Photoelectric conversion device and method for manufacturing same

A technology for a photoelectric conversion device and a manufacturing method, applied in photovoltaic power generation, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem that the penetration rate cannot reach the block photoelectric conversion device, and the high-efficiency productivity cannot be realized at the same time. Reliability concerns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0069] One aspect of the present invention is characterized in that the semiconductor layer exhibiting photoelectric conversion includes crystals in an amorphous structure, and the crystals penetrate between a pair of impurity semiconductor layers joined to form an internal electric field. In this embodiment mode, a photoelectric conversion device in which a plurality of unit elements are stacked is shown. When one aspect of the present invention is applied to a stacked photoelectric conversion device such as a tandem type or a stacked type, as a layer exhibiting photoelectric conversion of at least one unit element, it is applied in an amorphous structure including through A crystalline semiconductor layer between a pair of impurity semiconductor layers joined to form an internal electric field.

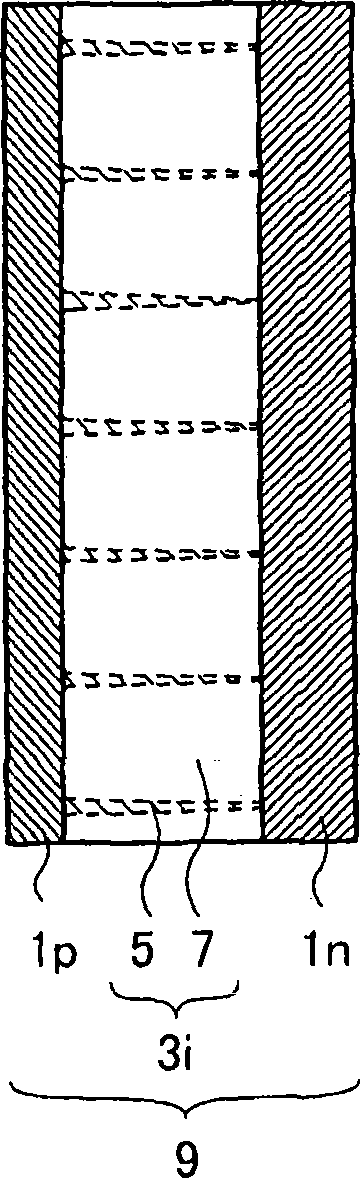

[0070] figure 1 A schematic diagram showing a unit cell according to one embodiment of the present invention. A unit element according to one mode of the present invention has a s...

Embodiment approach 2

[0124] In this embodiment mode, a photoelectric conversion device having a different structure from the above-described embodiment mode is shown. Specifically, the number of stacked unit elements and figure 2 Different examples of photoelectric conversion devices.

[0125] Figure 5A A single-junction photoelectric conversion device having one unit element is shown. This photoelectric conversion device is a unit cell 40 composed of a p-type semiconductor impurity semiconductor layer 41p, an i-type semiconductor semiconductor layer 43i, and an n-type semiconductor impurity semiconductor layer 41n stacked on a substrate 2 on which a first electrode 4 is formed. , and the second electrode 6 formed on the unit element 40, and includes at least one semiconductor junction. In the semiconductor layer 43 i , crystals 45 exist dispersedly in the amorphous structure 47 . Furthermore, the crystal 45 penetrates the semiconductor layer 43i between the impurity semiconductor layer 41p ...

Embodiment approach 3

[0129] In this embodiment mode, a photoelectric conversion device having a different structure from the above-described embodiment mode is shown. Specifically, an example is shown in which a low-concentration impurity semiconductor layer of the same conductivity type as the impurity semiconductor layer of one conductivity type is formed at a junction between the impurity semiconductor layer of one conductivity type and the intrinsic semiconductor layer.

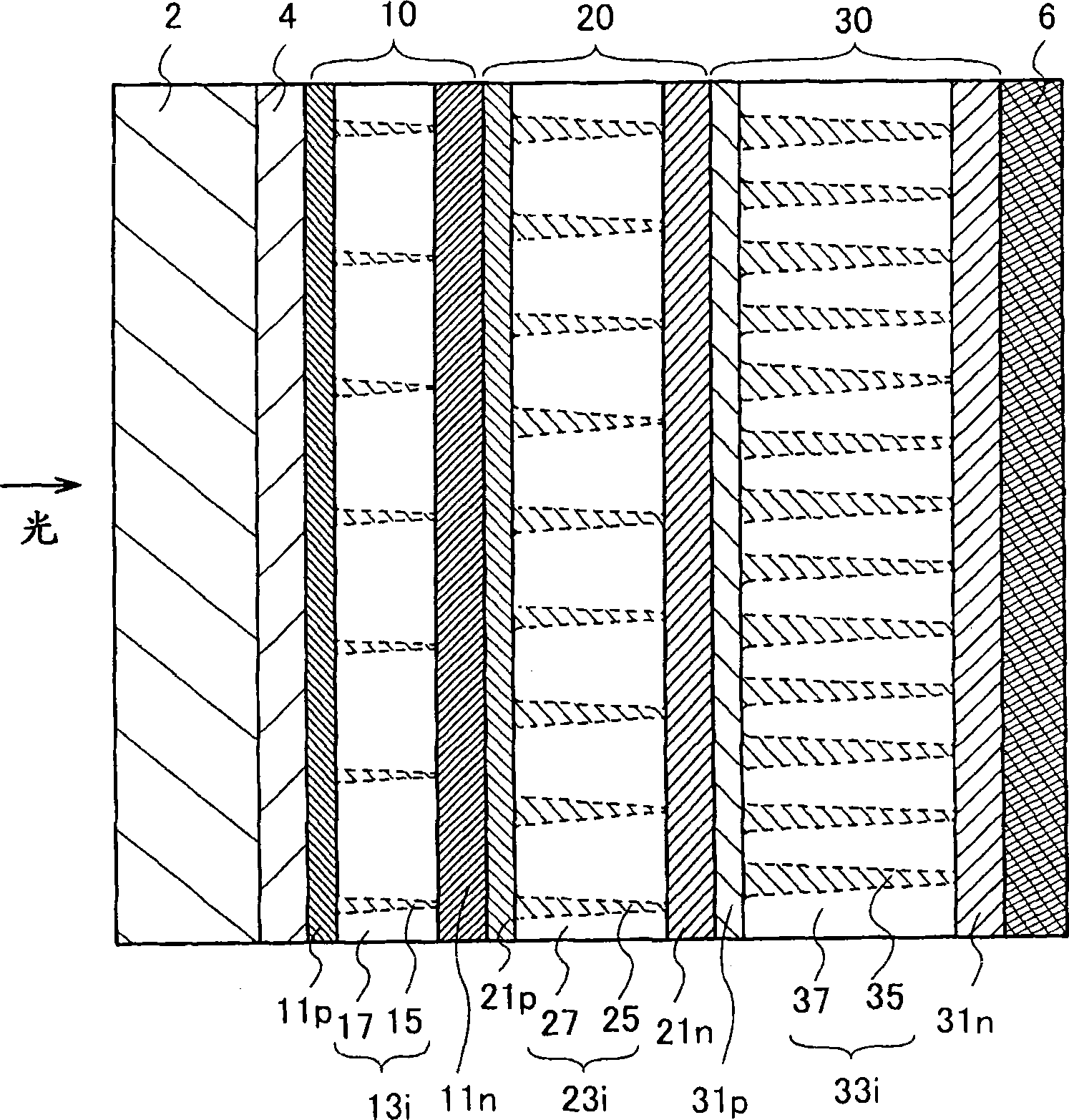

[0130] Figures 6A to 6C A stacked photoelectric conversion device formed with three unit elements is shown. exist Figure 6A Among them, a first unit element 10, a second unit element 20, a third unit element 30, and a second electrode 6 are disposed from the side of the substrate 2 on which the first electrode 4 is formed, and the first unit element 10 is stacked with a first The impurity semiconductor layer 11p, the first low-concentration impurity semiconductor layer 12p - , a first semiconductor layer 13i and a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com