Film-forming apparatus

A technology of film forming device and mounting part, which is applied to spray devices, spray devices, liquid spray devices, etc., can solve the problems of large-scale, difficult maintenance, and heavy-duty water mist supply parts, shortening the conveying distance, and inhibiting condensation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

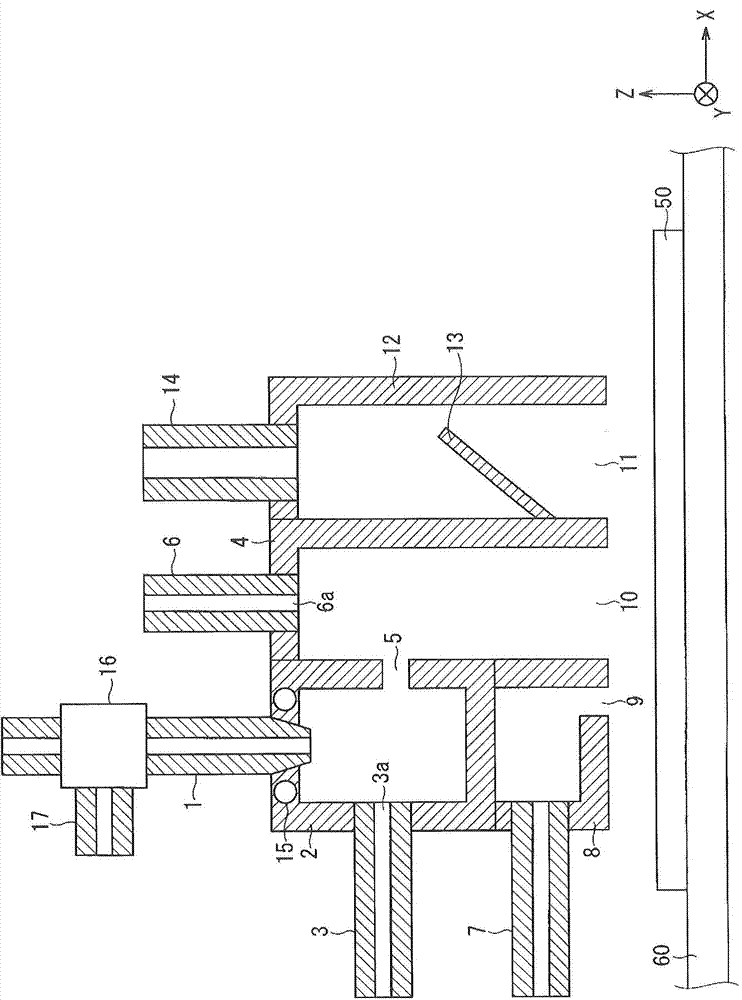

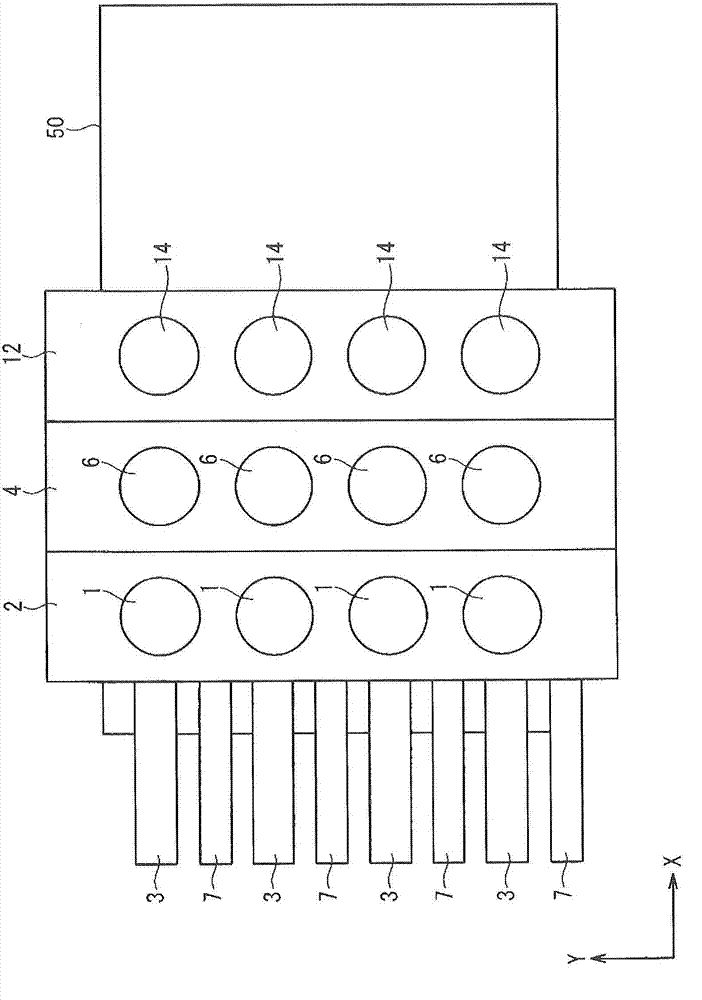

[0033] figure 1 It is a cross-sectional view showing the structure of a main part (more specifically, the vicinity of a solution spraying part that sprays a solution onto a substrate in a mist form) of the film forming apparatus according to this embodiment. here, figure 1 The X-Y-Z directions are shown in . in addition, figure 2 is shown from figure 1 Observation from above figure 1 A top view of the composition of the structure shown. here, figure 2 The X-Y direction is shown. In addition, in figure 2 In order to simplify the drawings, the illustration of the constituent members 16, 17, 60 is omitted.

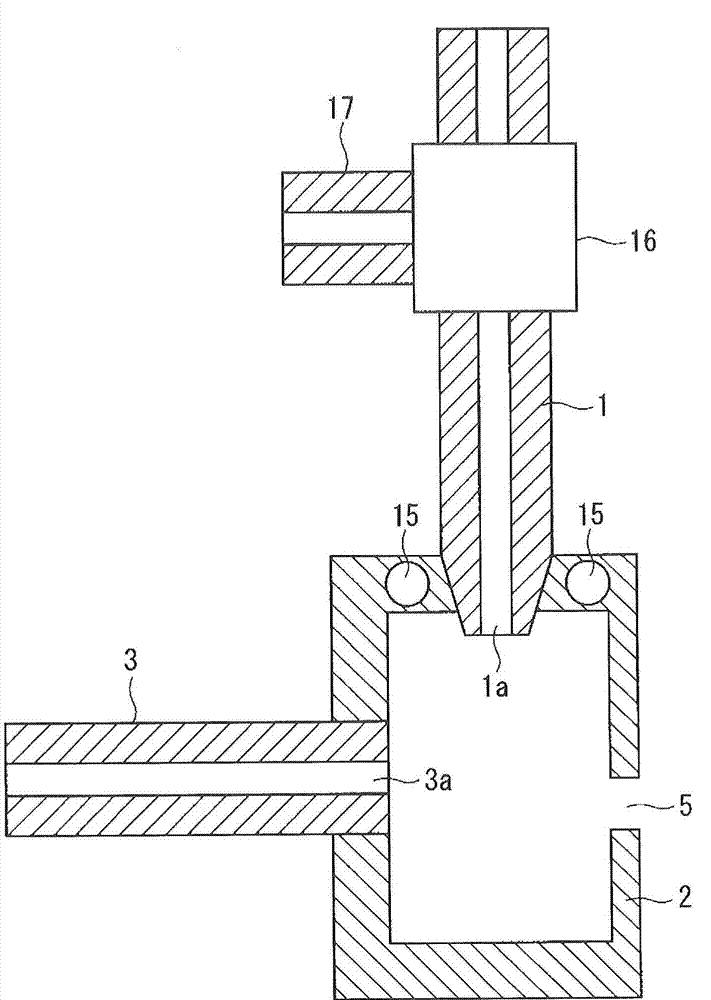

[0034] in addition, image 3 is showing figure 1 Shown is an enlarged cross-sectional view of the structure of the first chamber 2 and the components 1 , 3 etc. connected to the first chamber 2 . in addition, Figure 4 is showing figure 1 Shown is an enlarged cross-sectional view of the structure of the second chamber 4 and of the component parts 6 connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com