Patents

Literature

34results about How to "Good photoelectric conversion characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparing method of photoelectrochemical sensor based on sandwich cardiac troponin T marked by Ag2Se@CdSe and application

InactiveCN104849331AGood photoelectric conversion characteristicsImprove photoelectric signal responseBiological testingMaterial electrochemical variablesCardiac muscleEngineering

The invention relates to a preparing method of a photoelectrochemical sensor based on sandwich cardiac troponin T marked by Ag2Se@CdSe and application, and belongs to the technical field of novel functional materials and biosensing detection. According to concrete contents of the preparing method and the application, CeO2-TiO2 composite nanometer materials with photoelectrocatalytic activity are used as optical activity substrate materials; Ag2Se@CdSe is used as an antibody marker; the sandwich photoelectrochemical sensor is prepared through the signal amplification effect of the marker Ag2Se@CdSe on the substrate materials, and is used for the high-sensitivity detection of the cardiac troponin T of myocardial damage specific marker. The method has the important significance on the early diagnosis and treatment of acute myocardial infarction.

Owner:UNIV OF JINAN

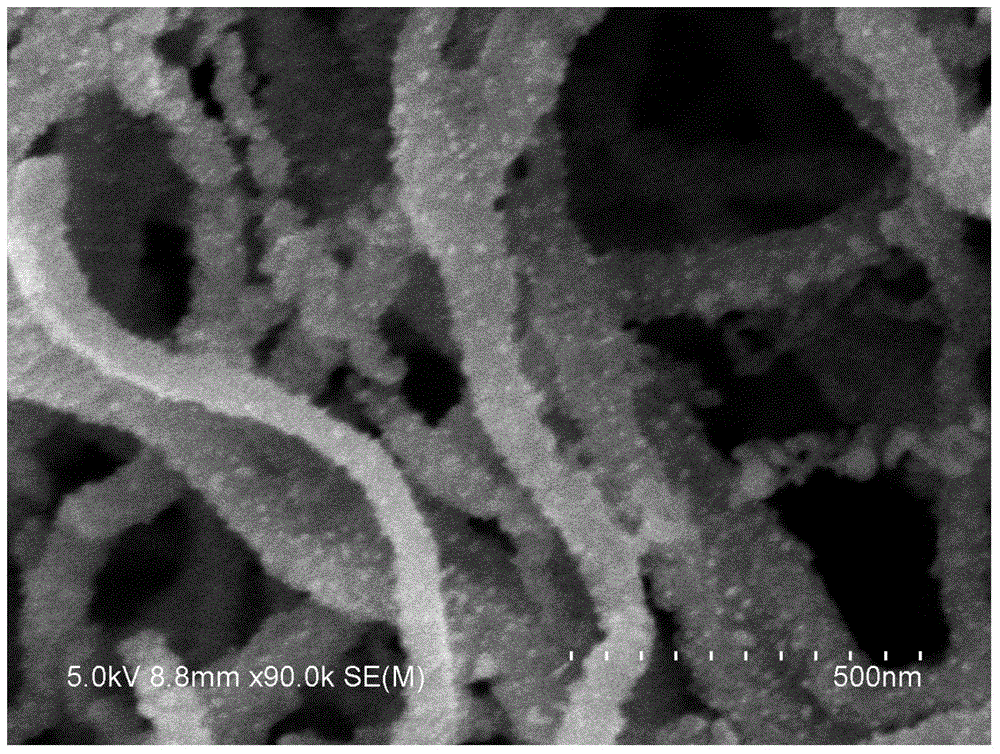

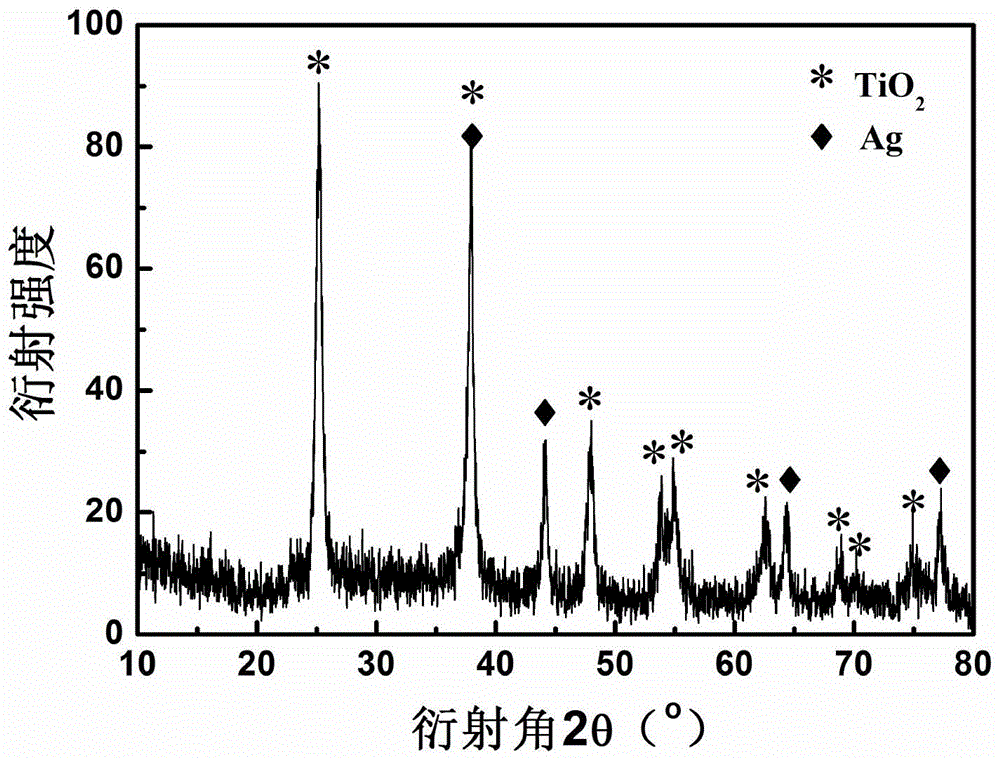

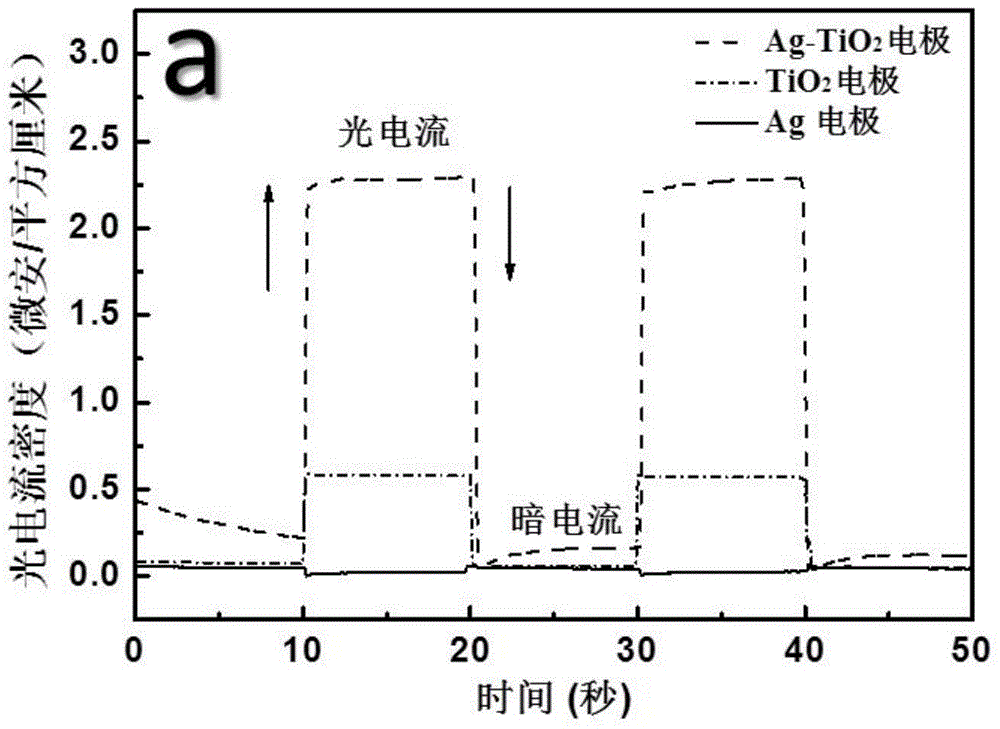

Ag-TiO2 composite fiber preparation method

InactiveCN104928802ASimple preparation processGood photoelectric conversion characteristicsInorganic material artificial filamentsFilament/thread formingFiberElectron hole

The invention provides an Ag-TiO2 composite fiber preparation method. The Ag-TiO2 composite fiber preparation method includes the steps of adding silver nitrate absolute ethyl alcohol in a glacial acetic acid solution of tetrabutyl titanate by drops, mixing, adding polyvinylpyrrolidone, stirring and standing until all air bubbles disappear to obtain a polymeric pecursor solution; moving the polymeric pecursor solution in an injector, preparing a nanofiber precursor by means of electrostatic spinning, and baking in the air to obtain an Ag-TiO2 composite fiber. Size and shape of the Ag-TiO2 composite fiber can be controlled by means of adjusting spinning parameters and procedure parameters of electrostatic spinning. A photoelectric property of a material can be optimized by means of adjusting an Ag nanocrystalline deposit rate in the Ag-TiO2 composite fiber. Compared with a TiO2 photoelectric conversion material in the prior art, the Ag-TiO2 composite fiber preparation method has the advantages that the defects of small specific surface area, high photo-generated electron-hole compositing probability rate and low photo-generated carrier quantization efficiency of a TiO2 material are overcome, Ag nanocrystallines in the Ag-TiO2 composite fiber are highly adjustable, and the Ag-TiO2 composite fiber preparation method is simple and easy to repeat.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

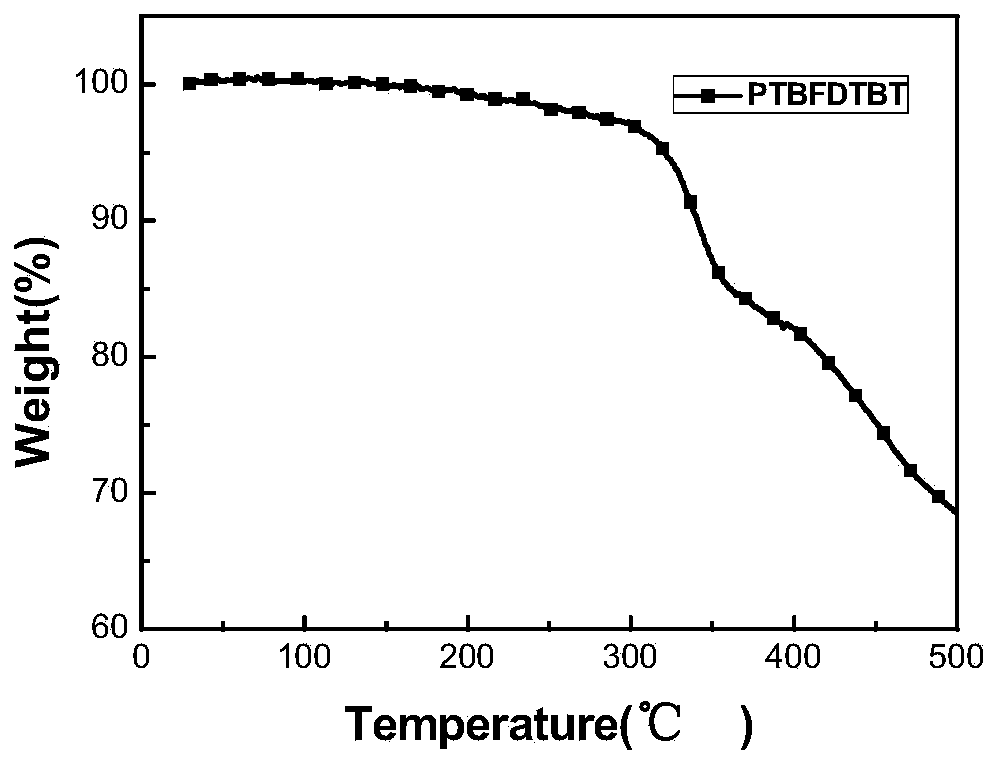

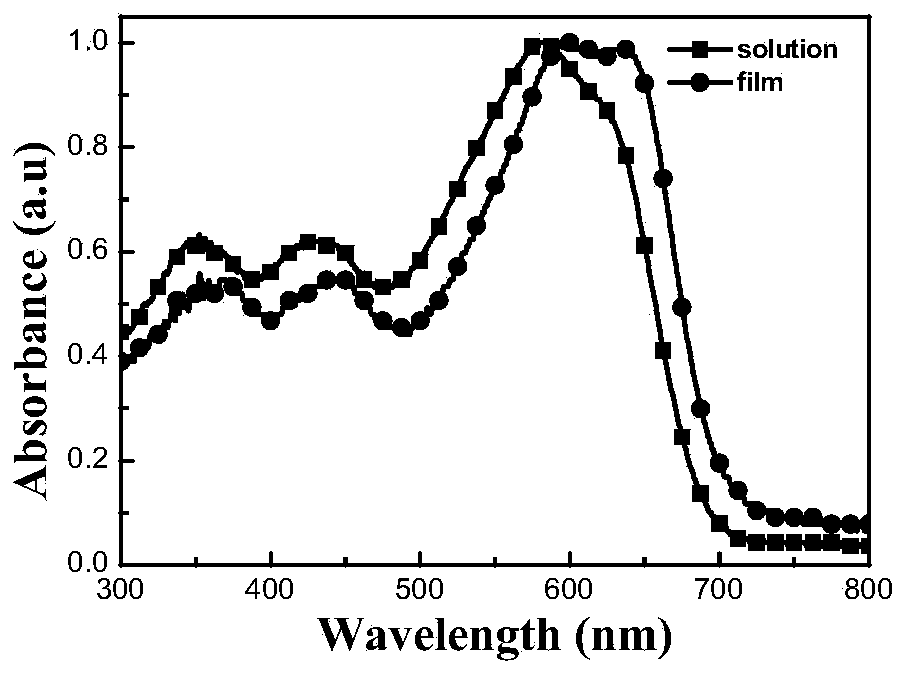

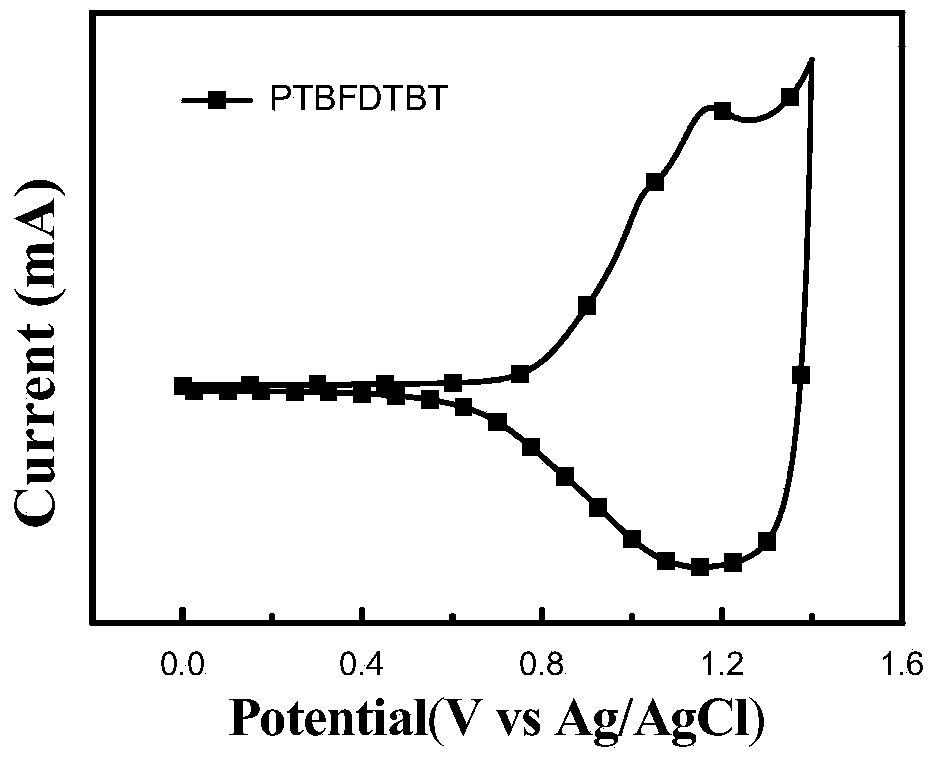

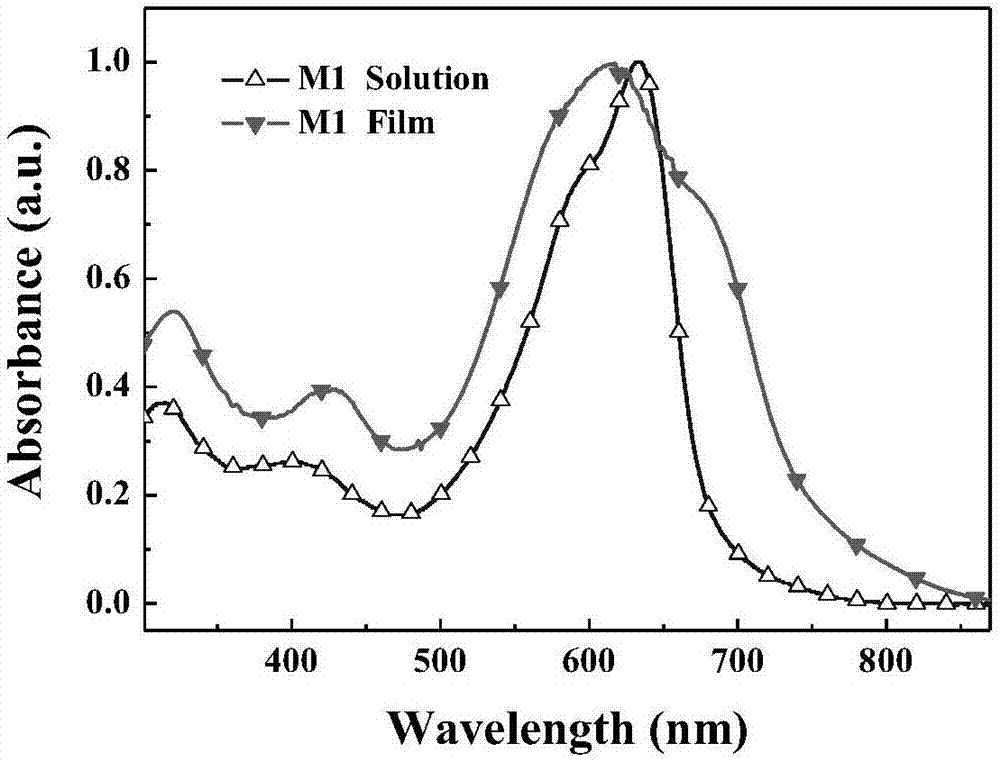

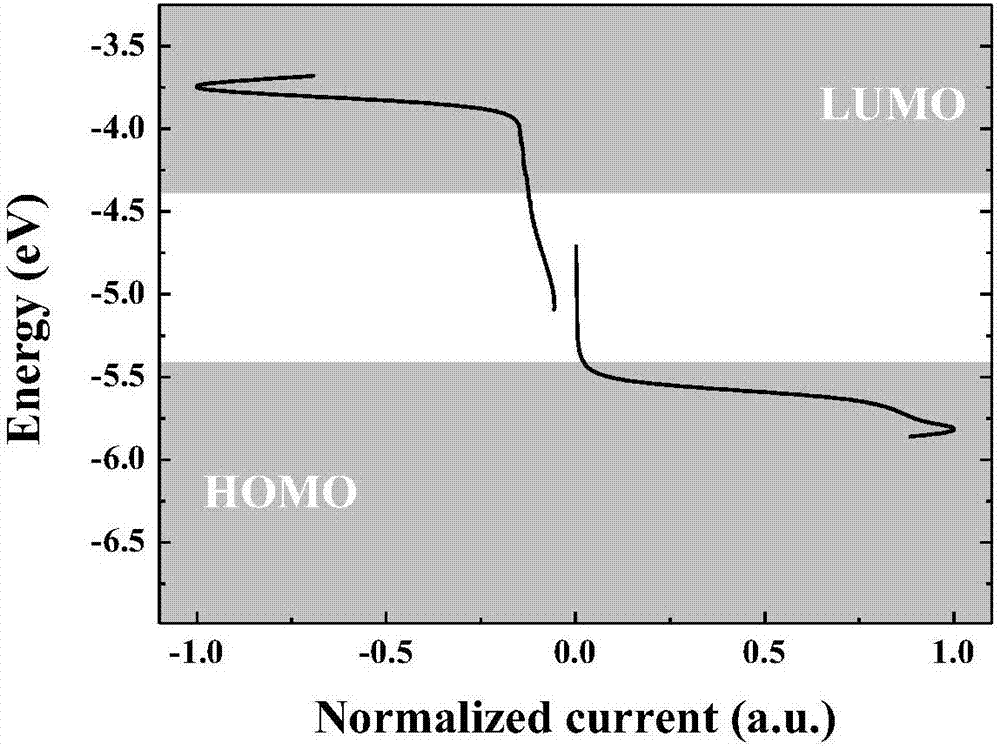

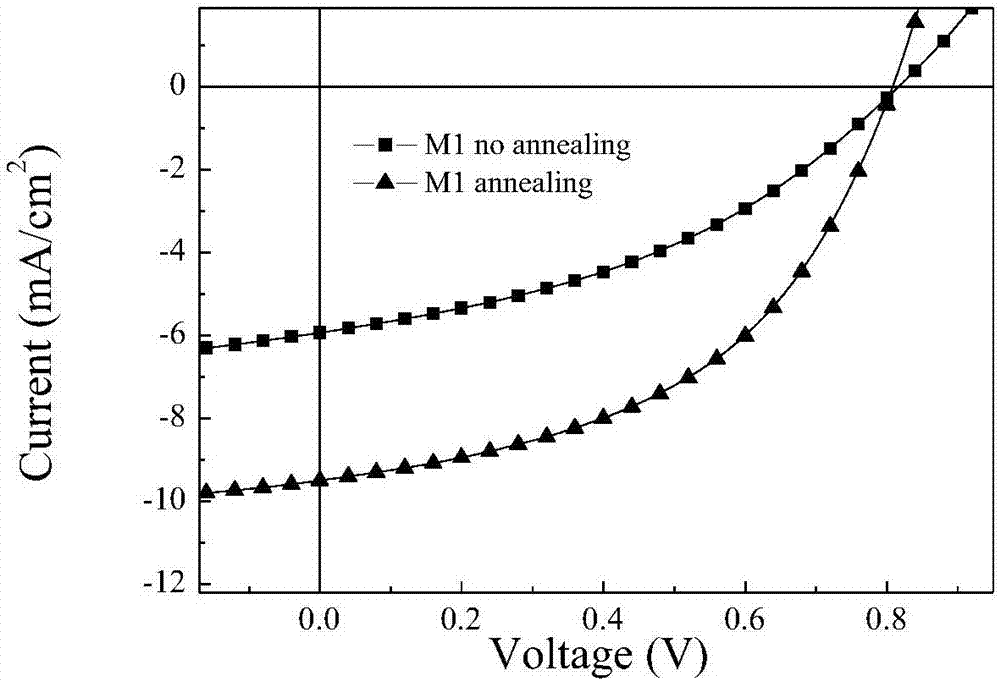

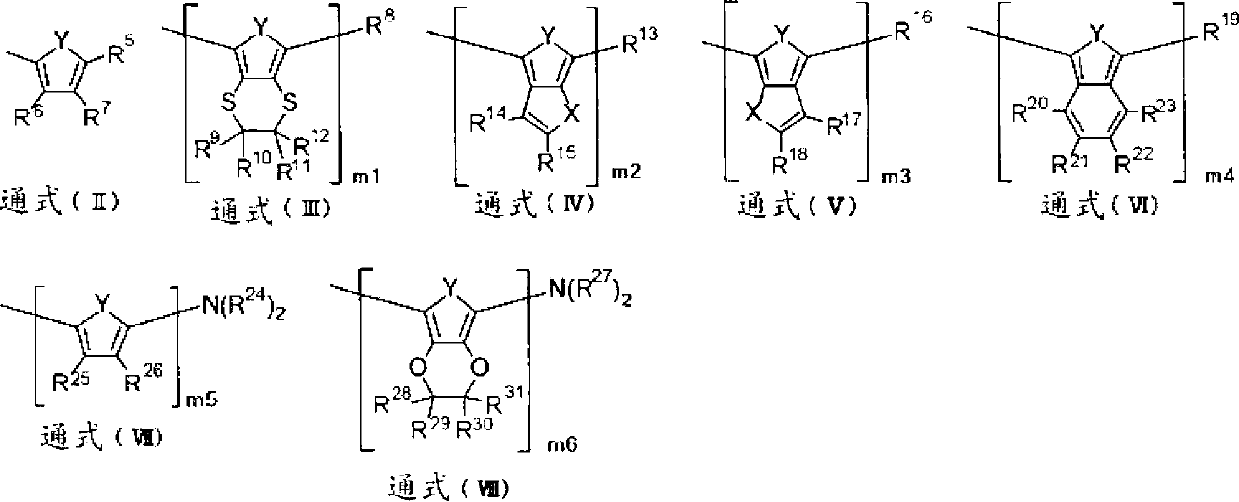

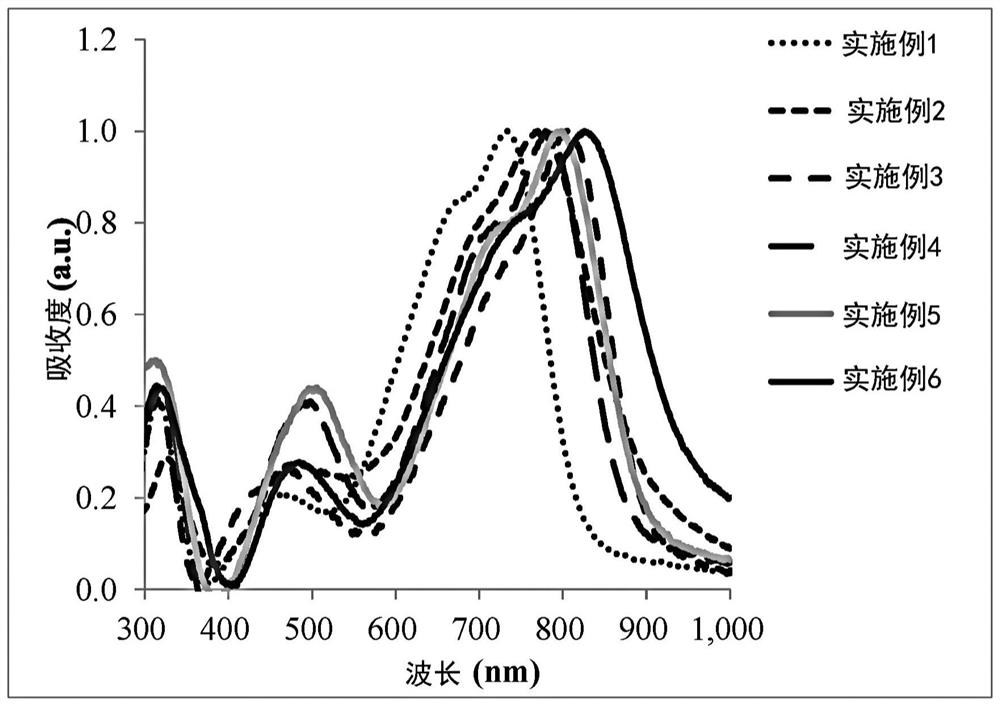

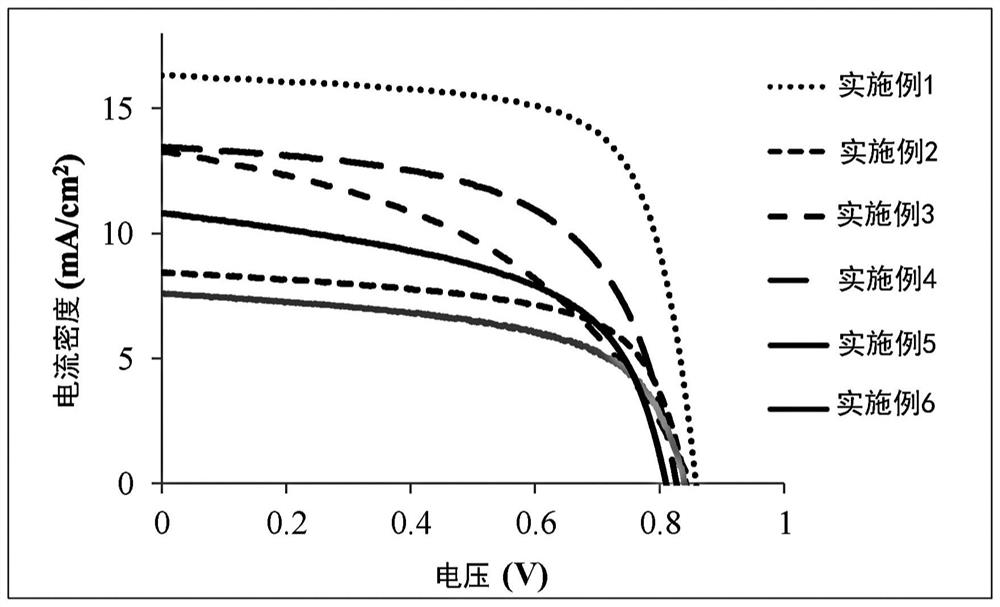

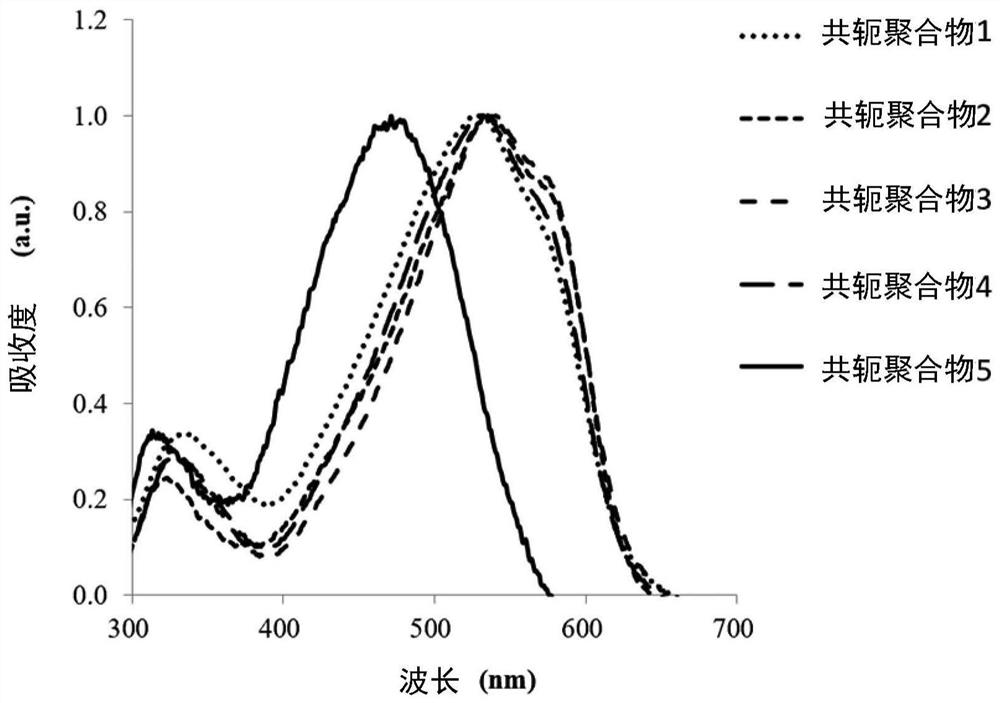

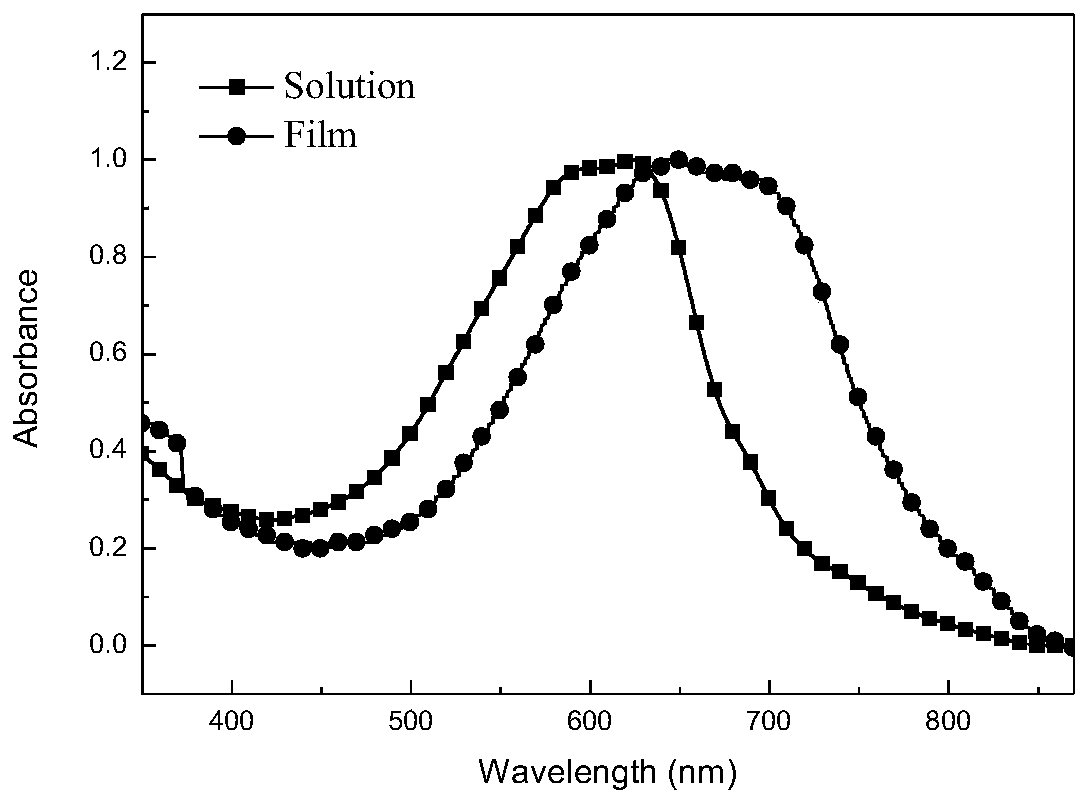

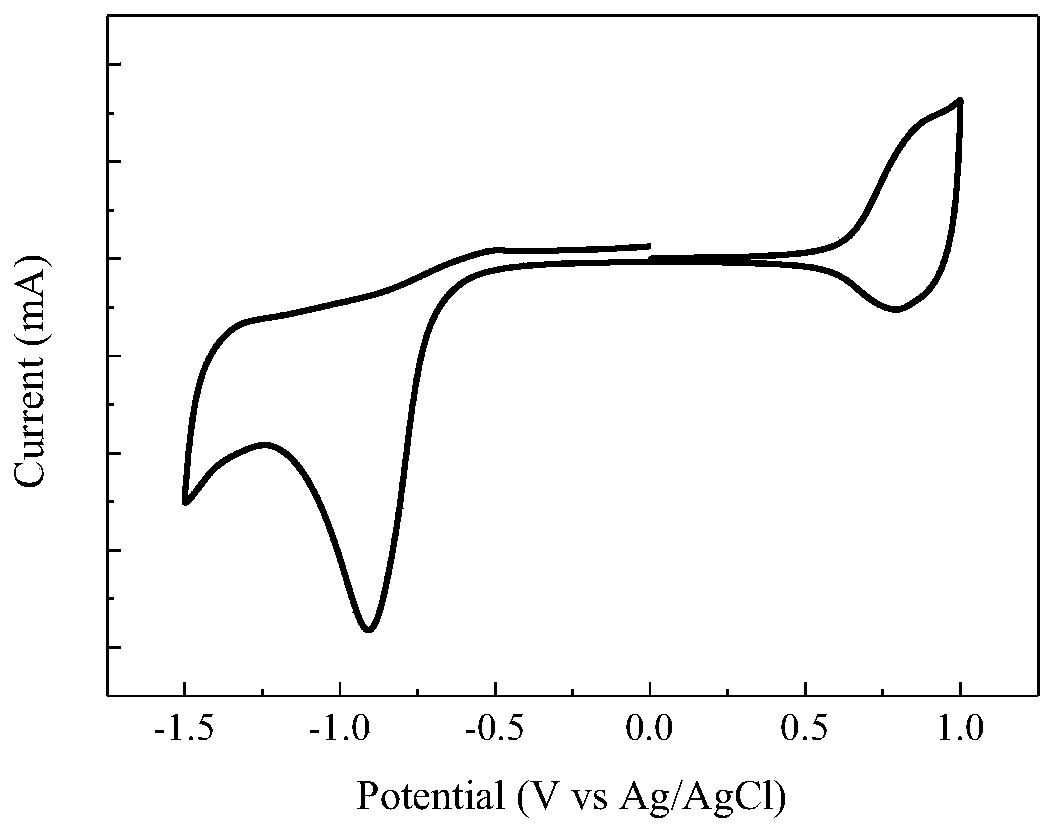

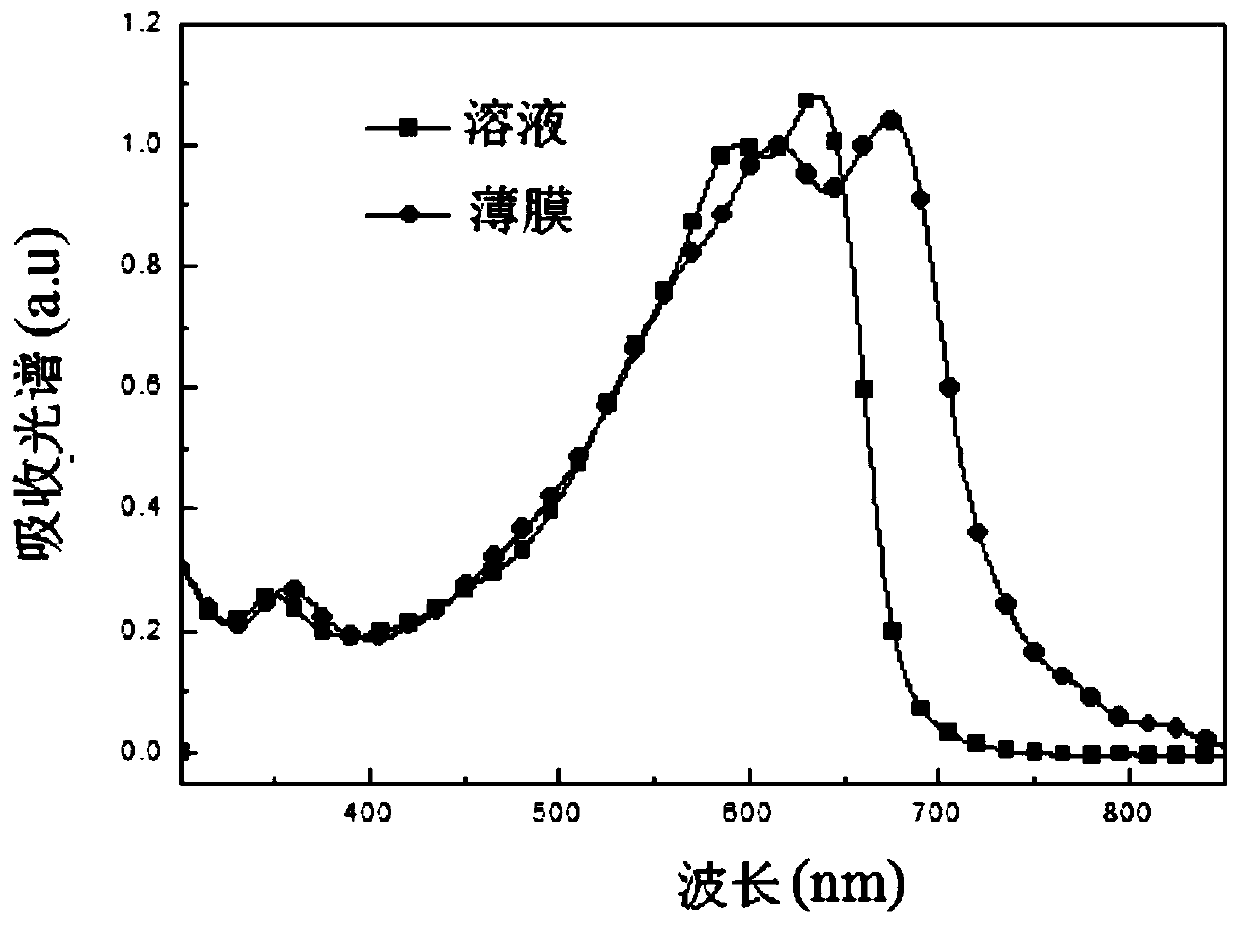

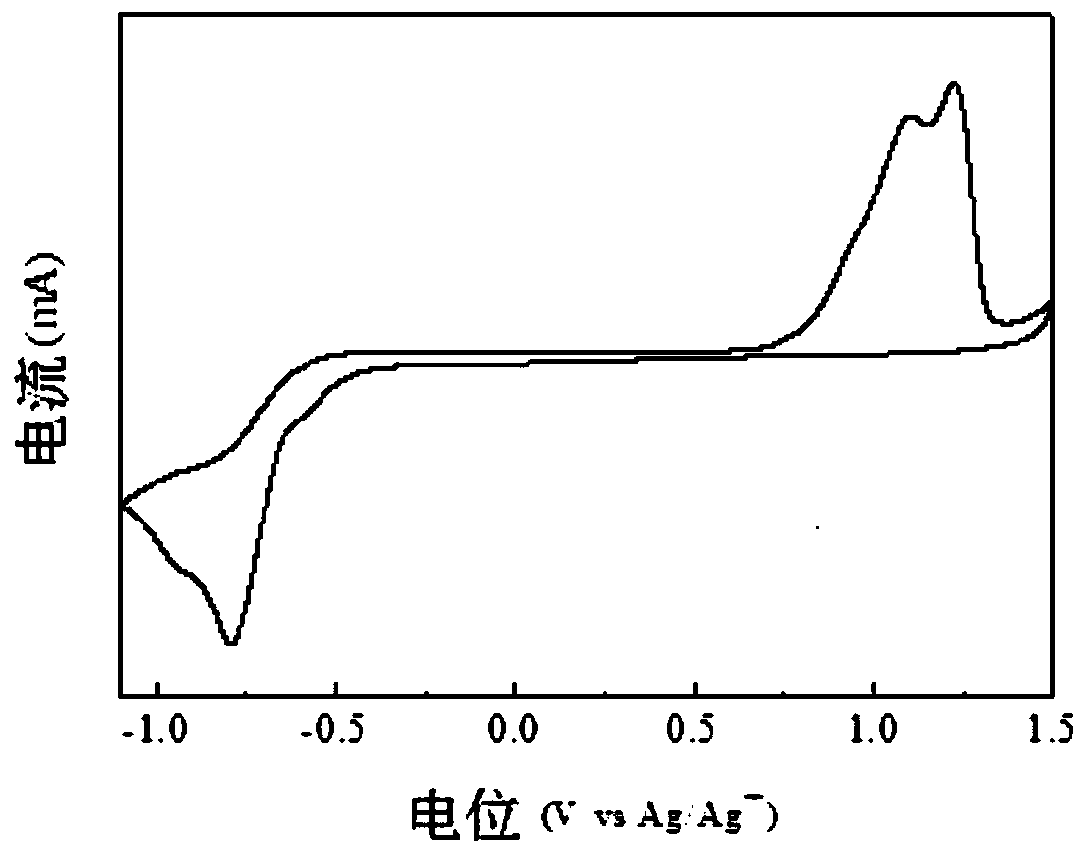

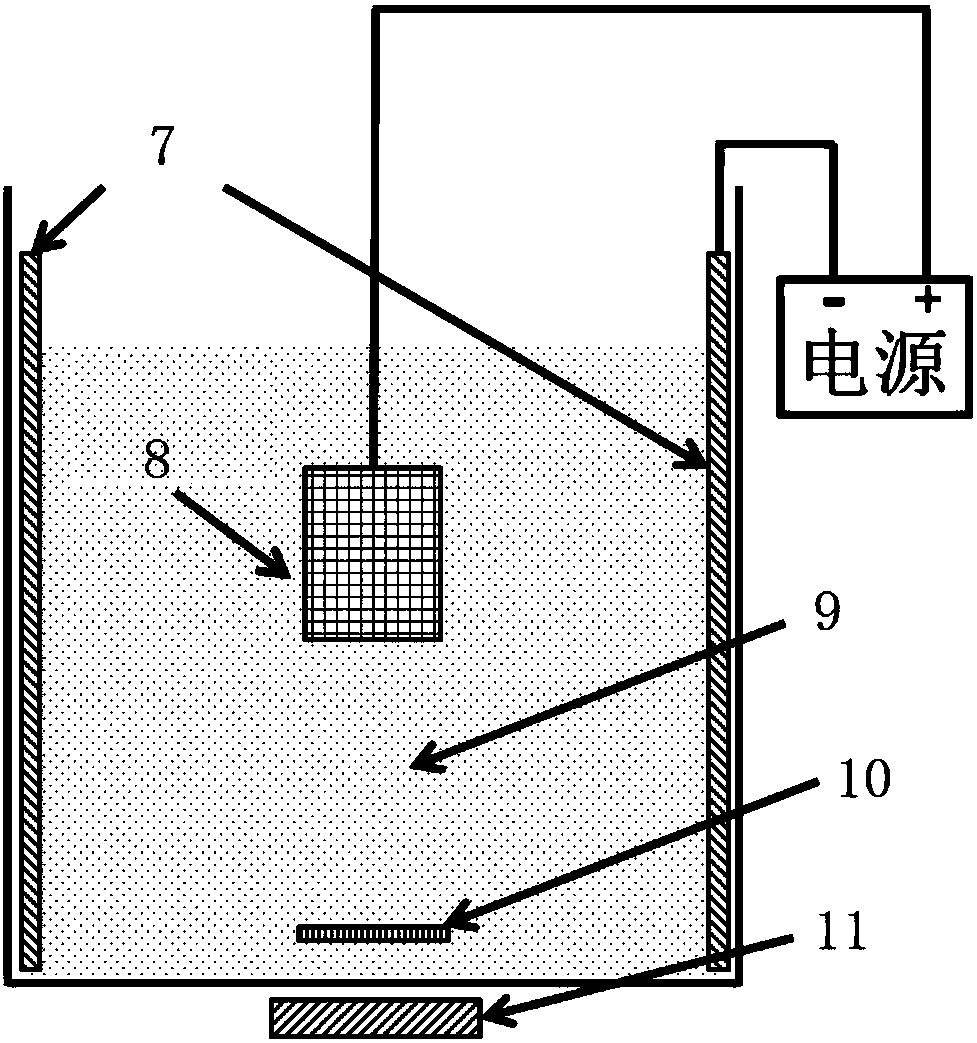

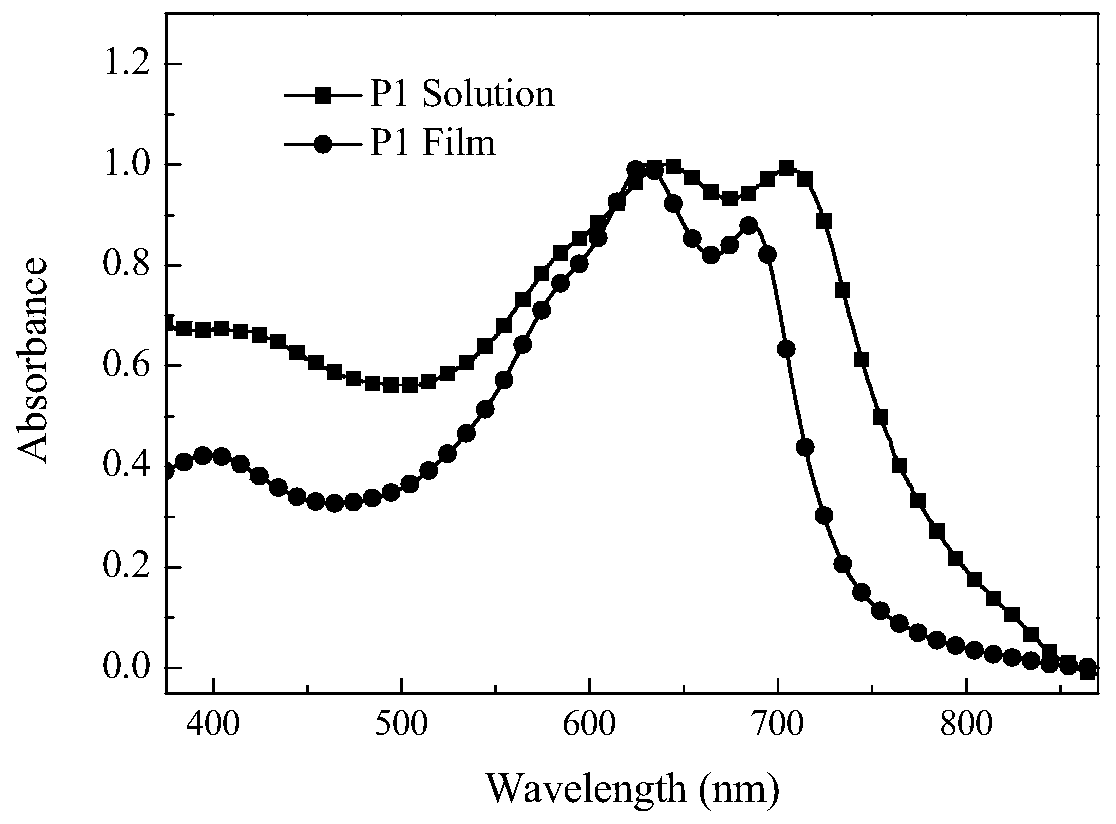

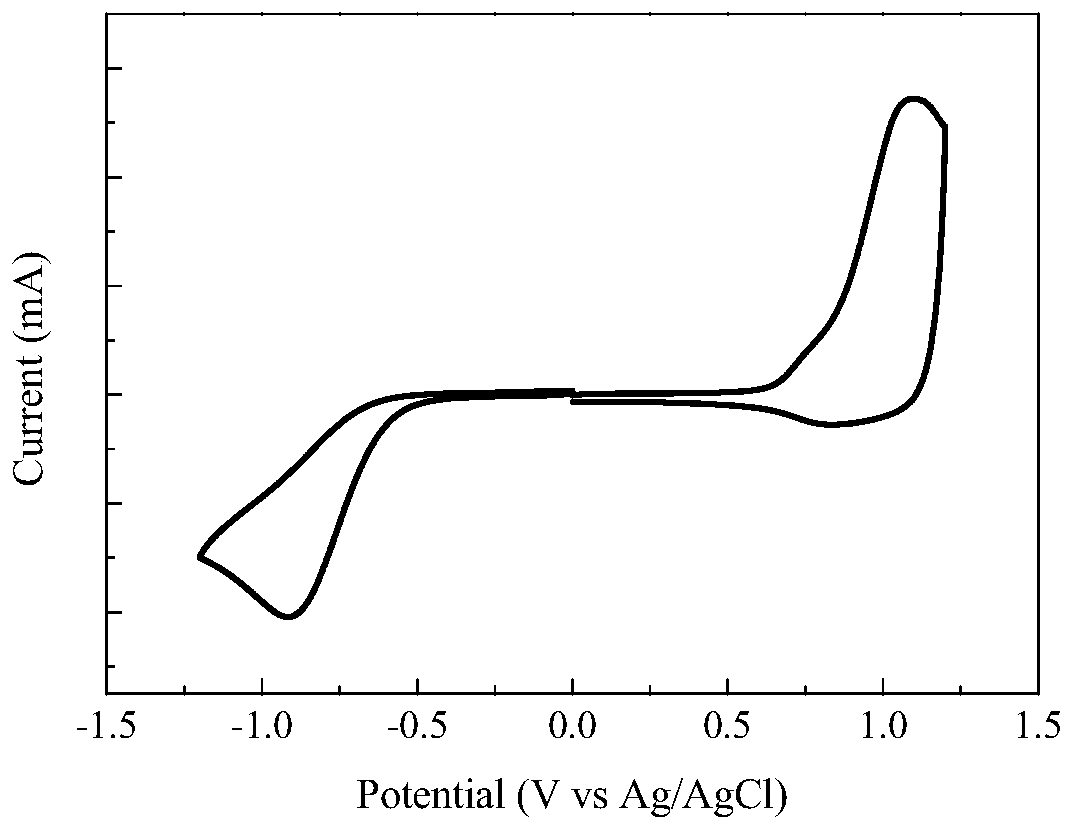

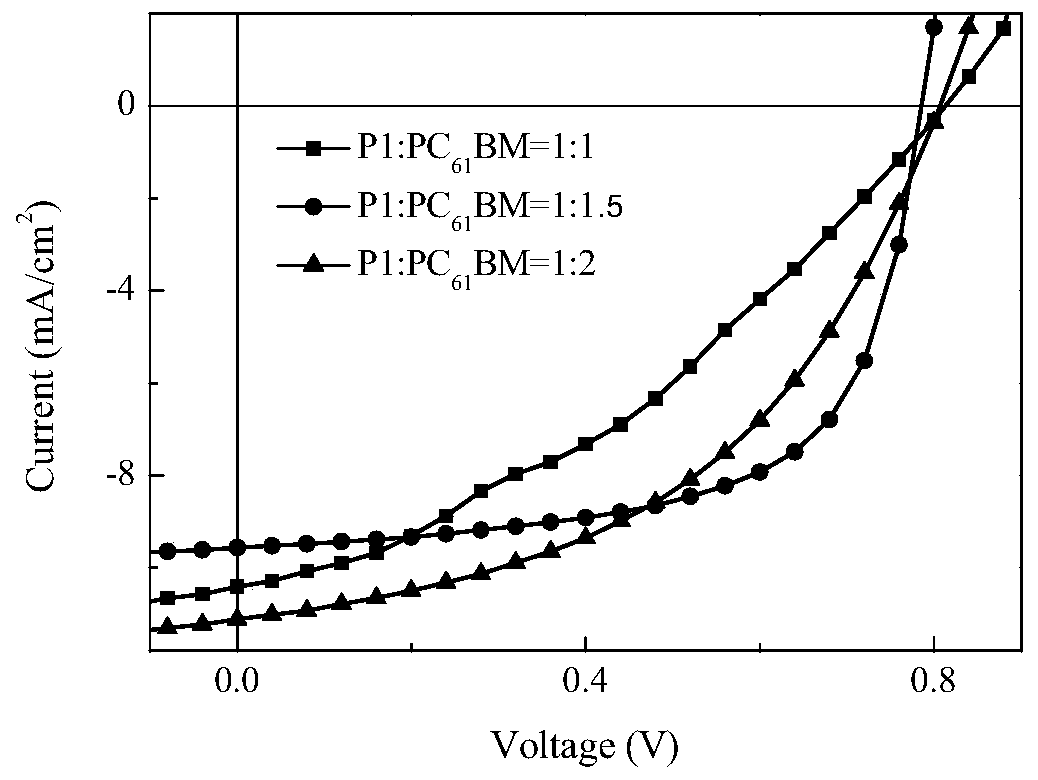

Thieno (2, 3-f) benzofuran compound, polymers thereof and application of polymers

InactiveCN103936760AImprove solubilityBroaden applicationOrganic chemistryFinal product manufactureUnit structureElectrochemistry

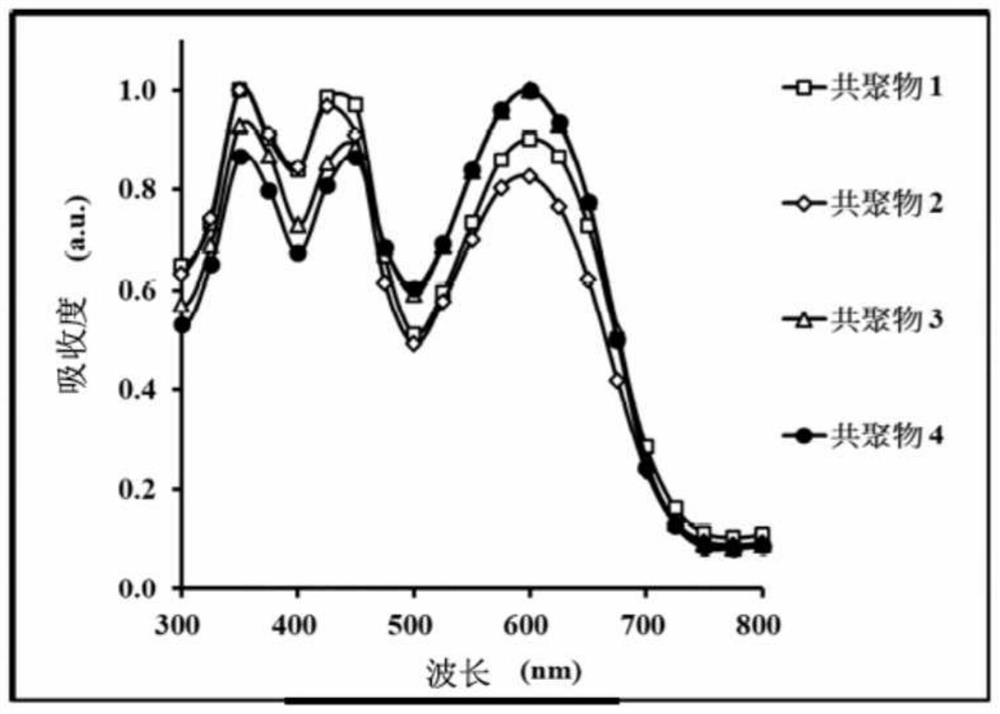

The invention discloses a thieno (2, 3-f) benzofuran compound, polymers thereof and an application of the polymers. A series of polymers with thieno (2, 3-f) benzofuran compound unit structures are synthesized from the thieno (2, 3-f) benzofuran compound, benzothiadiazole, benzotriazole, benzoxadiazole and other monomers through a Stille coupling polymerization method. The polymers have good thermal stability and electrochemical performance and can be mixed with commonly used fullerene and organic acceptor substances to prepare polymer solar cells with high photoelectric conversion rate, the photoelectric conversion efficiency of single-layer polymer solar cell devices can be as high as 6.4%, and the polymer materials have huge commercial prospects in application of the solar cells.

Owner:CENT SOUTH UNIV

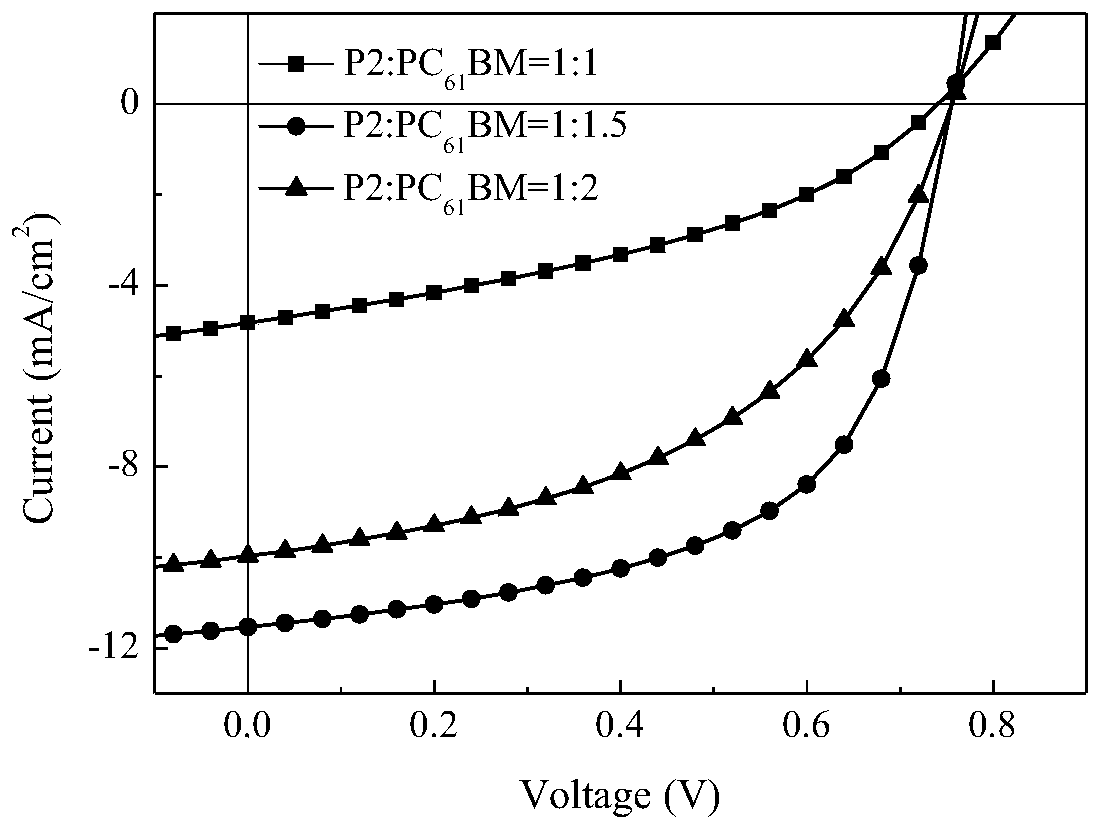

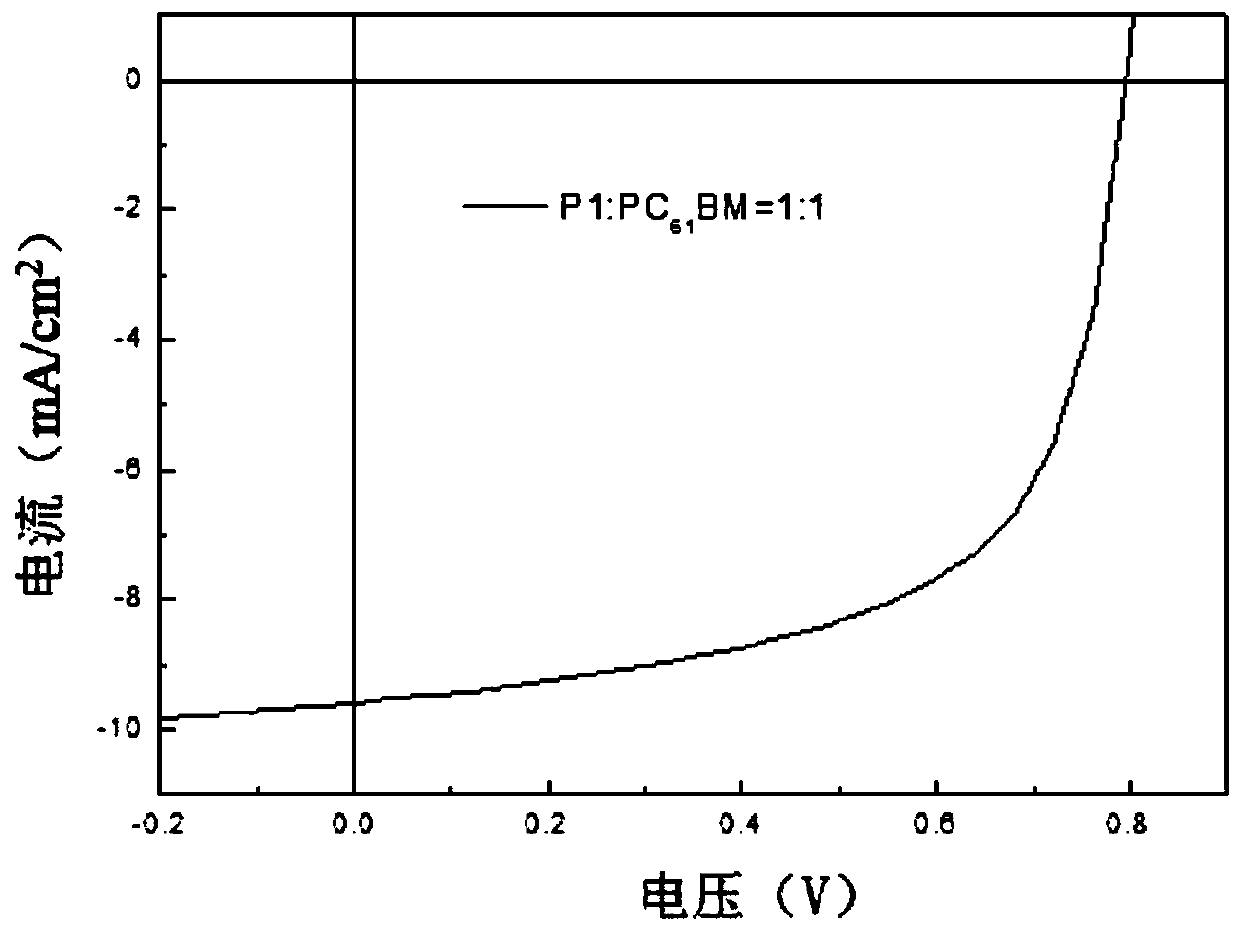

Two-dimensional conjugated benzodifuran organic micro-molecular photovoltaic material, and preparation method and application thereof

ActiveCN106977531AImprove machinabilityGood photoelectric conversion characteristicsOrganic chemistrySolid-state devicesOrganic solar cellElectron donor

The invention discloses a two-dimensional conjugated BDF organic micro-molecular photovoltaic material, and a preparation method and an application thereof. Two-dimensional conjugated BDF organic micro-molecules with the structure represented by formula (I) are obtained by connecting a thiophene conjugate side chain-containing benzo[1,2-b;3,4-b]difuran (BDF) unit with another aryl heterocycle through a Stille coupling technology. The organic micro-molecular photovoltaic material has wide visible region absorption, suitable HOMO and LUMO energy levels and narrow band gap. Organic solar cells are produced by using the organic molecules as an electron donor and PC61BM as an electron receptor, the maximum energy conversion efficiency of the organic solar cells reaches up to 3.7%, and the organic solar cells have a good photoelectric conversion efficiency.

Owner:HUNAN UNIV OF ARTS & SCI

Preparation method and application of photoelectrochemical sensor based on Au@TiO2/Bi2S3 modified electrode

InactiveCN104865300AImprove photoelectric performanceGood photoelectric conversion characteristicsMaterial electrochemical variablesMedicineEngineering

The invention relates to a preparation method and an application of a photoelectrochemical sensor which is used for detection of a breast cancer marker CA15-3 and based on an Au@TiO2 / Bi2S3 modified electrode, and belongs to the technical field of novel functional materials and biosensing detection. Specifically, an Au@TiO2 core-shell nanomaterial with photoelectrocatalysis activity and a Bi2S3 nanorod are compounded on an electrode, the marker-free photoelectrochemical sensor is prepared, and the breast cancer marker CA15-3 is rapidly detected in an ultra-sensitive manner. The method has a great significance in early diagnosis and judgment after healing of breast cancer.

Owner:UNIV OF JINAN

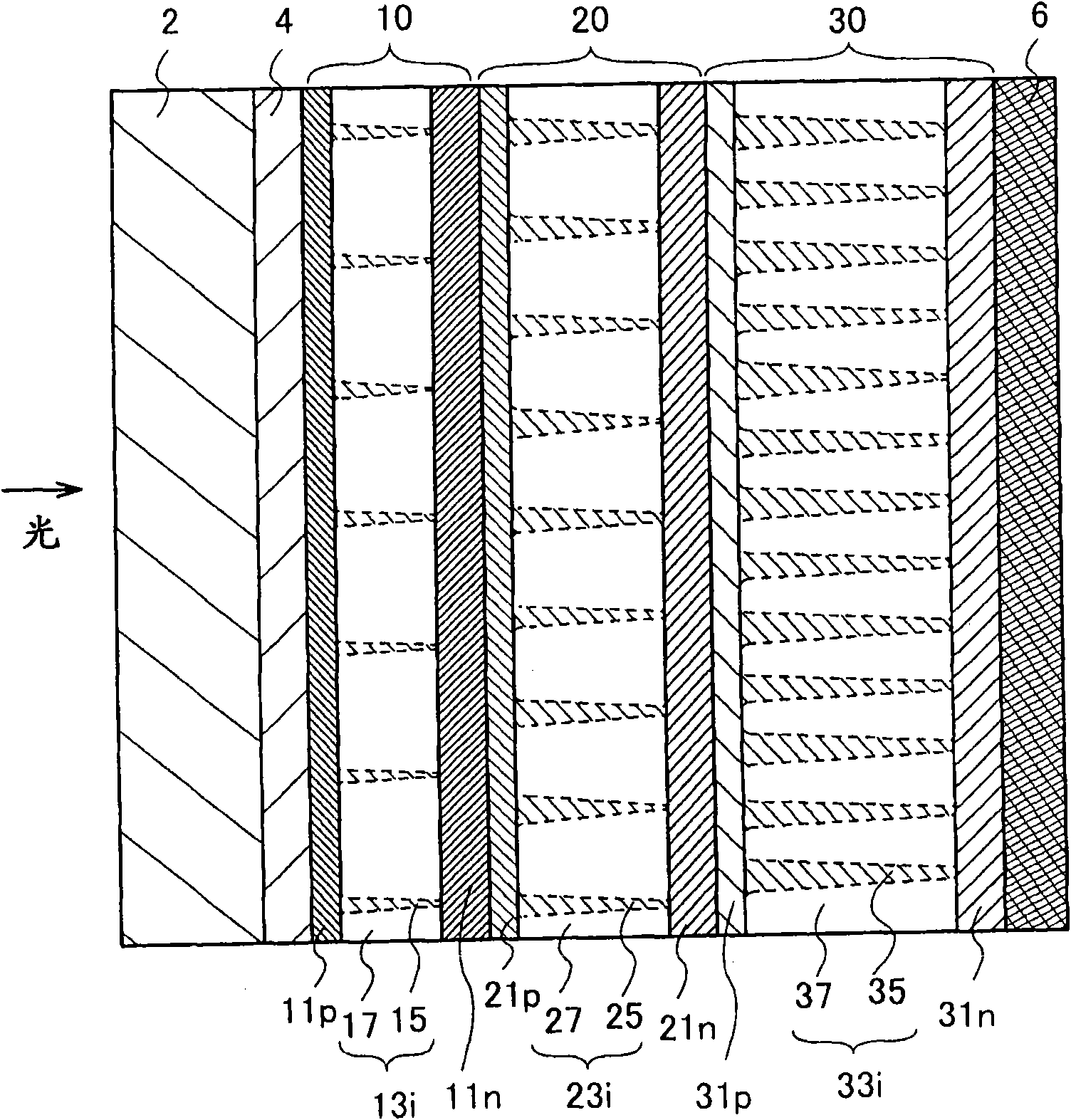

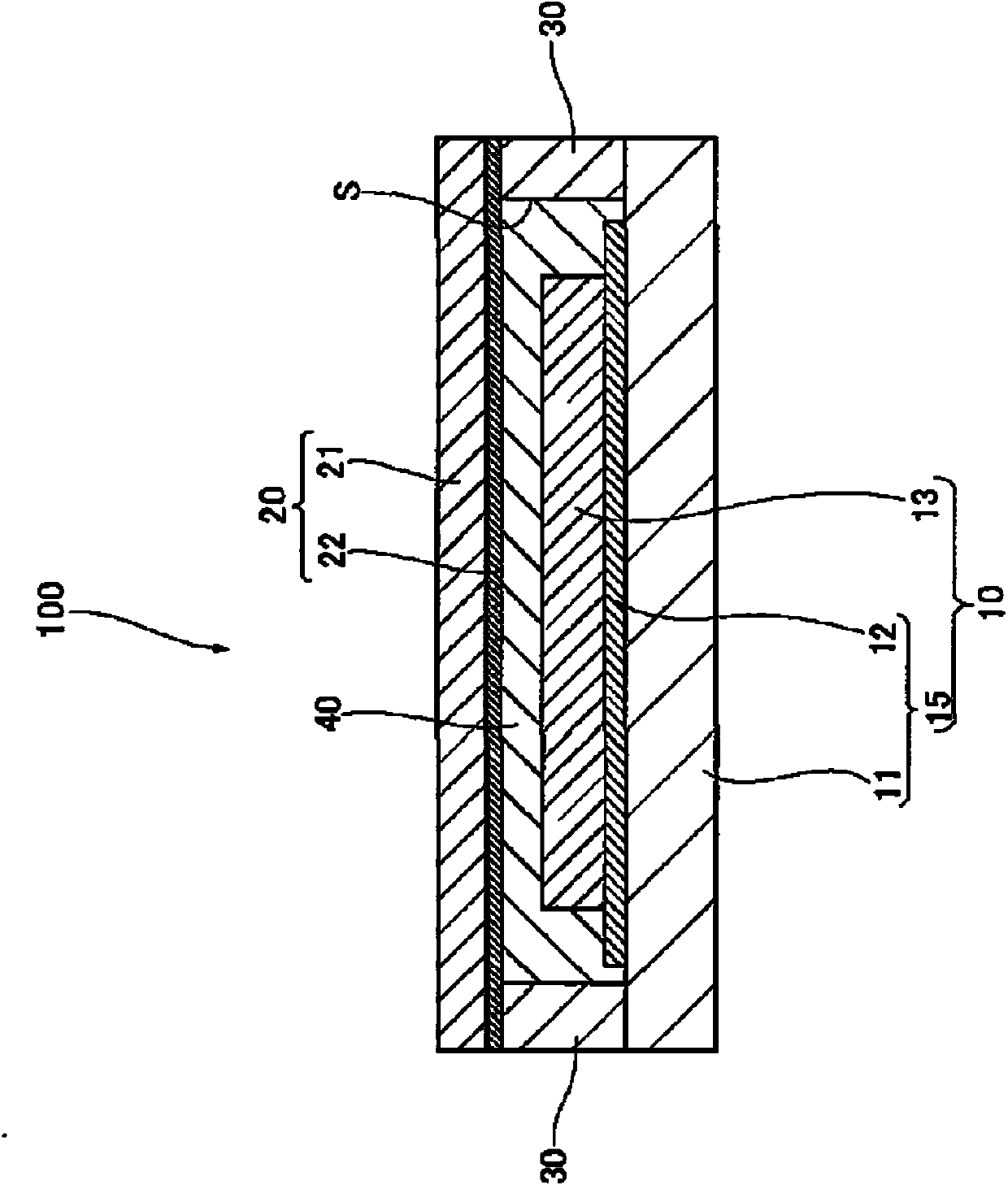

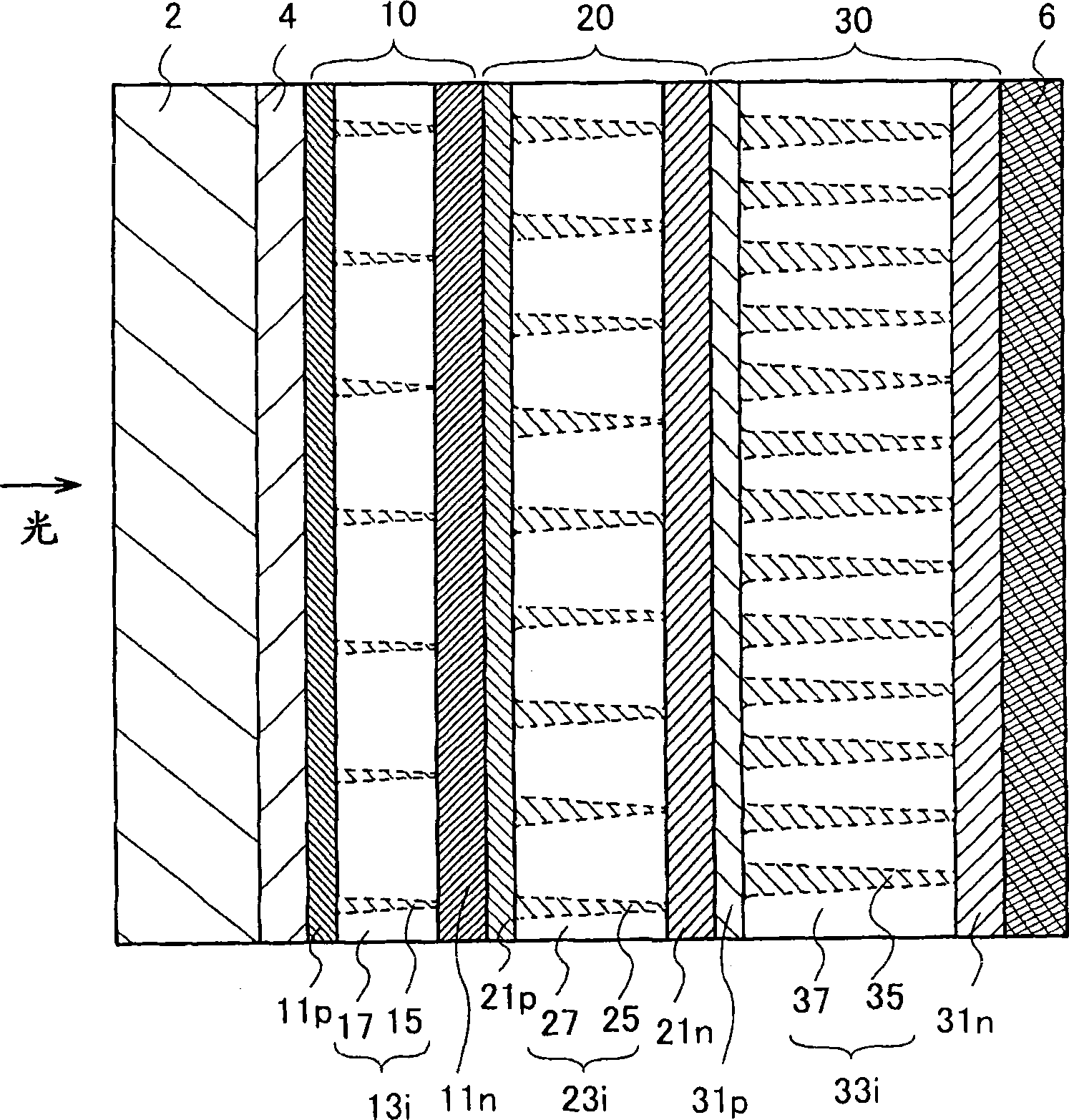

Photoelectric conversion device and method for manufacturing the same

InactiveCN101593778AImprove productivityReduce photodegradationFinal product manufacturePhotovoltaic energy generationSemiconductor materialsSemiconductor structure

The object of the present invention is to realize high efficiency and improved productivity at the same time. A photoelectric conversion device comprises a unit having a semiconductor structure, the unit comprises: a conductive first impurity semiconductor layer; a conductive second impurity semiconductor layer reverse to the conductive first impurity semiconductor layer; and a semiconductor layer comprising a crystal region over the first impurity semiconductor layer and the second impurity semiconductor layer in an amorphous structure. The flow ratio of the dilution gas is set more than 1 time and less than 10 times of the semiconductor material gas, preferably setting more than 1 time and less than 6 times, and leading in a reaction space to generate plasma to form a semiconductor layer comprising a crystal region.

Owner:SEMICON ENERGY LAB CO LTD

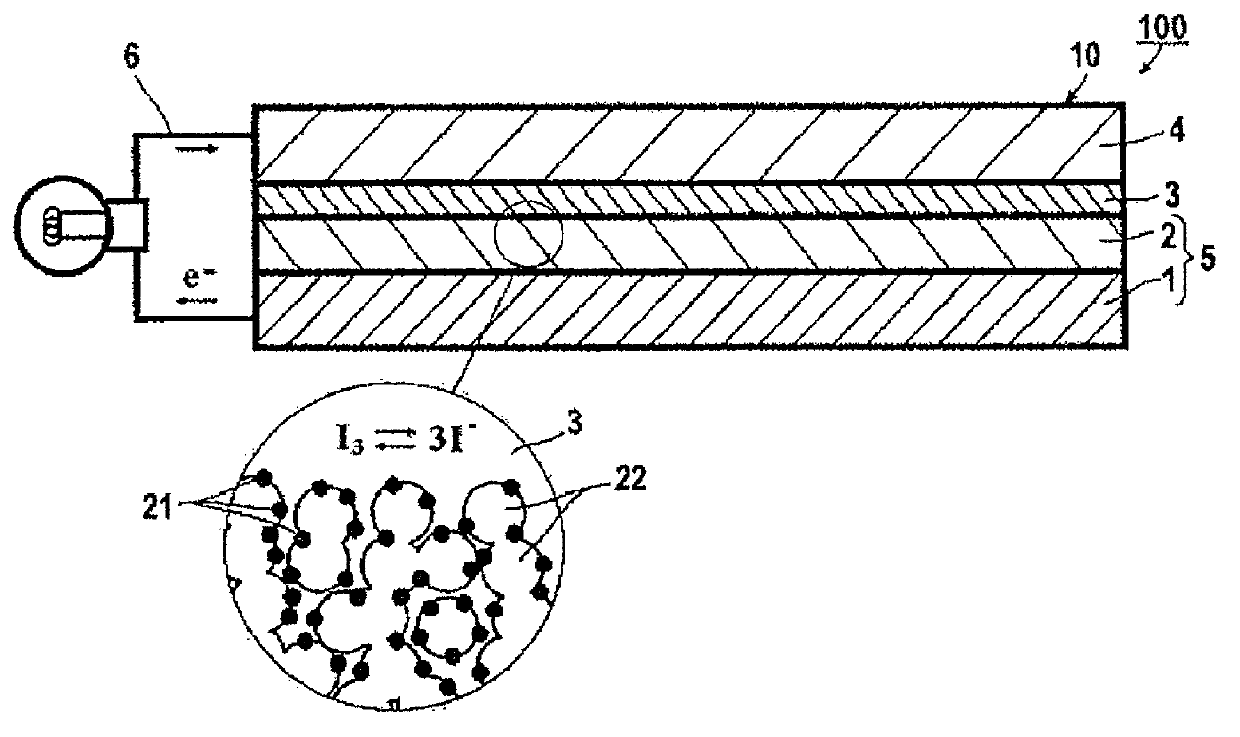

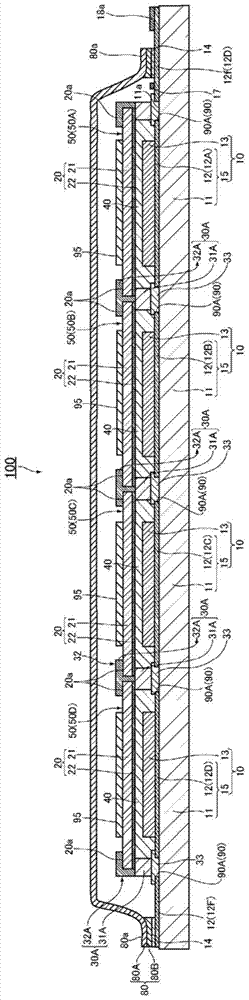

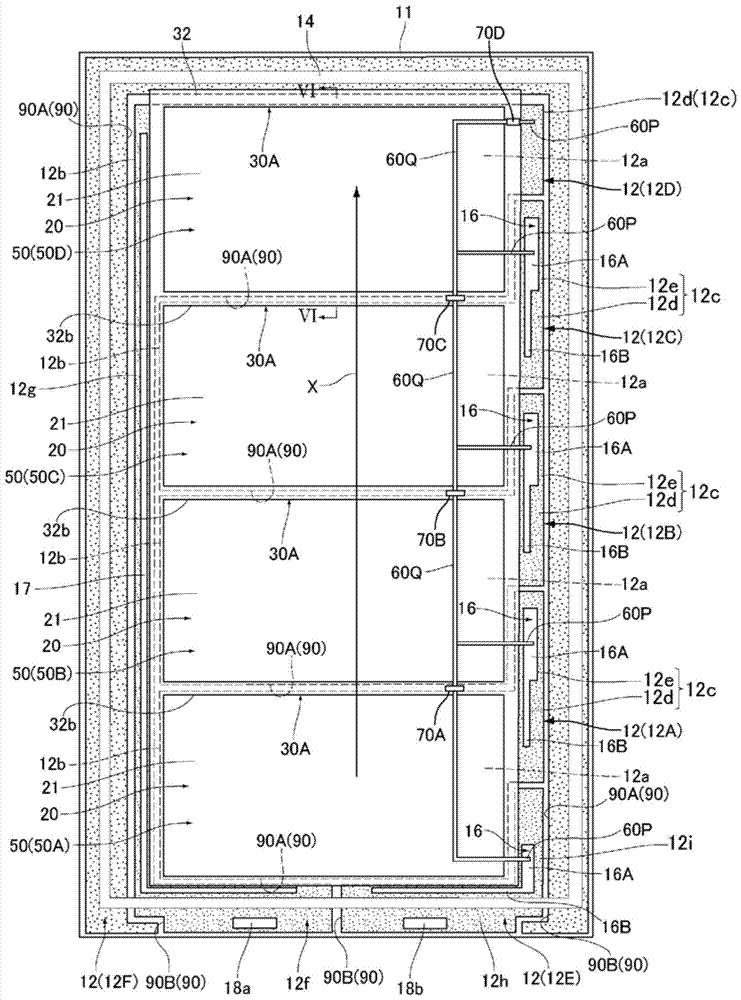

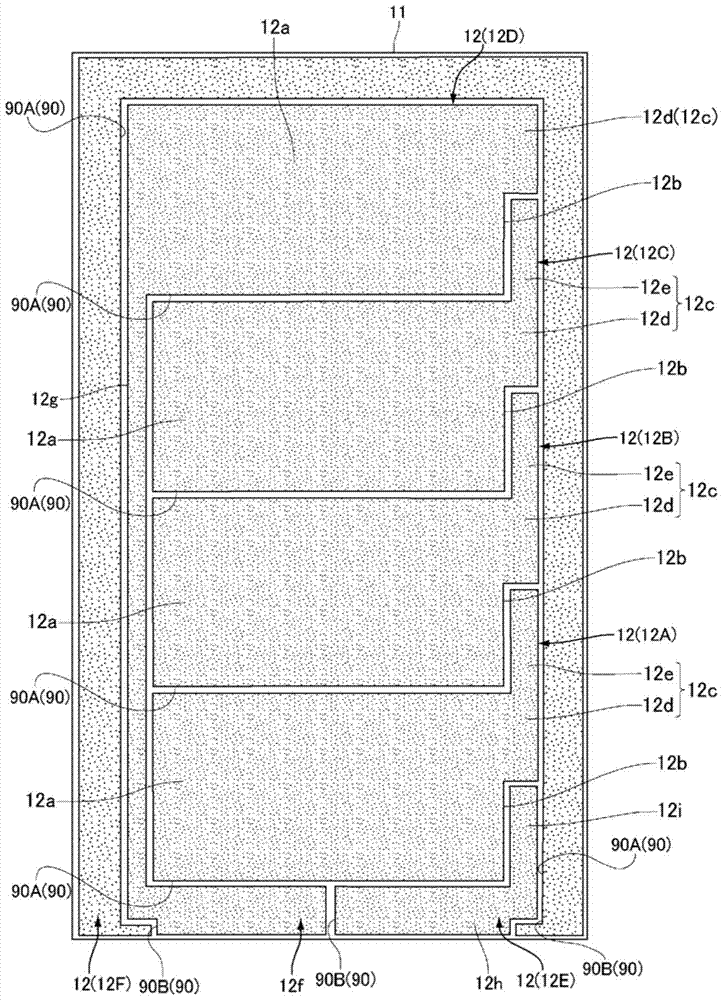

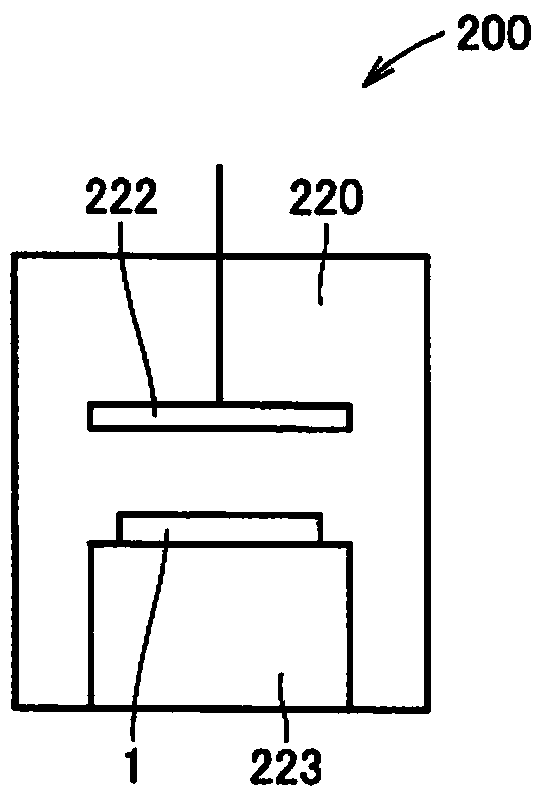

Dye-sensitized solar cell element for low luminance

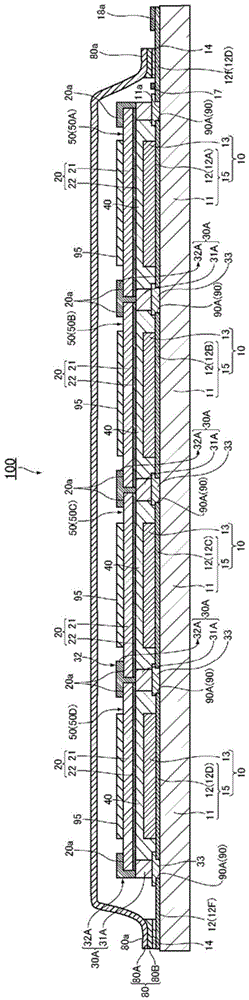

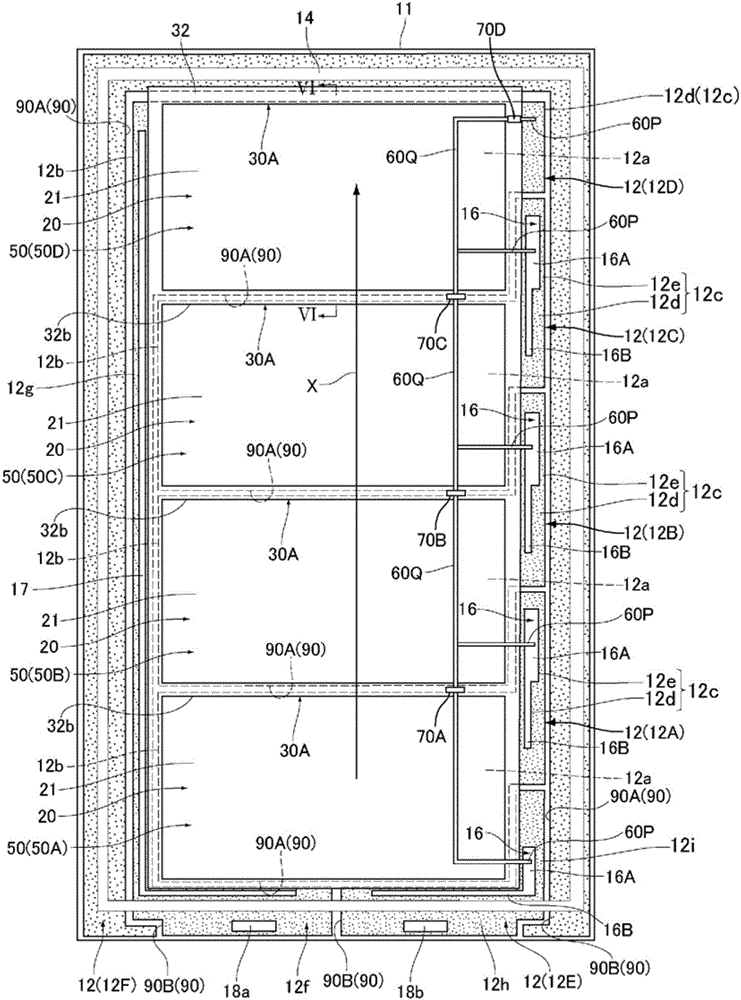

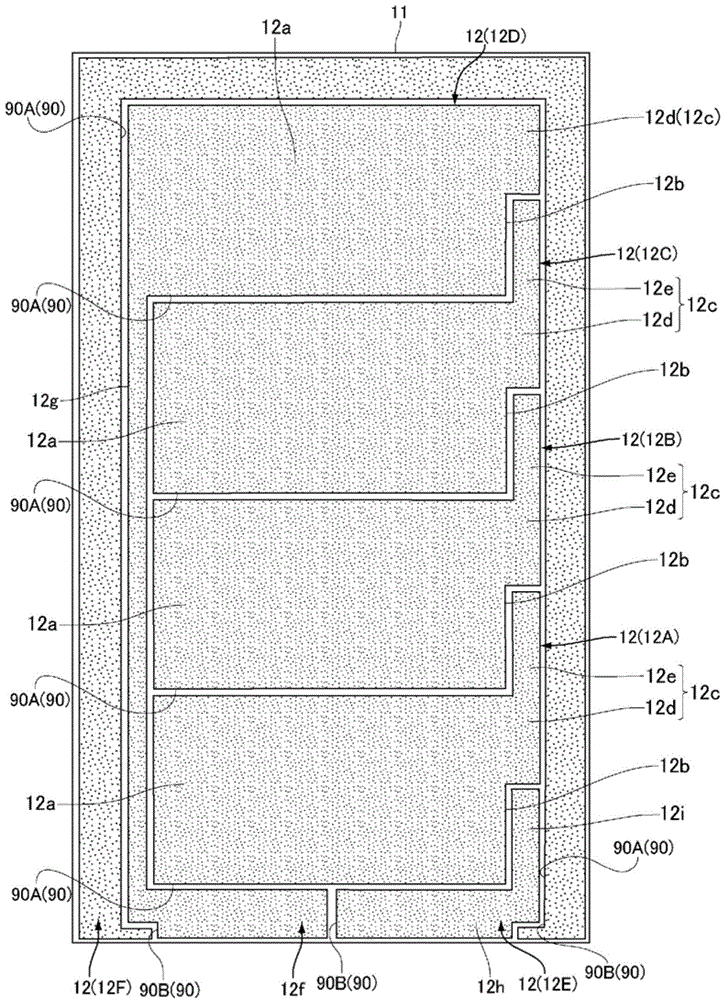

ActiveCN104380407AGood photoelectric conversion characteristicsSave spaceLight-sensitive devicesCapacitor electrolytes/absorbentsIlluminanceTransparent conducting film

This dye-sensitized solar cell element for low luminance comprises: at least one dye-sensitized solar cell; a first current drawing part for drawing an electric current from at least one dye-sensitized solar cell; and a second current drawing part for drawing an electric current from at least one dye-sensitized solar cell. Each dye-sensitized solar cell is provided with: a first electrode which has a transparent substrate and a transparent conductive film that is provided on the transparent substrate; a second electrode which faces the first electrode and has a metal substrate; an oxide semiconductor layer which is provided on the first electrode or on the second electrode; and an annular sealing part which joins the first electrode and the second electrode with each other. The first current drawing part is contained in the transparent conductive film of one dye-sensitized solar cell among the at least one dye-sensitized solar cell. The second current drawing part is electrically connected to the metal substrate of the second electrode of one dye-sensitized solar cell among the at least one dye-sensitized solar cell. The first current drawing part and the second current drawing part are arranged to be adjacent to each other.

Owner:THE FUJIKURA CABLE WORKS LTD

Chemical sensor simultaneously having light sensitivity and gas sensitivity

InactiveCN107807157AWide range of usesHigh light sensitivityMaterial electrochemical variablesElectrical resistance and conductanceGas detector

The present invention provides a chemical sensor simultaneously having light sensitivity and gas sensitivity, and relates to a semiconductor device specially adapted for various gases and illuminationdetection. The chemical sensor comprises the sensitive layer of a chemical sensor, a planar Au plating ceramic substrate, a leading wire and a gas sensor base, wherein the sensitive layer of the chemical sensor is a thin film layer obtained by doping a CH3NH3PbI3 perovskite precursor liquid and WO3 nanometer powder, and a heating layer made of a special material and a Au plating electrode are arranged on the planar ceramic sheet. According to the present invention, by preparing the CH3NH3PbI3 perovskite precursor liquid and WO3 nanometer powder mixing chemical sensor, the gas sensitivity of the sensor is improved, the sensitivity to gases is improved, the chemical sensor has good sensitivity to light, and the resistance of the sensor is reduced in the case of strong illumination so as toimprove the sensitivity to gases.

Owner:HEBEI UNIV OF TECH

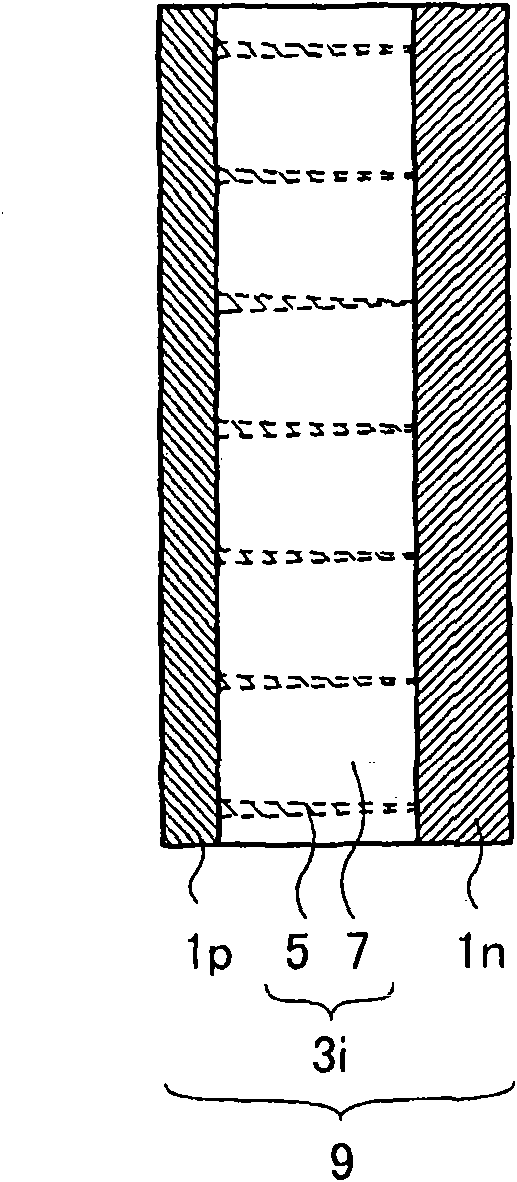

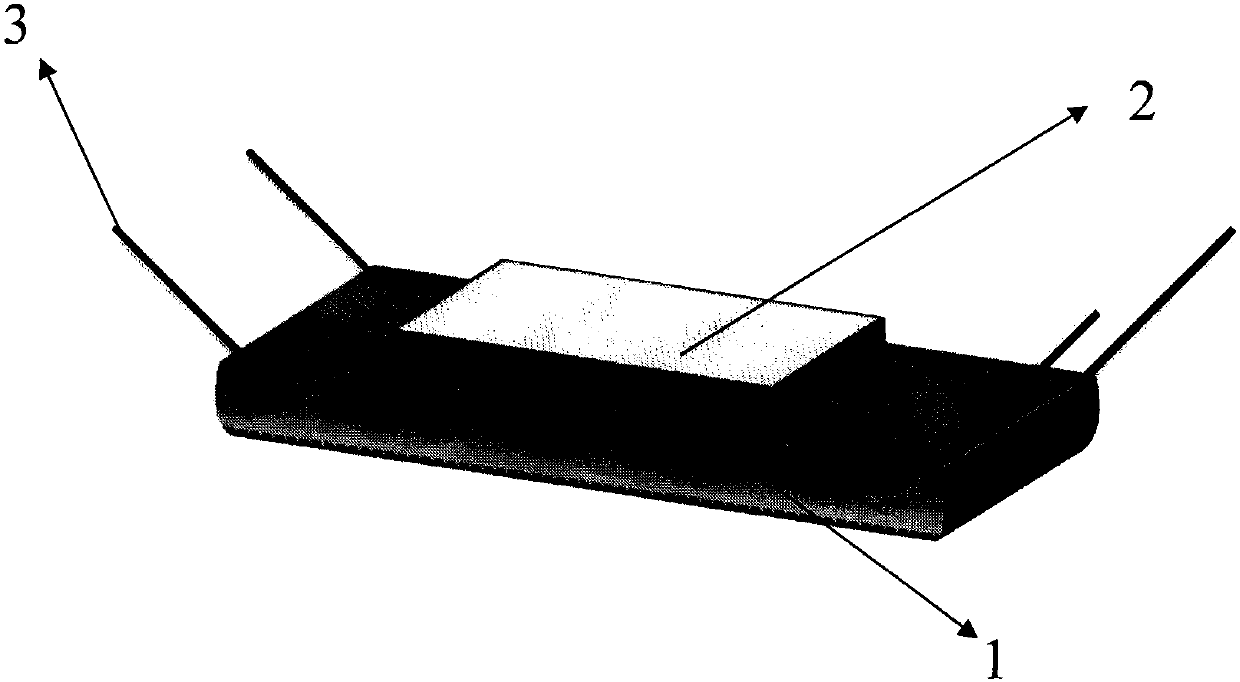

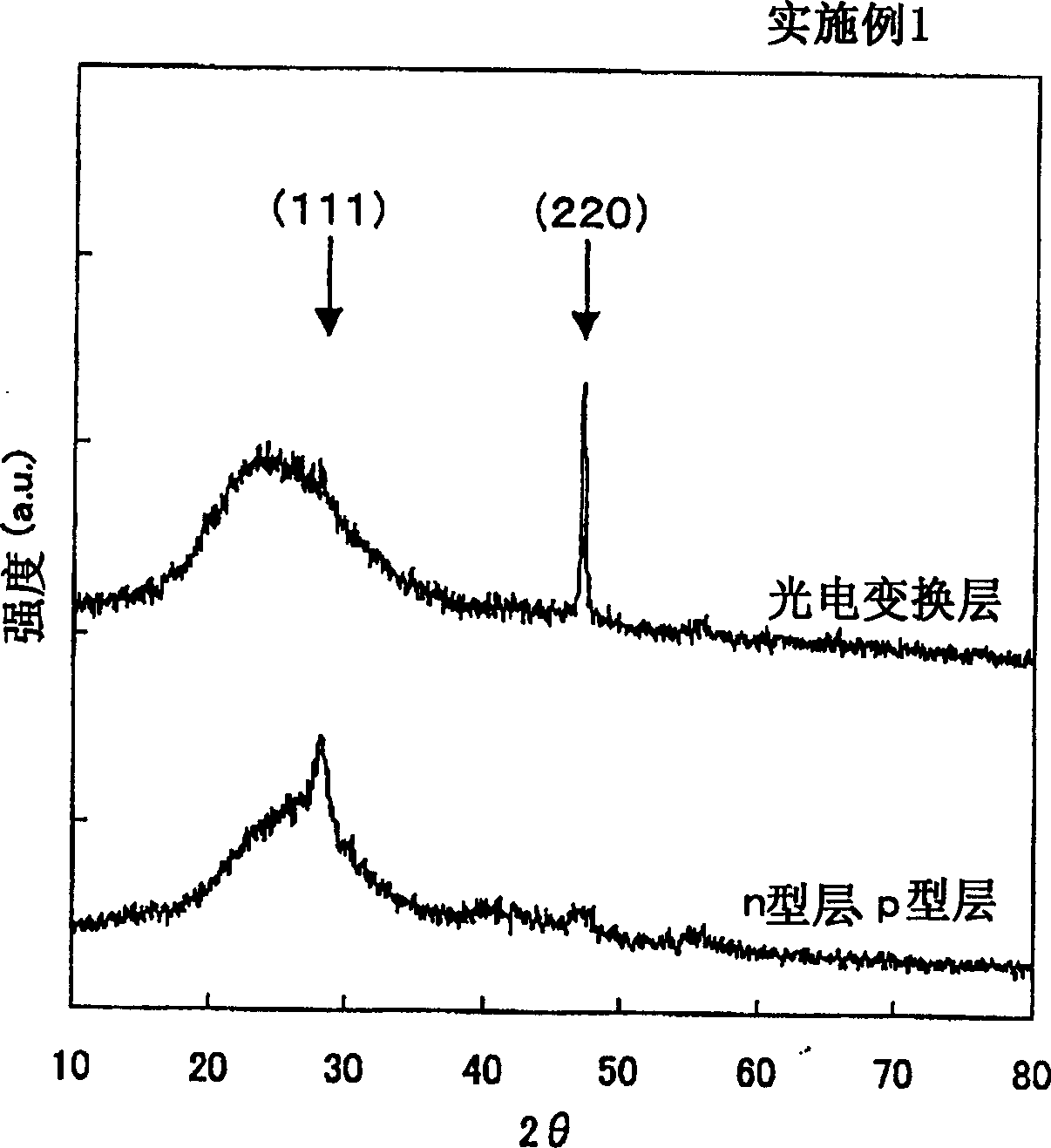

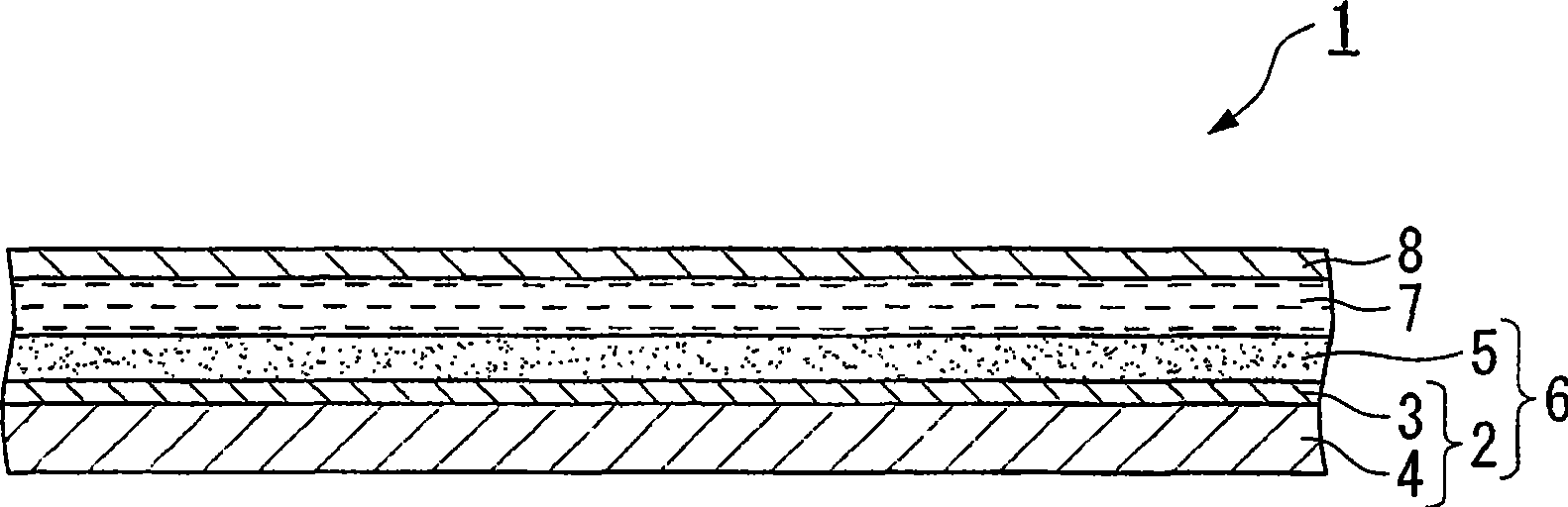

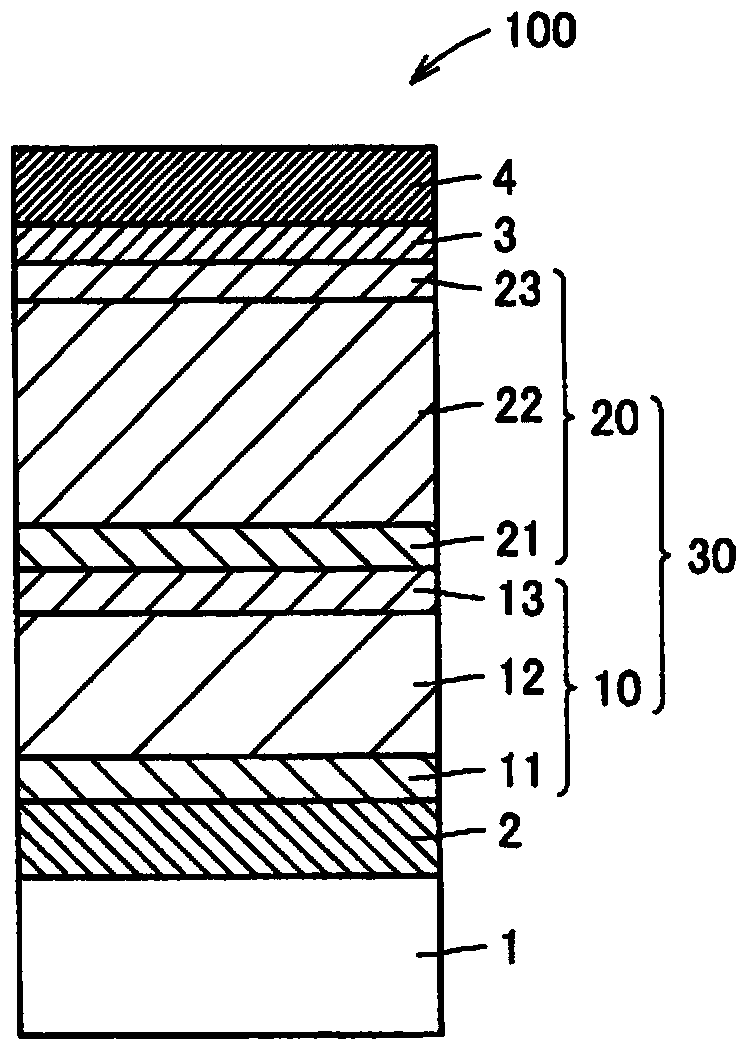

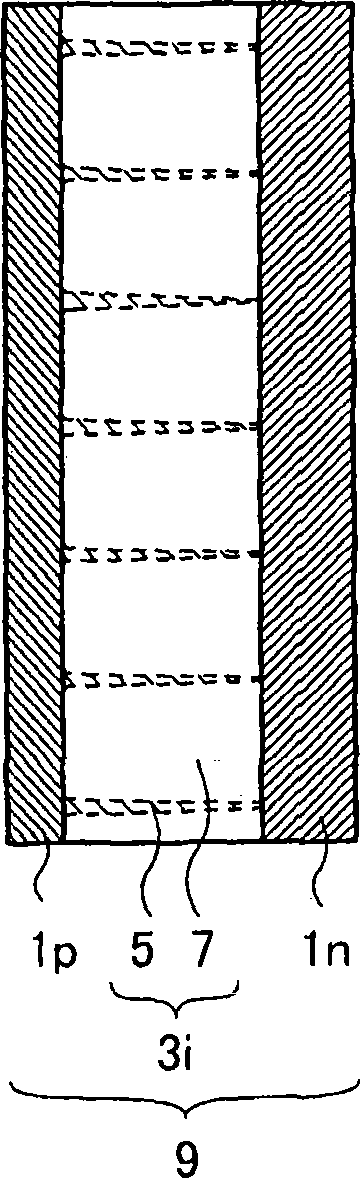

Photovoltaic apparatus

InactiveCN1595667AImprove membrane qualityGood photoelectric conversion characteristicsPhotovoltaic energy generationSemiconductor devicesCrystal orientationEngineering

A photovoltaic apparatus capable of improving output characteristics is provided. This photovoltaic apparatus includes at least one power generation unit having a first conductivity type first non-single-crystalline semiconductor layer (3, 13, 43, 53, 63, 73, 83) including at least one layer, a substantially intrinsic second non-single-crystalline semiconductor layer (4, 14, 44, 54, 64, 74, 84) including at least one layer and a second conductivity type third non-single-crystalline semiconductor layer (5, 15, 45, 55, 65, 75, 85) including at least one layer, and at least one of the layer constituting the first non-single-crystalline semiconductor layer, the layer constituting the second non-single-crystalline semiconductor layer and the layer constituting the third non-single crystalline semiconductor layer has a preferred crystal orientation plane different from those of the remaining layers.

Owner:SANYO ELECTRIC CO LTD

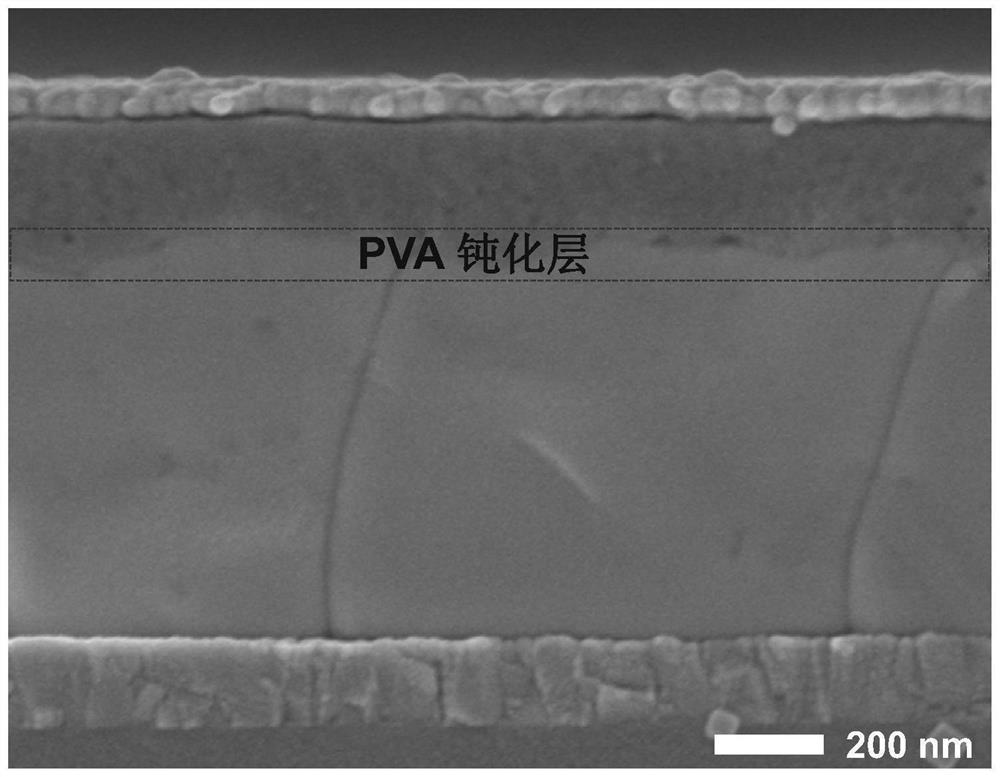

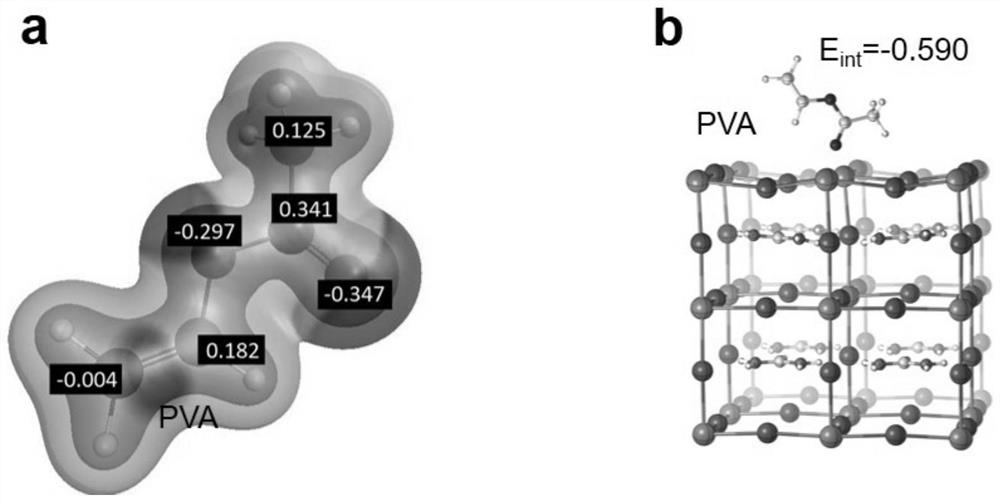

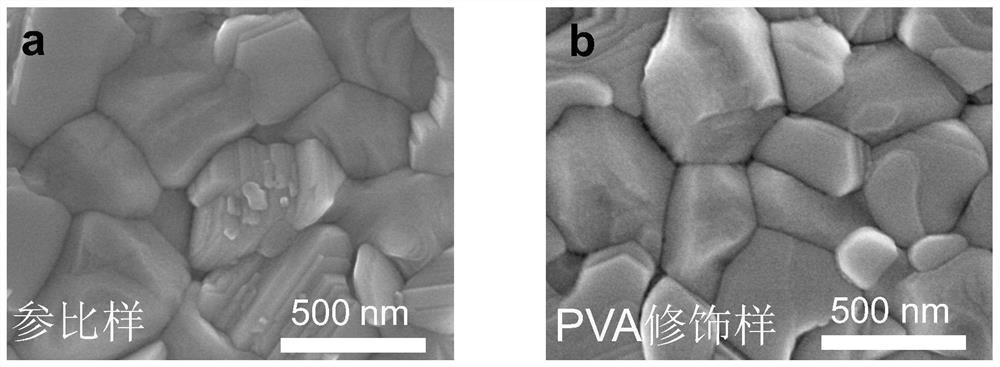

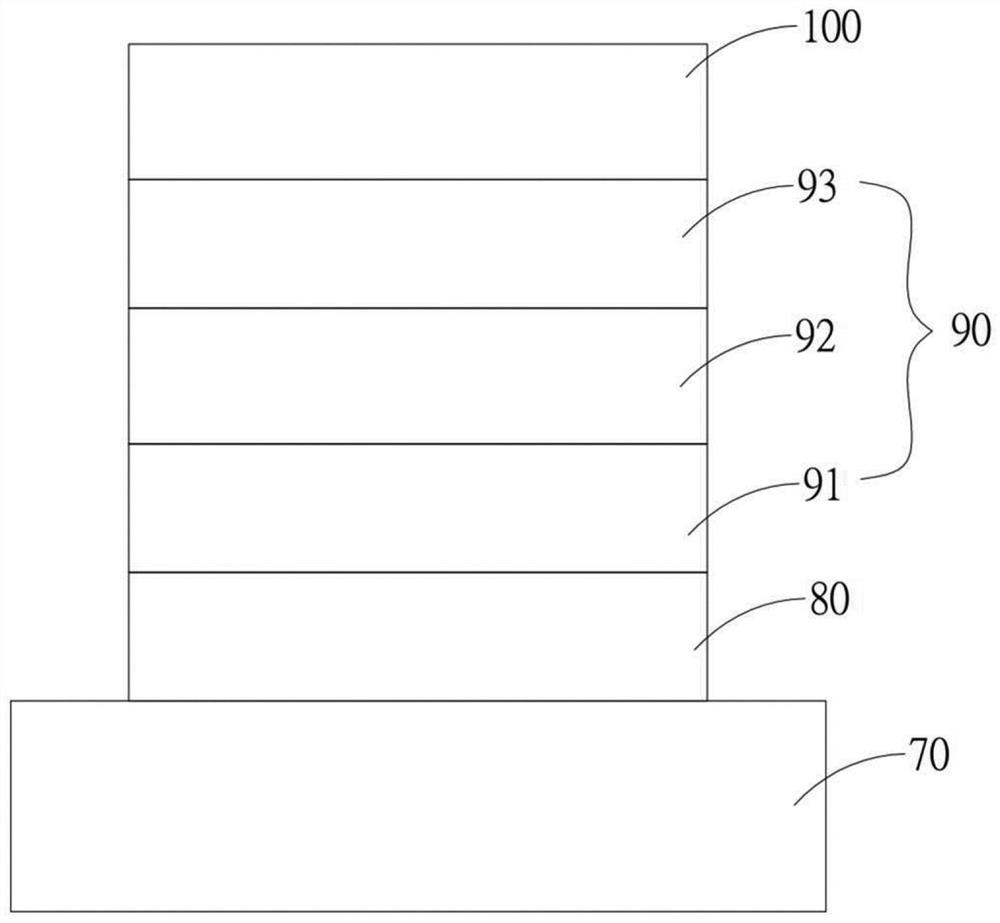

Perovskite solar cell device based on polyvinyl acetate passivation film surface/interface defects and preparation method thereof

PendingCN113725366AGood light stabilityGood photoelectric conversion characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingPerovskite (structure)Hole transport layer

The invention provides a perovskite solar cell device based on polyvinyl acetate passivation film surface / interface defects and a preparation method thereof. The basic structure of the perovskite solar cell photovoltaic device comprises a conductive substrate, an electron transport layer, an organic-inorganic hybrid metal halide perovskite light absorption layer, an interface defect passivation layer, a hole transport layer and a photo-anode. The perovskite thin film solar photovoltaic device is simple in preparation method and low in cost, the PVA interface defect passivation layer greatly reduces interface non-radiative recombination loss, ion migration and performance degradation of the interface of the light absorption layer and the hole transport layer are inhibited, the photoelectric conversion efficiency and long-term stability of the device are improved, and important theoretical basis and technical support are provided for practicability of the efficient and stable perovskite solar cell.

Owner:DALIAN UNIV OF TECH

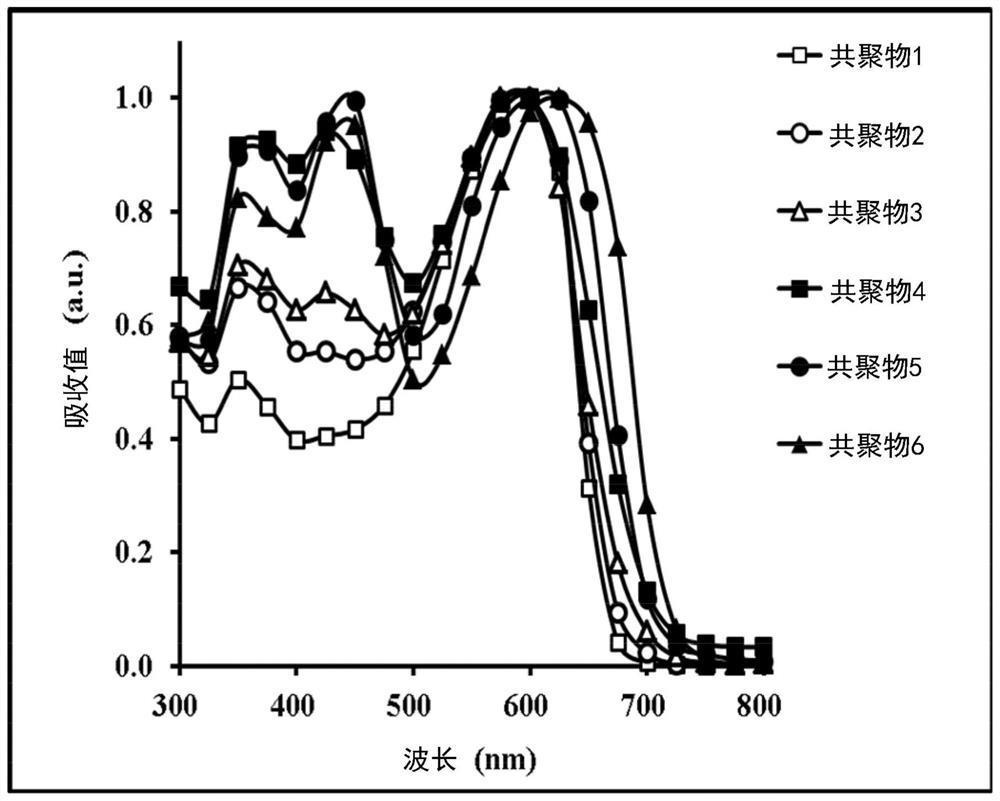

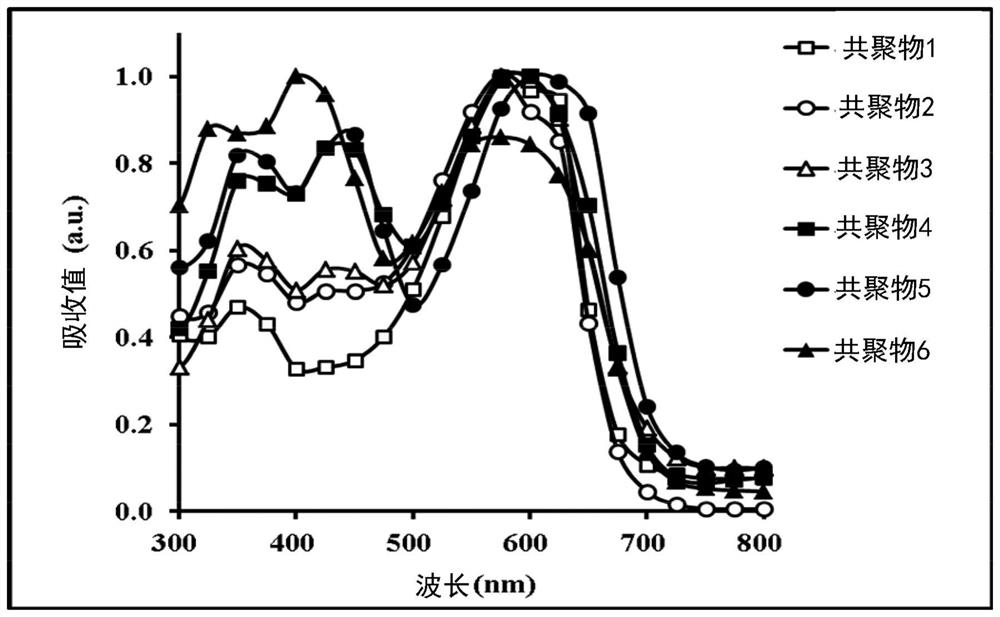

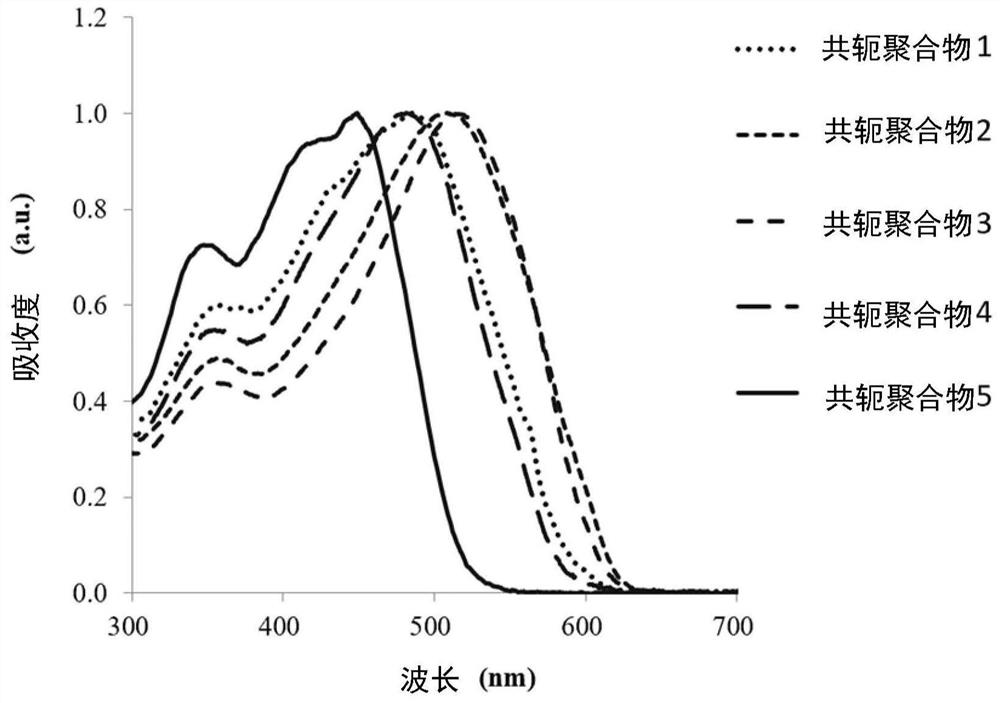

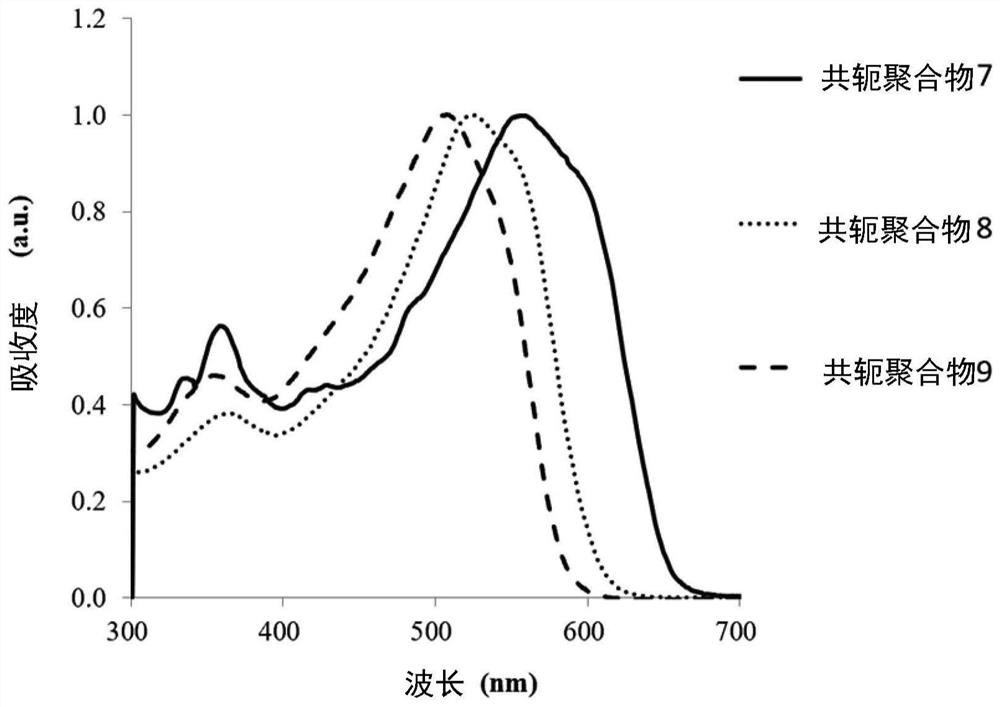

Copolymer and organic photovoltaic element

ActiveCN113061235AImprove energy conversion efficiencyGood photoelectric conversion characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingElectron donorPhotoelectric conversion

The invention discloses a copolymer as an electron donor material and an organic photovoltaic element comprising the copolymer, and the copolymer comprises a repeating unit represented by chemical formula (I). The copolymer has wide absorption wavelength distribution and high absorbance in an ultraviolet-visible region, so that the copolymer can be used as an electron donor material with a wide energy gap, and the copolymer has excellent photoelectric conversion characteristics.

Owner:WAYS TECHN CORP

Copolymer and organic photovoltaic element

ActiveCN113214456AImprove energy conversion efficiencyGood photoelectric conversion characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingElectron donorPhotoelectric conversion

A copolymer as an electron donor material and an organic photovoltaic element comprising the copolymer are provided. The copolymer has wide absorption wavelength distribution and high absorbance in an ultraviolet-visible region, so that the copolymer can be used as an electron donor material with a wide energy gap, and the copolymer has excellent photoelectric conversion characteristics.

Owner:WAYS TECHN CORP

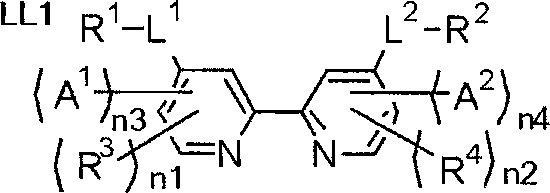

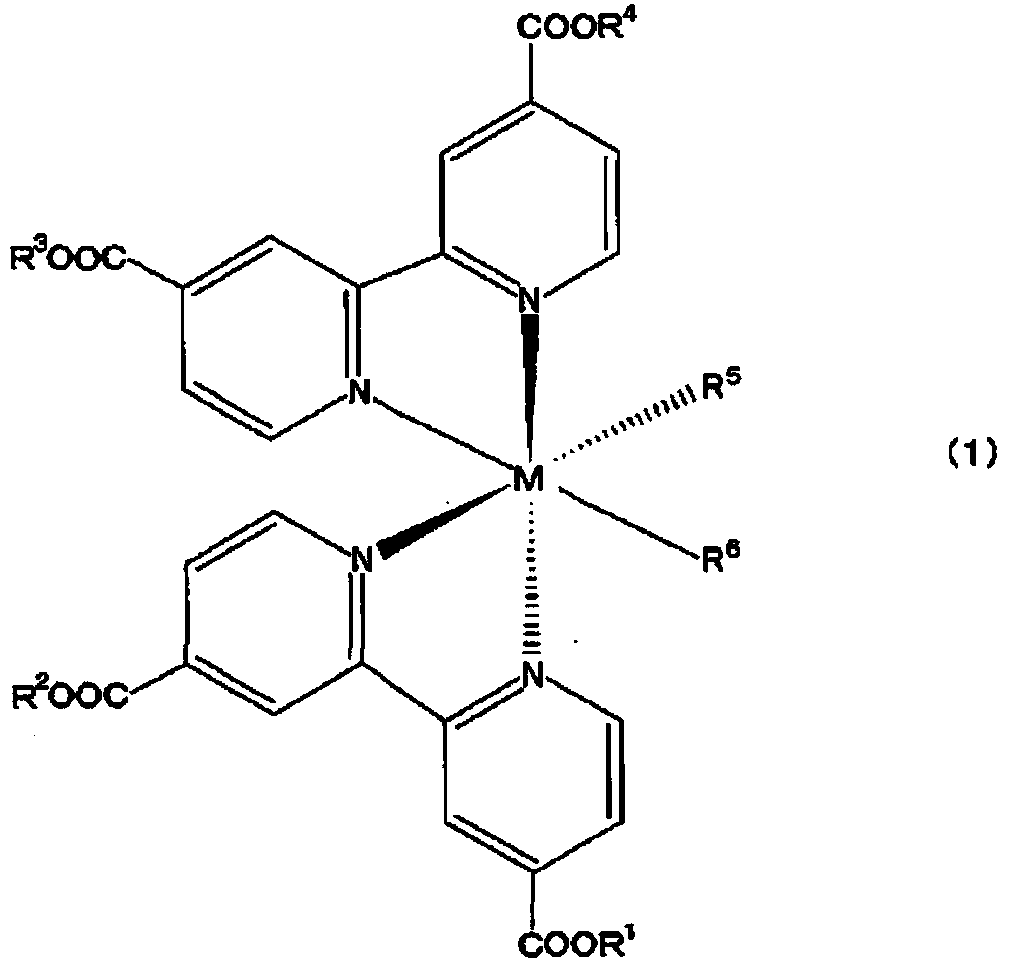

Metal complex dye, photoelectric conversion element, and dye-sensitized solar cell

InactiveCN102869729AIncreased durabilityGood photoelectric conversion characteristicsRuthenium organic compoundsMethine/polymethine dyesPhotoelectric conversionSolar cell

Disclosed is a metal complex dye which is characterized by having a ligand (LL1) that has a structure represented by general formula (I). (In general formula (I), R1 and R2 each represents a specific substituent; L1 and L2 each represents at least one group that is selected from among an ethenylene group, an ethynylene group and an arylene group, and is conjugated with R1, R2 and bipyridine; the ethenylene group and the arylene group may be substituted or unsubstituted; R3 and R4 each represents a substituent; n1 and n2 each represents an integer of 0-3; A1 and A2 each represents an acidic group or a salt thereof; and n3 and n4 each represents an integer of 0-3.)

Owner:FUJIFILM CORP

Non-fullerene electron acceptor material and organic photovoltaic cell

ActiveCN112390813AImprove energy conversion efficiencyGood photoelectric conversion characteristicsOrganic chemistrySolid-state devicesActive layerFullerene

The invention provides a non-fullerene electron acceptor material represented by formula (I), and an organic photovoltaic cell having an active layer comprising the non-fullerene electron acceptor material. When the non-fullerene electron acceptor material is used as an electron acceptor, the energy conversion efficiency (PCE) of an organic photovoltaic cell can be effectively improved.

Owner:WAYS TECHN CORP

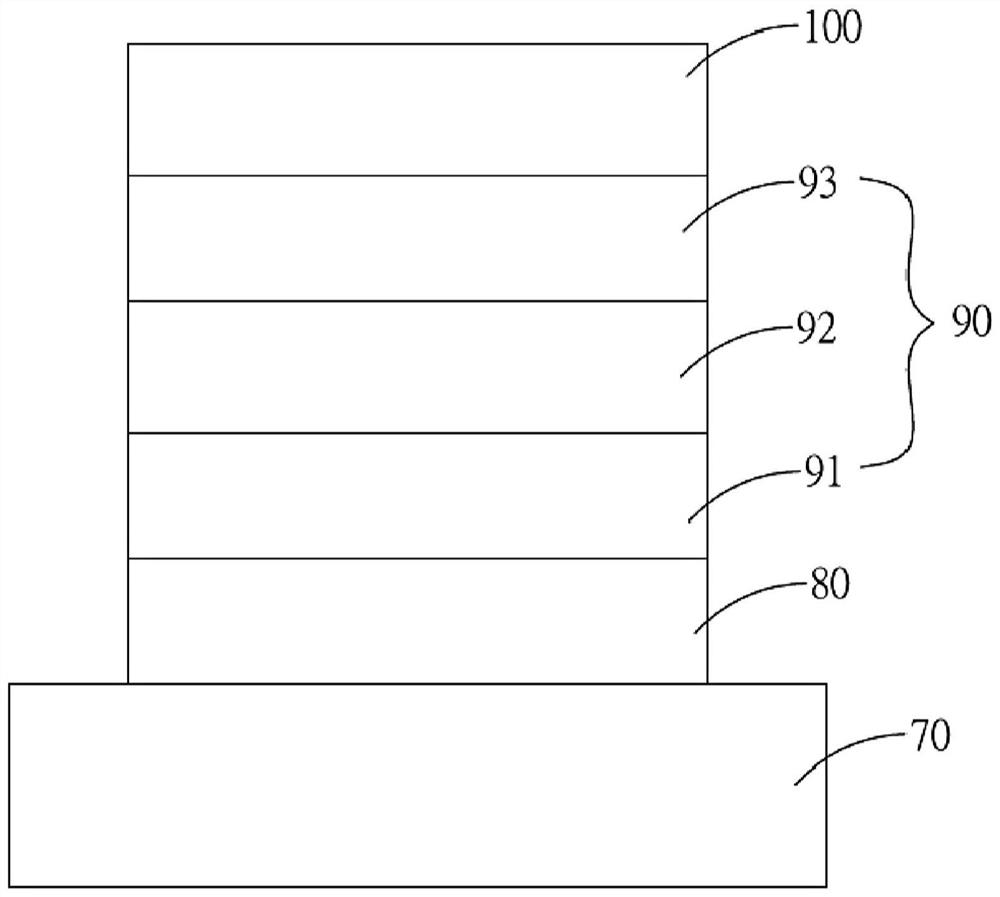

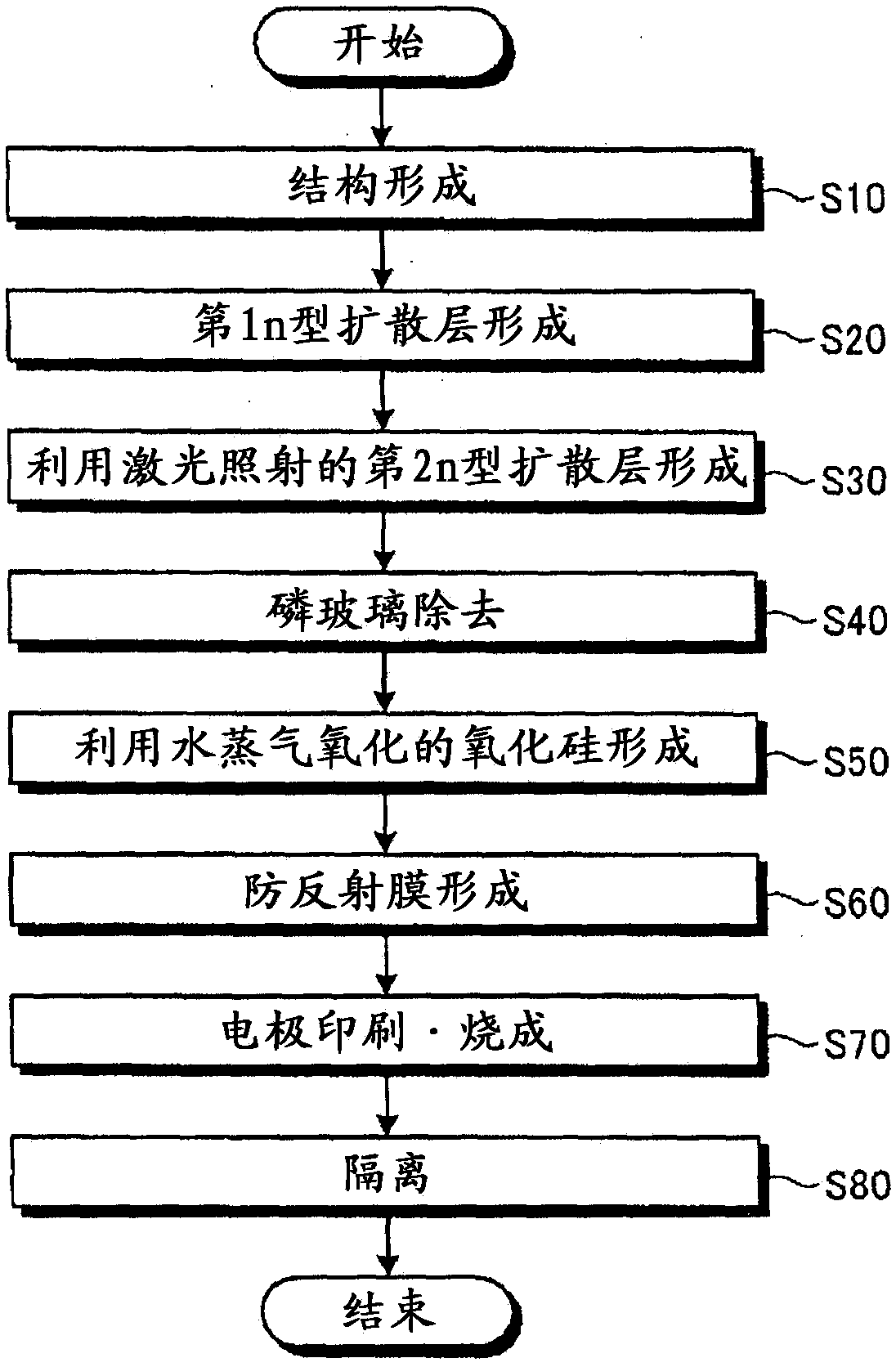

Solar cell, method for producing solar cell, and solar cell module

InactiveCN104254922AWell formedGood photoelectric conversion characteristicsFinal product manufacturePhotovoltaic energy generationRefractive indexSolar cell

A solar cell comprises a first conduction-type semiconductor substrate having on one surface a second conduction-type impurity-diffusing layer wherein impurity elements are diffused; a passivation film formed on the impurity-diffusing layer from an oxide film of the material in the semiconductor substrate; an anti-reflection film formed on the passivation film from a translucent material having a refractive index different from that of the oxide film; a light-receiving front surface electrode that is connected electrically to the impurity-diffusing layer and is formed on the one surface of the semiconductor substrate; and a back surface electrode formed on the other surface of the semiconductor substrate. The impurity-diffusing layer is formed from a first impurity-diffusing layer, which is the light-receiving region and contains impurity elements at a first concentration, and a second impurity-diffusing layer, which is the lower region of the light-receiving front surface electrode and contains impurity elements at a second concentration higher than the first concentration, wherein the surface state of the first impurity-diffusing layer and second impurity-diffusing layer is the same and the thickness of the passivation film on the second impurity-diffusing layer is thinner than the film thickness of the passivation film on the first impurity-diffusing layer.

Owner:MITSUBISHI ELECTRIC CORP

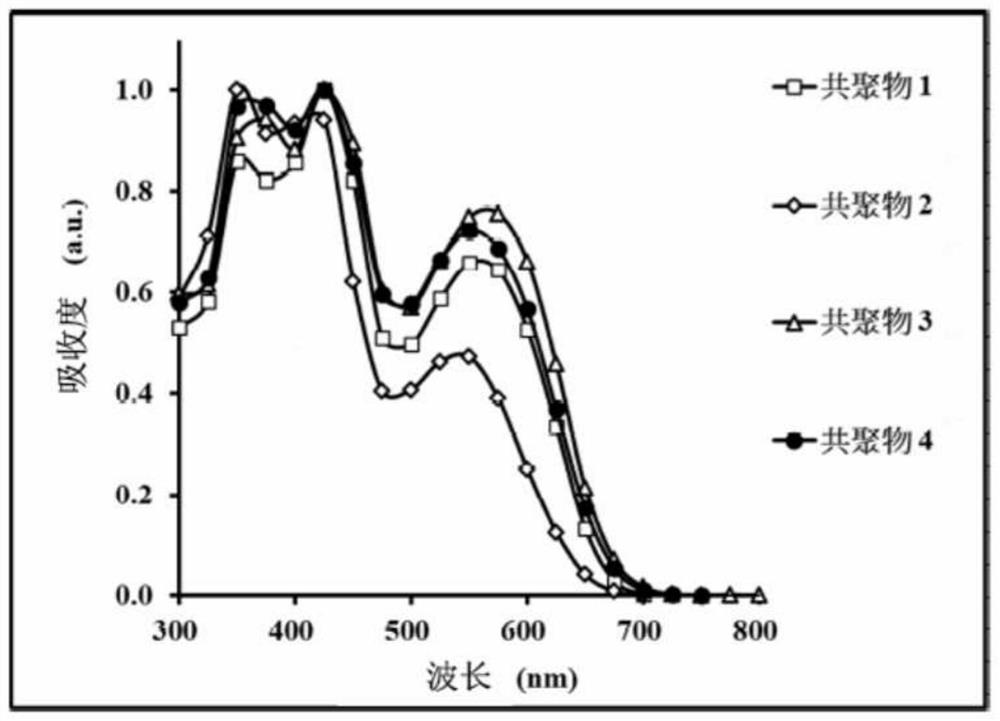

Conjugated polymer and organic photovoltaic element

PendingCN112708112AImprove energy conversion efficiencyGood photoelectric conversion characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingElectron donorThiophene derivatives

The invention provides a conjugated polymer used as an electron donor material, a group of a thiophene derivative on a main chain of the conjugated polymer is used as a weak electron withdrawing group and is matched with an electron donating group on the main chain, and an absorption spectrum and a material energy level are controlled in a wide energy gap range. The conjugated polymer has wide absorption wavelength distribution and high absorbance in an ultraviolet-visible region, so that the conjugated polymer can be used as an electron donor material with a wide energy gap, and the conjugated polymer has excellent photoelectric conversion characteristics. In addition, the invention also provides an organic photoelectric element of which the active layer comprises the conjugated polymer.

Owner:WAYS TECHN CORP

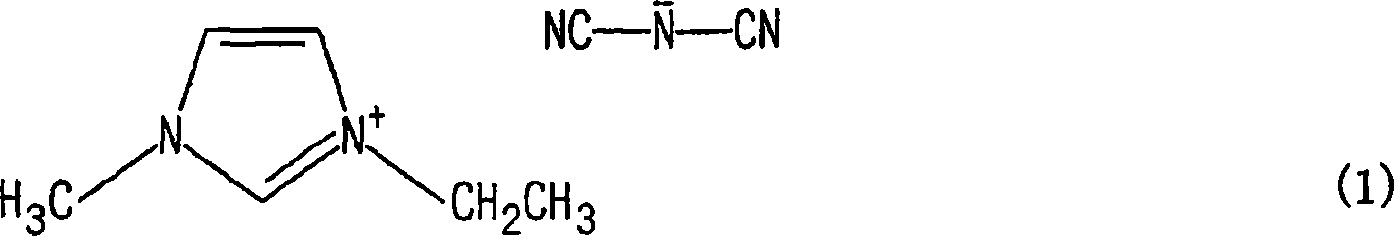

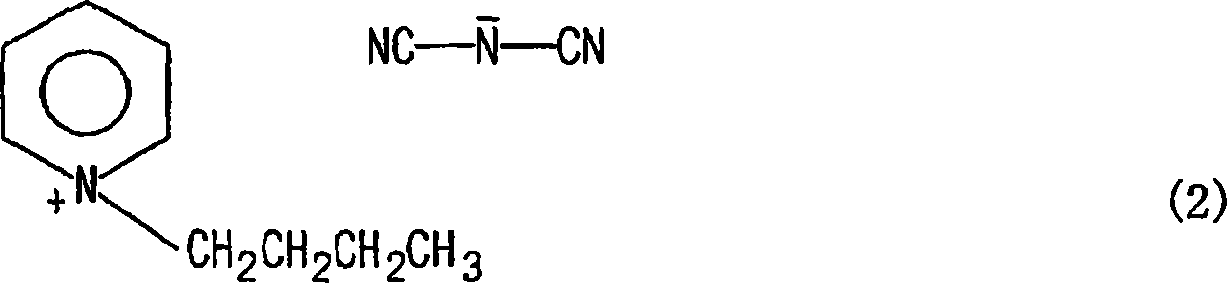

Electrolyte composition and photoelectric converter using same

InactiveCN1846328AImprove featuresGood photoelectric conversion characteristicsLight-sensitive devicesConductive materialHalogenElectrolyte composition

An electrolyte composition containing ionic liquid having dicyanamide anions as anions. Examples of cations of the ionic liquid, may include, for example, cations having quaternized nitrogen atom. This electrolyte composition may contain halogen-based oxidized / reduced pair. This electrolyte composition is used as an electrolyte of a photoelectric conversion element.

Owner:THE FUJIKURA CABLE WORKS LTD

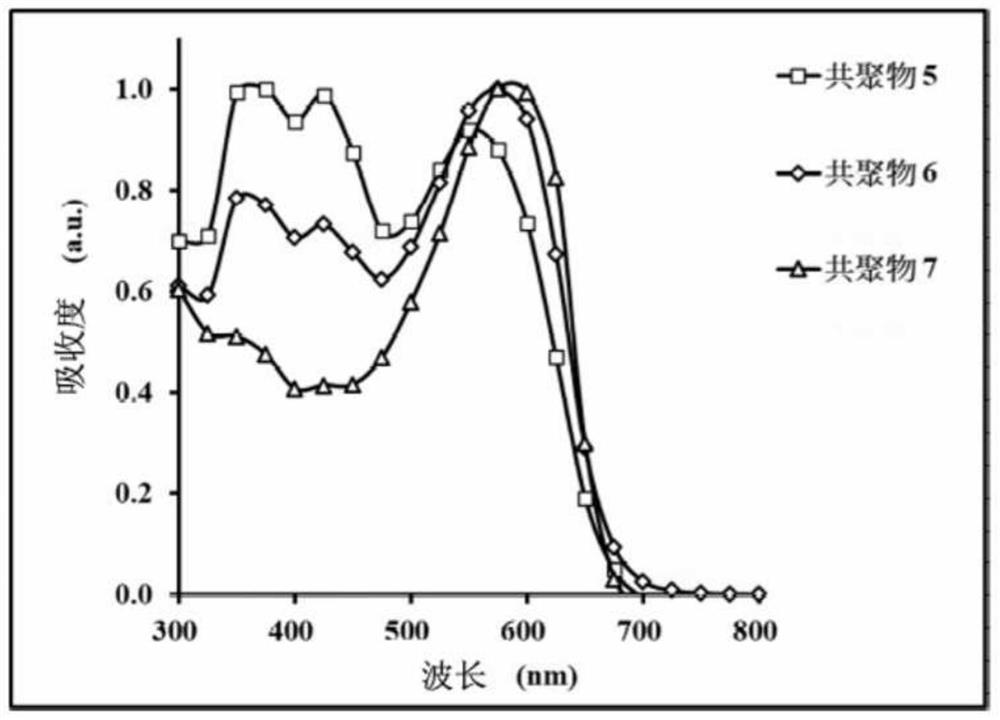

Fluorine-containing two-dimensional conjugate benzo-difuran and pyrazine copolymer photovoltaic material, and preparation method and application thereof

InactiveCN110372849AImprove machinabilityGood photoelectric conversion characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingPyrazineStructural formula

The invention relates to the technical field of polymer photovoltaic materials, in particular to a fluorine-containing two-dimensional conjugate benzo-difuran and pyrazine copolymer photovoltaic material, and a preparation method and application thereof. The structural formula of the fluorine-containing two-dimensional conjugate benzo-difuran and pyrazine copolymer photovoltaic material is shown as follows (please see the specifications for the formula), wherein R is an alkyl group. A copolymer is an electronic donor material, and the fluorine-containing two-dimensional conjugate benzo-difuranand pyrazine copolymer photovoltaic material is applied to a polymer solar cell, has wide visible region absorption, the low HOMO energy level, the relative narrow band gap and the high photovoltaicconversion efficiency.

Owner:HUNAN UNIV OF ARTS & SCI

Preparation method and application of a photoelectrochemical sensor based on ag2secdse-labeled sandwich cardiac troponin T

InactiveCN104849331BGood photoelectric conversion characteristicsImprove photoelectric signal responseBiological testingMaterial electrochemical variablesAntiendomysial antibodiesCardiac muscle

The invention relates to a preparation method and application of a photoelectrochemical sensor based on Ag2SeCdSe-labeled sandwich cardiac troponin T, and belongs to the technical fields of new functional materials and biosensing detection. Specifically, the present invention uses CeO2-TiO2 composite nanomaterials with photocatalytic activity as the photoactive base material, uses Ag2SeCdSe as the antibody marker, and prepares a sandwich-type photoelectrochemical sensor through the signal amplification effect of the marker Ag2SeCdSe on the base material, which is used for myocardial Highly sensitive detection of the injury-specific marker cardiac troponin T. This method is of great significance to the early diagnosis and treatment of acute myocardial infarction.

Owner:UNIV OF JINAN

Dye-sensitized solar cell element for low illumination

ActiveCN104380407BGood photoelectric conversion characteristicsSave spaceLight-sensitive devicesCapacitor electrolytes/absorbentsTransparent conducting filmSemiconductor

The present invention provides a dye-sensitized solar cell element for low-illuminance, which has: at least one dye-sensitized solar cell; a first current acquisition part for acquiring current from at least one dye-sensitized solar cell; a second current acquisition A part, which is used to obtain current from at least one dye-sensitized solar cell, the dye-sensitized solar cell has: a first electrode, which has a transparent substrate, and a transparent conductive film arranged on the transparent substrate; The first electrode faces, and has a metal substrate; an oxide semiconductor layer, which is provided on the first electrode or the second electrode; and a ring-shaped sealing part, which connects the first electrode and the second electrode to obtain the first current. a transparent conductive film of a dye-sensitized solar cell in at least one dye-sensitized solar cell, a second current acquisition part and a metal of a second electrode of a dye-sensitized solar cell in at least one dye-sensitized solar cell The substrates are electrically connected, and the first current acquisition part and the second current acquisition part are arranged adjacent to each other.

Owner:THE FUJIKURA CABLE WORKS LTD

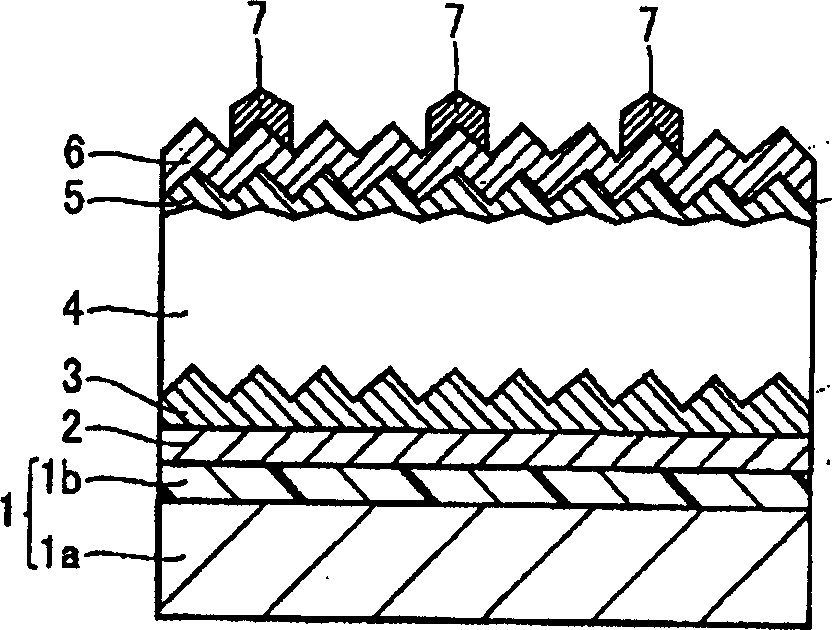

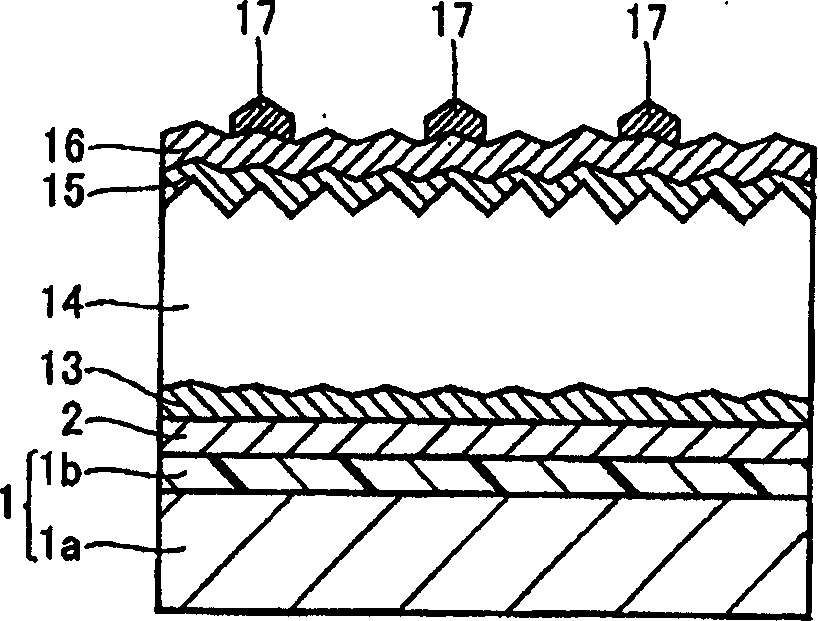

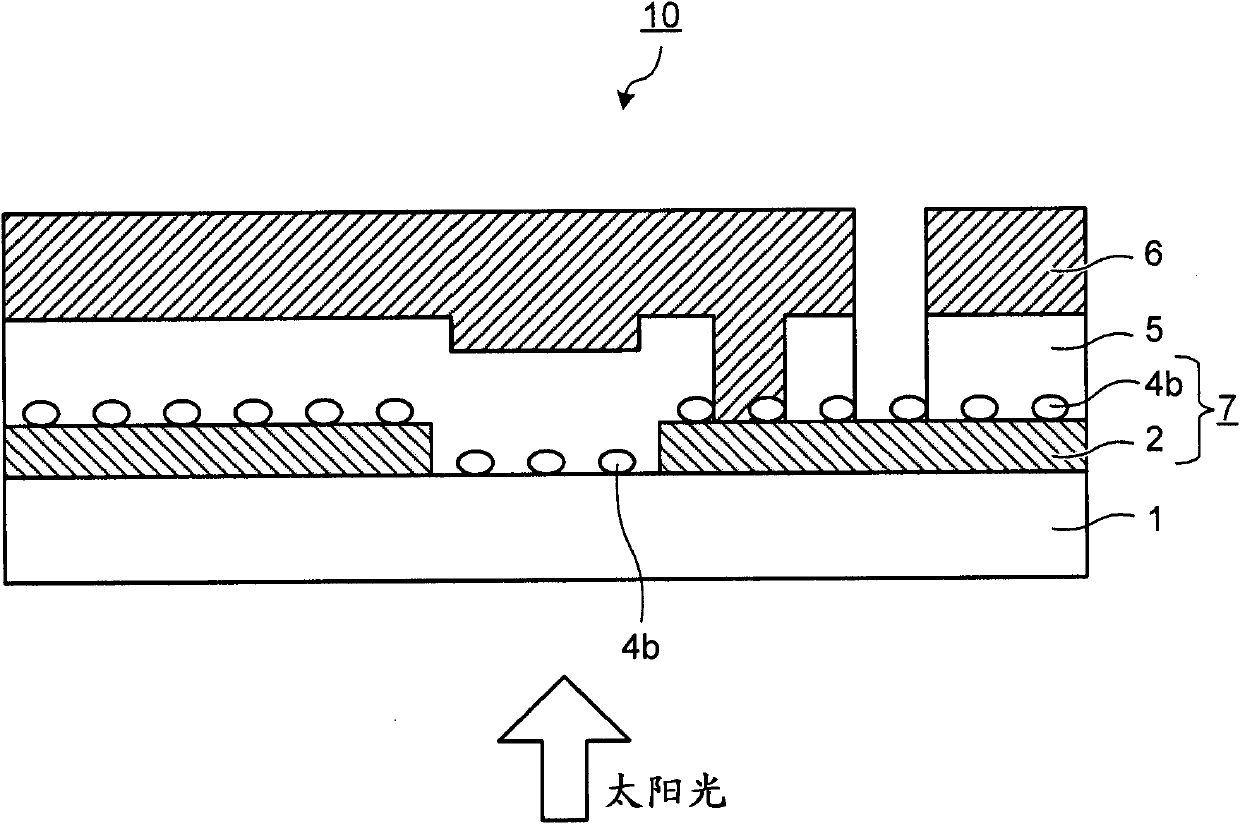

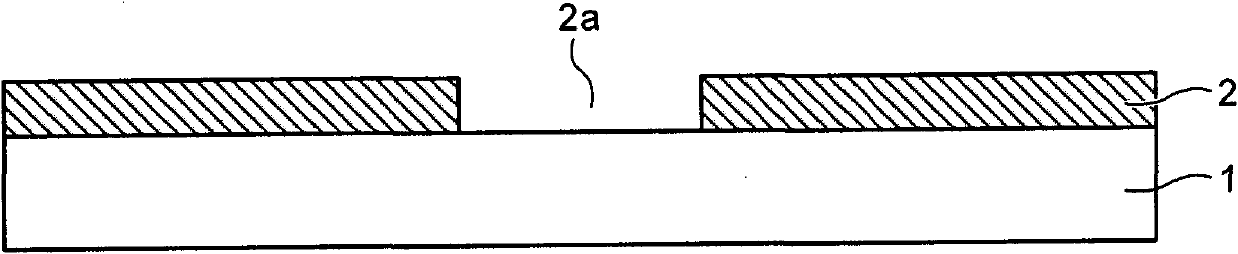

Thin film solar cell and manufacturing method thereof

InactiveCN102089884AReduce defectsImprove reliabilityPhotovoltaic energy generationSemiconductor devicesSurface roughnessTransparent conducting film

A thin film solar cell having a transparent electrode with minute surface irregularities with low surface roughness and for which an an-plane resistance that is approximately uniform can be obtained by forming on a transparent insulating substrate (1) multiple first transparent conductive films (2) that are separated from each other within the substrate plane, forming a second transparent conductive film on the first transparent conductive film (2), forming first granular bodies (4a) dispersed on the first transparent conductive film (2) by etching the second transparent conductive film into a granule form, forming a power generating layer (5) on the first transparent conductive film (2) and on the dispersed first granular bodies (4a), and forming a back electrode layer (6) on the power generating layer (5).

Owner:MITSUBISHI ELECTRIC CORP

Benzodithiophene and pyrazine copolymer, preparing method and application

InactiveCN110204692AImprove machinabilityGood photoelectric conversion characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingElectron donorStructural formula

The invention discloses a benzodithiophene and pyrazine copolymer, a preparing method and application. The structural formula of the copolymer is shown as follows, wherein R is alkyl groups. The copolymer serves as an electron donor material, is applied to polymer solar cells, and has a wide visible region absorption range, a low HOMO level, a relatively-narrow bandgap and high photoelectric conversion efficiency.

Owner:HUNAN UNIV OF ARTS & SCI

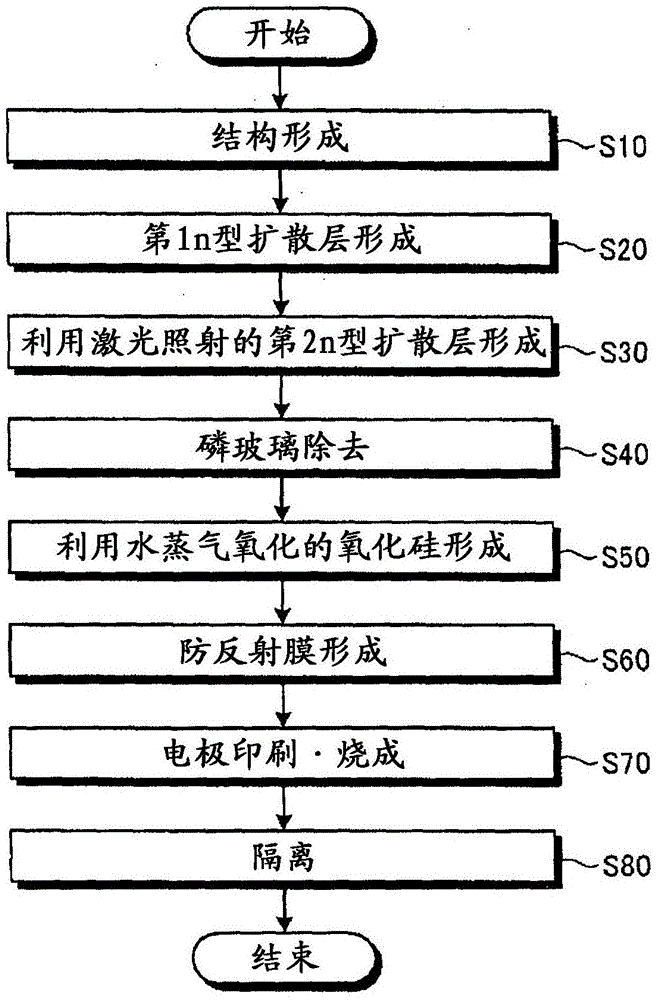

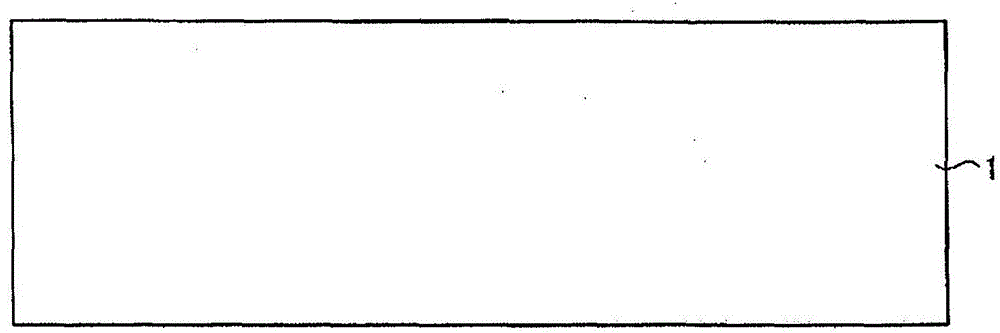

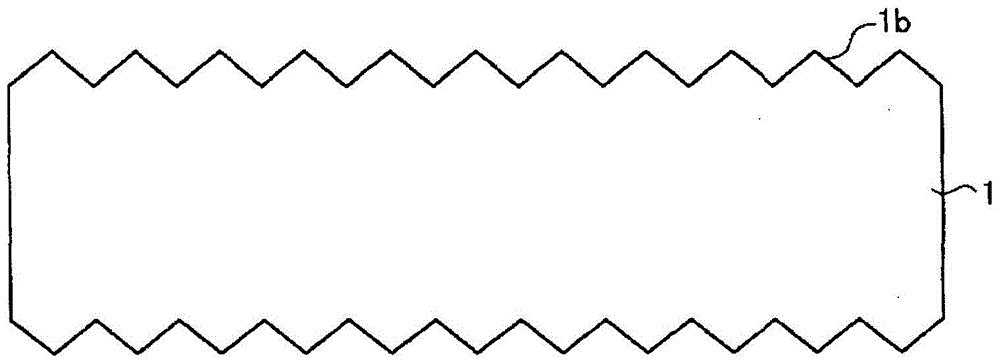

Solar cell, method for manufacturing solar cell, and solar cell module

InactiveCN104254922BWell formedGood photoelectric conversion characteristicsSemiconductor devicesImpurity diffusionRefractive index

The present invention relates to a solar cell, a method for manufacturing the solar cell, and a solar cell module. The solar cell includes: a semiconductor substrate of the first conductivity type having an impurity diffusion layer in which an impurity element of the second conductivity type is diffused on one side; A passivation film composed of a film; an anti-reflection film formed on a passivation film made of a light-transmitting material having a refractive index different from the above-mentioned oxide film; electrically connected to the impurity diffusion layer and formed on one side of the semiconductor substrate The formed light-receiving side electrode; and the back-side electrode formed on the other side of the above-mentioned semiconductor substrate, and the impurity diffusion layer includes: a first impurity diffusion layer that is a light-receiving region and contains an impurity element at a first concentration; and a light-receiving region. The lower region of the surface side electrode contains a second impurity diffusion layer with an impurity element at a second concentration higher than the first concentration, the surfaces of the first impurity diffusion layer and the second impurity diffusion layer are formed in a uniform surface state, and the second impurity diffusion layer The film thickness of the passivation film on the diffusion layer is thinner than the film thickness of the passivation film on the first impurity diffusion layer.

Owner:MITSUBISHI ELECTRIC CORP

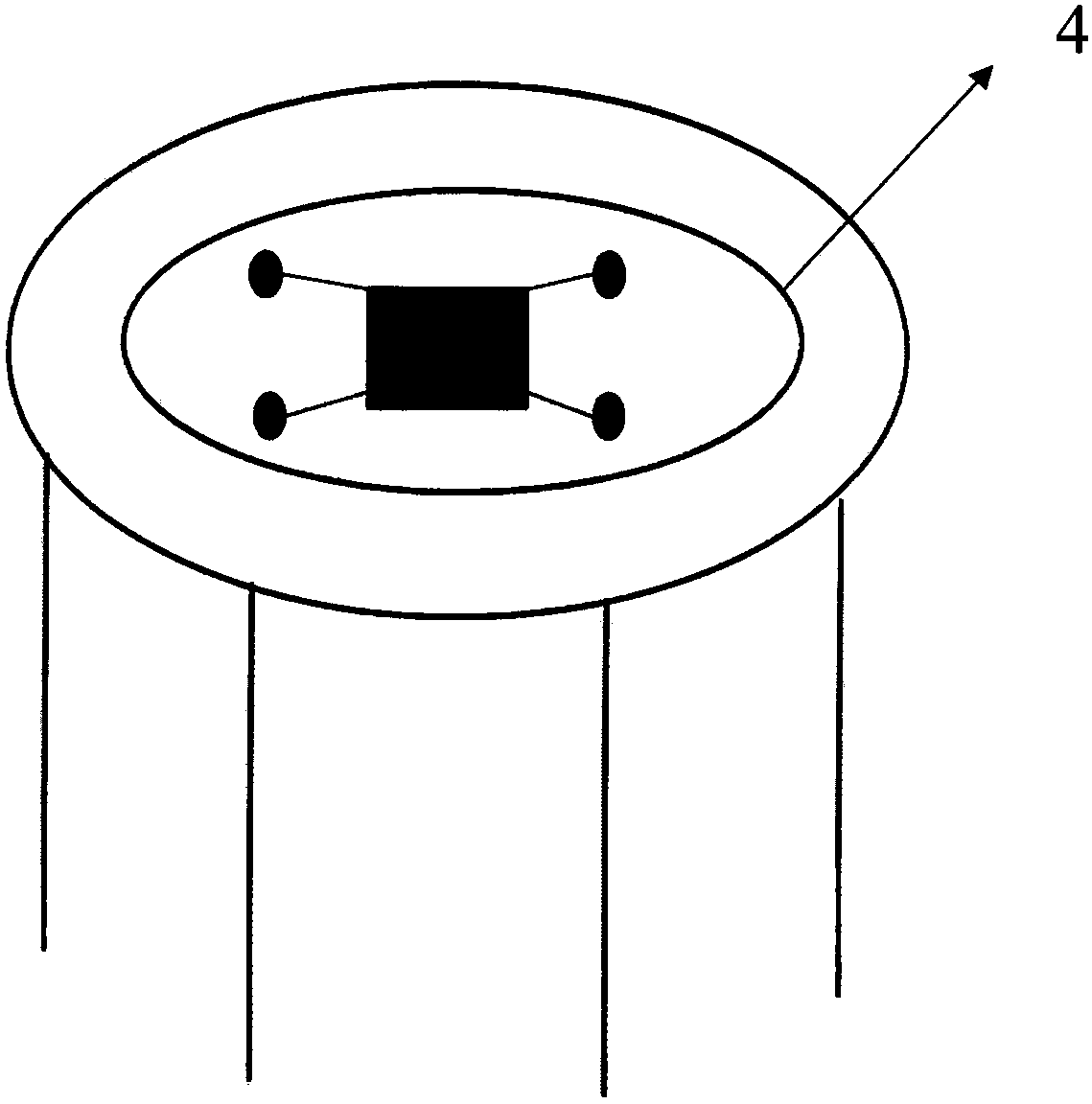

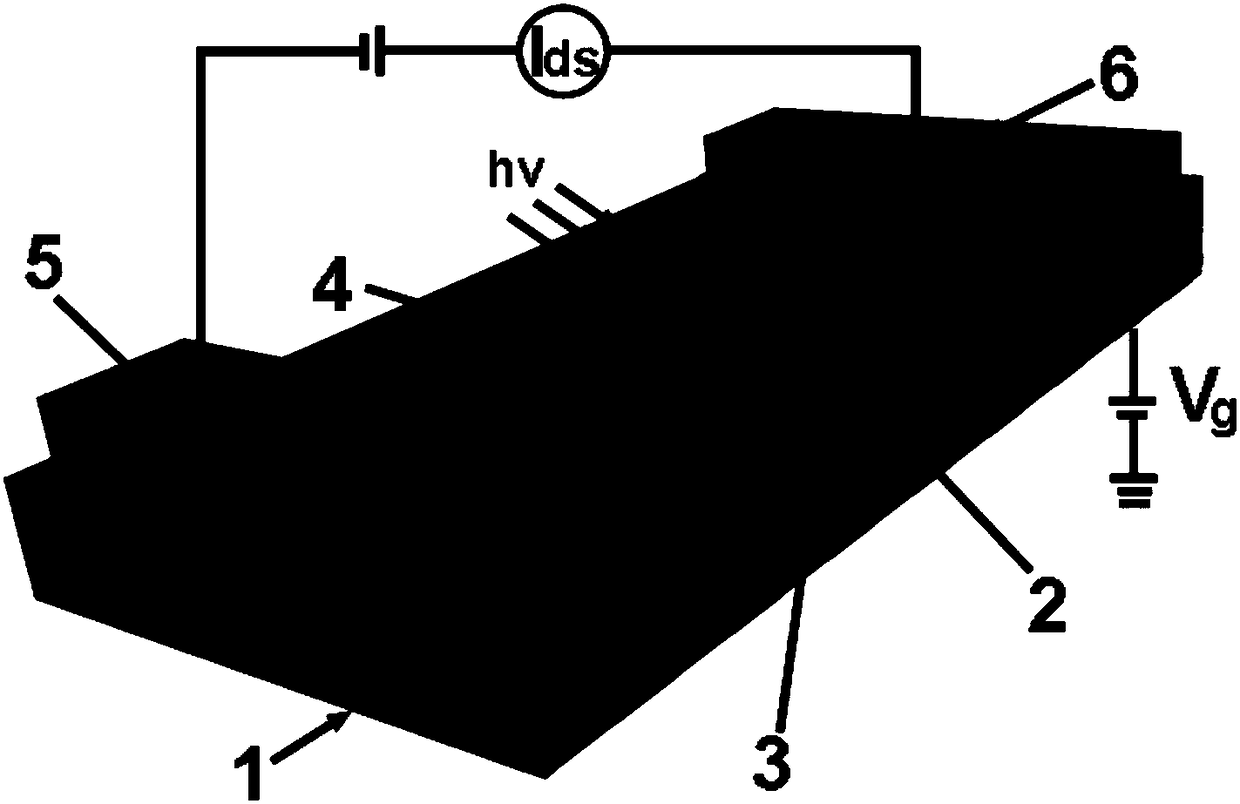

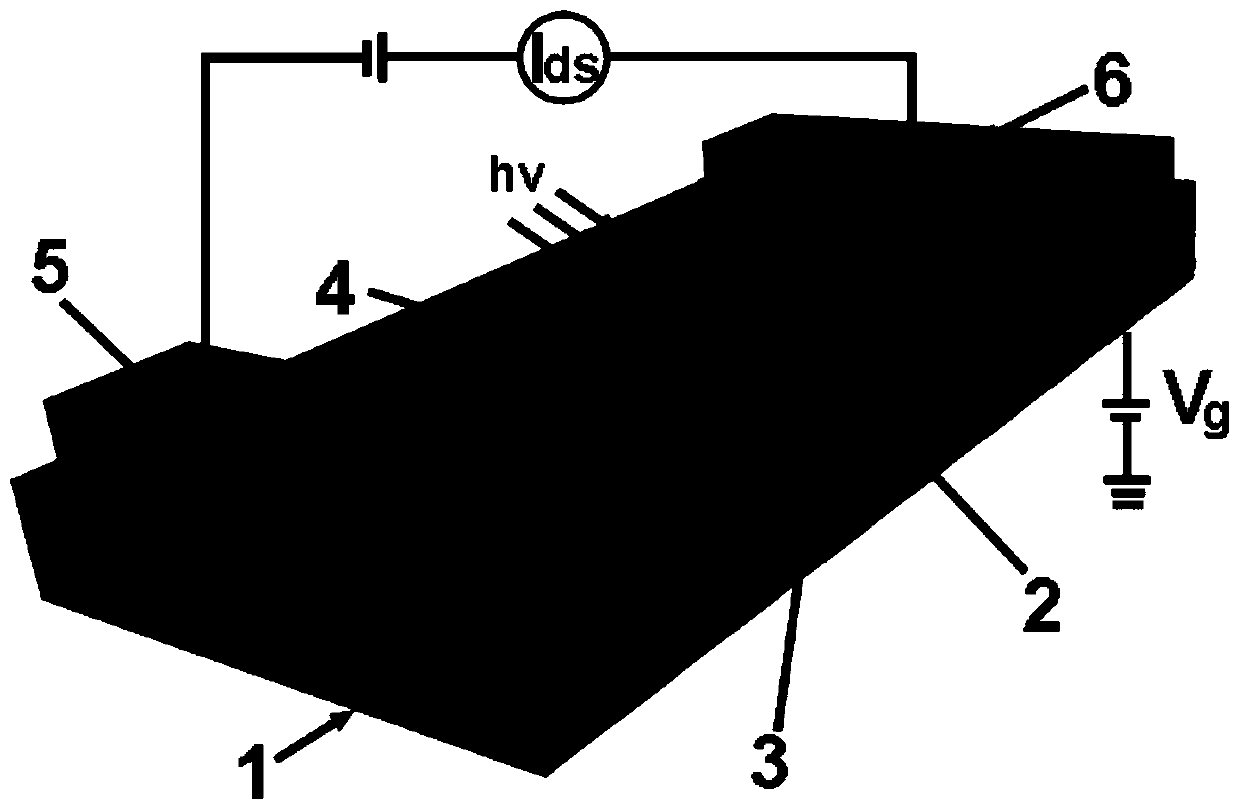

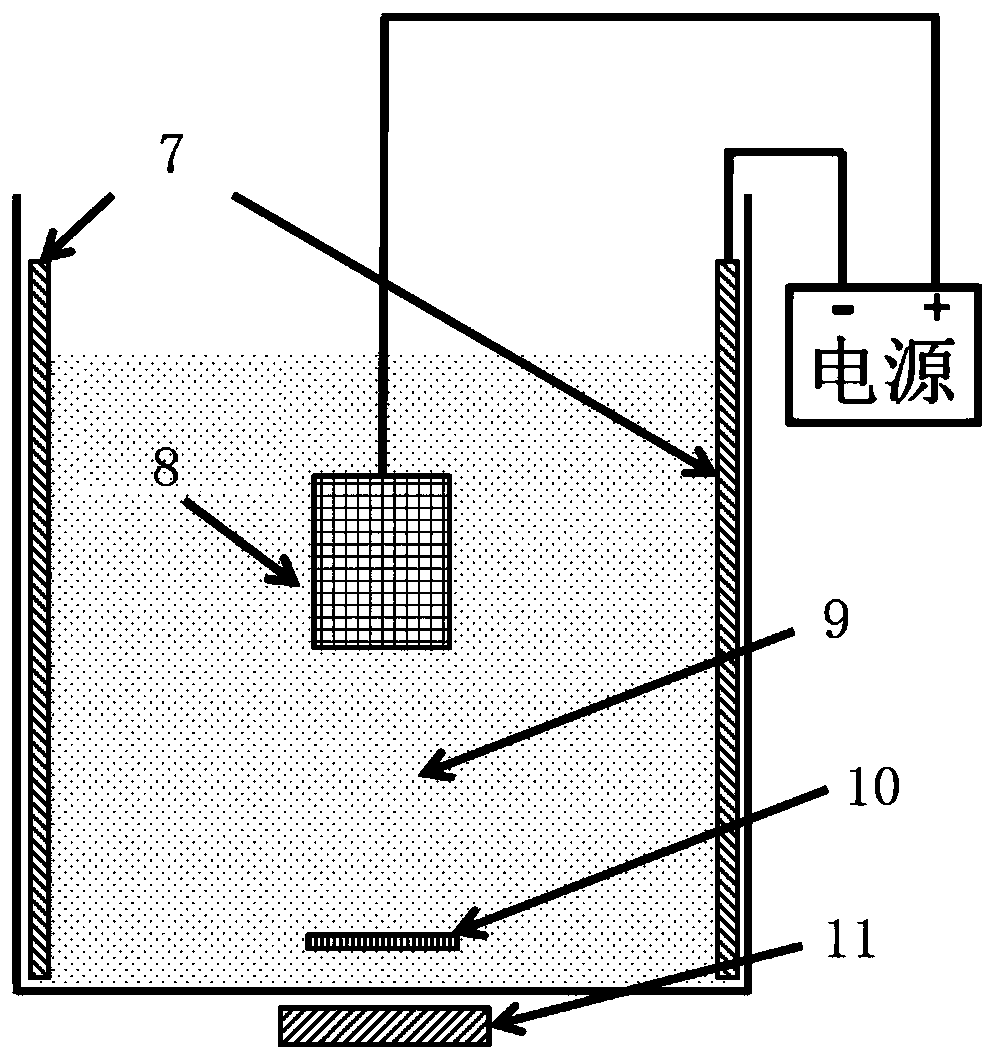

MnWO4 nano-plate photosensitive field-effect transistor and manufacturing method thereof

ActiveCN108198896ASimple processLow costMaterial nanotechnologyFinal product manufactureMicro arc oxidationPlasma electrolytic oxidation

The invention belongs to the inorganic semiconductor nanomaterial technology and device application field, and especially relates to a MnWO4 nano-plate photosensitive field-effect transistor and a manufacturing method thereof. The MnWO4 nano-plate photosensitive field-effect transistor comprises a grid metal electrode, Si substrate and a SiO2 insulation layer in sequence from the bottom up. The upper surface of the SiO2 insulation layer is provided with a single MnWO4 nano-plate, a source metal electrode and a drain metal electrode. The source metal electrode and the drain metal electrode arecovered on the two ends of the single MnWO4 nano-plate respectively and form ohmic contact. The method produces the MnWO4 nano-plate having large area, high yield and excellent crystal quality througha micro-arc oxidation method; and furthermore, the MnWO4 nano-plate is utilized to prepare the MnWO4 nano-plate photosensitive field-effect transistor in a back-gate structure. The method is simple in process, is low in cost, can grow the MnWO4 nano-plate material having high crystal quality on a large scale, and facilitates industrial promotion.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Benzodifuran containing chlorine and pyrazine copolymer photovoltaic material, preparation method and application

InactiveCN110343237AGood machinabilityGood photoelectric conversion characteristicsSolid-state devicesSemiconductor/solid-state device manufacturingNarrow bandElectron donor

The invention discloses a benzodifuran containing chlorine and pyrazine copolymer photovoltaic material, a preparation method and an application. A structural formula is as shown in the specification,wherein R is an alkyl group. The copolymer is an electron donor material, and is applied to a polymer solar battery, and the material has wide absorption in the visible region, a relatively low HOMOlevel, a relatively narrow band gap, and relatively high photoelectric conversion efficiency.

Owner:HUNAN UNIV OF ARTS & SCI

a kind of mnwo 4 Nanoplate photosensitive field effect transistor and manufacturing method thereof

ActiveCN108198896BSimple processLow costMaterial nanotechnologyFinal product manufactureMicro arc oxidationInsulation layer

The invention belongs to the inorganic semiconductor nanomaterial technology and device application field, and especially relates to a MnWO4 nano-plate photosensitive field-effect transistor and a manufacturing method thereof. The MnWO4 nano-plate photosensitive field-effect transistor comprises a grid metal electrode, Si substrate and a SiO2 insulation layer in sequence from the bottom up. The upper surface of the SiO2 insulation layer is provided with a single MnWO4 nano-plate, a source metal electrode and a drain metal electrode. The source metal electrode and the drain metal electrode arecovered on the two ends of the single MnWO4 nano-plate respectively and form ohmic contact. The method produces the MnWO4 nano-plate having large area, high yield and excellent crystal quality througha micro-arc oxidation method; and furthermore, the MnWO4 nano-plate is utilized to prepare the MnWO4 nano-plate photosensitive field-effect transistor in a back-gate structure. The method is simple in process, is low in cost, can grow the MnWO4 nano-plate material having high crystal quality on a large scale, and facilitates industrial promotion.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

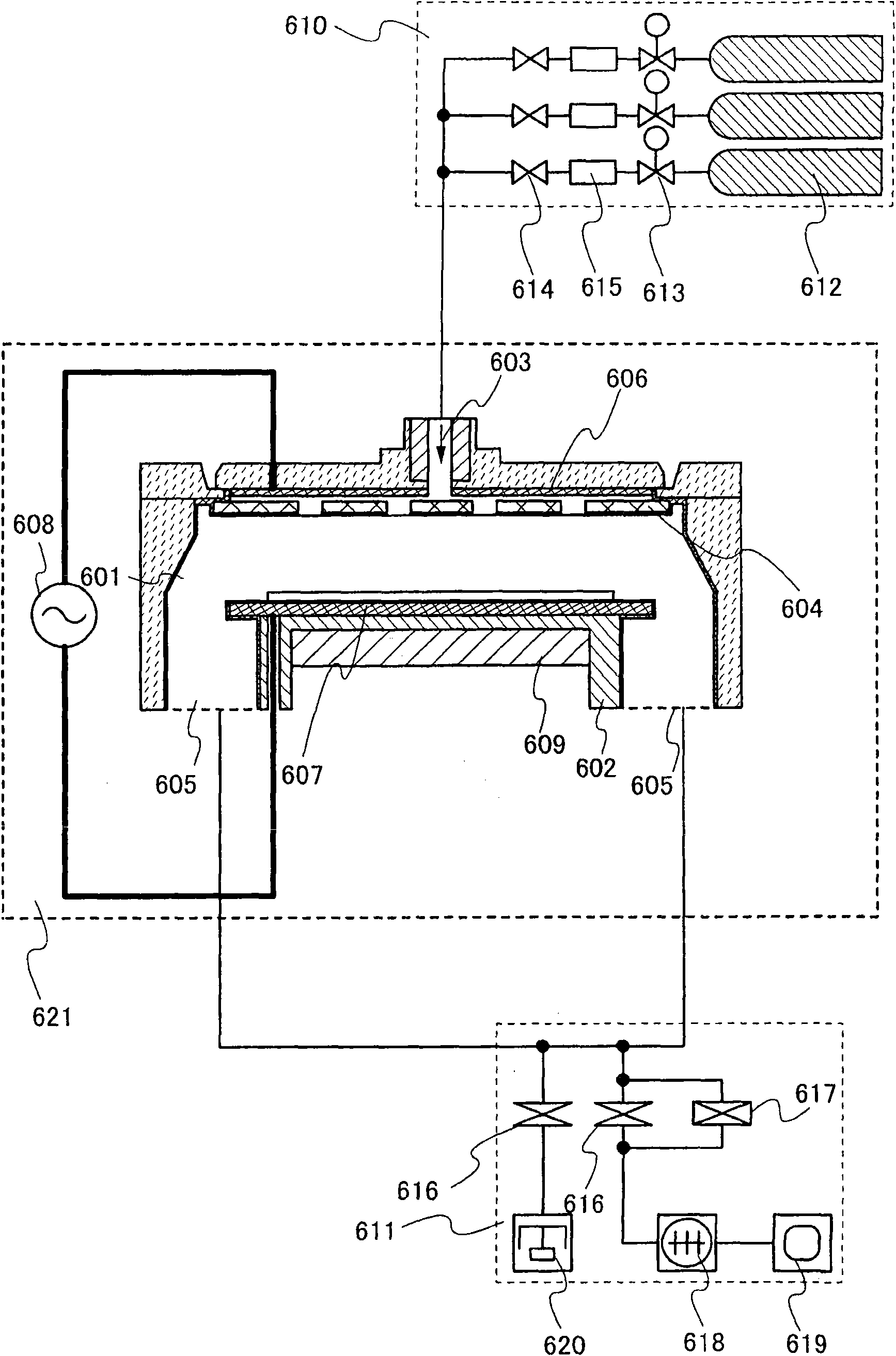

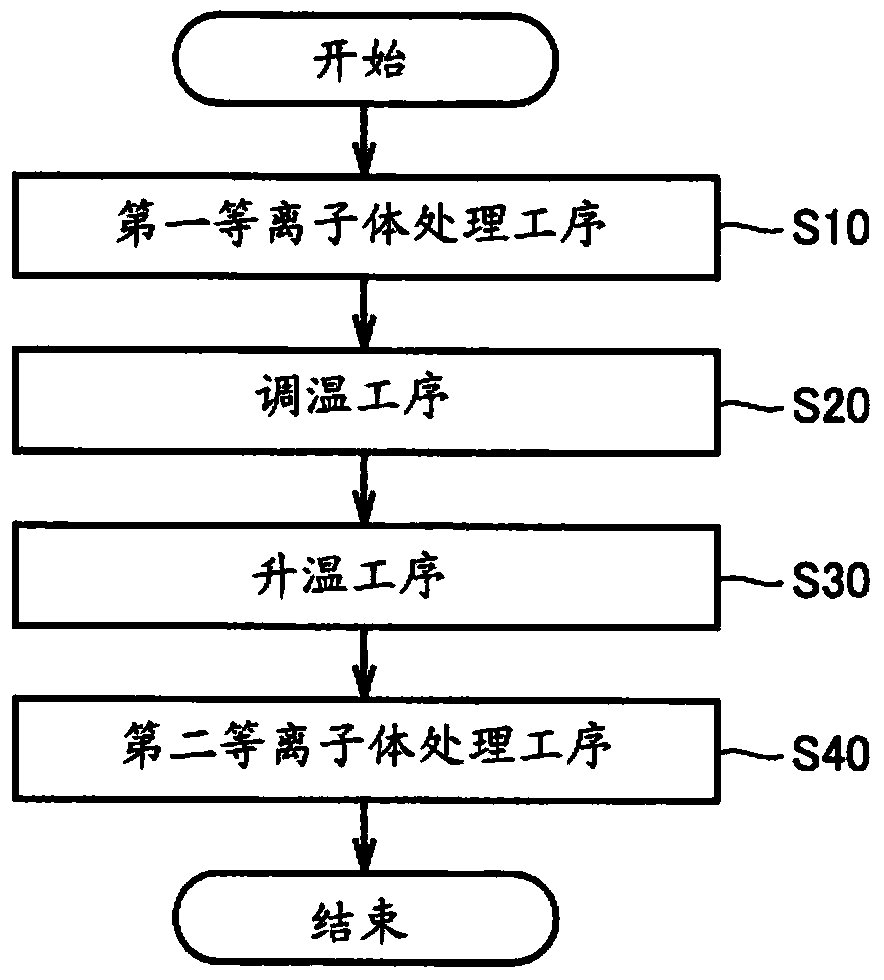

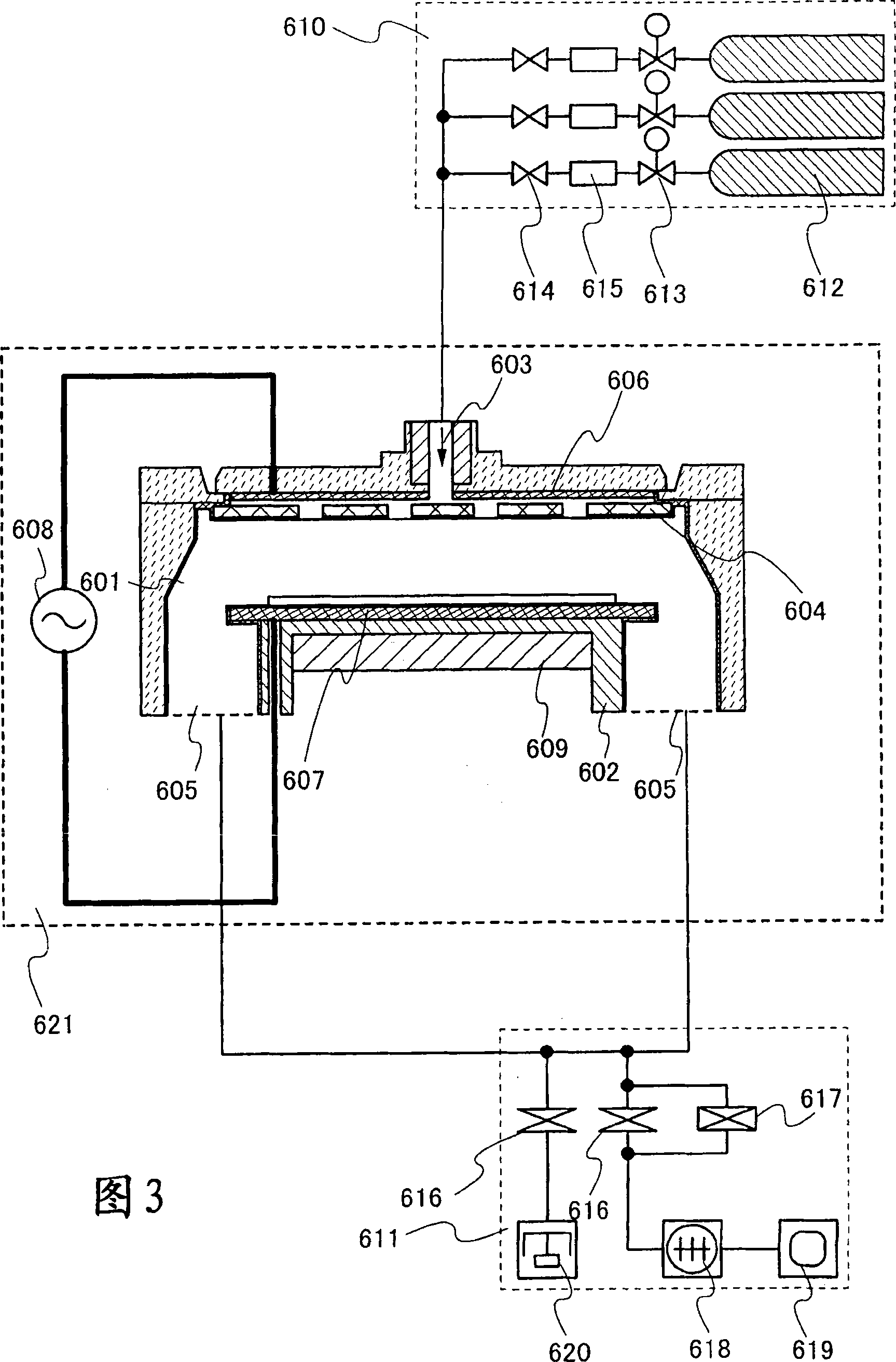

Method of manufacturing photoelectric conversion device

InactiveCN103988320AEfficient preparationGood photoelectric conversion characteristicsSemiconductor/solid-state device testing/measurementFinal product manufacturePhotoelectric conversionEngineering

The present invention provides a method of manufacturing a photoelectric conversion device for forming a semiconductor layer on a substrate by the plasma CVD method. The method includes a first plasma processing step in which a processing temperature reaches a first temperature; a second plasma processing step in which the processing temperature reaches a second temperature; a temperature regulating step of lowering the processing temperature to a third temperature lower than the first temperature and the second temperature after the first plasma processing step and before the second plasma processing step; and a temperature raising step of raising the processing temperature from the third temperature to the second temperature. The first plasma processing step, the temperature regulating step, the temperature raising step, and the second plasma processing step are carried out within the same reaction chamber.

Owner:SHARP KK

Dye-sensitized solar cell for low light intensities

InactiveCN103380535AGood photoelectric conversion characteristicsElectrolytic capacitorsSolid-state devicesSorbentSolar cell

The present invention is a dye-sensitized solar cell for low light intensities which is provided with: a first electrode, which has a transparent substrate and a transparent conductive film provided on the transparent substrate; a second electrode, which faces the first electrode; an oxide semiconductor layer, which is provided on the first electrode or the second electrode; an electrolyte, which is provided between the first electrode and the second electrode; a photosensitization dye, which is adsorbed to the oxide semiconductor layer; and a co-adsorption agent which is adsorbed to the oxide semiconductor layer together with the photosensitization dye. Therein, the photosensitization dye is a metal-complex compound represented by formula (1), and the co-adsorption agent includes an organic compound represented by formula (2), or similar. (In formula (1) M represents Ru, R1, R2, R3 and R4 each independently represents a monovalent cation, and R5 and R6 each independently represents a halogen group, or similar.) (In formula (2) n represents an integer 0-5, and R7 represents a monovalent group having a p-conjugated structure, or similar.)

Owner:THE FUJIKURA CABLE WORKS LTD

Photoelectric conversion device and method for manufacturing same

InactiveCN101593778BImprove productivityReduce photodegradationFinal product manufacturePhotovoltaic energy generationSemiconductor materialsPhotoelectric conversion

A photoelectric conversion device and a method for manufacturing the same are provided. The photoelectric conversion device includes a first semiconductor layer including a first impurity element over a substrate, a second semiconductor layer including an amorphous layer and a crystal over the first semiconductor layer, and a third semiconductor layer including a second impurity element over the second semiconductor layer. The crystal penetrates between the first semiconductor layer and the third semiconductor layer.

Owner:SEMICON ENERGY LAB CO LTD

Thieno[2,3-f]benzofuran compounds and their polymers and applications of polymers

InactiveCN103936760BImprove solubilityImprove thermal stabilityOrganic chemistryFinal product manufactureThiadiazolesPolymer chemistry

The invention discloses a thieno[2,3-f]benzofuran compound and its polymer and the application of the polymer. The thieno[2,3-f]benzofuran compound is combined with benzothiadiazole, benzofuran Monomers such as triazole and benzoxadiazole synthesized a series of polymers with thieno[2,3-f]benzofuran compound unit structure through Stille coupling polymerization method, the thermal stability and electrical stability of the polymers With good chemical properties, it can be mixed with commonly used fullerene and organic acceptor substances to prepare polymer solar cells with high photoelectric conversion efficiency. The photoelectric conversion efficiency of single-layer polymer solar cell devices is as high as 6.4%. The polymer material is used in solar cells There are huge commercial prospects in the application of .

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Thieno[2,3-f]benzofuran compounds and their polymers and applications of polymers Thieno[2,3-f]benzofuran compounds and their polymers and applications of polymers](https://images-eureka.patsnap.com/patent_img/aa268673-cfaa-40db-812e-48389a29718a/HDA0000496844250000011.PNG)

![Thieno[2,3-f]benzofuran compounds and their polymers and applications of polymers Thieno[2,3-f]benzofuran compounds and their polymers and applications of polymers](https://images-eureka.patsnap.com/patent_img/aa268673-cfaa-40db-812e-48389a29718a/HDA0000496844250000012.PNG)

![Thieno[2,3-f]benzofuran compounds and their polymers and applications of polymers Thieno[2,3-f]benzofuran compounds and their polymers and applications of polymers](https://images-eureka.patsnap.com/patent_img/aa268673-cfaa-40db-812e-48389a29718a/HDA0000496844250000021.PNG)