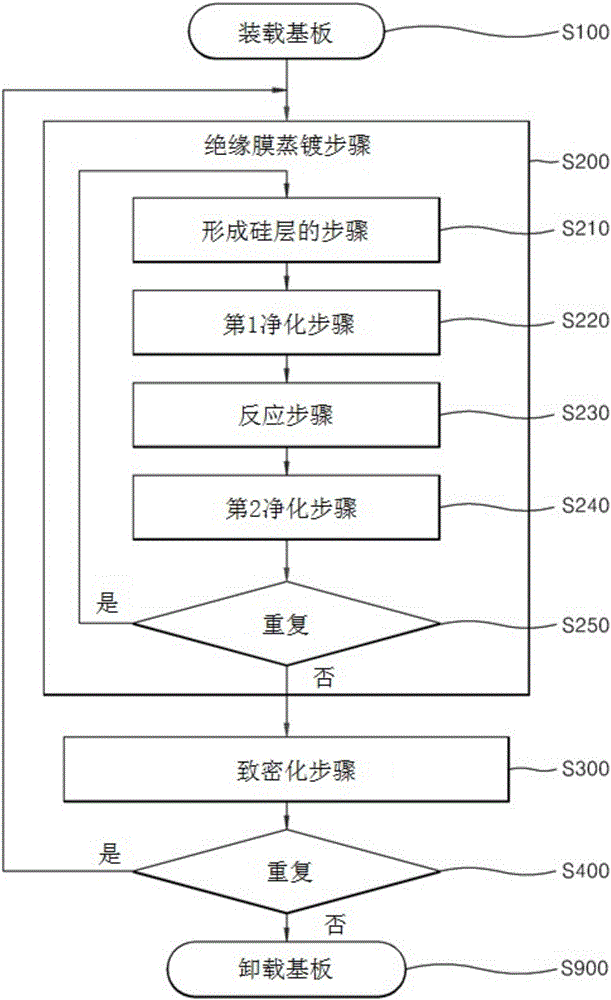

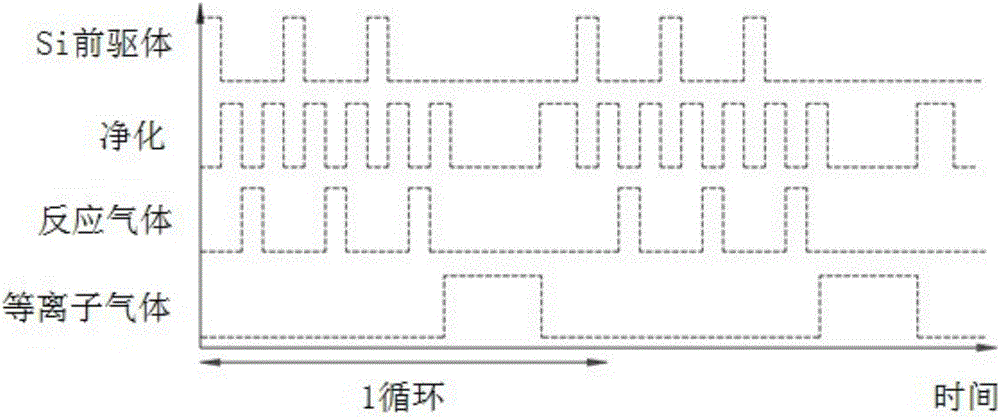

ActiveCN106489190AImprove membrane qualitySemiconductor/solid-state device manufacturingReaction stepSilicon

According to one embodiment of the present invention, a method for depositing an insulating film on a recessed portion in a substrate, in which the recessed portion having an aspect ratio of 5:1 or greater is formed, comprises: an insulating film deposition step of performing an adsorption step of injecting a silicon precursor into a chamber in which the substrate is loaded so as to adsorb silicon onto the substrate, a first purge step of removing an unreacted silicon precursor and a reaction byproduct from the inside of the chamber, a reaction step of forming the silicon, having been adsorbed, by providing a first reaction source to the interior of the chamber as an insulating film including silicon, and a second purge step of removing an unreacted first reaction source and a reaction byproduct from the interior of the chamber; and a densification step of forming a plasma atmosphere inside the chamber by applying RF power thereto, and densifying the insulating film including silicon by using the plasma atmosphere, wherein the frequency of the RF power ranges from 400 kHz to 2 MHz.

Owner:EUGENE TECH CO LTD

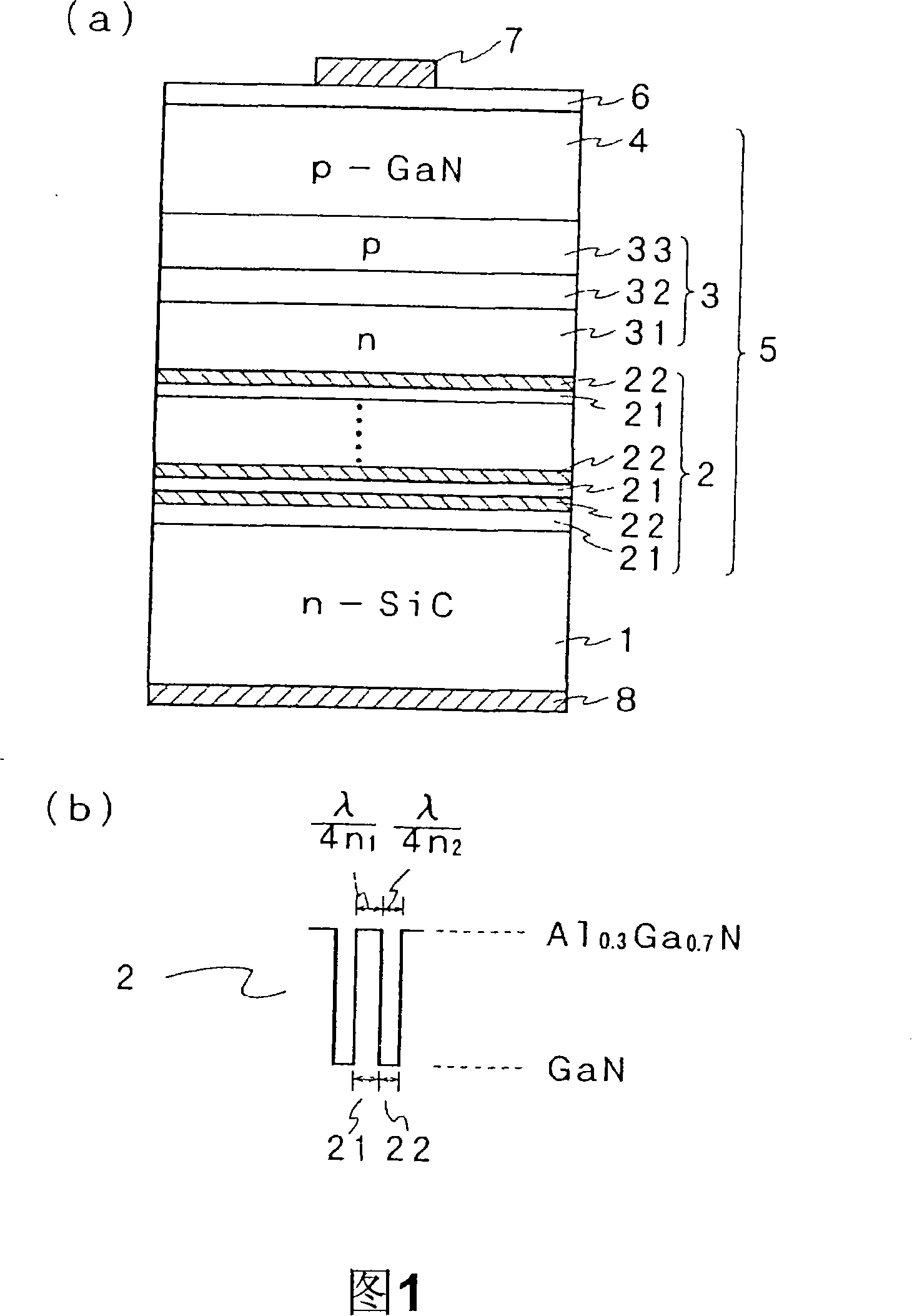

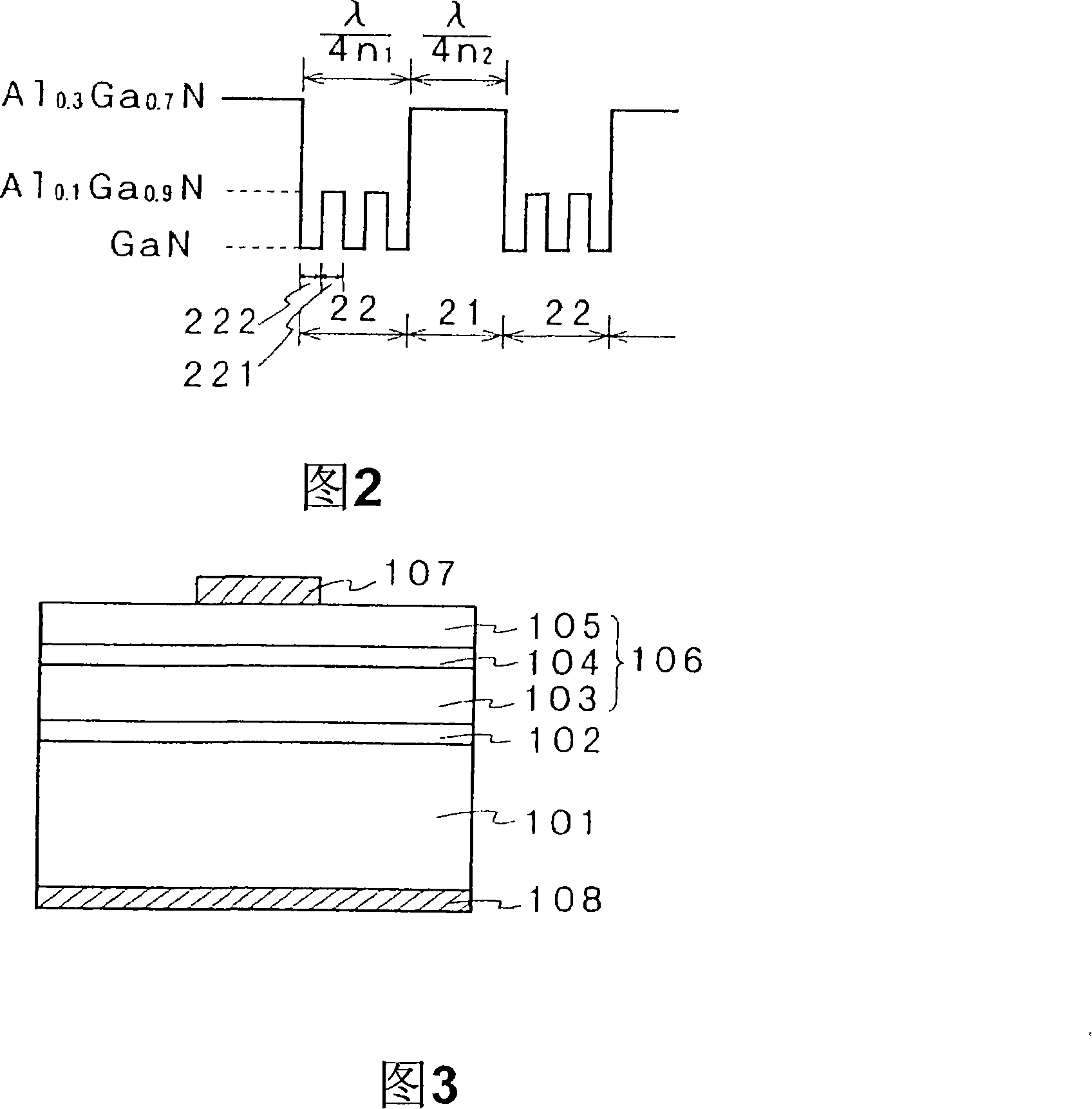

Nitride semiconductor light emitting element

InactiveCN101180743AHigh crystallinityImprove membrane qualityLaser detailsSemiconductor lasersLattice mismatchRefractive index

Owner:ROHM CO LTD

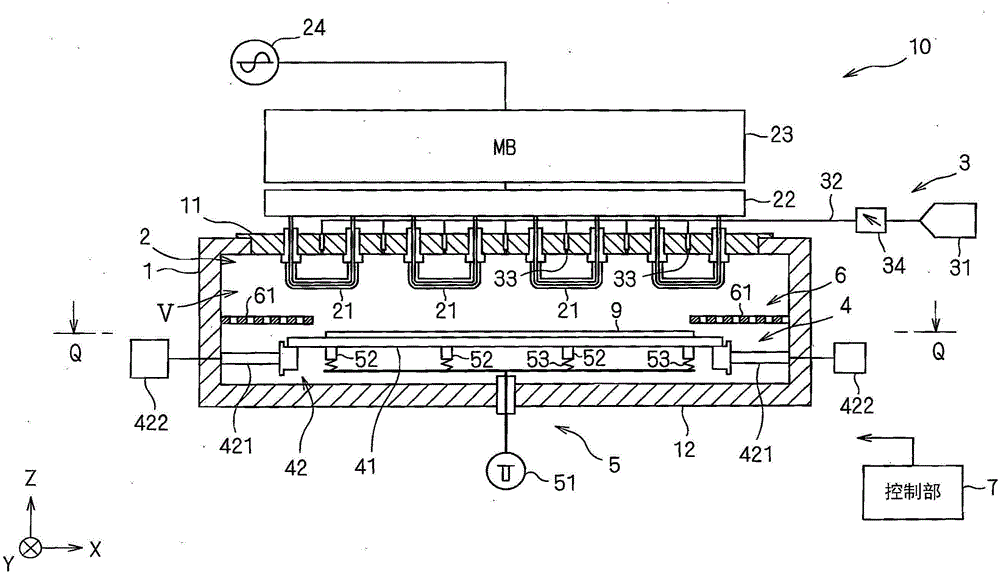

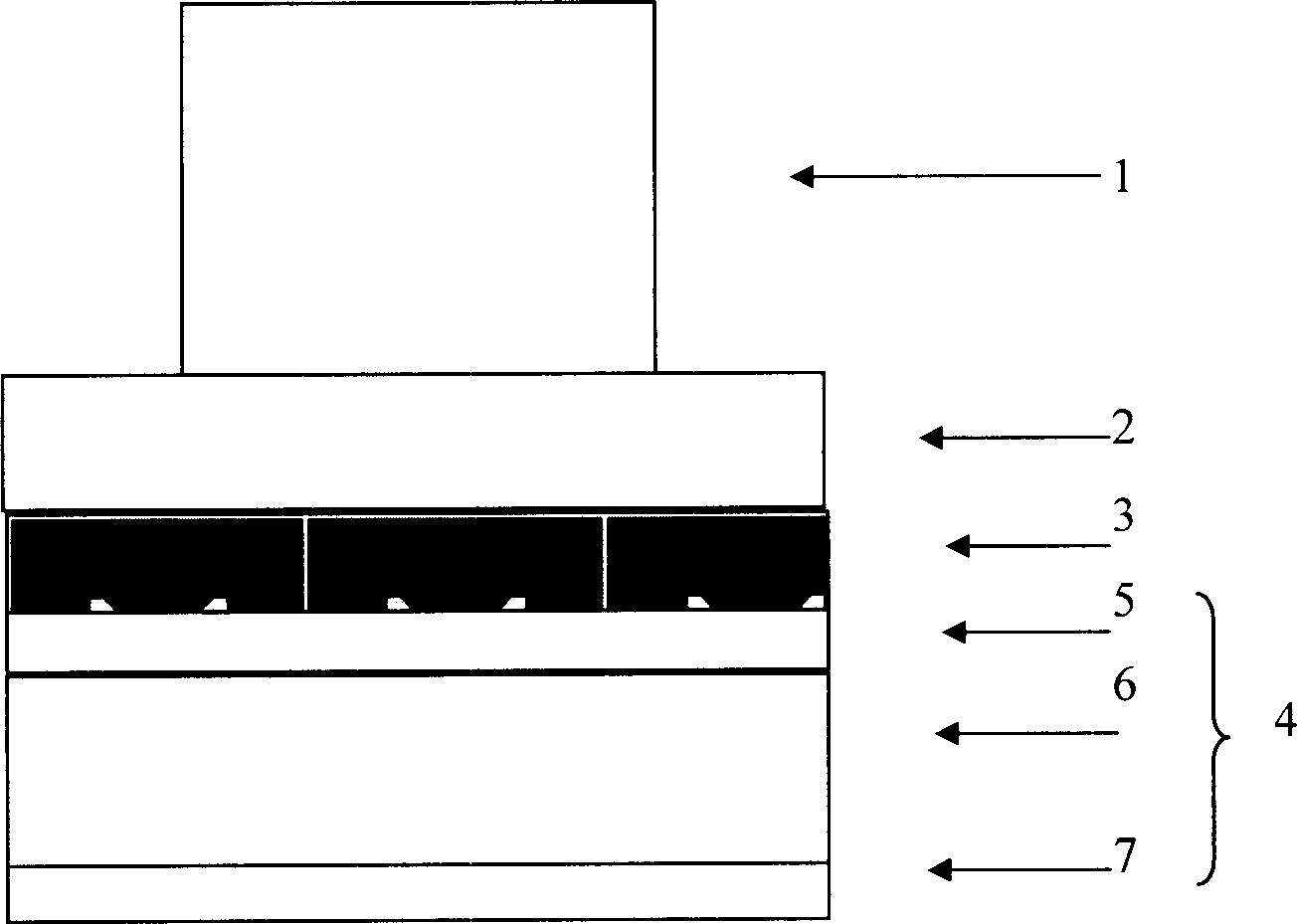

Film forming device and method

ActiveCN104947067AHigh film forming efficiencySimple structureVacuum evaporation coatingSputtering coatingEngineeringHigh frequency

The invention provides a film forming device and method capable of improving filming efficiency of a diamond film; the film forming device (10) comprises the following elements: a chamber (1) with a processing room (V); a low inductance coupling antenna (21) arranged in the processing room (V); a high frequency power supply portion (24) intermittently supplying power to the inductance coupling antenna (21); an air supply portion (3) supplying hydrocarbon air to the processing room (V); a relative mobile portion (4) enabling a substrate material (9), being object material of film formation, to move against the inductance coupling antenna (21); a voltage application portion (5) used for applying cathode voltage to the substrate material (9) when high frequency power is temporally stopped to the inductance coupling antenna (21).

Owner:SCREEN HLDG CO LTD

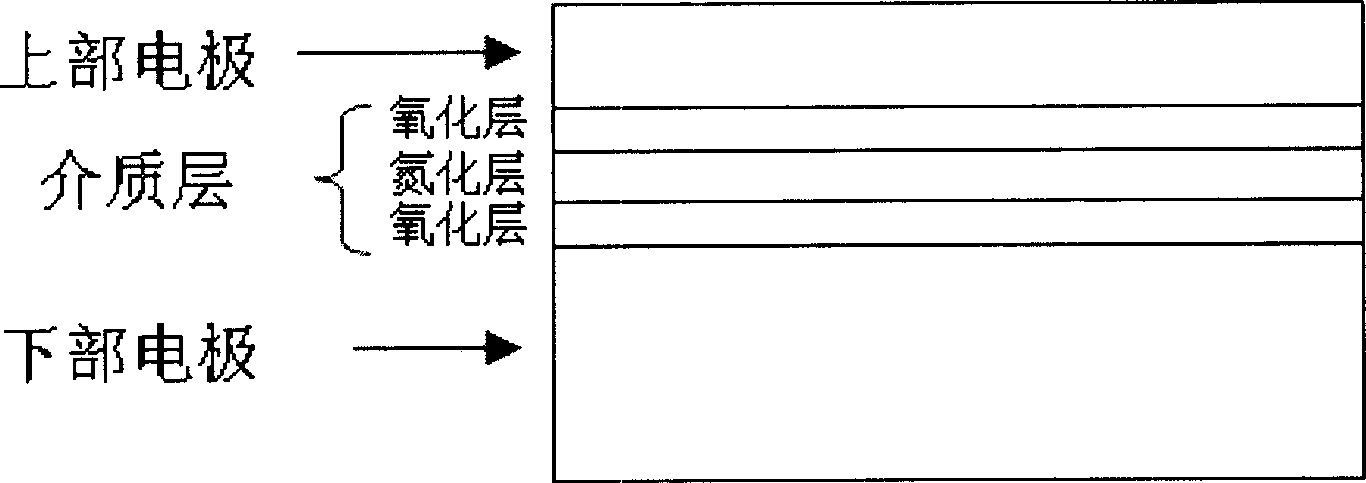

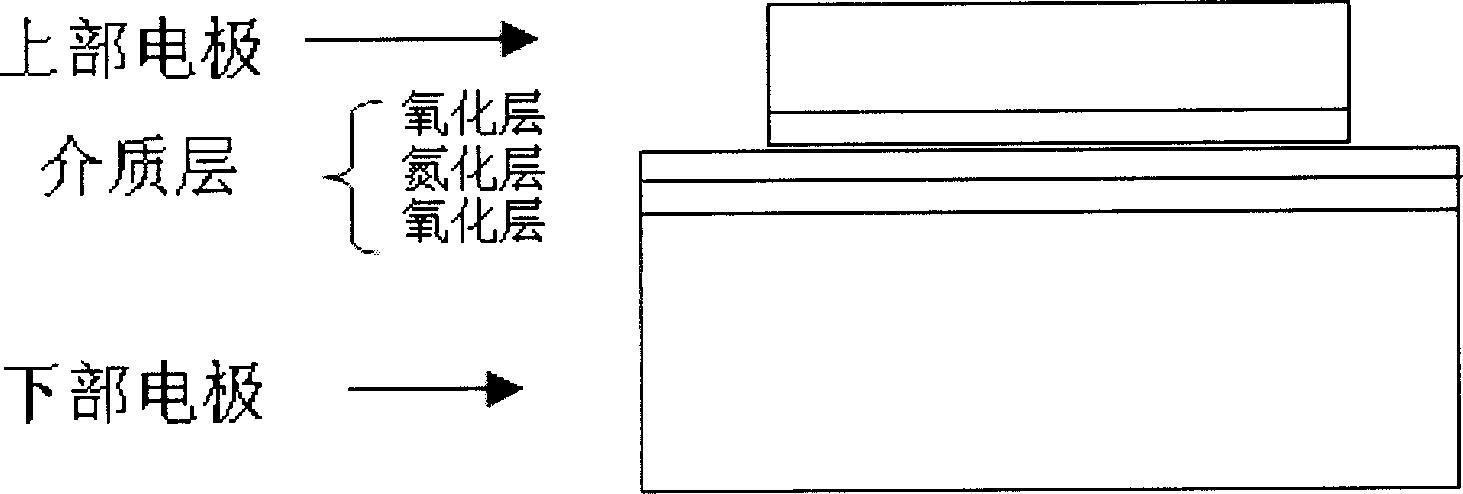

Structure of semiconductor metal capacitor and etching method

InactiveCN1893119AUniform thicknessImprove membrane qualityTransistorSemiconductor/solid-state device manufacturingCapacitanceSemiconductor alloys

The structure of semiconductor alloy capacitance includes lower electrode, dielectric layer and upper electrode in sequence from lower to upper. The dielectric layer includes an oxide film layer, an ammoniated film layer, and another oxide film layer from lower to upper. Using multiple dielectric layers, the structure makes semiconductor alloy capacitance possible to reserve each advantage of oxide film layer, and ammoniated film layer, and overcome disadvantage of small dielectric coefficients of the film layers, and lot of pinholes on the film layers. The invention also discloses method for etching the capacitance. After etching out upper electrode, and using condition of selection ration in high etching speed, the method etches out uppermost oxide film layer, and stops etching operation when the ammoniated film layer is met. Advantages are: easy of implementation, large technical window for etching time, even thickness of dielectric layer, and raised quality and efficiency.

Owner:SHANGHAI HUA HONG NEC ELECTRONICS

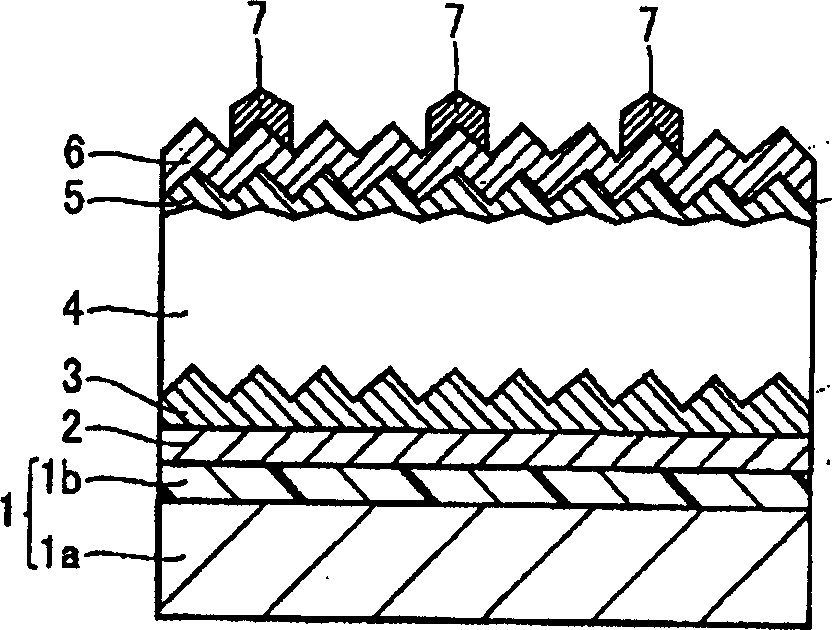

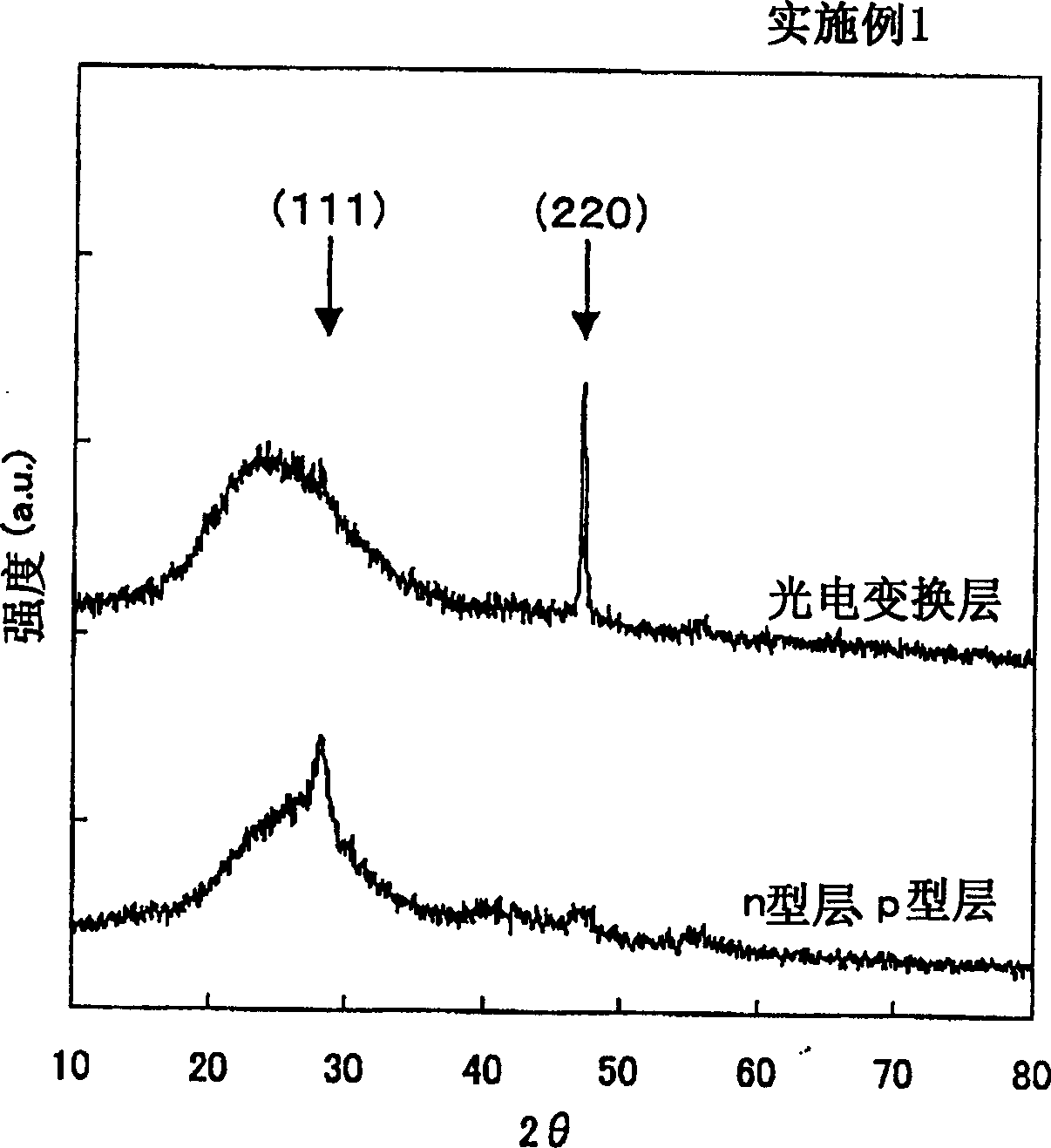

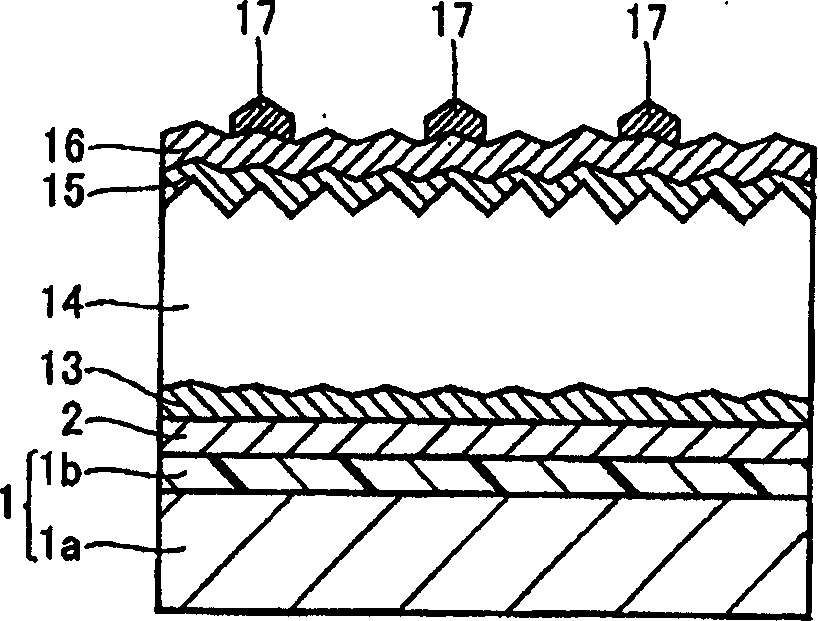

Photovoltaic apparatus

InactiveCN1595667AImprove membrane qualityGood photoelectric conversion characteristicsPhotovoltaic energy generationSemiconductor devicesCrystal orientationEngineering

A photovoltaic apparatus capable of improving output characteristics is provided. This photovoltaic apparatus includes at least one power generation unit having a first conductivity type first non-single-crystalline semiconductor layer (3, 13, 43, 53, 63, 73, 83) including at least one layer, a substantially intrinsic second non-single-crystalline semiconductor layer (4, 14, 44, 54, 64, 74, 84) including at least one layer and a second conductivity type third non-single-crystalline semiconductor layer (5, 15, 45, 55, 65, 75, 85) including at least one layer, and at least one of the layer constituting the first non-single-crystalline semiconductor layer, the layer constituting the second non-single-crystalline semiconductor layer and the layer constituting the third non-single crystalline semiconductor layer has a preferred crystal orientation plane different from those of the remaining layers.

Owner:SANYO ELECTRIC CO LTD

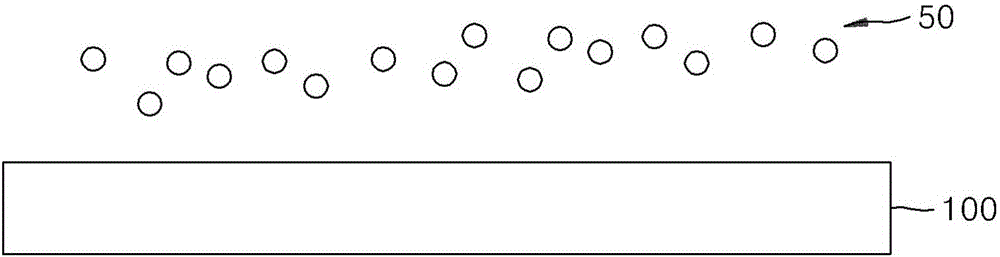

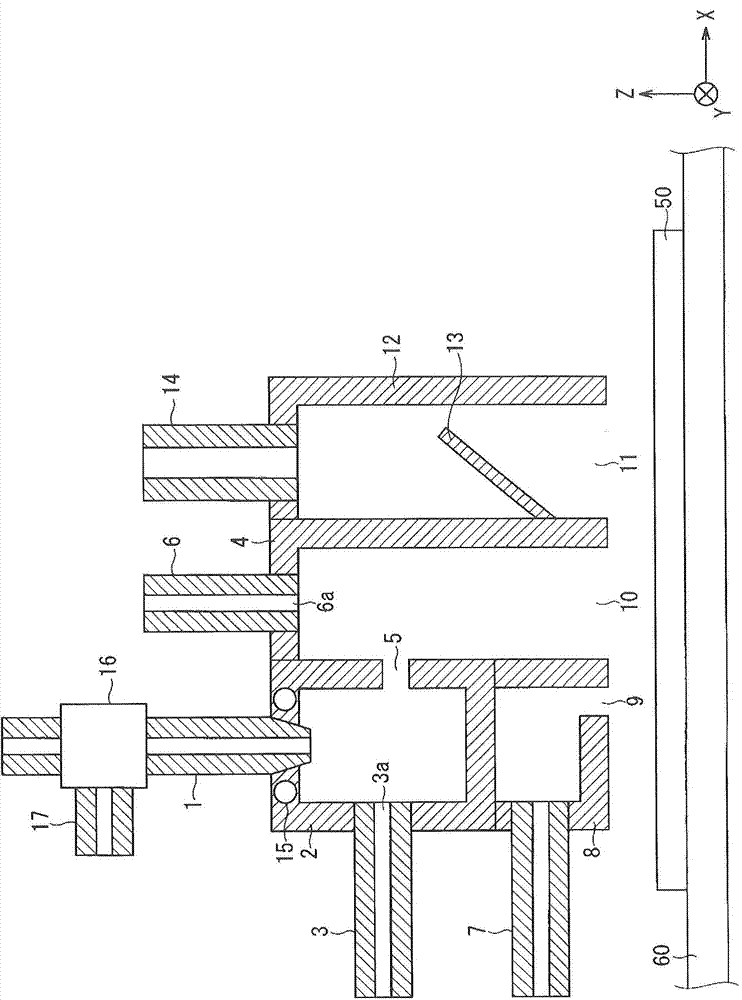

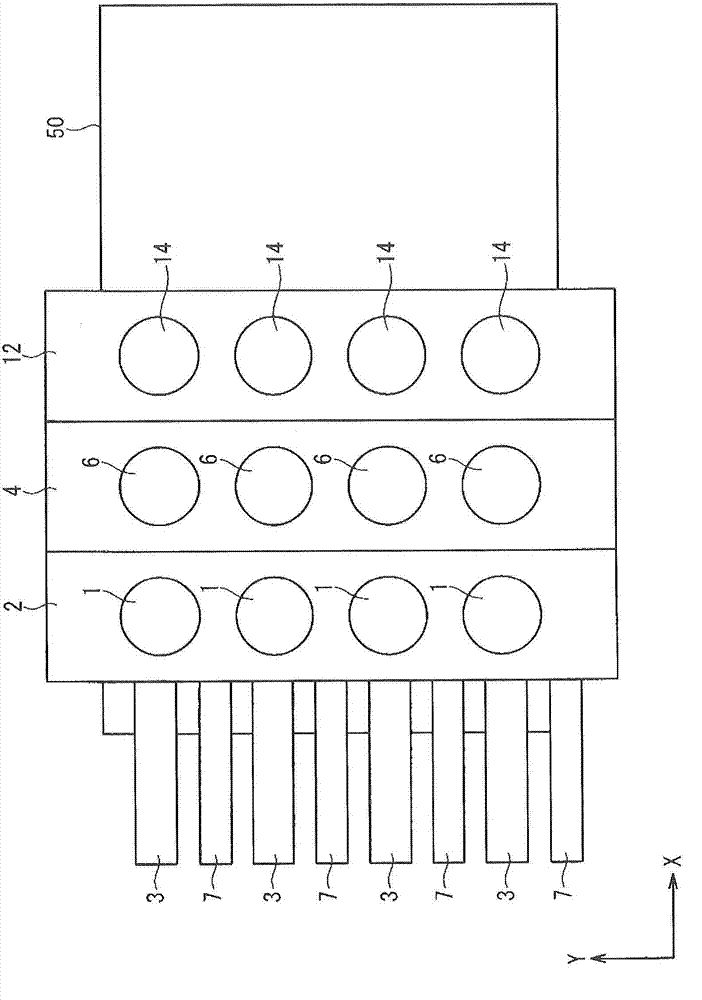

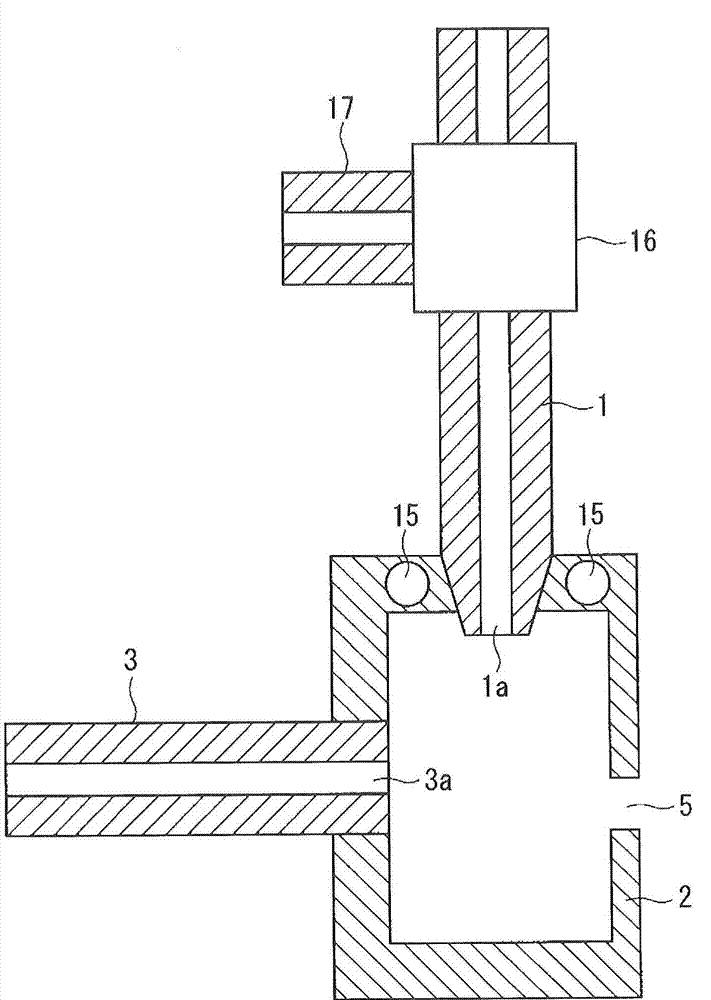

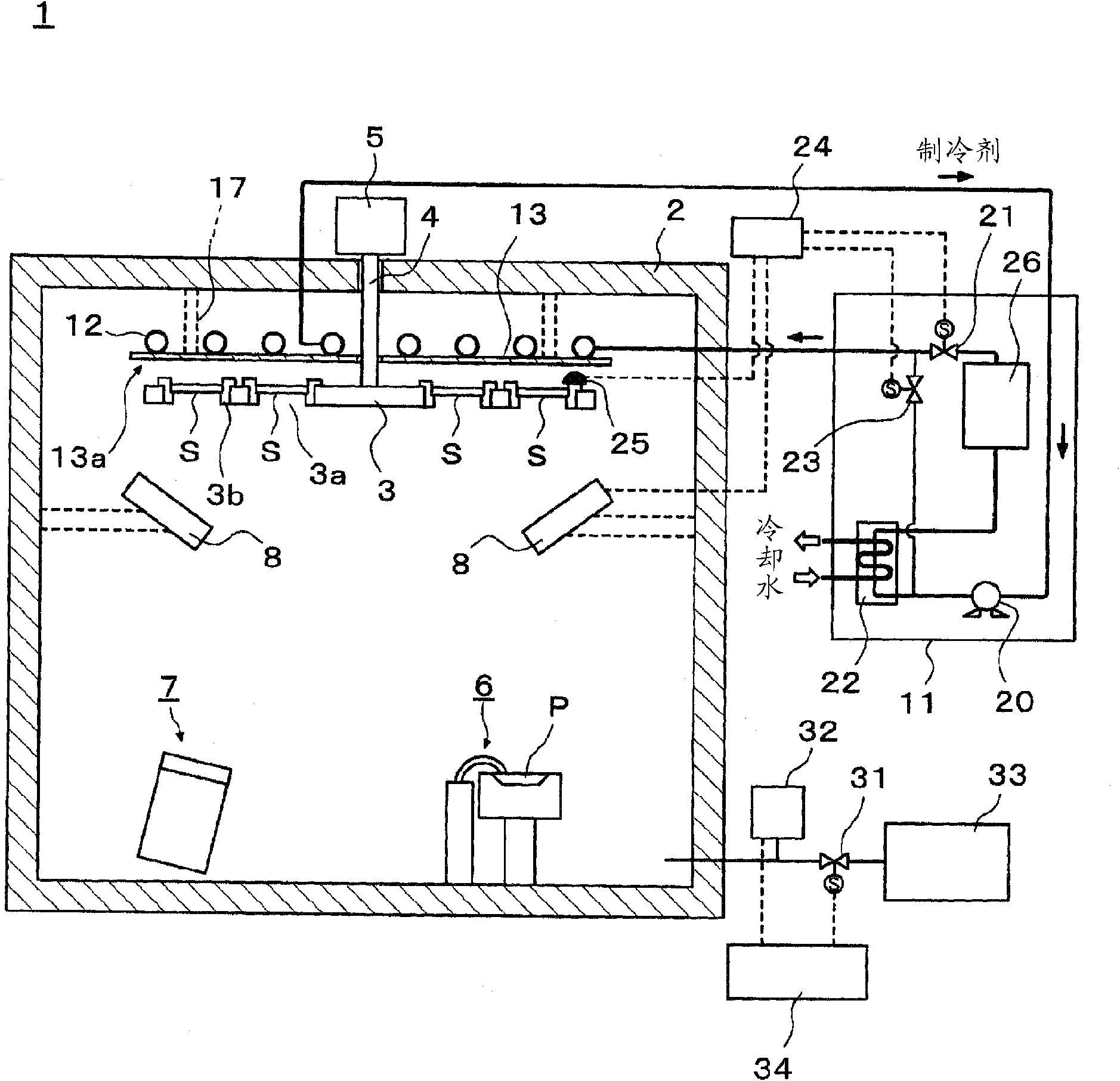

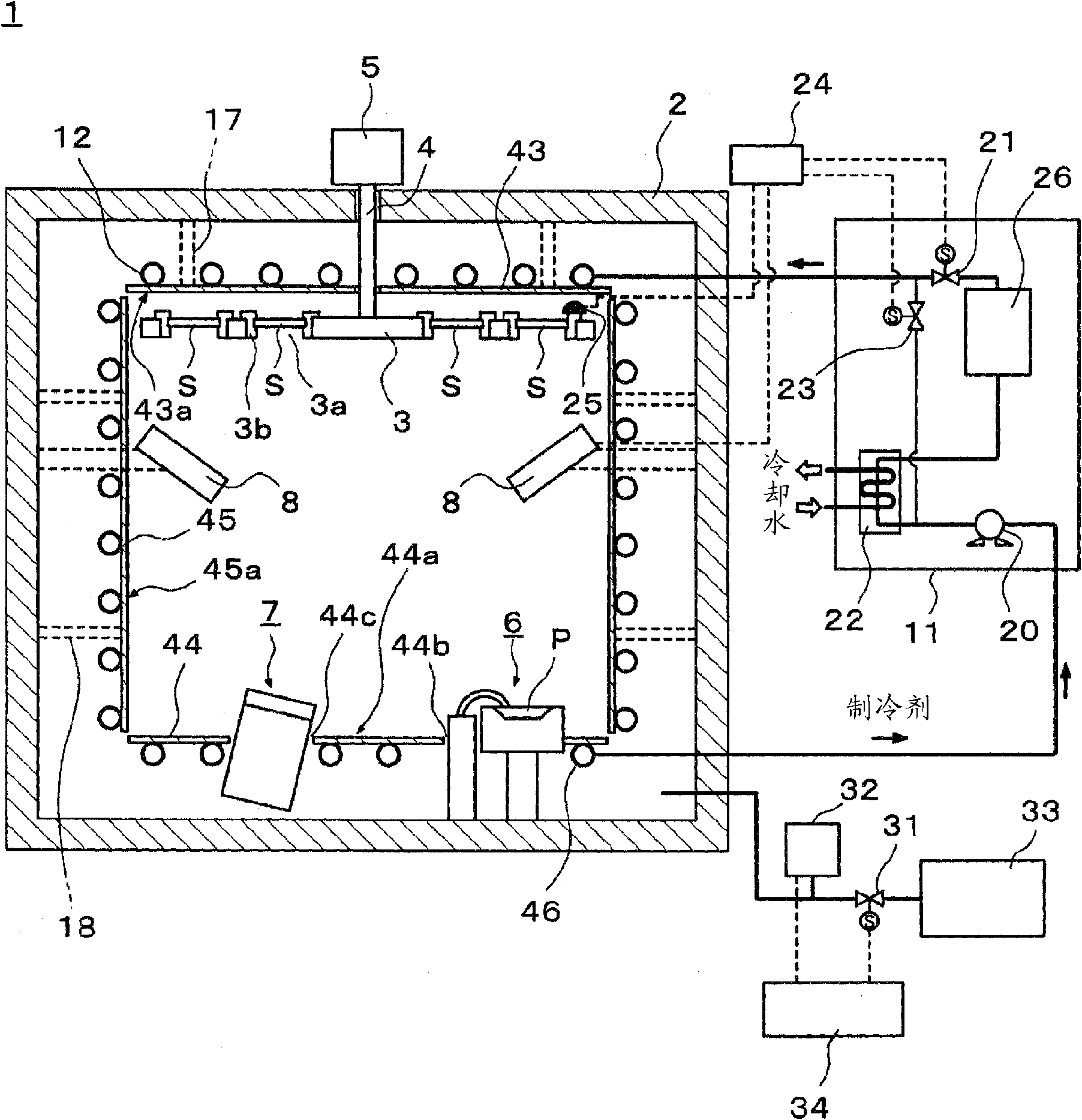

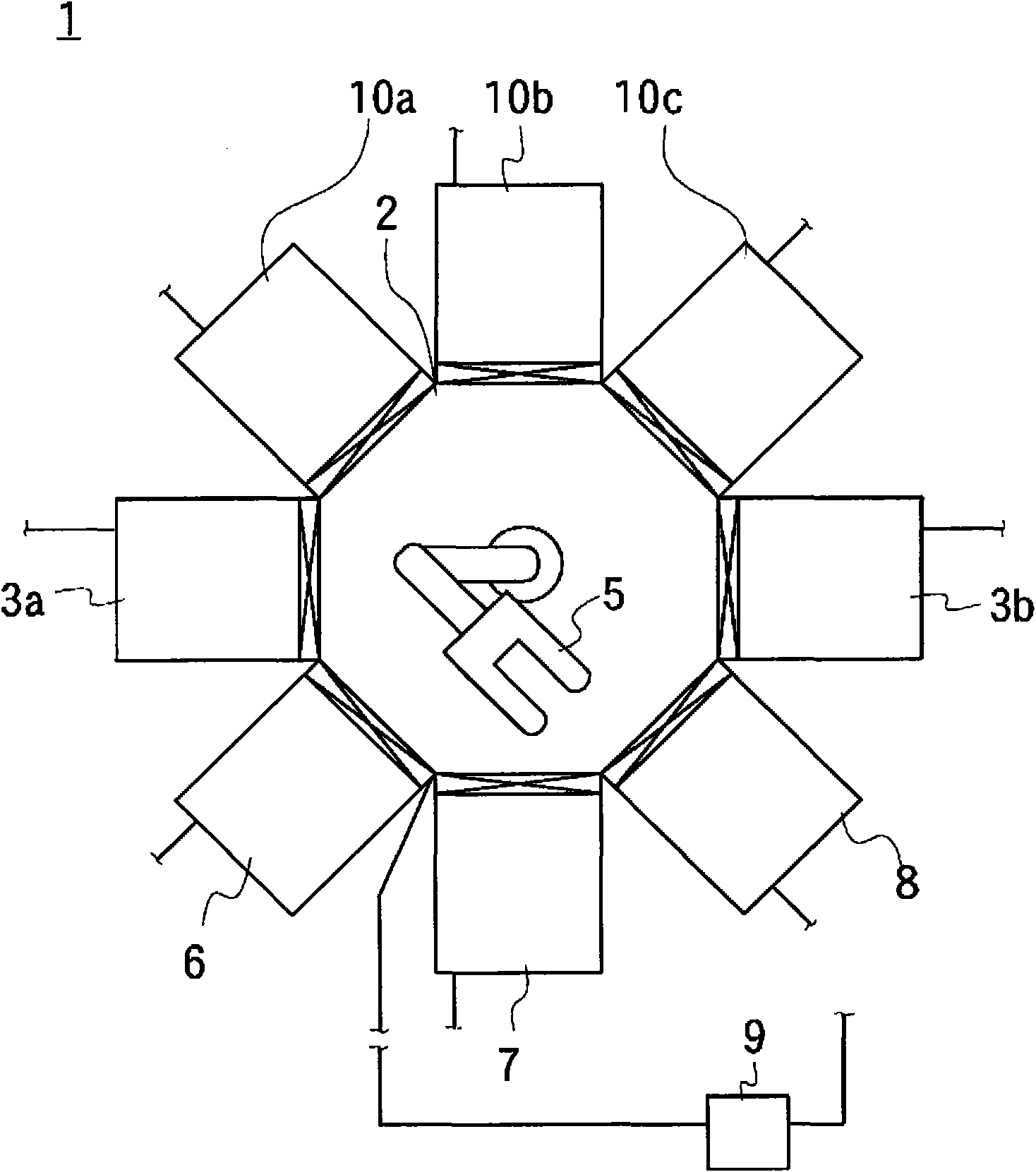

Film-forming apparatus

ActiveCN104755174AShorten the transportation distancePrevent coagulationSpray nozzlesLiquid spraying apparatusSpray nozzleEngineering

The present invention provides a film-forming apparatus, which is capable of forming, on a substrate, a film having excellent film qualities, and which is capable of effectively using a solution in a film-forming process, said film-forming apparatus having a small size as a whole. This film-forming apparatus is provided with a spray nozzle (1), a first chamber (2), a first gas supply port (3a), a second chamber (4), a through hole (5), and a spraying port (10). The solution jetted in a droplet form from the spray nozzle (1) is stored in the first chamber (2), and the solution is atomized in the first chamber (2) by means of a gas supplied through the first gas supply port (3a). The atomized solution moves from the first chamber (2) to the second chamber (4) through the through hole (5), and is sprayed toward a substrate (50) from the spraying port (10) that is provided in the second chamber (4).

Owner:TOSHIBA MITSUBISHI-ELECTRIC IND SYST CORP

Method of manufacturing semiconductor device

InactiveCN1542947AReduce legacy stressImprove membrane qualityTransistorBathroom accessoriesSemiconductorThermal oxide

A method of manufacturing a semiconductor device includes the steps of: forming first and second active areas at a main surface of a silicon substrate; forming a first thermal oxide film on the main surface of the silicon substrate; selectively removing a prescribed portion of the first thermal oxide film to expose the second active area; forming a second thermal oxide film on the first and second active areas; performing an annealing process on the first and second thermal oxide films at or above a temperature for forming the second thermal oxide film; and forming first and second gate electrodes on the first and second active areas such that the first and second thermal oxide films undergoing the annealing process lie between them. Consequently, a method of manufacturing a semiconductor device wherein residual stress inside a semiconductor substrate is reduced is provided.

Owner:RENESAS TECH CORP

Magnesium oxide single crystal and method for producing same

ActiveCN101146936AImprove membrane qualityImprove qualityPolycrystalline material growthVacuum evaporation coatingSingle crystalCalcium content

The present invention provides a single crystal MgO used to obtain a magnesium oxide (MgO) single crystal vapor deposition material which can prevent splashing without reducing the vapor deposition time when the vapor deposition material is vapor deposited by an electron beam vapor deposition method or the like. and providing a single crystal MgO used to obtain a single crystal MgO substrate capable of forming, for example, a superconductor thin film excellent in superconducting properties. The calcium content of the single crystal MgO is 150×10-6 to 1000×10-6 kg / kg, the silicon content is 10×10-6 kg / kg or less, and the polished surface of the single crystal MgO is analyzed by TOF-SIMS The change in the detected amount of calcium fragment ions was 30% or less in terms of CV value. Also provided are a single crystal MgO vapor deposition material obtained from the single crystal MgO and a single crystal MgO substrate for thin film formation.

Owner:TATEHO CHEM IND CO

Method for preparing ultraviolet excited or vacuum ultraviolet excited green emitting phosphor

InactiveCN102888224AHigh luminous intensityHigh retention rateLuminescent compositionsMass ratioPhosphor

The invention discloses a method for preparing ultraviolet excited or vacuum ultraviolet excited green emitting phosphor. The method comprises the following steps of: weighing Al2O3, MgO, Tb3O4 and CeO2 in a mass ratio, sieving all raw materials by using a 100-mesh sieve, mixing by a dry method, introducing one or more of BaCO3, MgCl2, AlF3, MgF2, BaF2 and H3BO3 into the uniformly mixed raw materials, and fully mixing; loading the mixed powder into an alumina crucible; firing at high temperature at reducing atmosphere; crushing the fired fluorescent powder blocks, and sieving by using the 100-mesh sieve; dispersing by a wet method to obtain slurry; controlling the particle size to be 2 to 12 mu m; sieving the slurry which is obtained by wet-method dispersing by using a 500-mesh sieve; removing the sieving residues on the 500-mesh sieve; washing with water; and suction-filtering, drying and screening to obtain the green emitting phosphor. The green emitting phosphor has the characteristics of controllable particle size, high brightness, light failure, color development and low color bleaching.

Owner:CAIHONG GRP ELECTRONICS CO LTD

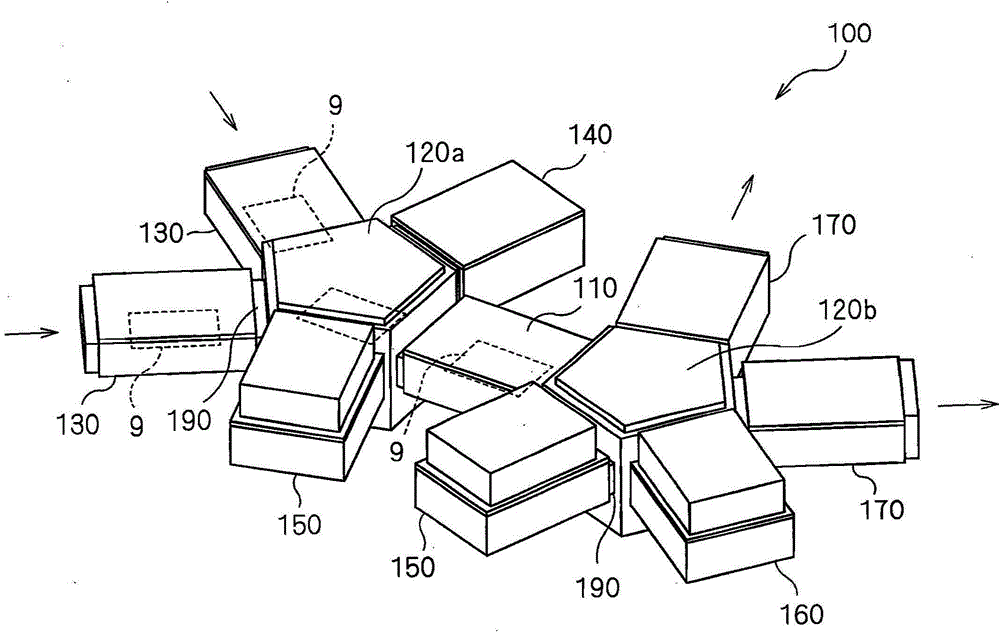

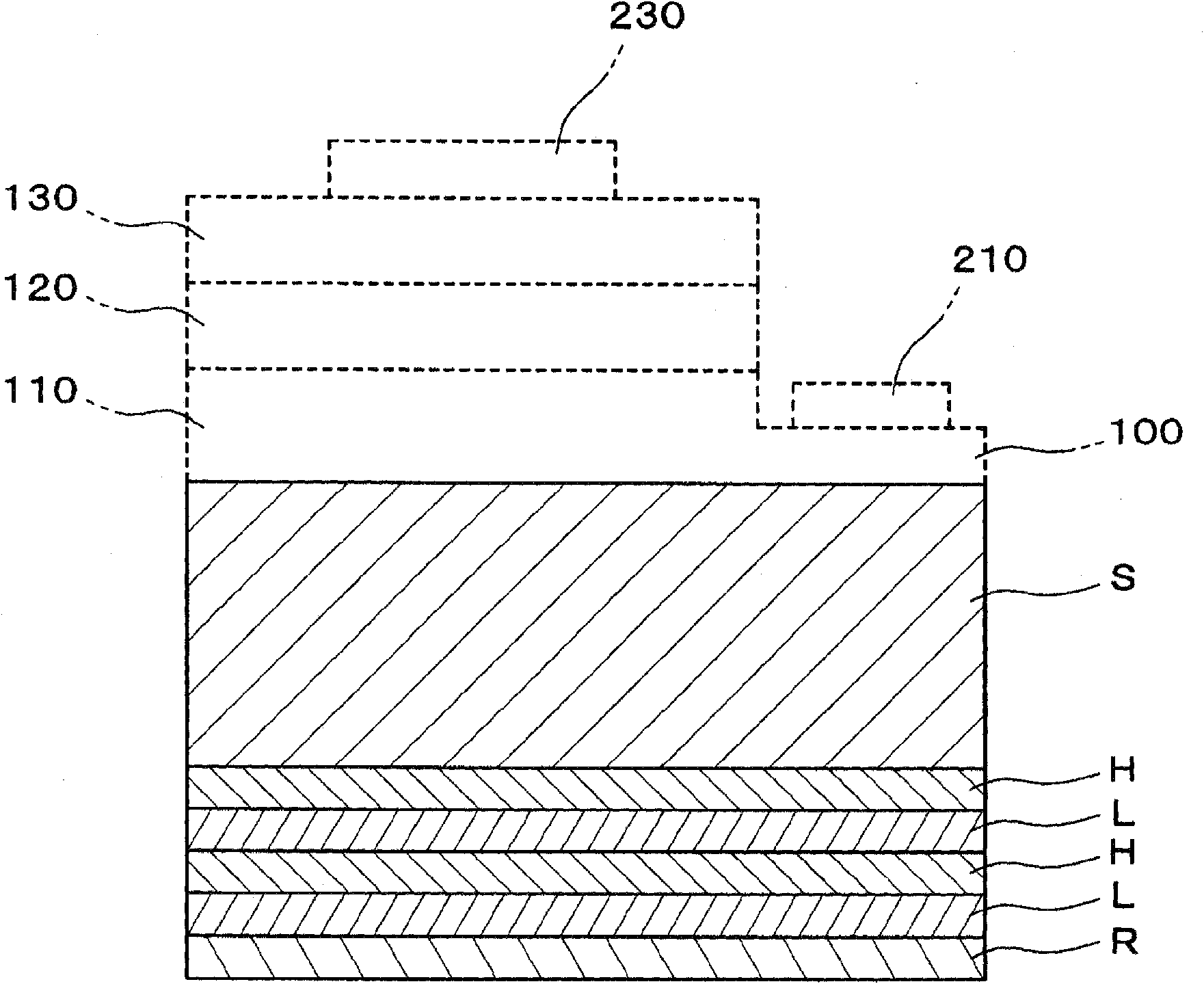

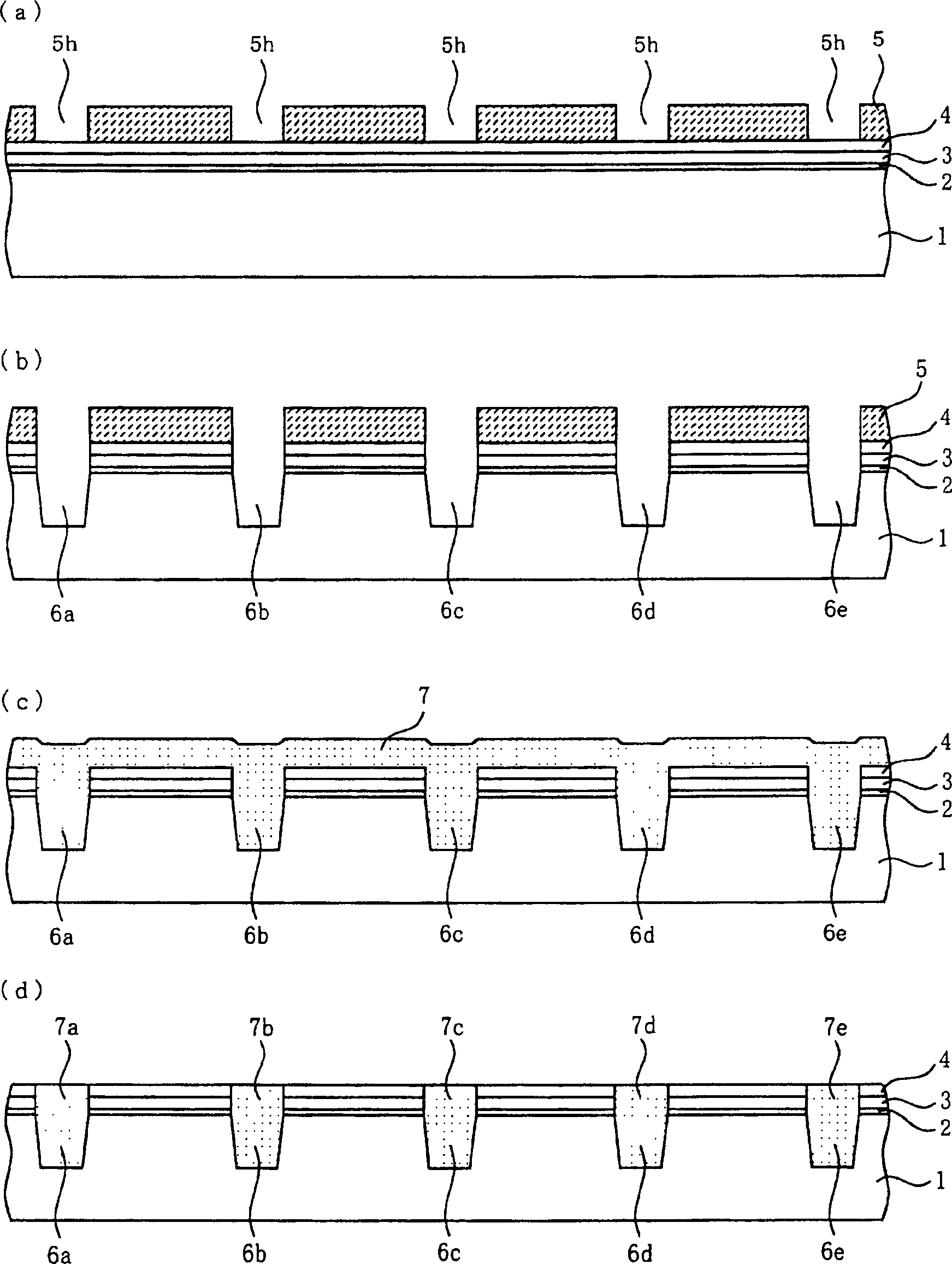

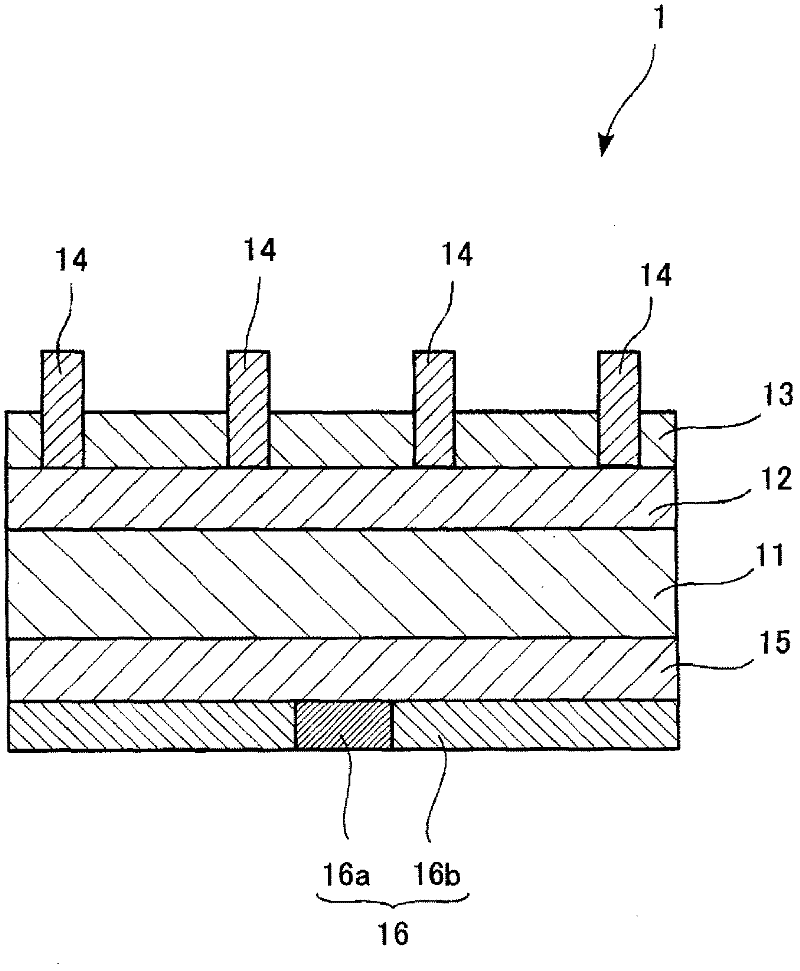

Process for production of semiconductor light-emitting element substrate

ActiveCN102439195AImprove workabilityImprove production efficiencyVacuum evaporation coatingSemiconductor/solid-state device manufacturingOptoelectronicsReflective layer

Disclosed is a process for producing a high-performance semiconductor light-emitting element substrate, which has a reduced production time. Specifically disclosed is a process for producing a semiconductor light-emitting element substrate, which is characterized by comprising: a substrate heating step (S3) of heating a substrate; a substrate washing step (S6) of washing the substrate (S); a dielectric material layer formation step (S7) of depositing dielectric material layers (H, L) on the substrate (S); a substrate heating termination step (S8) of terminating the heating of the substrate; a cooling step (S9) of absorbing a radiation heat by means of cooling means (11, 12, 13) to cool the substrate (S) and a substrate supporting means (3); and a reflective layer formation step (S11) of depositing a reflective layer (R) on the dielectric material layers (H, L).

Owner:SHINCRON KK

Preparation of europium gadolinium yttrium oxide red fluorescent powder

InactiveCN101434404AIncrease brightnessGood colorRare earth metal compoundsTenebresent compositionsCrucibleGadolinium

The invention discloses a preparation method of yttria gadolinium-europium red fluorescent powder, which comprises the steps of: mixing 60-80 weight percent of Y2O3, 10-40 weight percent of Gd2O3 and 1-10 weight percent of Eu2O3 by a dry method after the materials are screened by a 100-mesh screen, putting the uniformly mixed materials in a crucible, firing the materials for 4-10 hours under the high temperature of 900-1400 DEG C, screening the fired fluorescent powder blocks by the 100-mesh screen, scattering the powder into slurry by a wet method, washing the scattered slurry for 2-5 times, then filtering and drying the slurry for 8-24 hours at 110-120 DEG C, and screening the dried powder by the 100-mesh screen to obtain the yttria gadolinium-europium red fluorescent powder.

Owner:CAIHONG GRP ELECTRONICS CO LTD

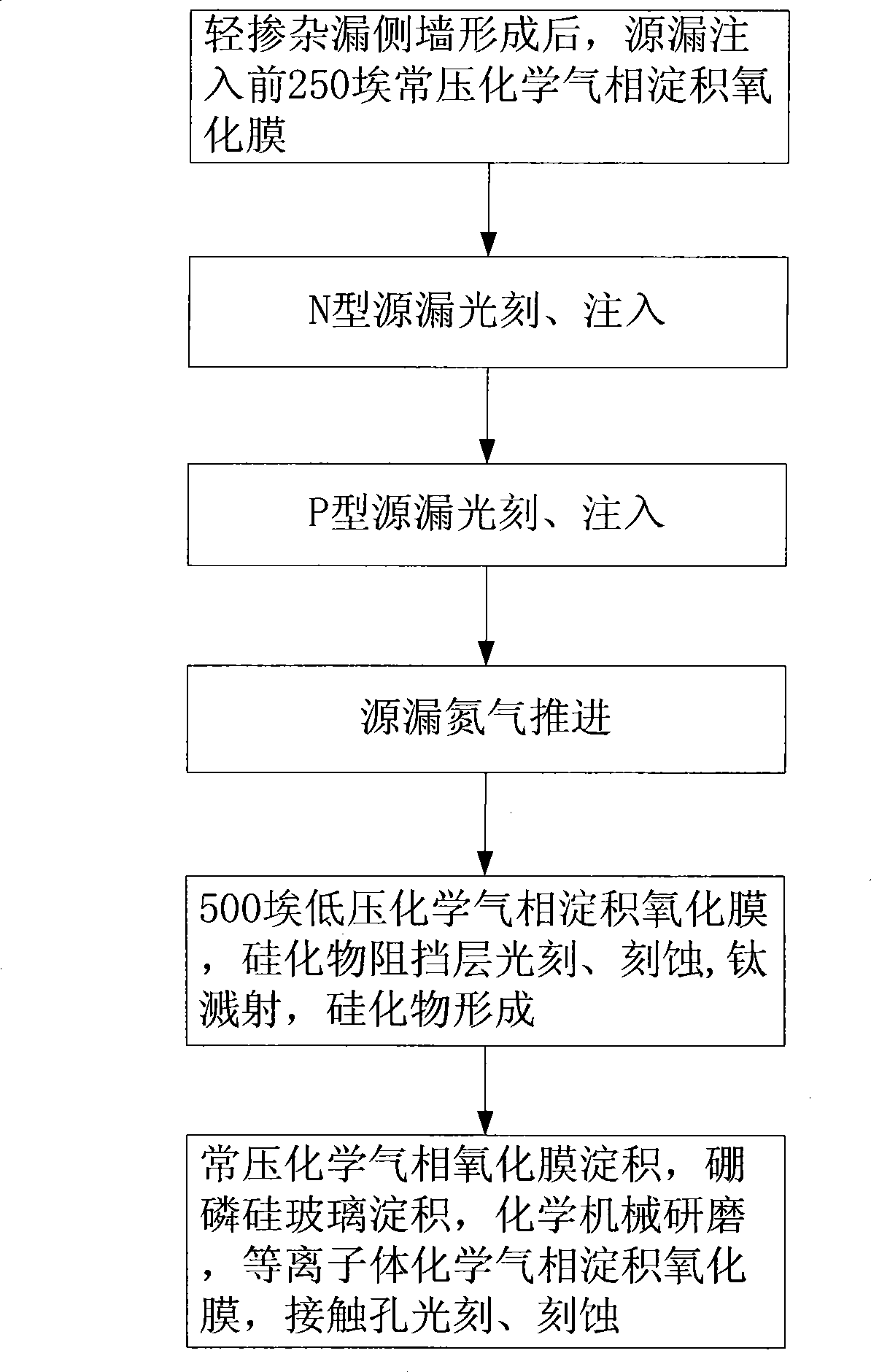

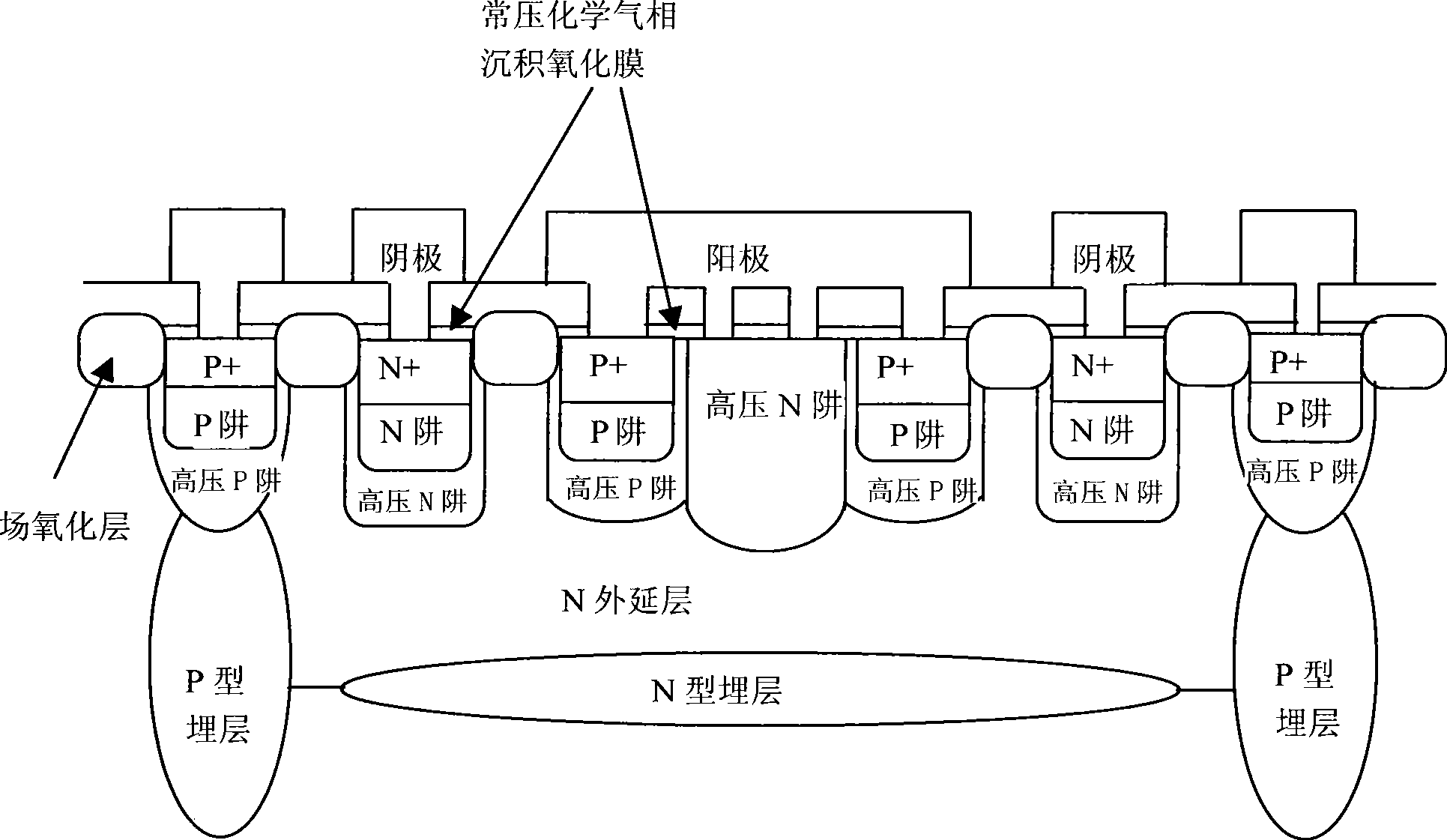

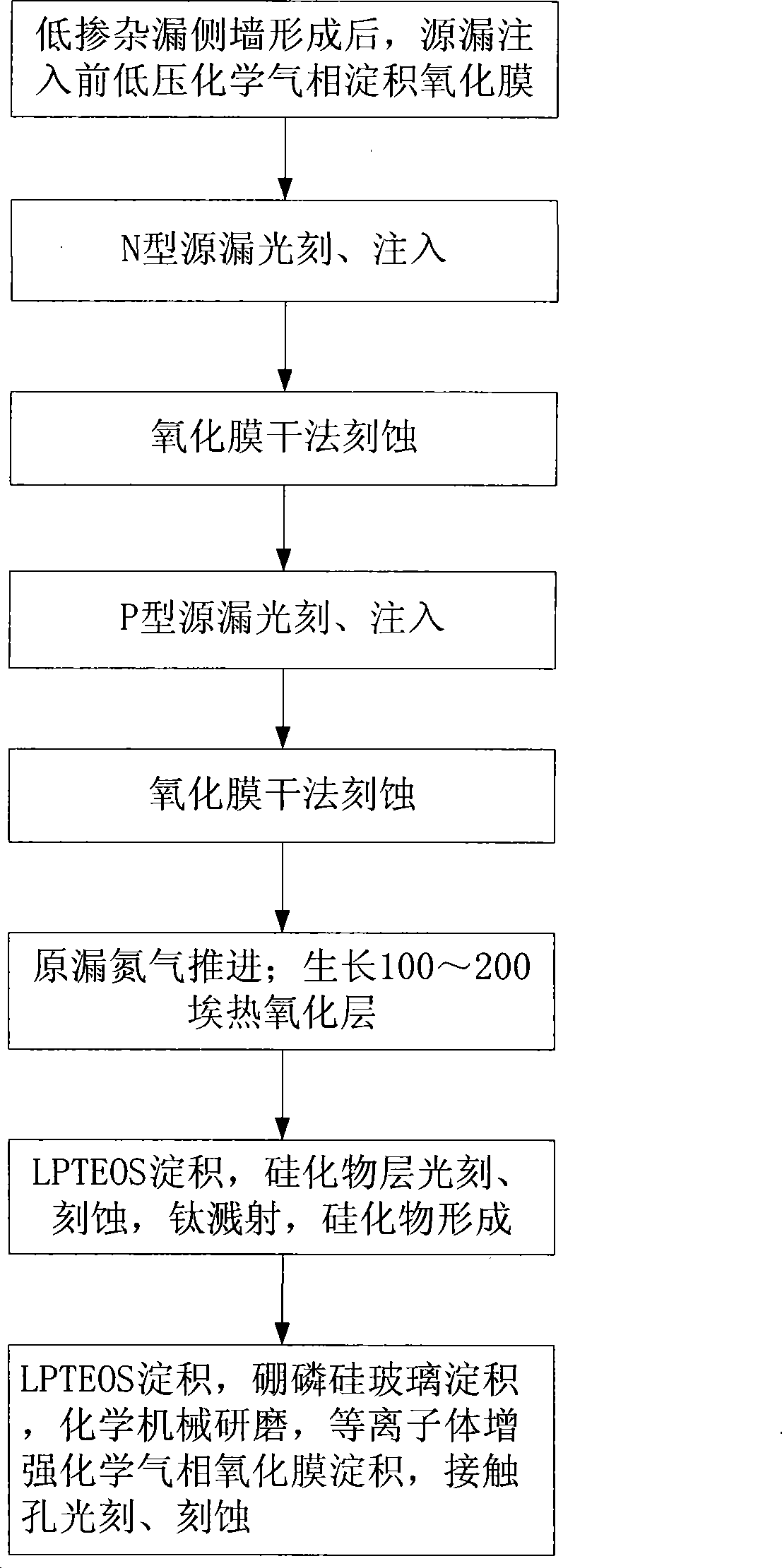

Manufacturing method for integrated schottky diode

ActiveCN101419938AUniform breakdown voltageImprove uniformitySemiconductor/solid-state device manufacturingGas phaseNitrogen

The invention discloses a manufacturing method of an integrated Schottky diode. A lightly doped drain side wall is formed and subject to low-pressure chemical vapor deposition, dry etching of the oxide film dry etching is performed after photoetching and implantation of N type source / drain and P type source / drain; and a thin thermal oxide layer is grown at the later stage of propelling source / drain nitrogen. The method helps greatly improve the uniformity of breakdown voltage of the Schottky diode without changing the existing process sequence and adding a heating process.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

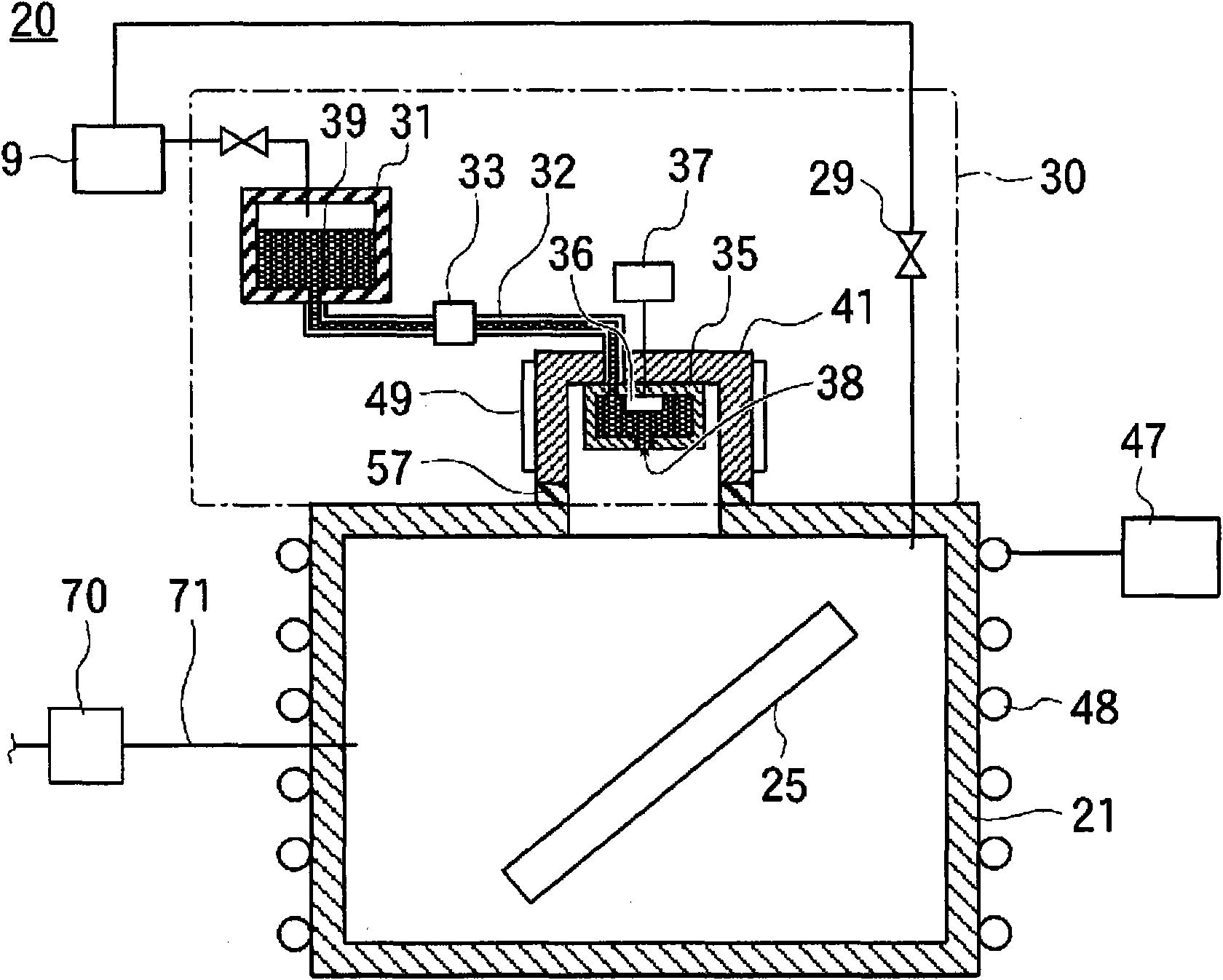

Vapor generator and vapor deposition apparatus

ActiveCN101946562AImprove membrane qualityEvaporation material deteriorationLiquid surface applicatorsElectroluminescent light sourcesVapor generatorEngineering

An organic thin film having excellent film qualities is formed. A vapor generating apparatus (20) is provided with an evaporation chamber (21), a jetting head (35) and a tank (31). A deposition material (39) is in the liquid state, stored in the tank (31) and supplied to the jetting head (35) from the tank (31). The jetting head (35) jets the deposition material (39), which has been supplied inside, from a jetting port (38), and places the deposition material on a heating member (25) inside the evaporation chamber (21). The jetting head (35) correctly supplies the deposition material (39) of a required quantity. Since only the required quantity of the deposition material (39) is heated, the organic thin film which does not deteriorate and has excellent film qualities is formed.

Owner:ULVAC INC

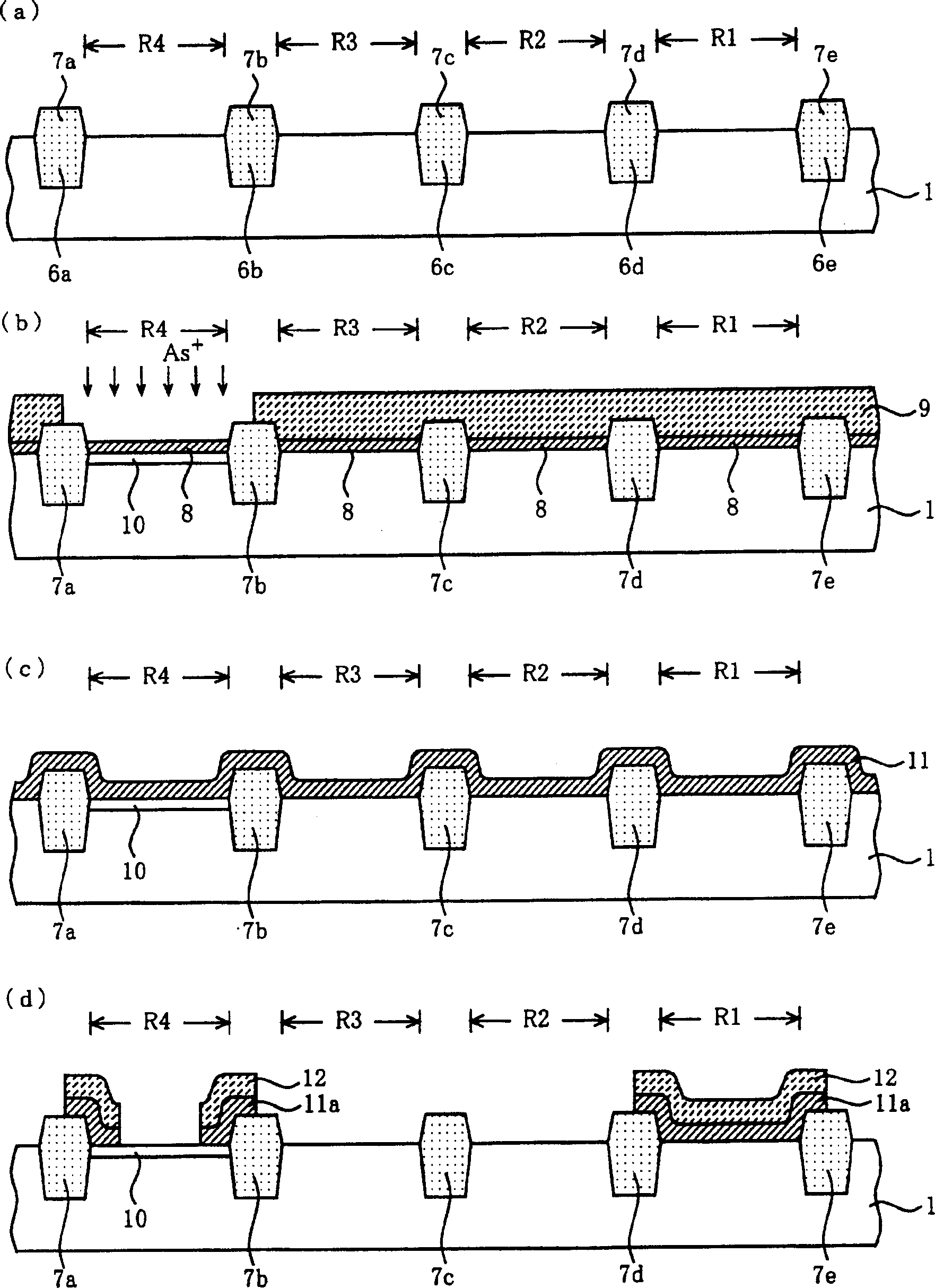

Semiconductor device manufacturing method

InactiveCN1825566AAvoid insulation breakdownUniform film qualityTransistorSemiconductor/solid-state device manufacturingCapacitanceEtching

The invention is to prevent dielectric breakdown of a capacitor in a semiconductor device having the capacitor and a MOS transistor formed on a same semiconductor substrate. A SiO2 film that is to be a gate insulation film of a high voltage MOS transistor is formed on a whole surface of a P-type semiconductor substrate. A photoresist layer is selectively formed in a high voltage MOS transistor formation region and on a part of a SiO2 film covering edges of trench isolation films adjacent to a capacitor formation region, and the SiO2 film is removed by etching using this photoresist layer as a mask. Since the photoresist layer functions as a mask in this etching, the edges of the trench isolation films adjacent to the capacitor are not cut too deep. The SiO2 film remaining in this etching and a SiO2 film to be formed thereafter form a capacitor insulation film.

Owner:SANYO ELECTRIC CO LTD

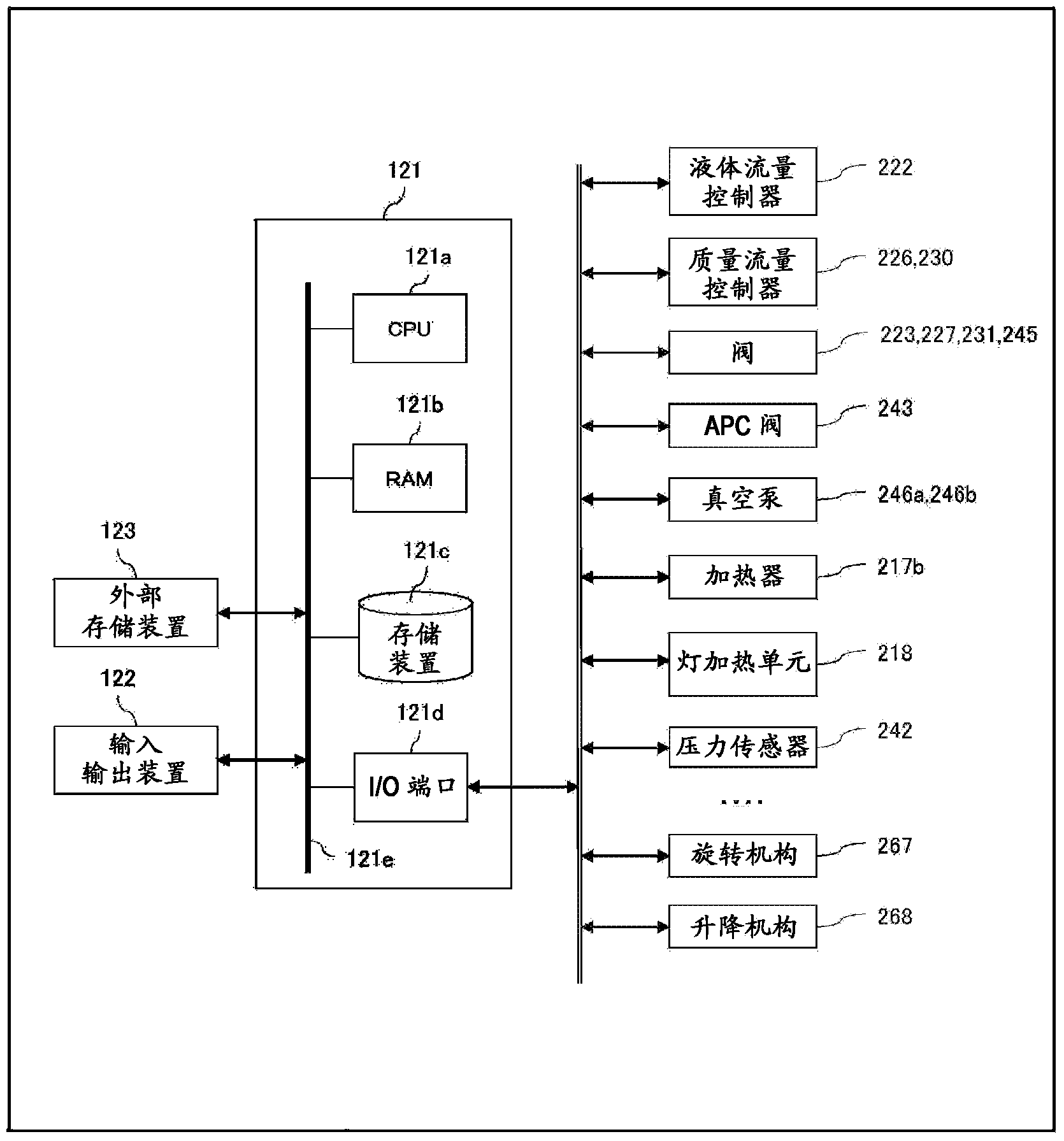

Production method for semiconductor device, production device for semiconductor device, and storage medium

ActiveCN103999198AImprove membrane qualityTransistorSolid-state devicesInternal pressureSilicon membrane

Provided is a method of manufacturing a semiconductor device. The method includes (a) loading a substrate having a silicon-containing film formed thereon into a process chamber; (b) supplying a gas into the process chamber from a gas supply unit until an inner pressure of the process chamber is equal to or greater than atmospheric pressure; and (c) supplying a process liquid from a process liquid supply unit to the substrate to oxidize the silicon-containing film.

Owner:KOKUSA ELECTRIC CO LTD

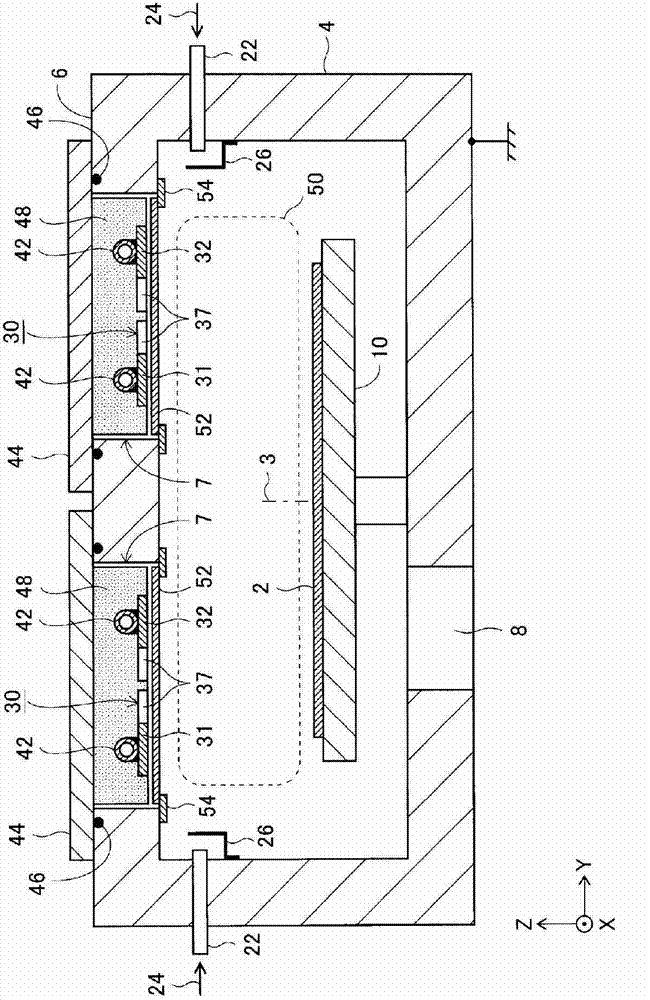

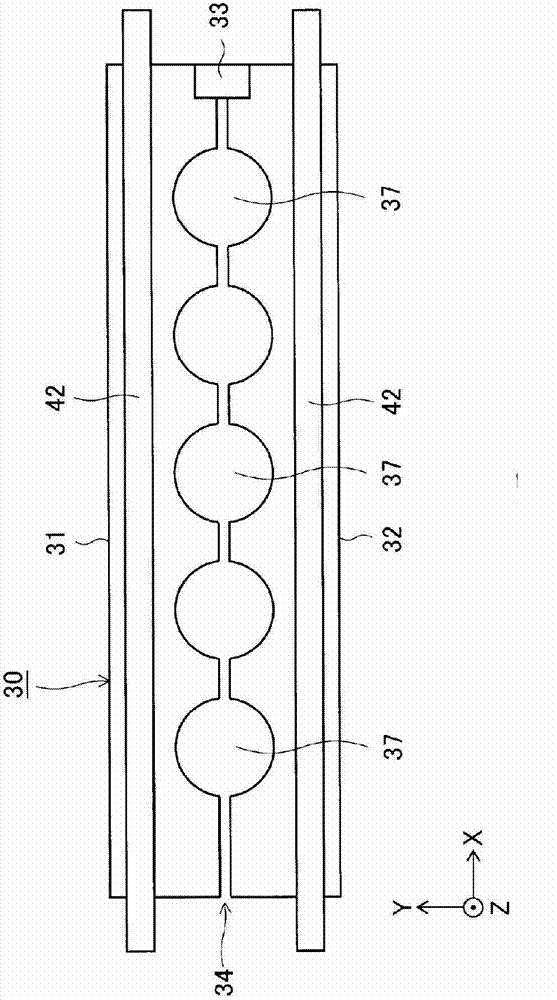

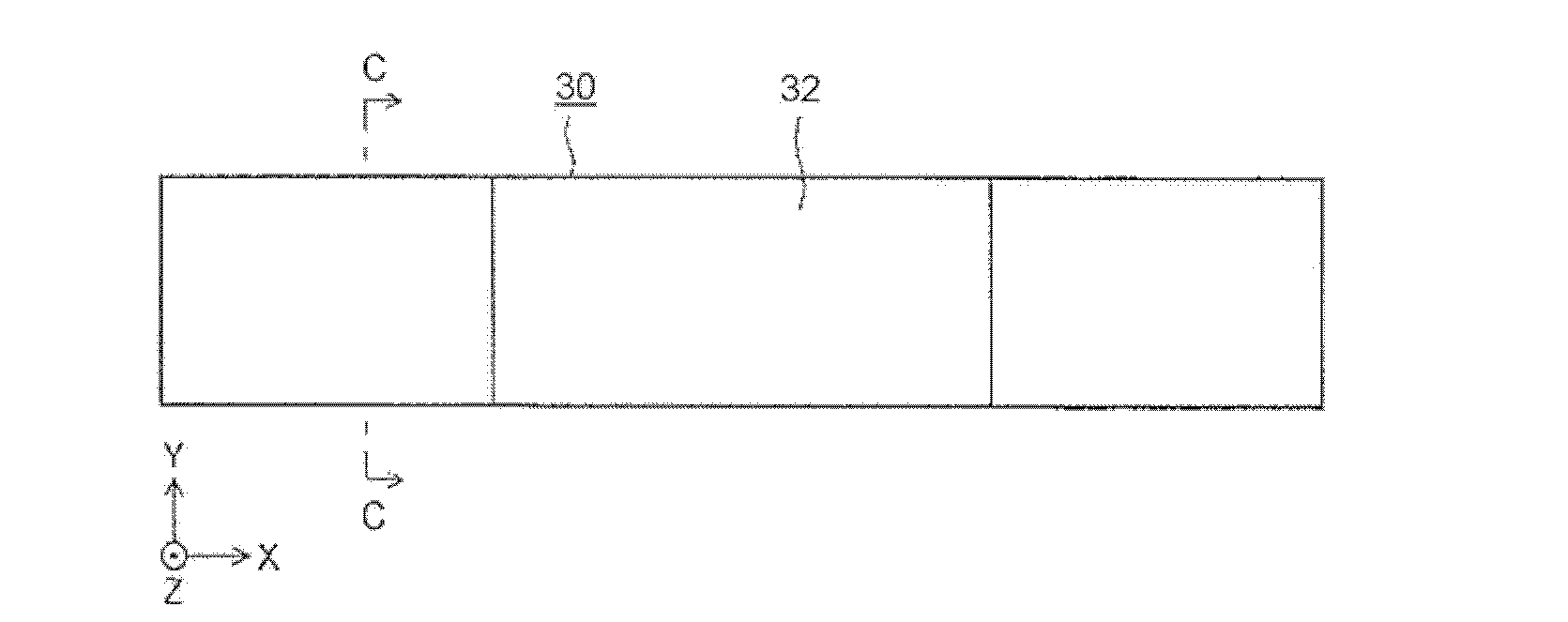

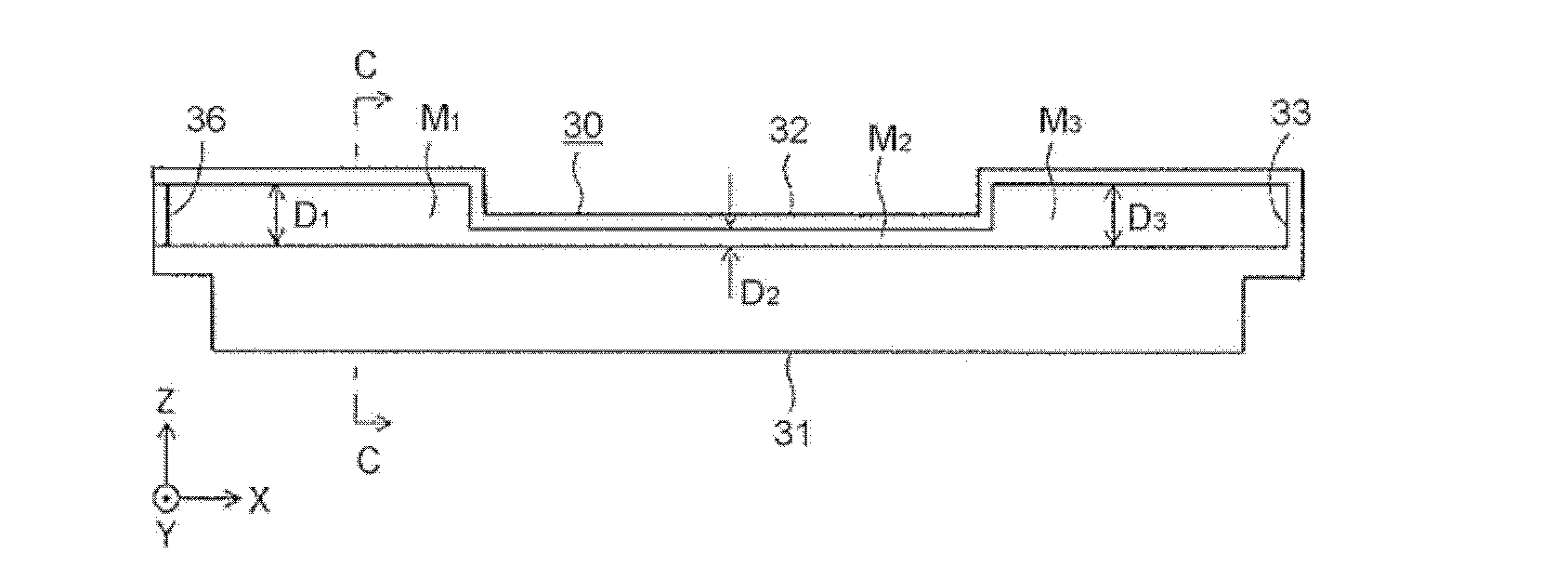

Plasma processing device

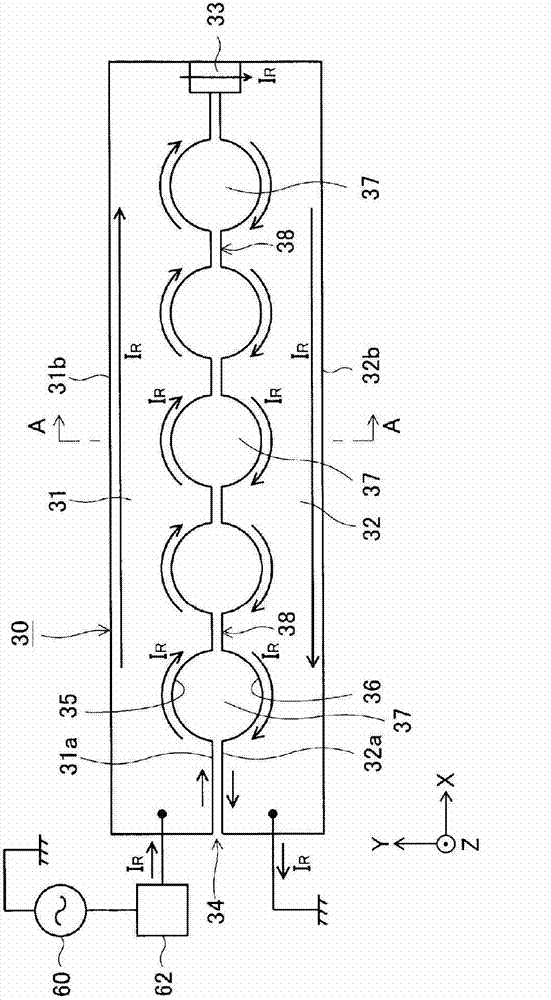

InactiveCN102647847AEffective inductance reductionEasy to reinforceElectric discharge tubesSemiconductor/solid-state device manufacturingElectrical conductorEngineering

The invention provides a plasma processing device which is an inductive coupling device and can reduce the effective inductance coefficient to restrain the plasma electrical potential more lower, and can control the plasma density distribution along the length direction through an antenna. Return conductors (31, 32) are arranged vertically on the vertical line (3) direction, namely the up and down direction (Z), of the surface of a substrate (2) and make the high frequency current (IR) flow retroactively to form an antenna with straight plane shape. The interval (D) of the up and down direction (Z) between the return conductors (31, 32) changes at the length direction (X).

Owner:NISSIN ELECTRIC CO LTD

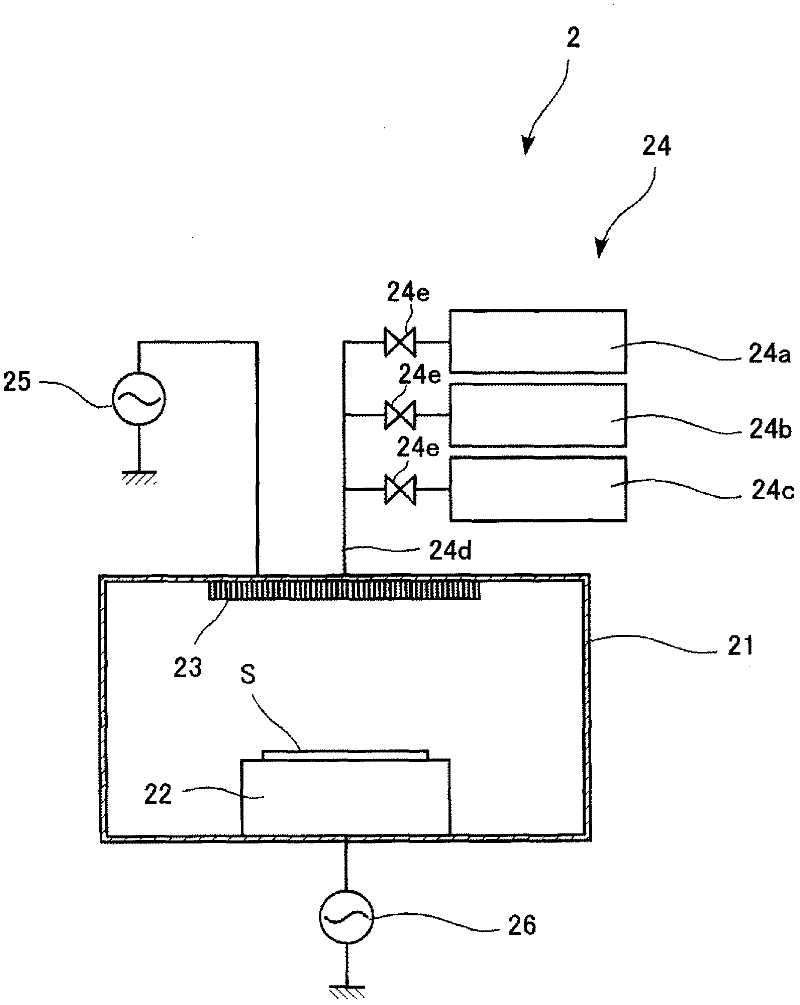

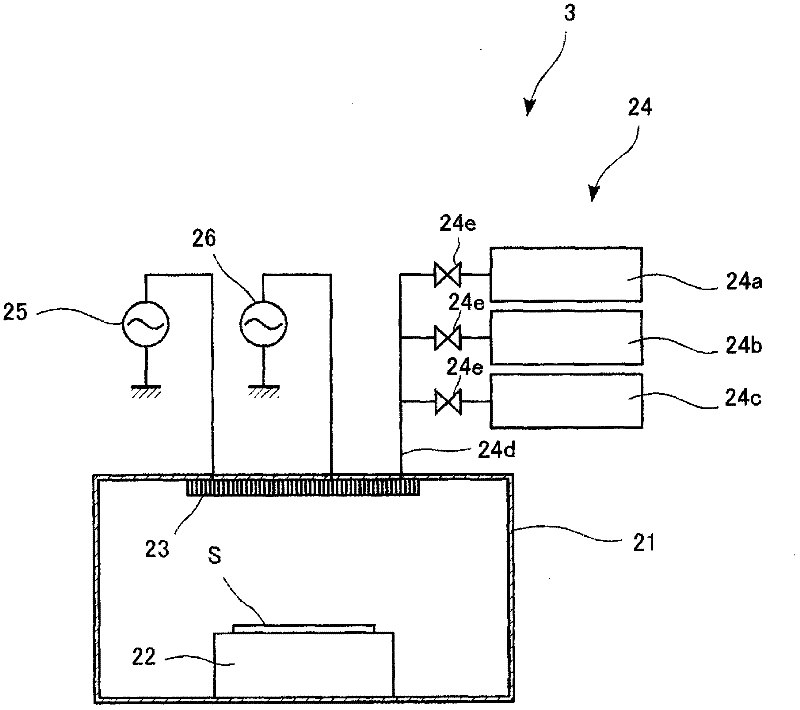

Film-forming apparatus and film-forming method for forming passivation film, and manufacturing method of solar cell element

ActiveCN102265407AImprove membrane qualityInhibition lossFinal product manufactureChemical vapor deposition coatingForming gasHigh frequency power

Provided are a film-forming method and a film-forming device for forming passivation films that can sufficiently inhibit loss due to carrier re-binding, and a solar cell element manufacturing method using same. The device is provided with a mounting part (22) for mounting the film-forming target, a high frequency power source (25), and a shower plate (23) that is provided to face the film-forming target (S) that is mounted on the mounting part (22), introduces the film-forming gas, and to which is connected the high frequency power source and to which a high frequency voltage is applied. A low frequency power source (26) is connected to the shower plate or the substrate-mounting part and applies a lower frequency voltage. The film-forming method is implemented using said film-forming device, and said film-forming method is implemented when forming passivation films.

Owner:ULVAC INC

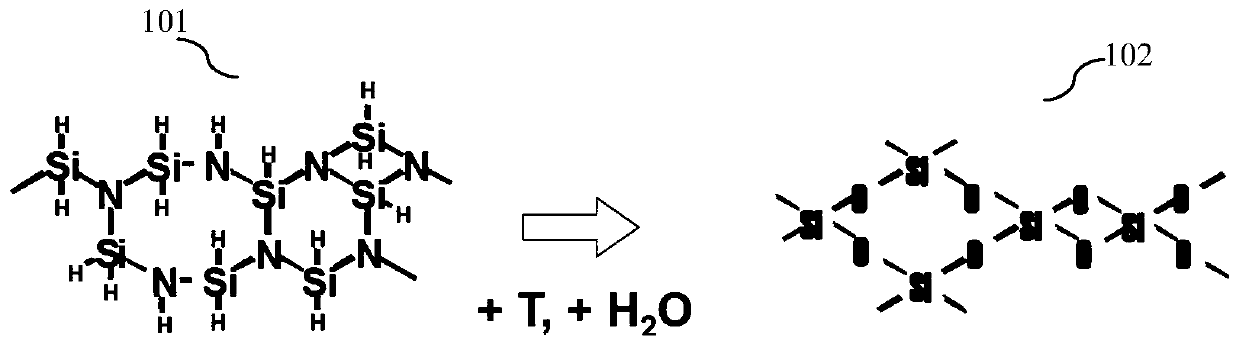

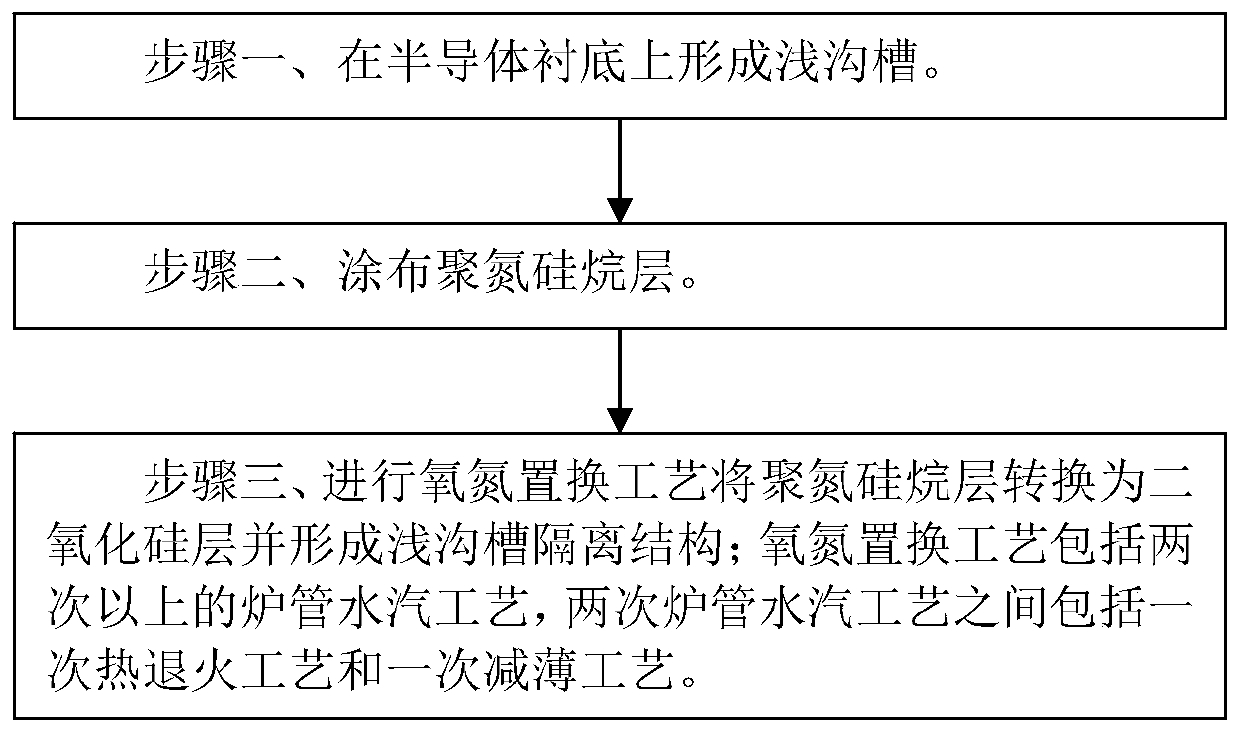

Manufacturing method of shallow trench isolation structure

ActiveCN110211916AEasy to fillImprove densification performanceSolid-state devicesSemiconductor/solid-state device manufacturingWater vaporNitrogen

The invention discloses a manufacturing method of a shallow trench isolation structure. The manufacturing method comprises the following steps: step 1, forming a shallow trench on a semiconductor substrate; step 2, coating a polyazosilane layer; and step 3, performing the oxygen-nitrogen replacement process to convert the polyazosilane layer into a silicon dioxide layer and form a shallow trench isolation structure; wherein the oxygen-nitrogen replacement process includes more than two times of furnace tube water vapor process, and a thermal annealing process and a thinning process are included between the two times of furnace tube water vapor process. The PSZ can be applied to realize good filling of the shallow trench, the oxygen-nitrogen replacement effect of the PSZ and the compactnessof the converted silicon dioxide can be improved so as to improve the film quality of the silicon dioxide and reduce the thermal process of the active region.

Owner:SHANGHAI HUALI INTEGRATED CIRCUTE MFG CO LTD

Method for coating potassium persulphate film on copper tube of condenser

InactiveCN103205743ASimple processFast film formationMetallic material coating processesPotassium persulfatePhysical chemistry

The invention belongs to a metal surface coating method and concretely relates to a method for coating a film on the inner surface of a copper tube of a condenser in a thermal power plant. The method comprises the following steps: 1, injecting clear water to a cleaning box, and heating; 2, preparing a coating liquid comprising water, potassium persulphate, sodium hydroxide and triethanolamine, wherein the coating liquid: water: potassium persulphate: sodium hydroxide: triethanolamine ratio is 1000:8-12:2-3:1-2; and 3, coating: starting a dosing pump, continuously adding the coating liquid prepared in step 2 to the condenser, maintaining the temperature designed in step 1, carrying out continuous cycle for 6-8h, and finishing coating. The potassium persulphate film forming method can reach a one-time coating quality standard, shortens the film forming time to 6-8h from at least 96h, can be used in the one-time coating of the copper tube of the condenser in the large and small repairing processes of a set, and has popularization application values.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

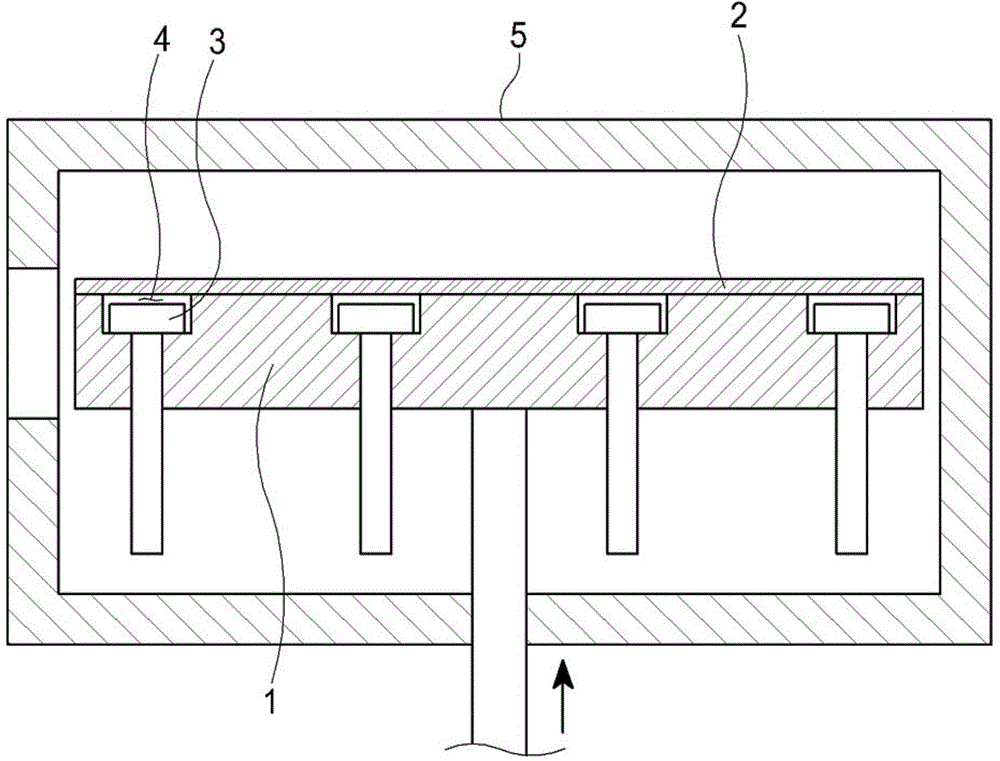

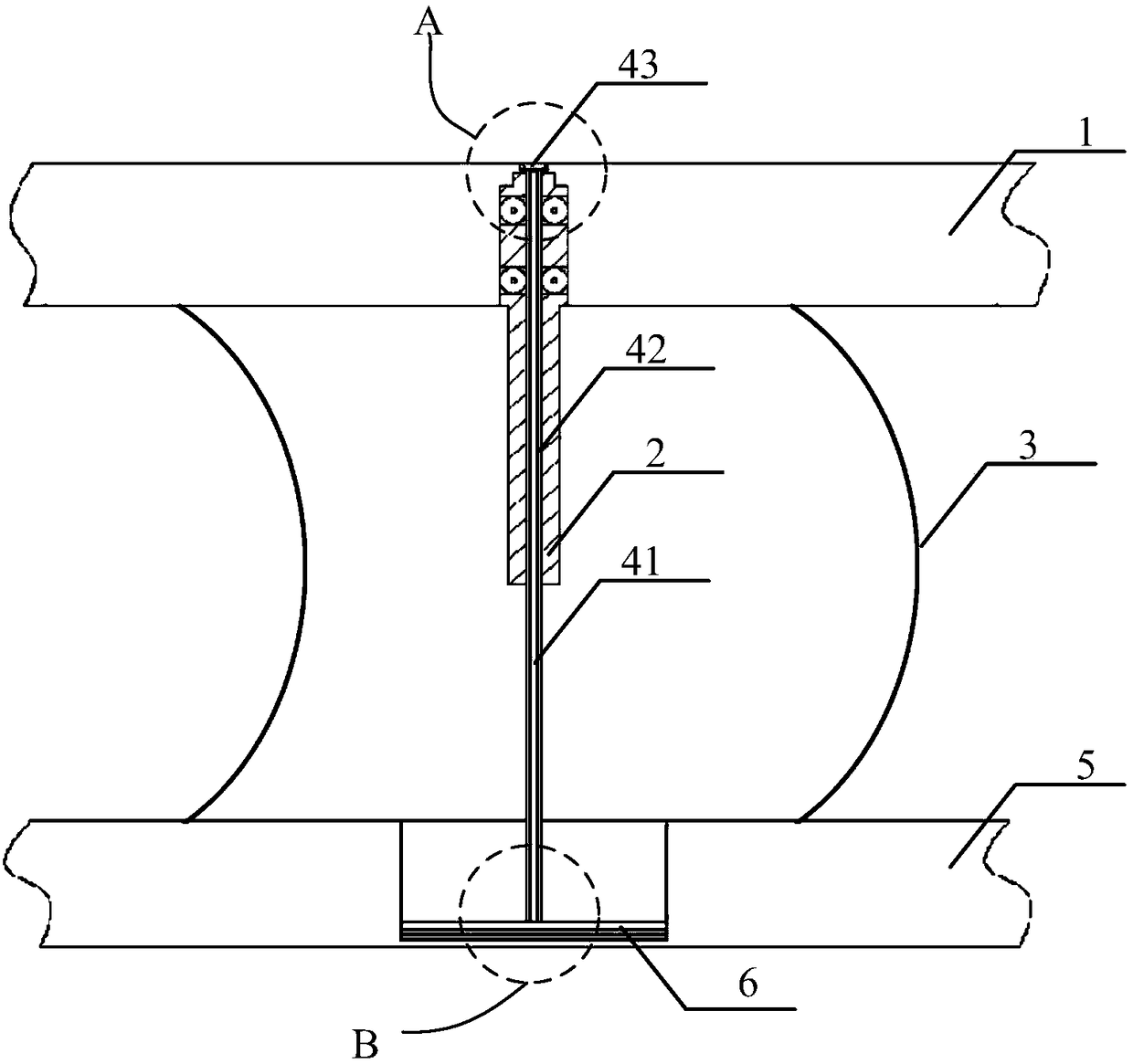

PECVD (Plasma Enhanced Vapor Deposition) reaction chamber and support pin for PECVD reaction chamber

ActiveCN108203817AReduce the number of capacitorsReduce capacitance differenceChemical vapor deposition coatingCapacitancePlasma density

The invention provides a PECVD (Plasma Enhanced Vapor Deposition) reaction chamber and a support pin for the PECVD reaction chamber, which belong to the technical field of semiconductors. The supportpin for the PECVD reaction chamber comprises a pin core , a pin sleeve coating outside the pin core, and at least one layer of spacer arranged on the bottom parts of the pin core and the pin sleeve, wherein the pin core and parts, corresponding to the pin core and the pin sleeve, of the gaskets are made of conductive materials; and the pin sleeve is made of a non-conductive material. According tothe support pin, the pin core is made of the conductive material, and the pin core and the gaskets are grounded, so that the whole support pin is grounded, the number of serially connected capacitorsof a Pin area can be reduced, the plasma density of the Pin area is improved, and a capacitor difference between the Pin area and a non-Pin area is reduced.

Owner:FUZHOU BOE OPTOELECTRONICS TECH CO LTD +1

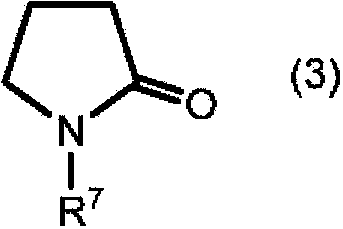

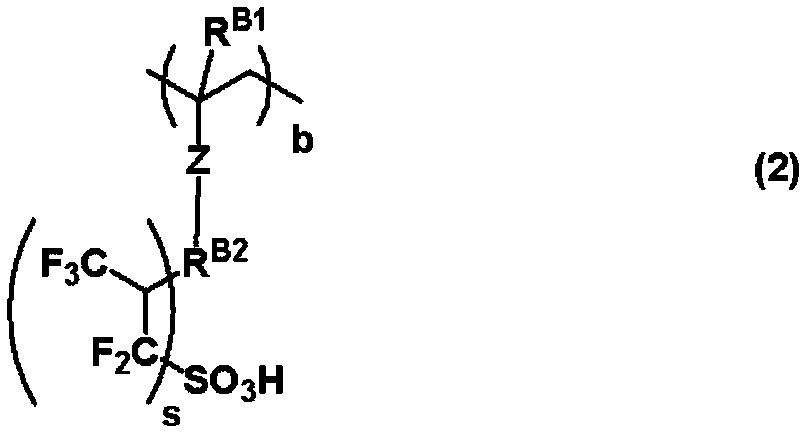

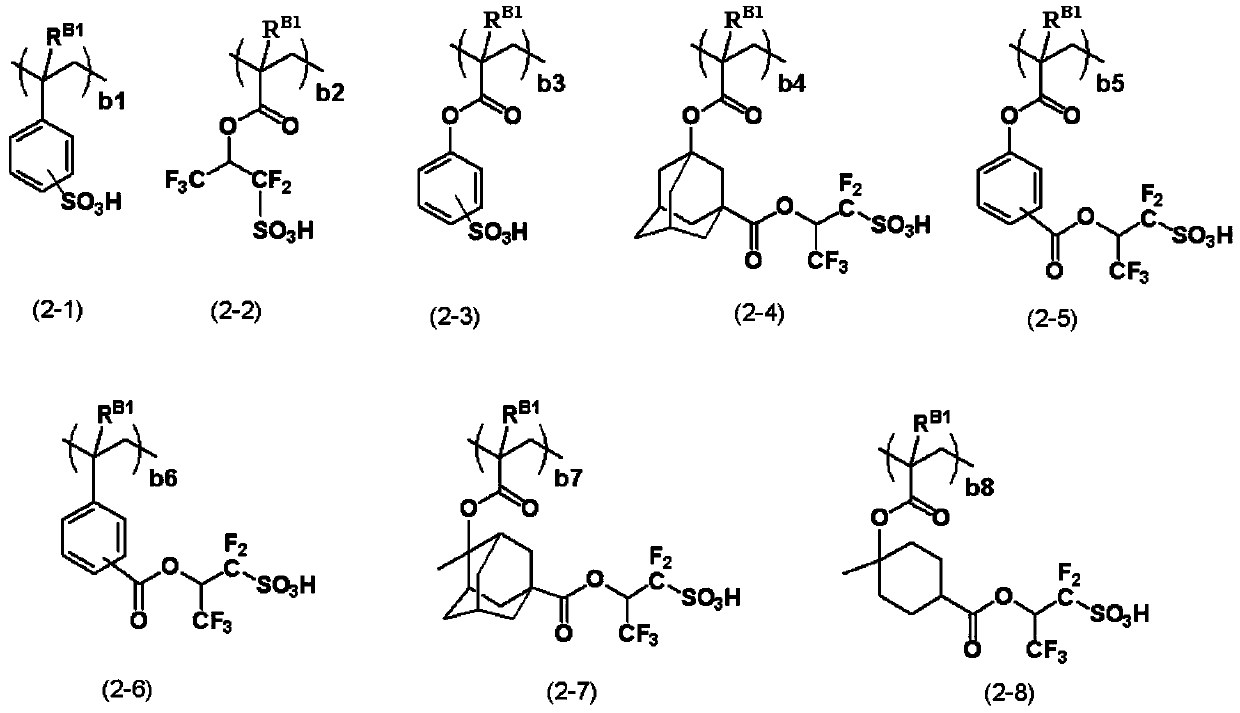

Conductive polymer composition, coated article, and patterning process

ActiveCN110016284AHigh positioning accuracyImprove conductivityConductive materialPhotomechanical apparatusPolymer scienceConductive polymer

The present invention is a conductive polymer composition, which has good filterability and film-formability of a flat film onto an electron beam resist, and is suitably usable for a antistatic film for electron beam resist drawing having lower surface resistivity (Omega / wei) to show excellent antistatic performance in an electron beam drawing process, and excellent peelability with HO or an alkaline developer after drawing. The conductive polymer composition includes (A) a polyaniline-based conductive polymer having two or more kinds of repeating units shown by the following general formula (1); and (B) a dopant polymer which contains a repeating unit shown by the following general formula (2) and has a weight-average molecular weight in a range of 1,000 to 500,000.

Owner:SHIN ETSU CHEM IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com