Patents

Literature

146 results about "Extrinsic semiconductor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An extrinsic semiconductor is one that has been doped; during manufacture of the semiconductor crystal a trace element or chemical called a doping agent has been incorporated chemically into the crystal, for the purpose of giving it different electrical properties than the pure semiconductor crystal, which is called an intrinsic semiconductor. In an extrinsic semiconductor it is these foreign dopant atoms in the crystal lattice that mainly provide the charge carriers which carry electric current through the crystal. The doping agents used are of two types, resulting in two types of extrinsic semiconductor. An electron donor dopant is an atom which, when incorporated in the crystal, releases a mobile conduction electron into the crystal lattice. An extrinsic semiconductor which has been doped with electron donor atoms is called an n-type semiconductor, because the majority of charge carriers in the crystal are negative electrons. An electron acceptor dopant is an atom which accepts an electron from the lattice, creating a vacancy where an electron should be called a hole which can move through the crystal like a positively charged particle. An extrinsic semiconductor which has been doped with electron acceptor atoms is called a p-type semiconductor, because the majority of charge carriers in the crystal are positive holes.

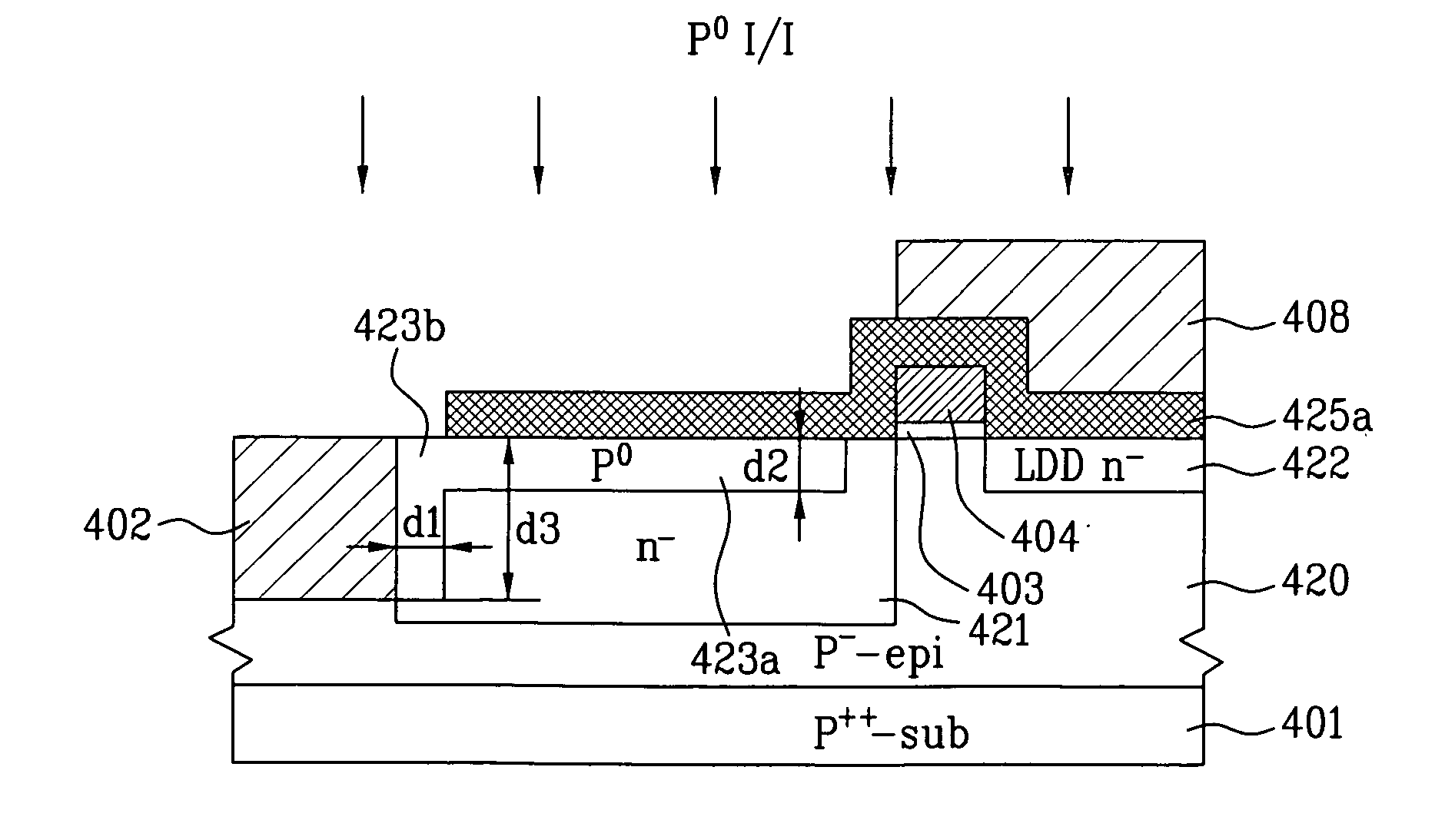

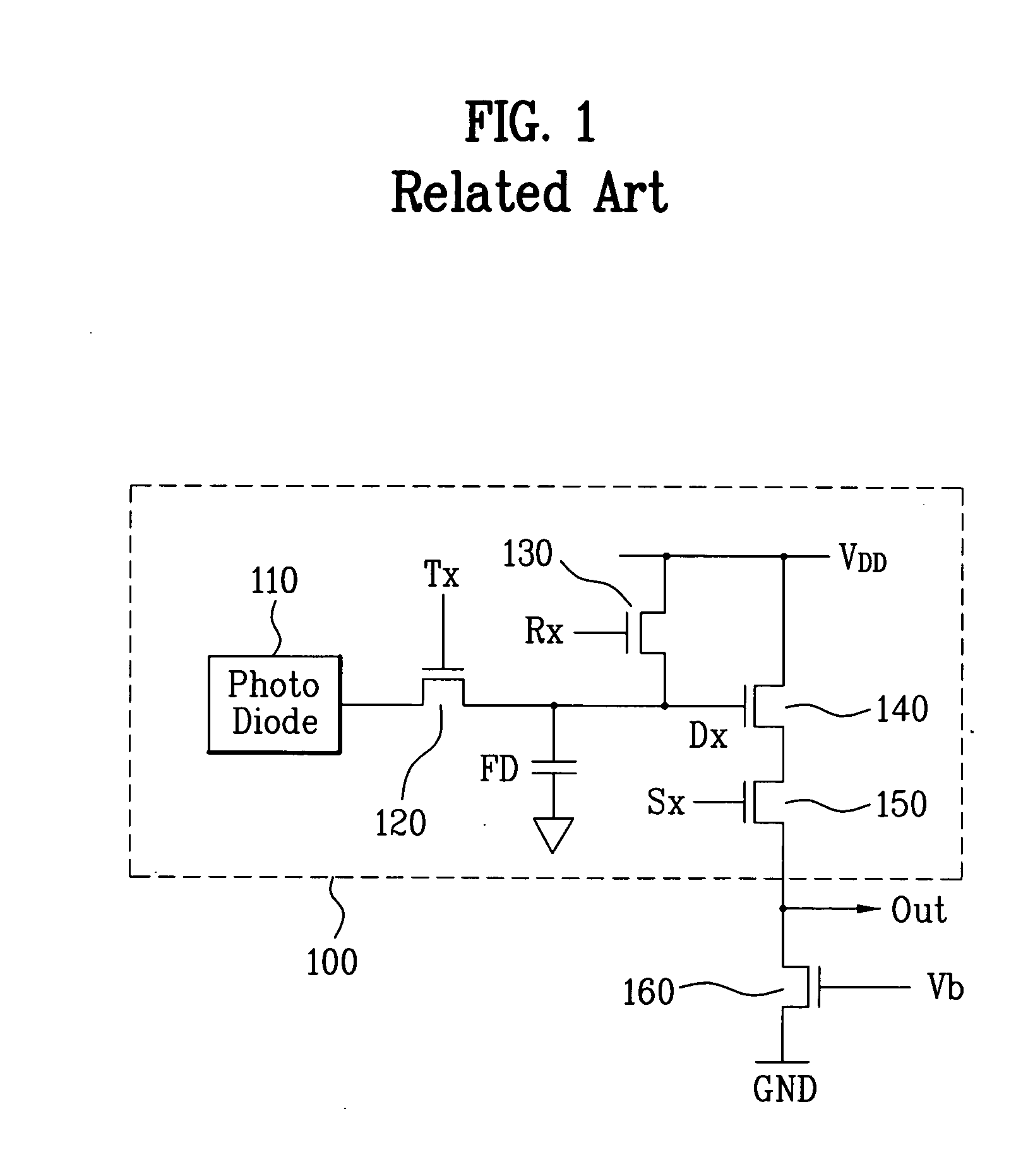

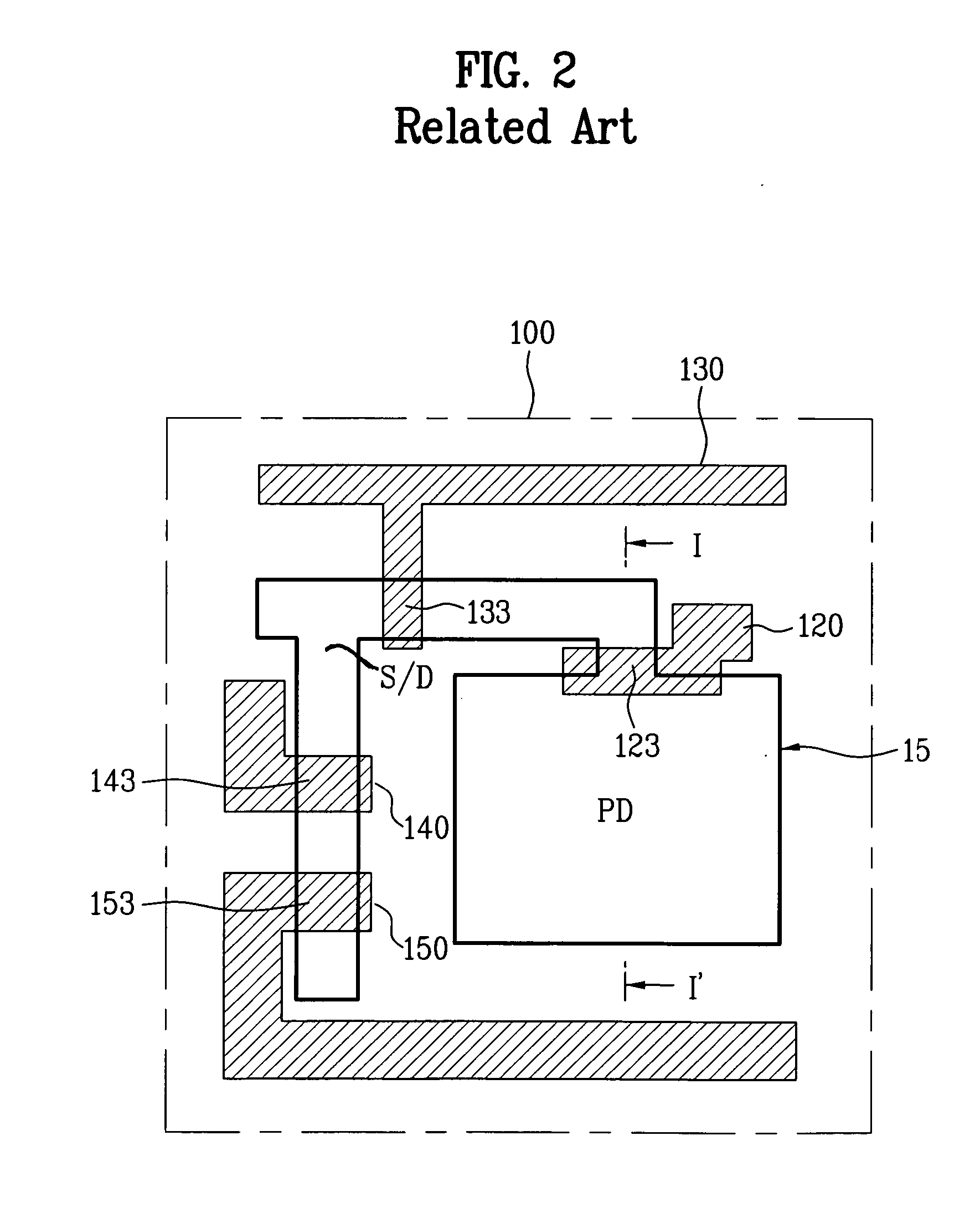

CMOS image sensor and method for fabricating the same

InactiveUS20050093036A1Reduce dark currentSolid-state devicesSemiconductor/solid-state device manufacturingCMOSPhotodiode

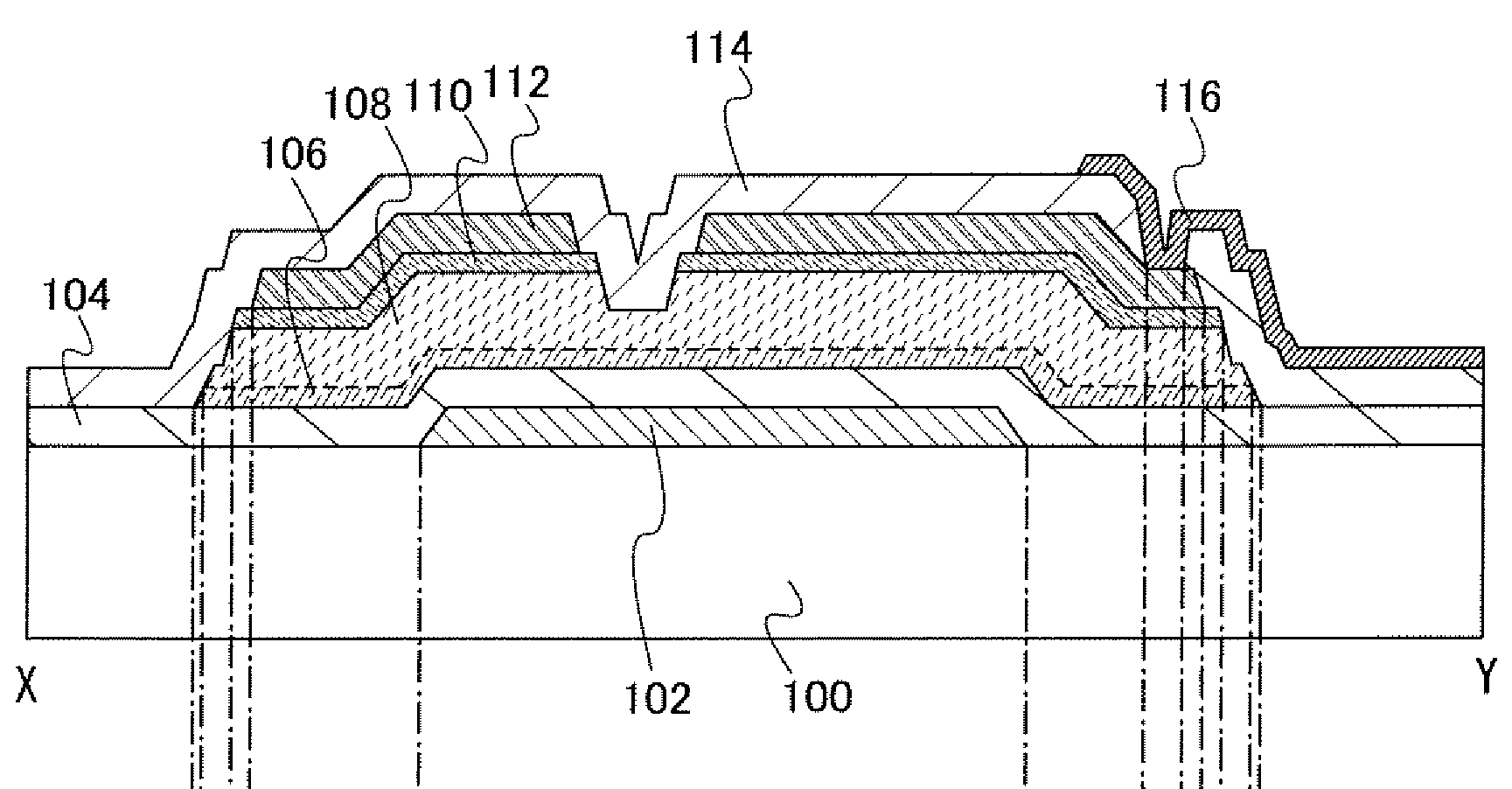

CMOS image sensor and method for fabricating the same, the CMOS image sensor including a second conductive type semiconductor substrate having an active region and a device isolation region defined therein, wherein the active region has a photodiode region and a transistor region defined therein, a device isolating film in the semiconductor substrate of the device isolation region, a first conductive type impurity region in the semiconductor substrate of the photodiode region, the first conductive type impurity region being spaced a distance from the device isolation film, and a second conductive type first impurity region in the semiconductor substrate between the first conductive type impurity region and the device isolation film, thereby reducing generation of a darkcurrent at an interface between the photodiode region and a field region.

Owner:COLUMBA TECH INC

Diode and display device including diode

InactiveUS20090159885A1Reduce contrastIncreased power consumptionSolid-state devicesDiodeImaging qualityDisplay device

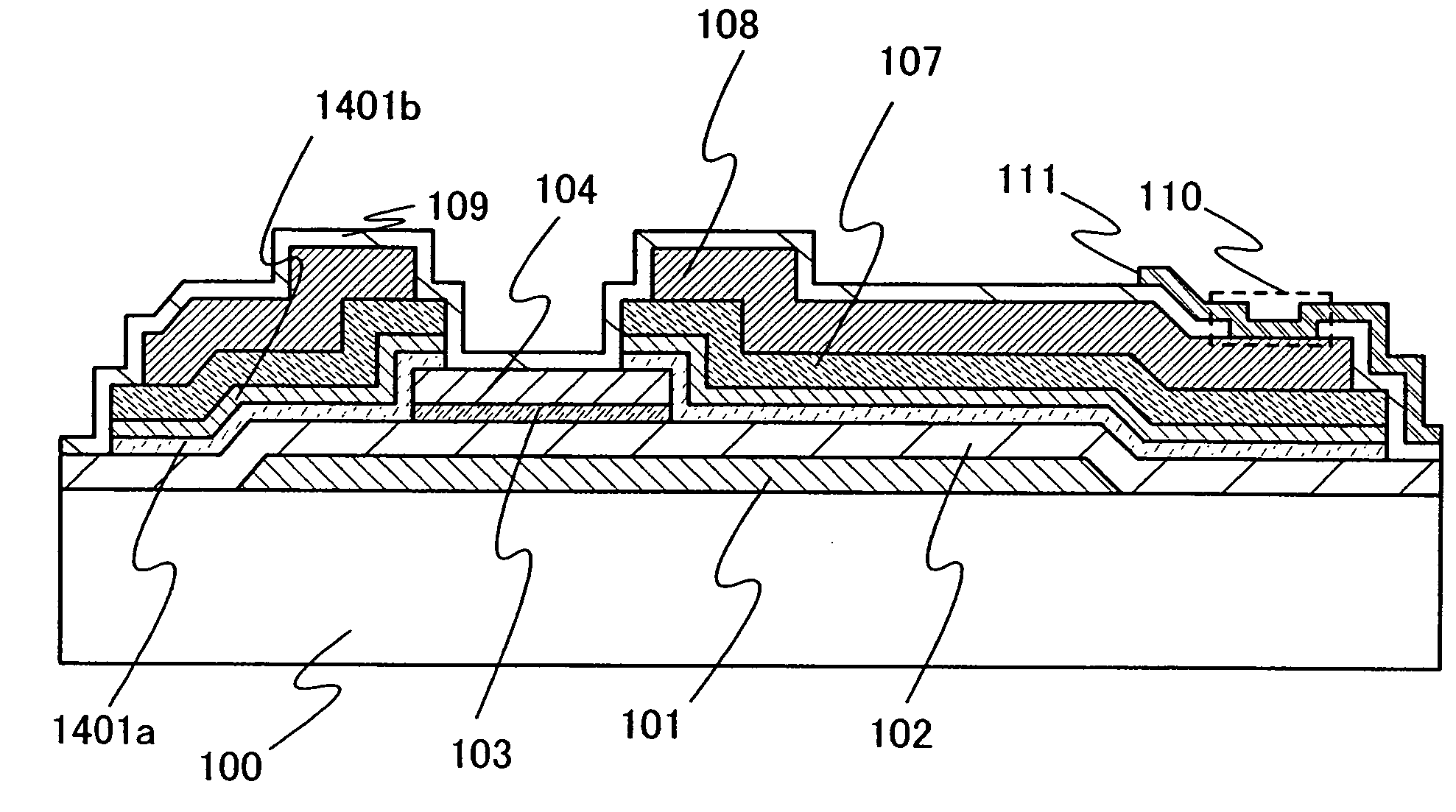

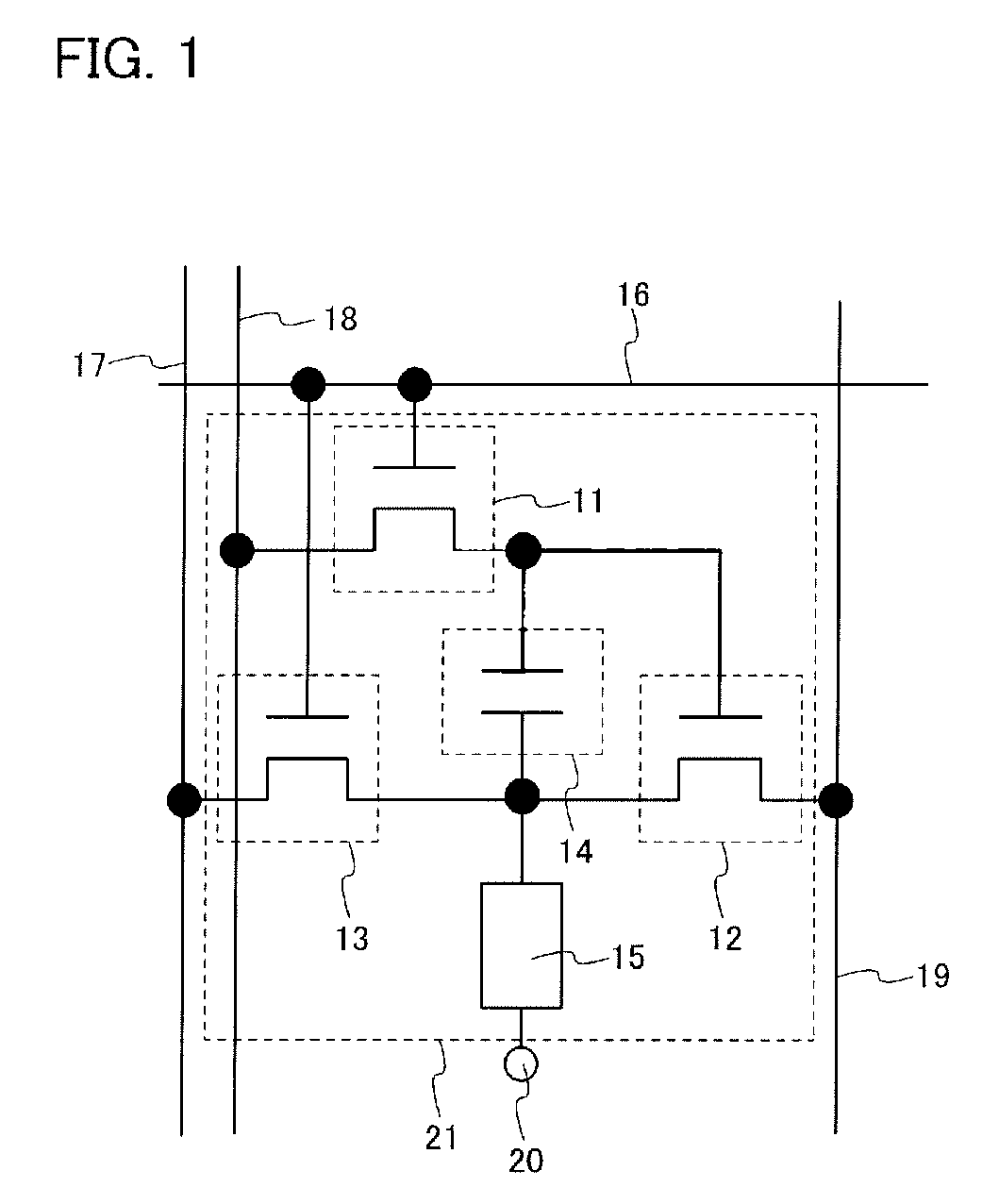

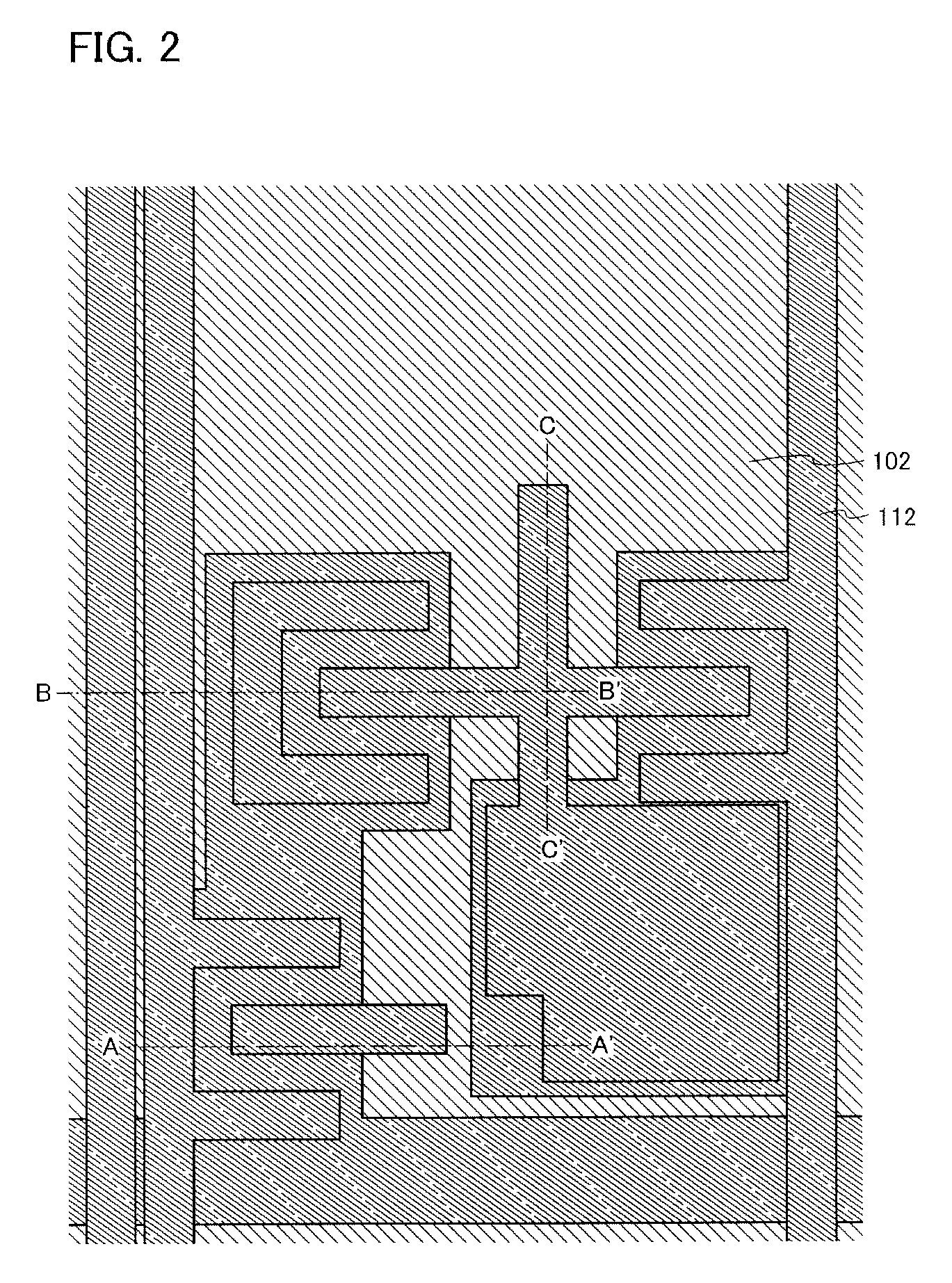

A thin film transistor which includes a microcrystalline semiconductor film over a gate electrode with a gate insulating film interposed therebetween to be in an inner region in which end portions of microcrystalline semiconductor film are in an inside of end portions of the gate electrode, an amorphous semiconductor film which covers top and side surfaces of the microcrystalline semiconductor film, and an impurity semiconductor film to which an impurity element imparting one conductivity is added, and which forms a source region and a drain region, wherein the microcrystalline semiconductor film includes an impurity element serving as a donor is provided to reduce off current of a thin film transistor, to reduce reverse bias current of a diode, and to improve an image quality of a display device using a thin film transistor.

Owner:SEMICON ENERGY LAB CO LTD

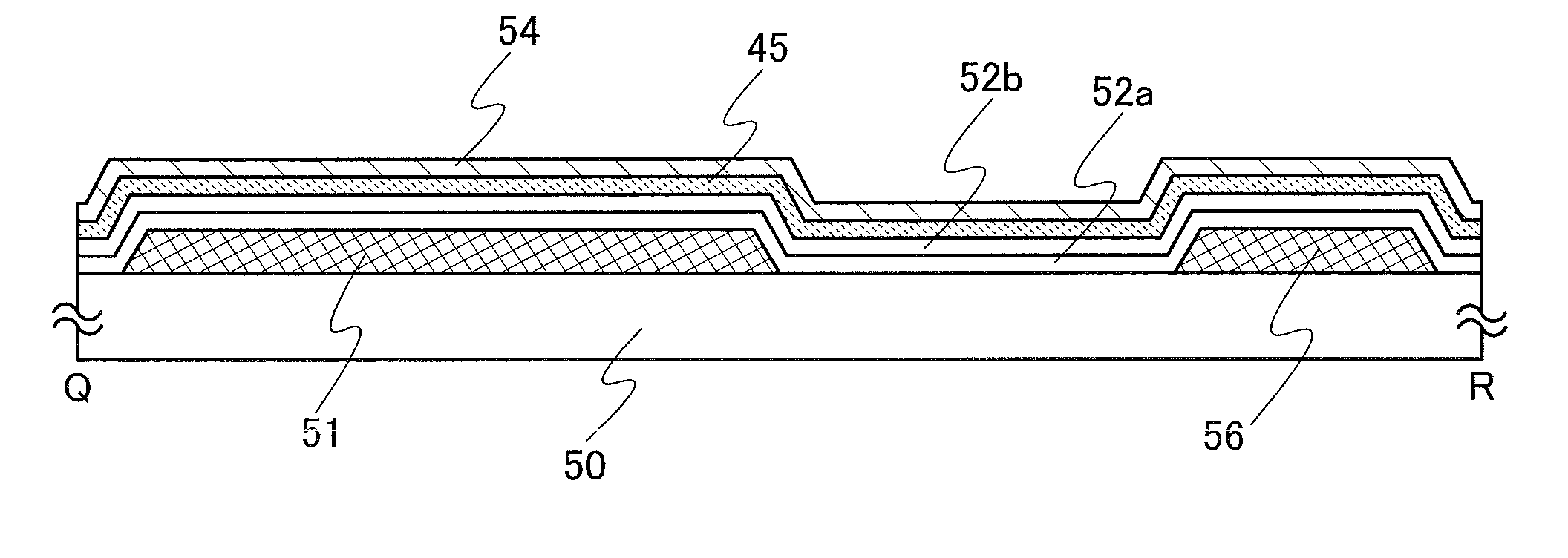

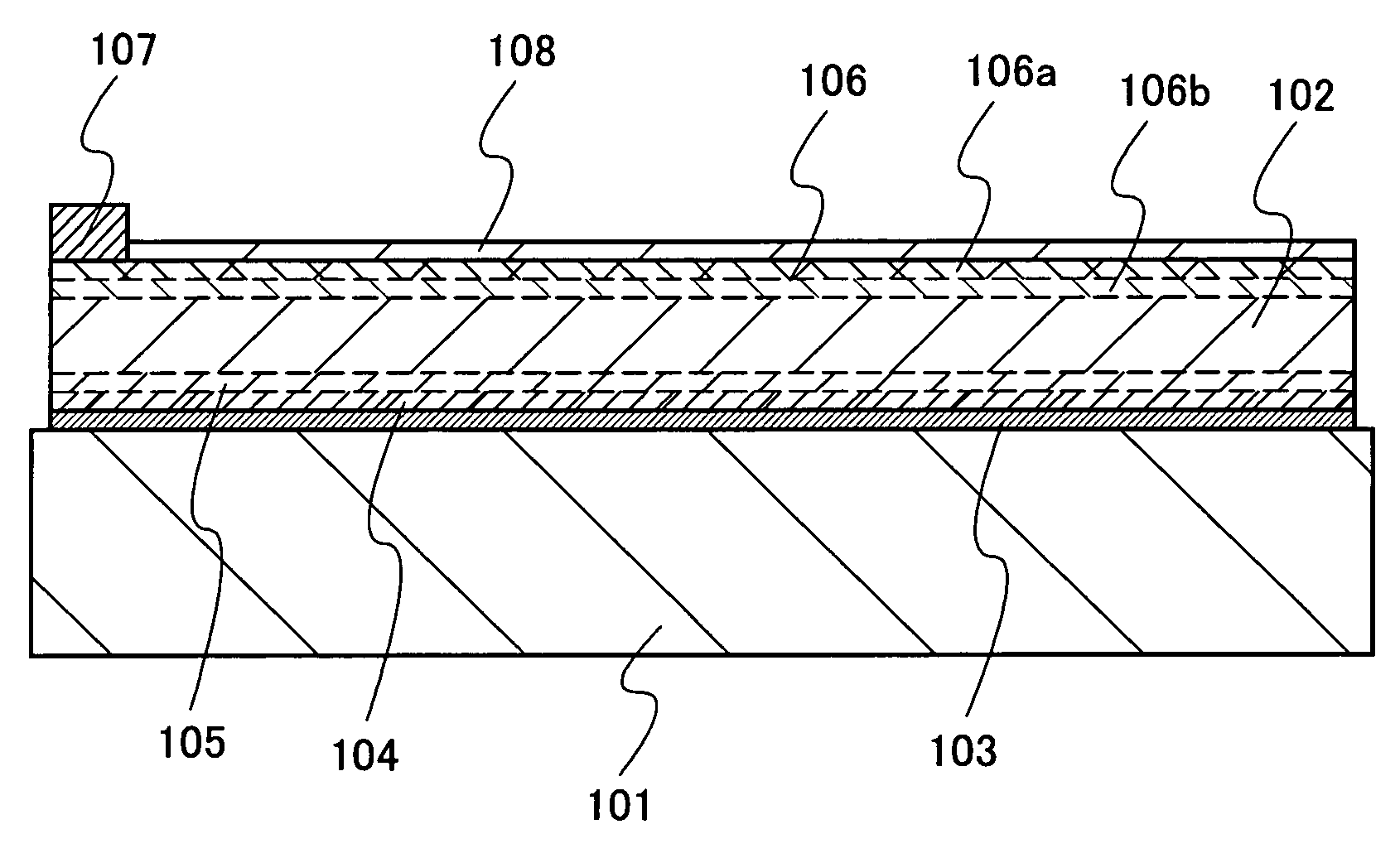

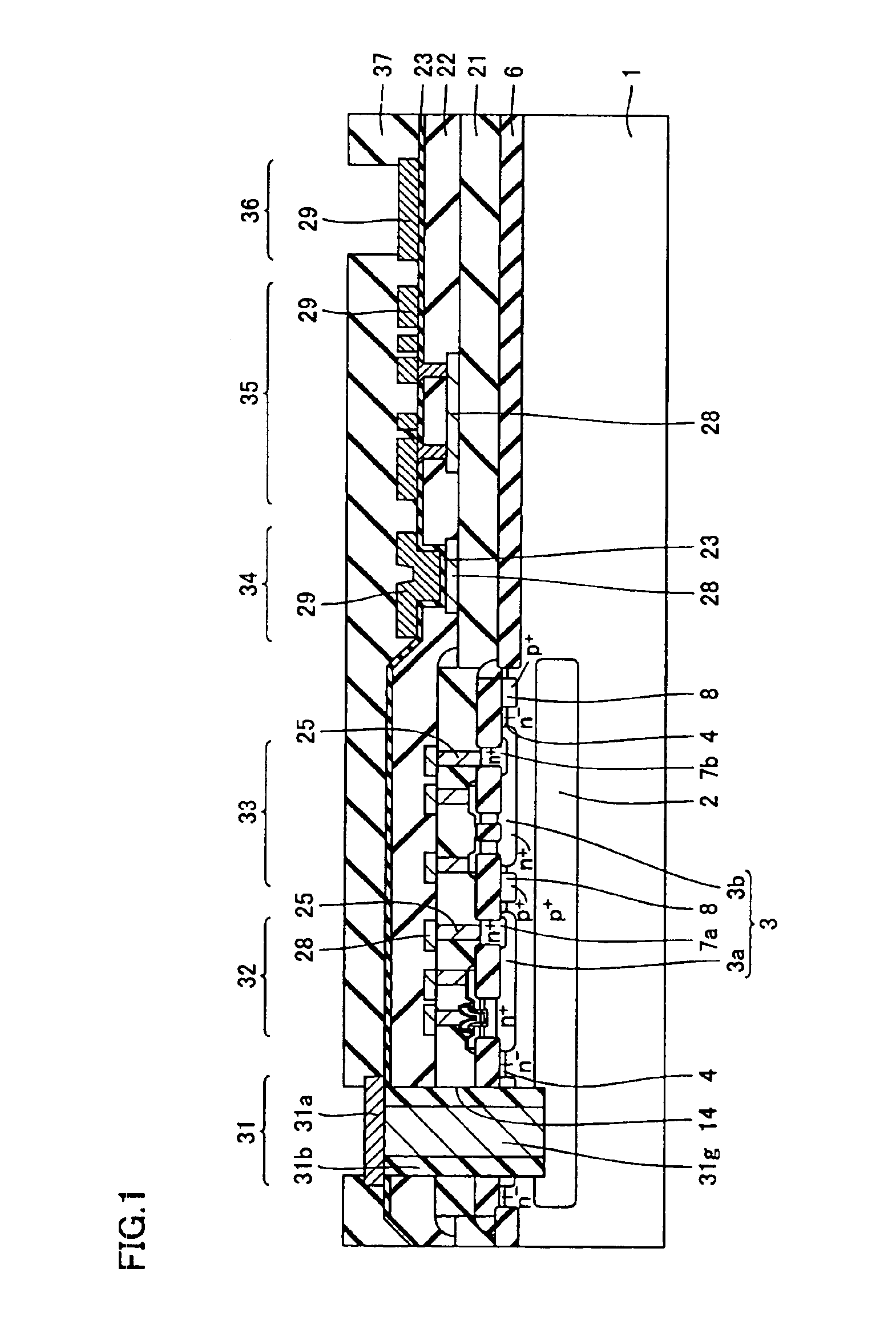

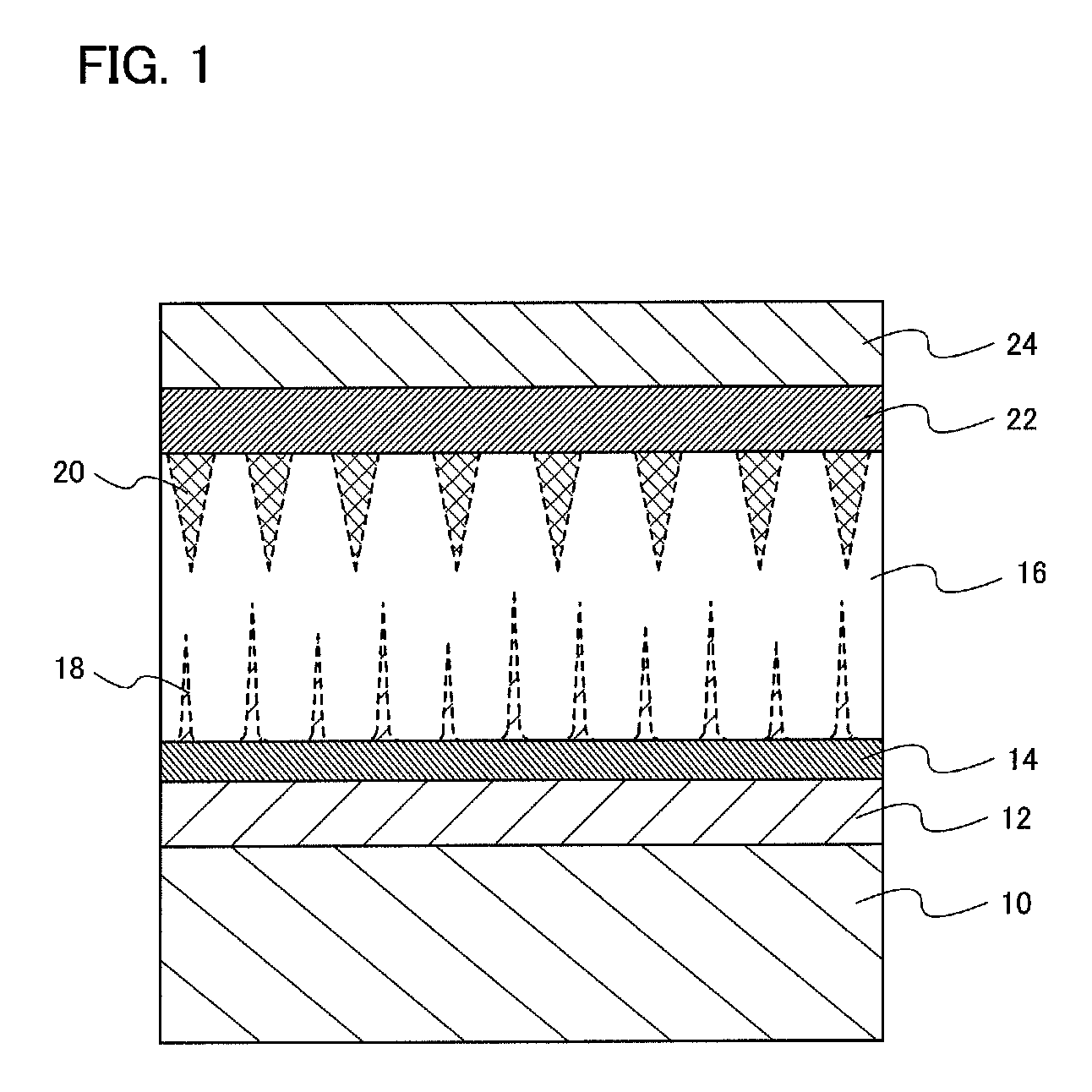

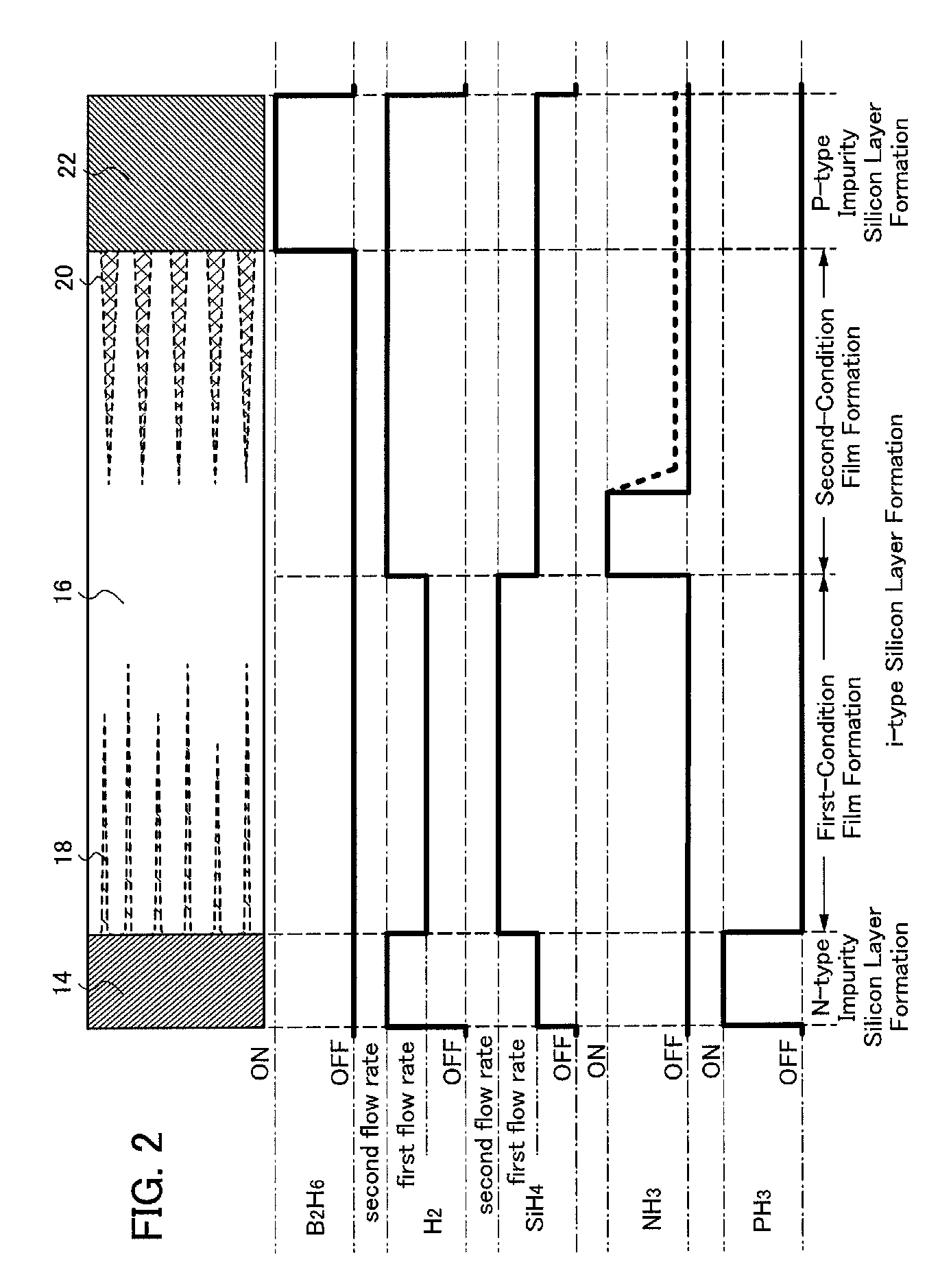

Photoelectric conversion device and method for manufacturing the same

InactiveUS20090120498A1Easy to useDeterioration of characteristicSemiconductor/solid-state device manufacturingPhotovoltaic energy generationSemiconductor materialsPhotoelectric conversion

A photoelectric conversion device with an excellent photoelectric conversion characteristic with a silicon semiconductor material effectively utilized. The photoelectric conversion device includes a first unit cell including a first electrode, a first impurity semiconductor layer, a single crystal semiconductor layer, and a second impurity semiconductor layer; and a second unit cell including a third impurity semiconductor layer, a non-single-crystal semiconductor layer, a fourth impurity semiconductor layer, and a second electrode. The second and third impurity semiconductor layers are in contact with each other so that the first and second unit cells are connected in series, and an insulating layer is provided for a surface of the first electrode and bonded to a supporting substrate.

Owner:SEMICON ENERGY LAB CO LTD

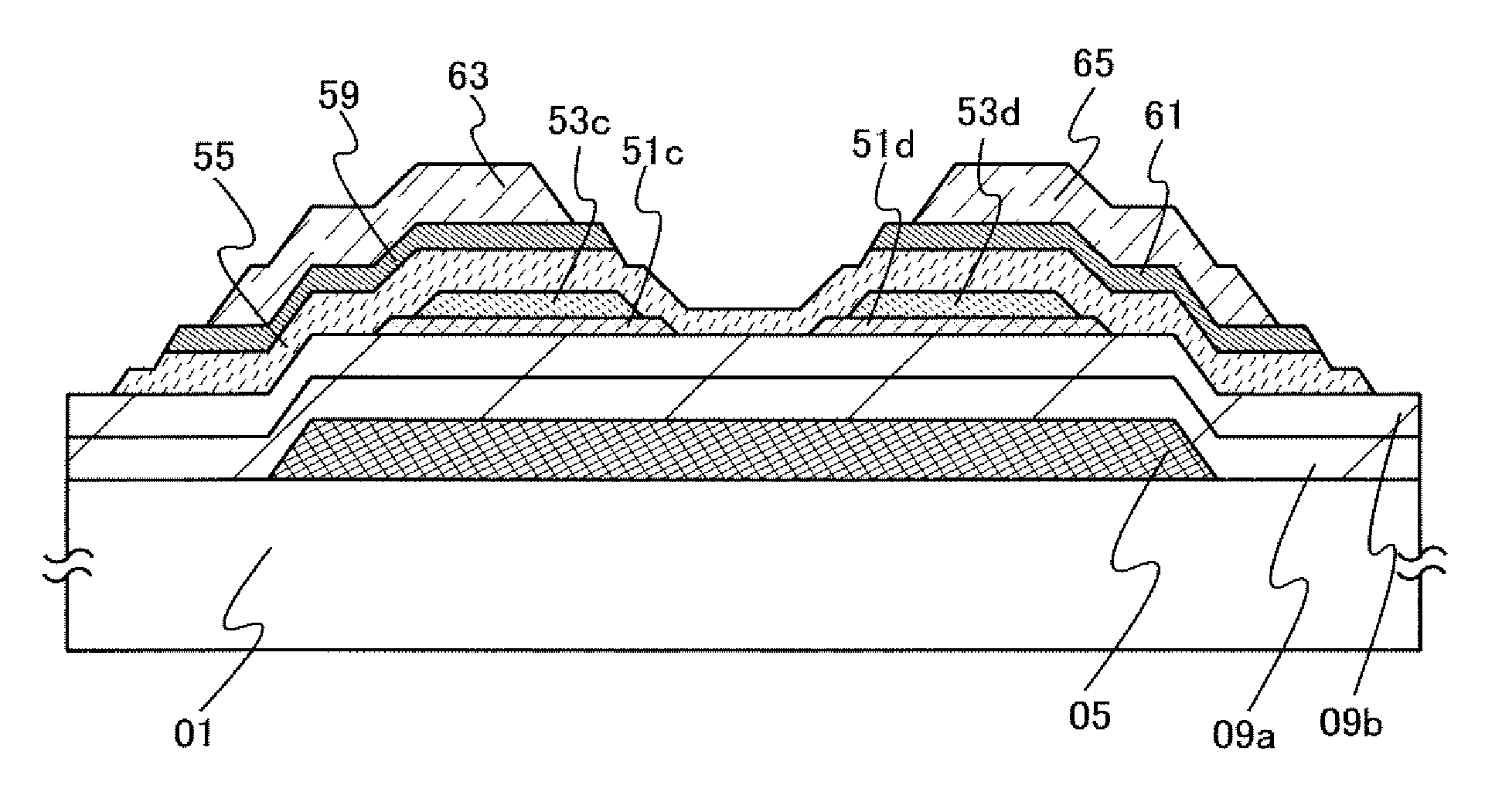

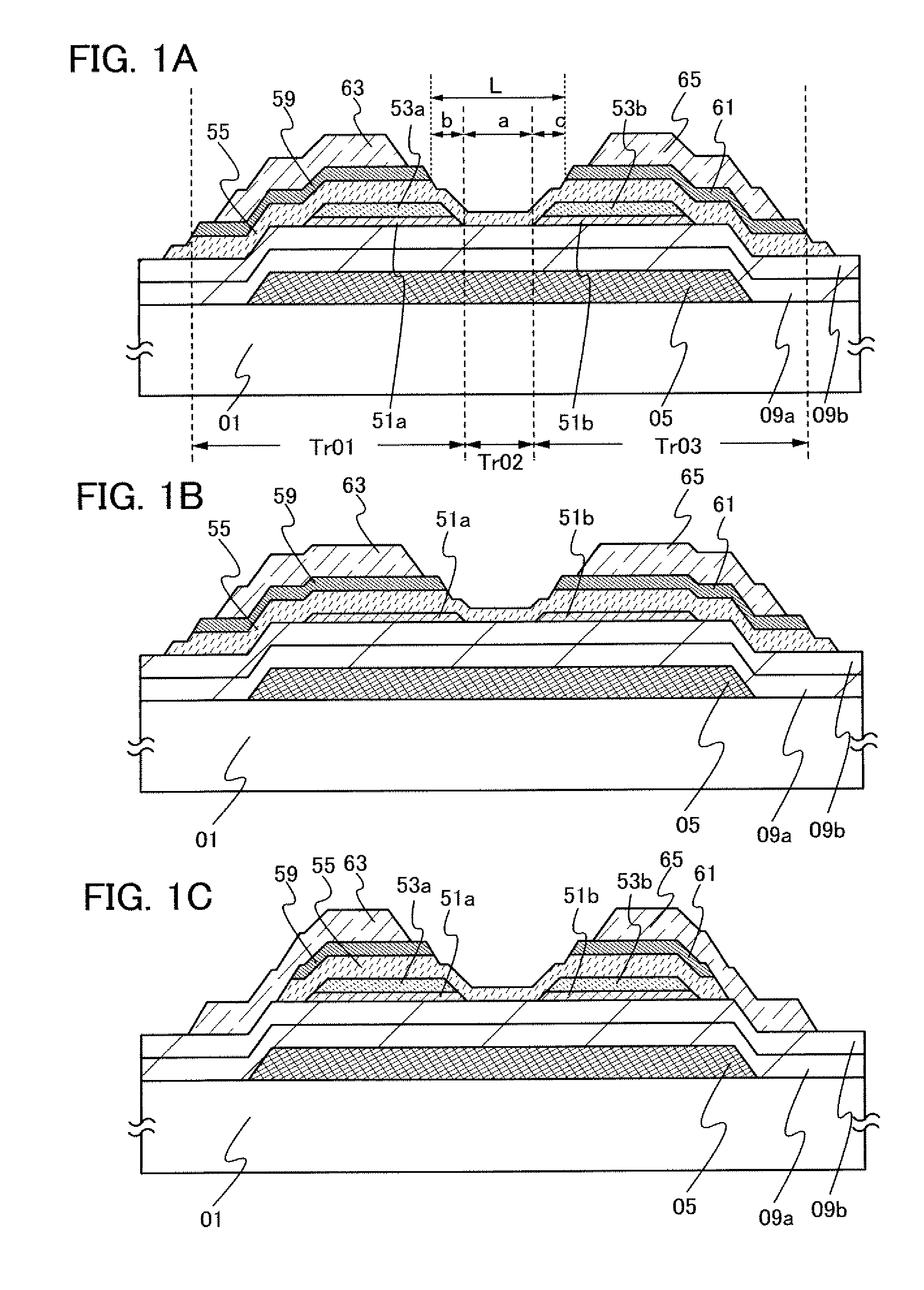

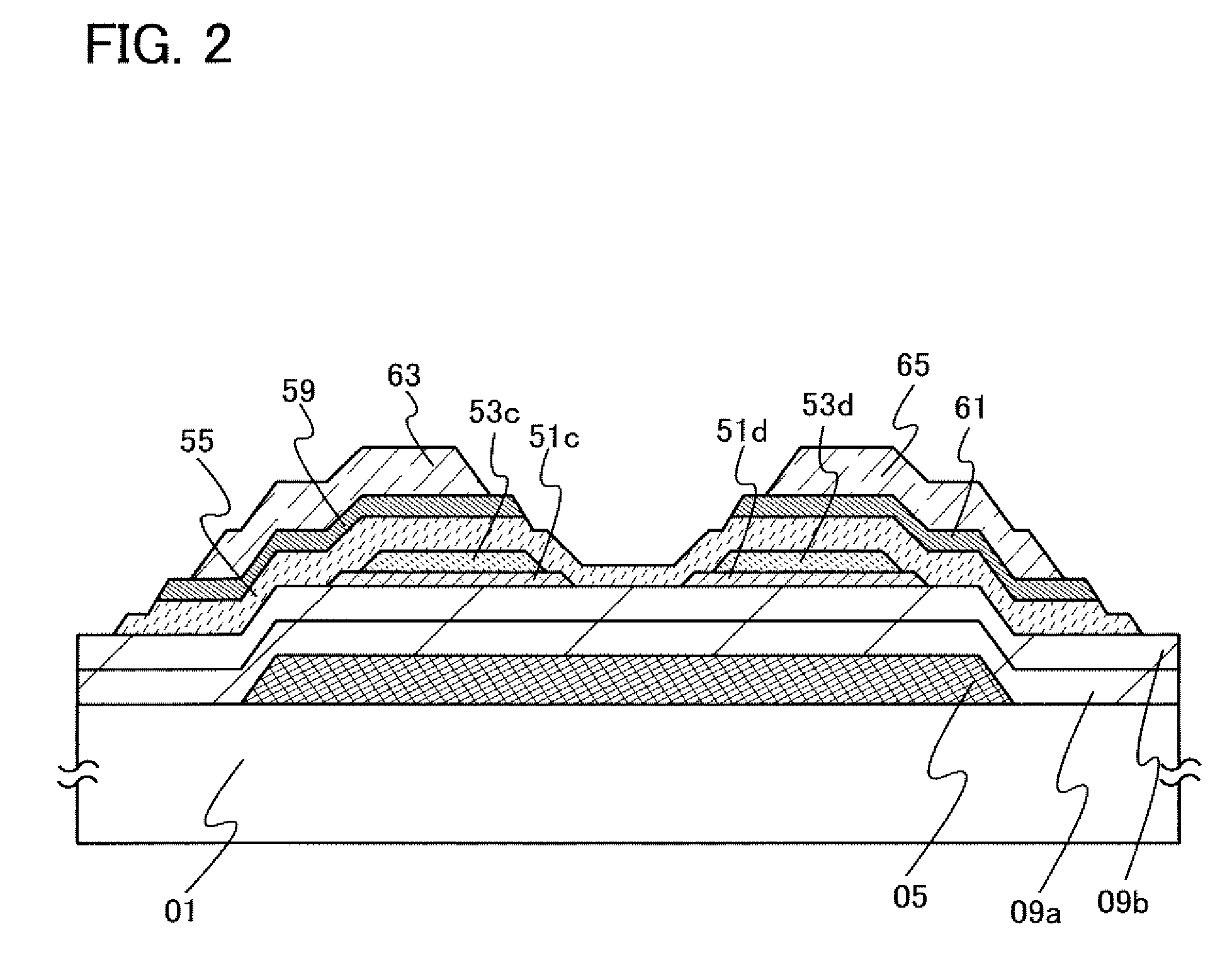

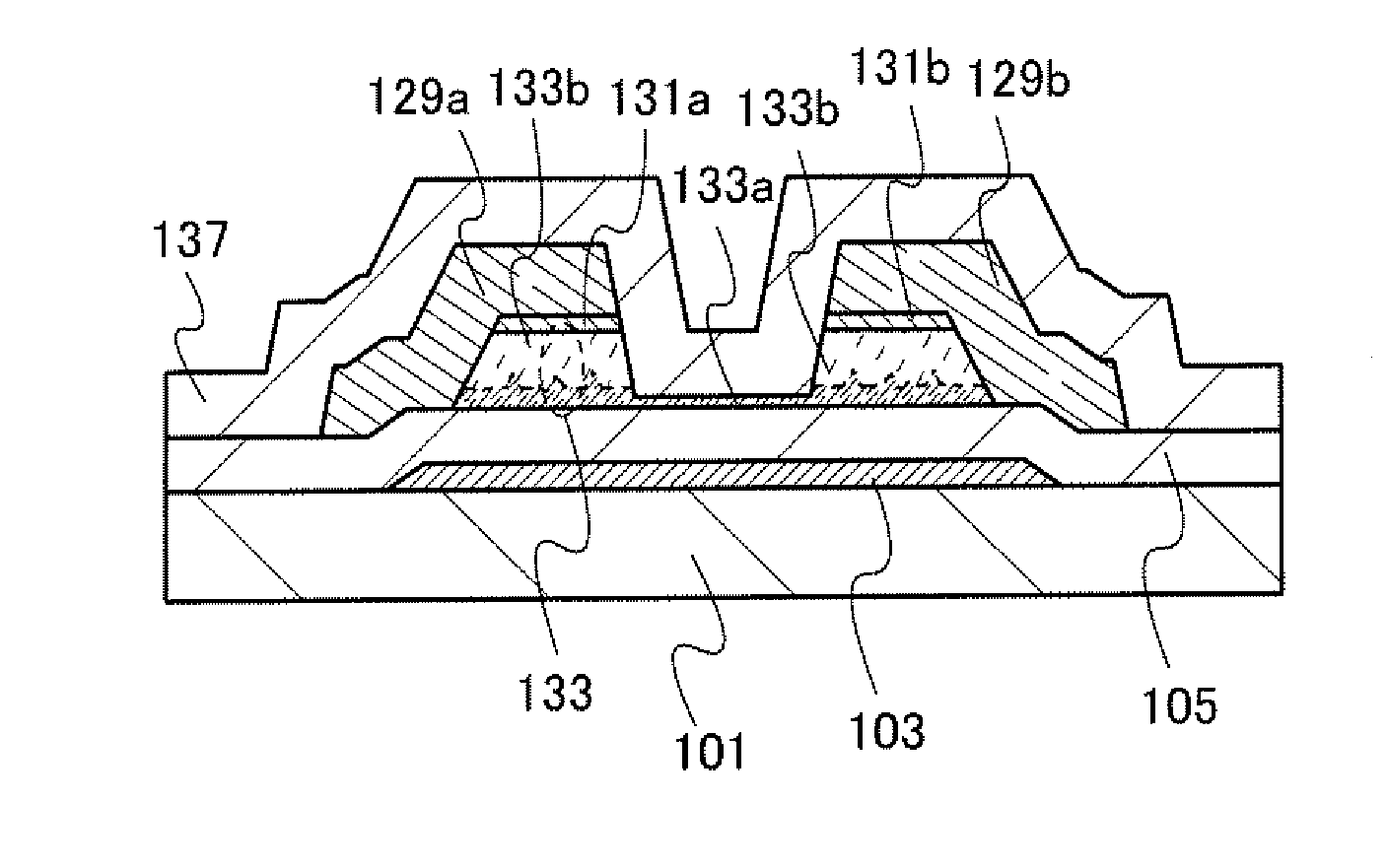

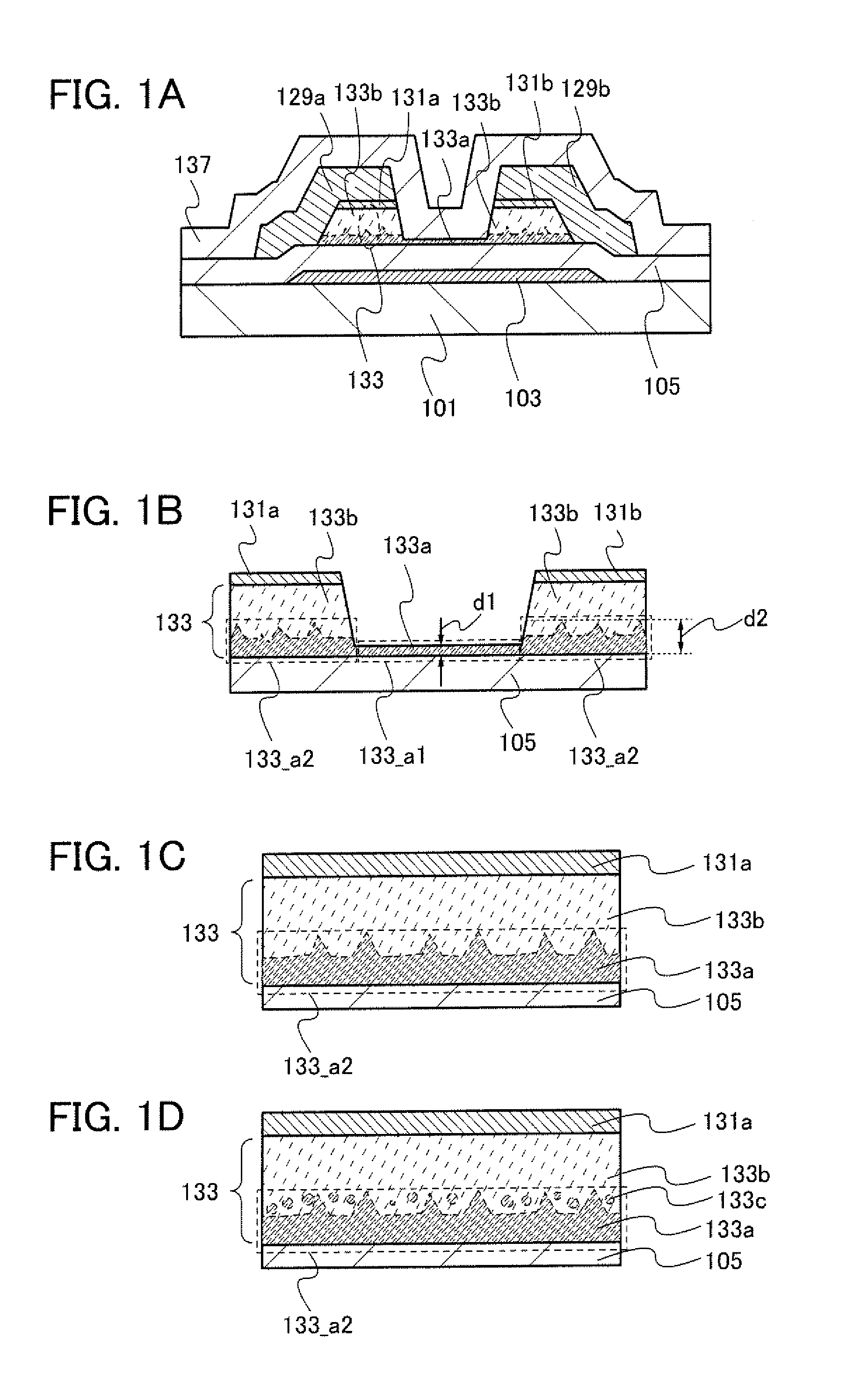

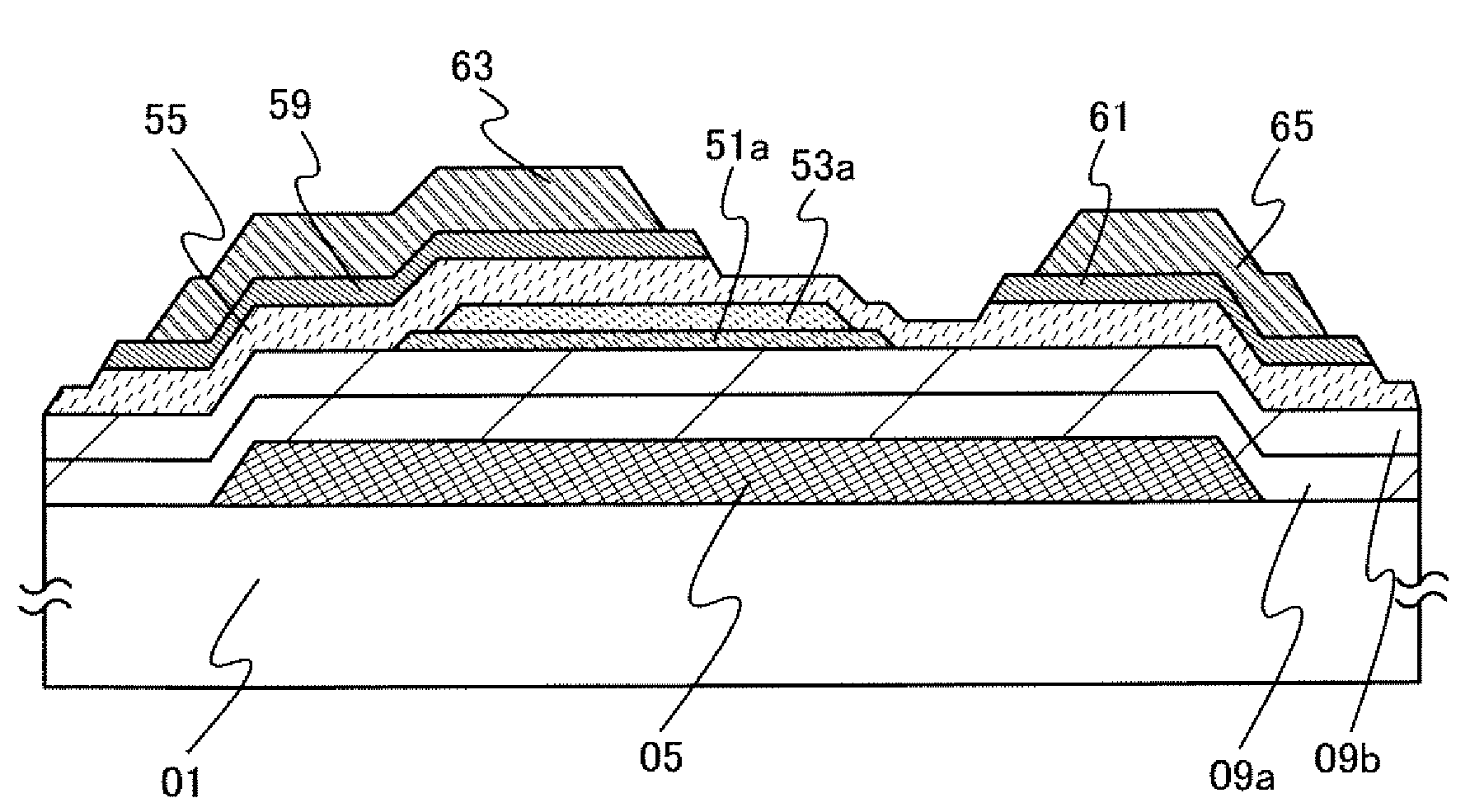

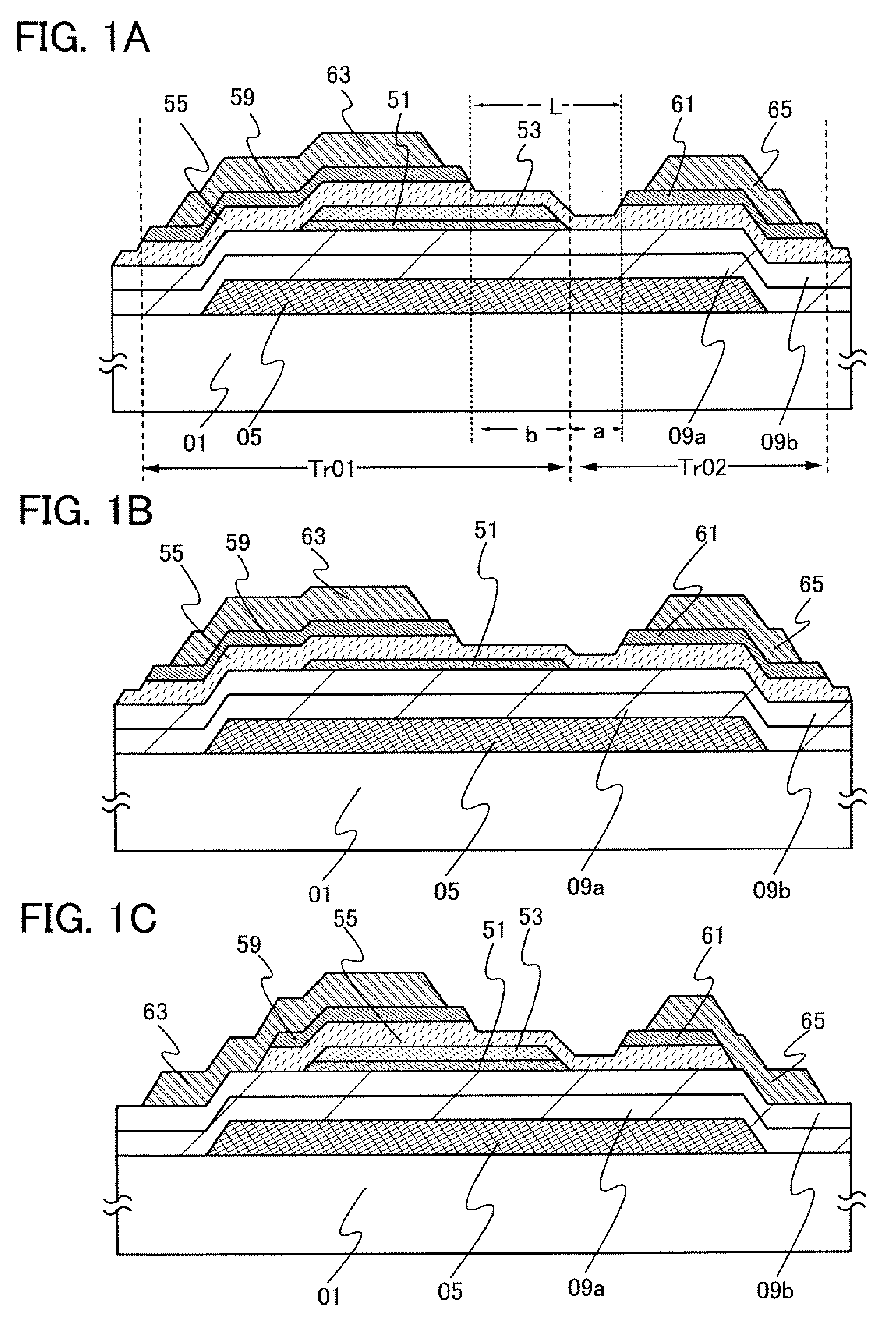

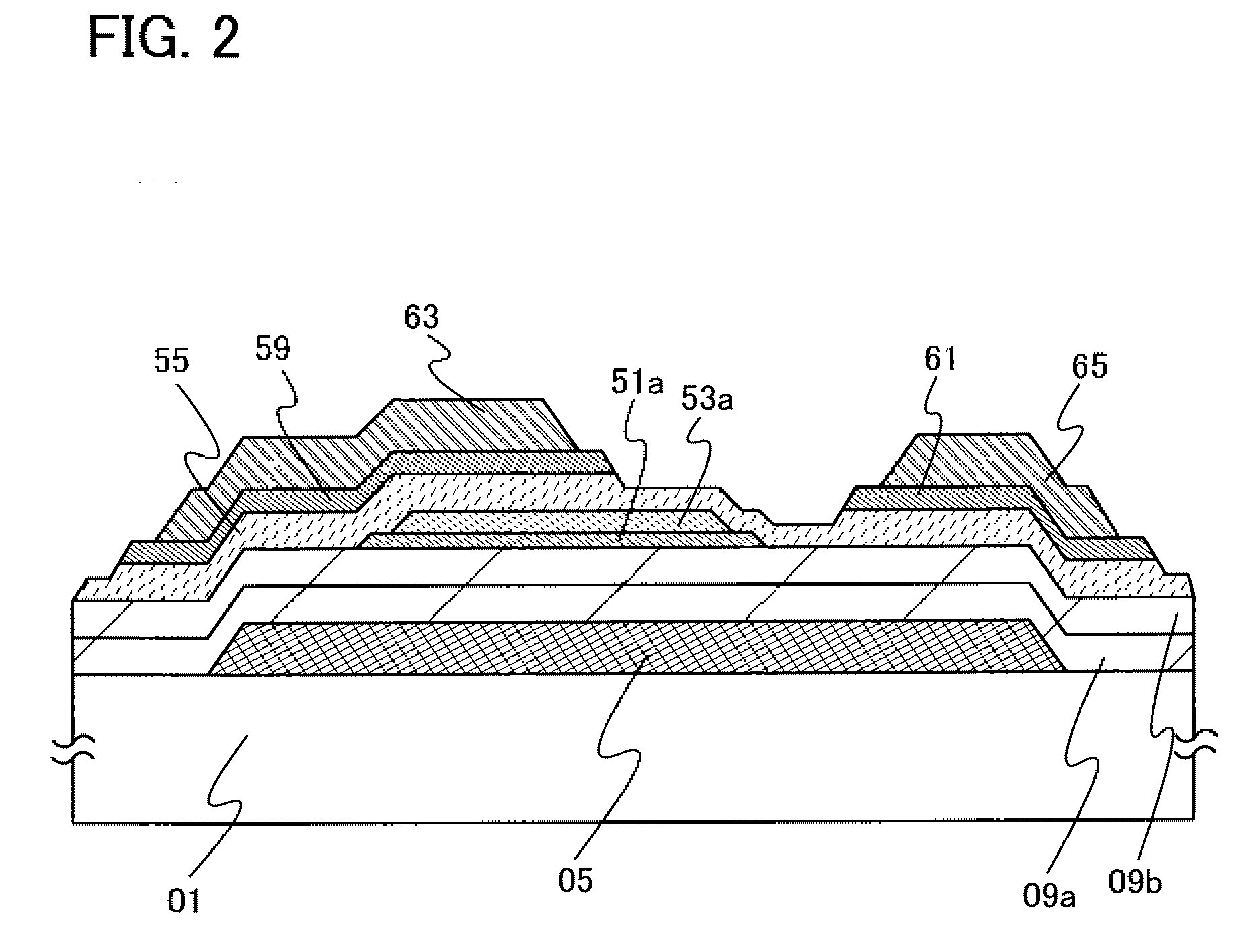

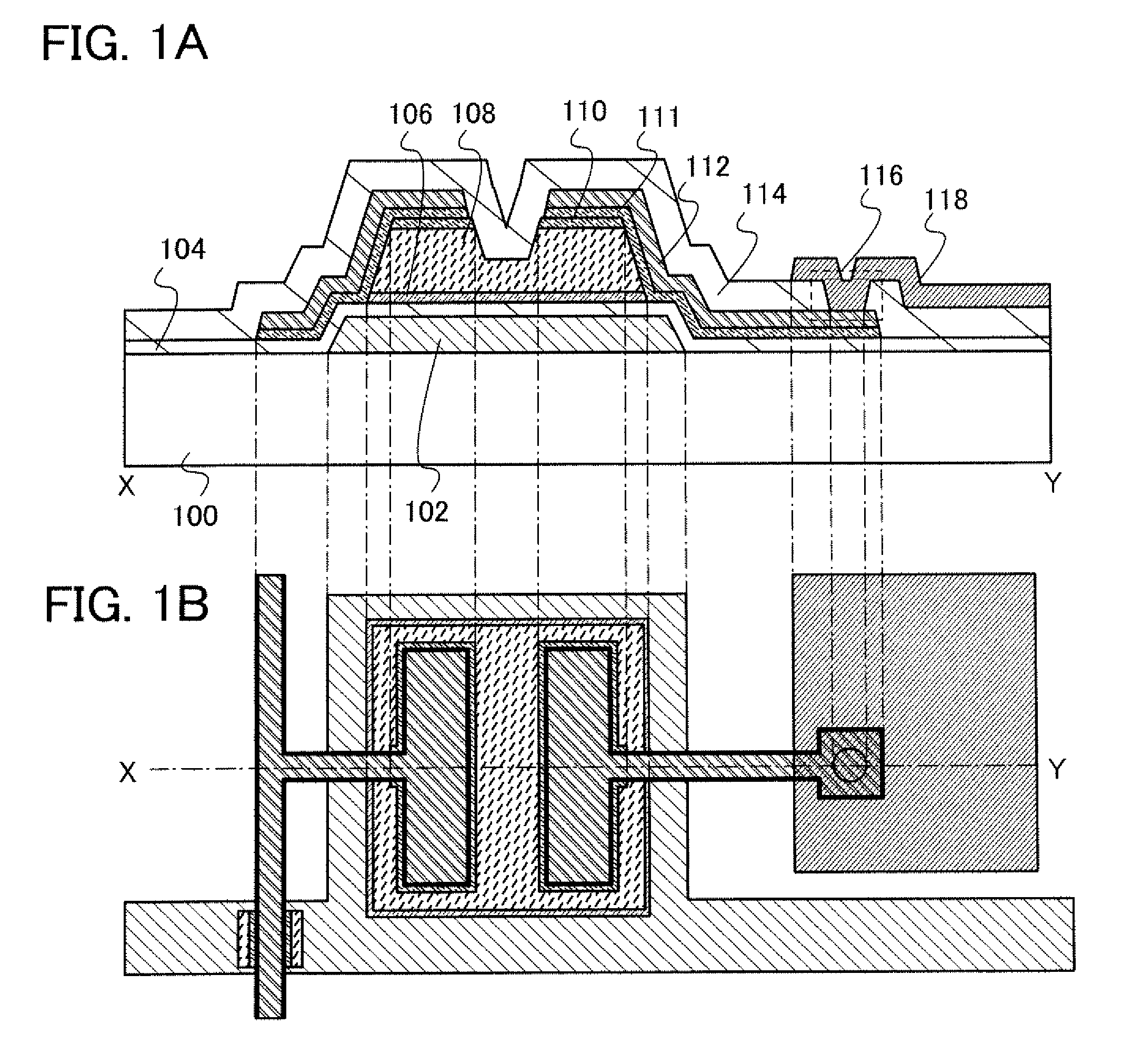

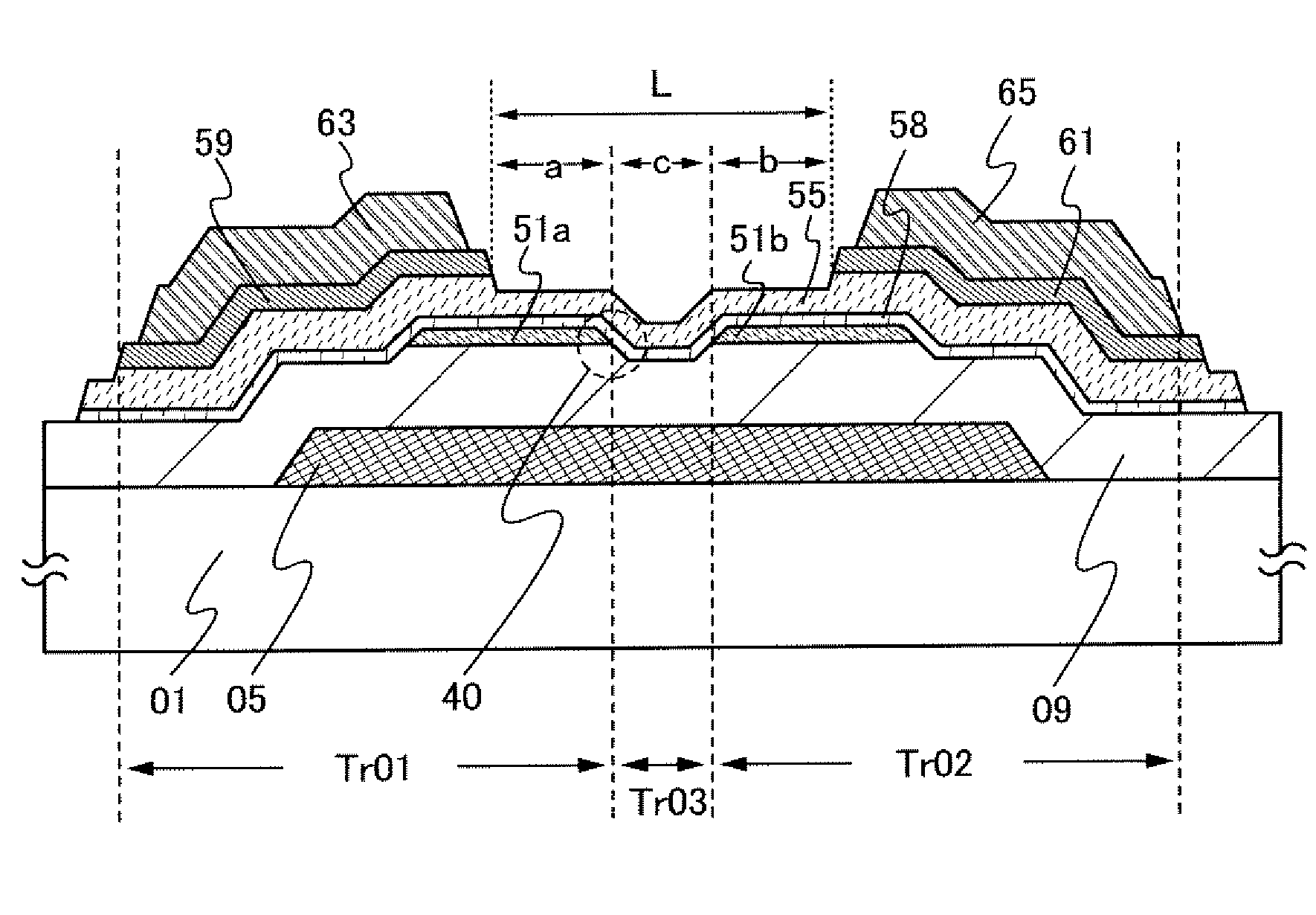

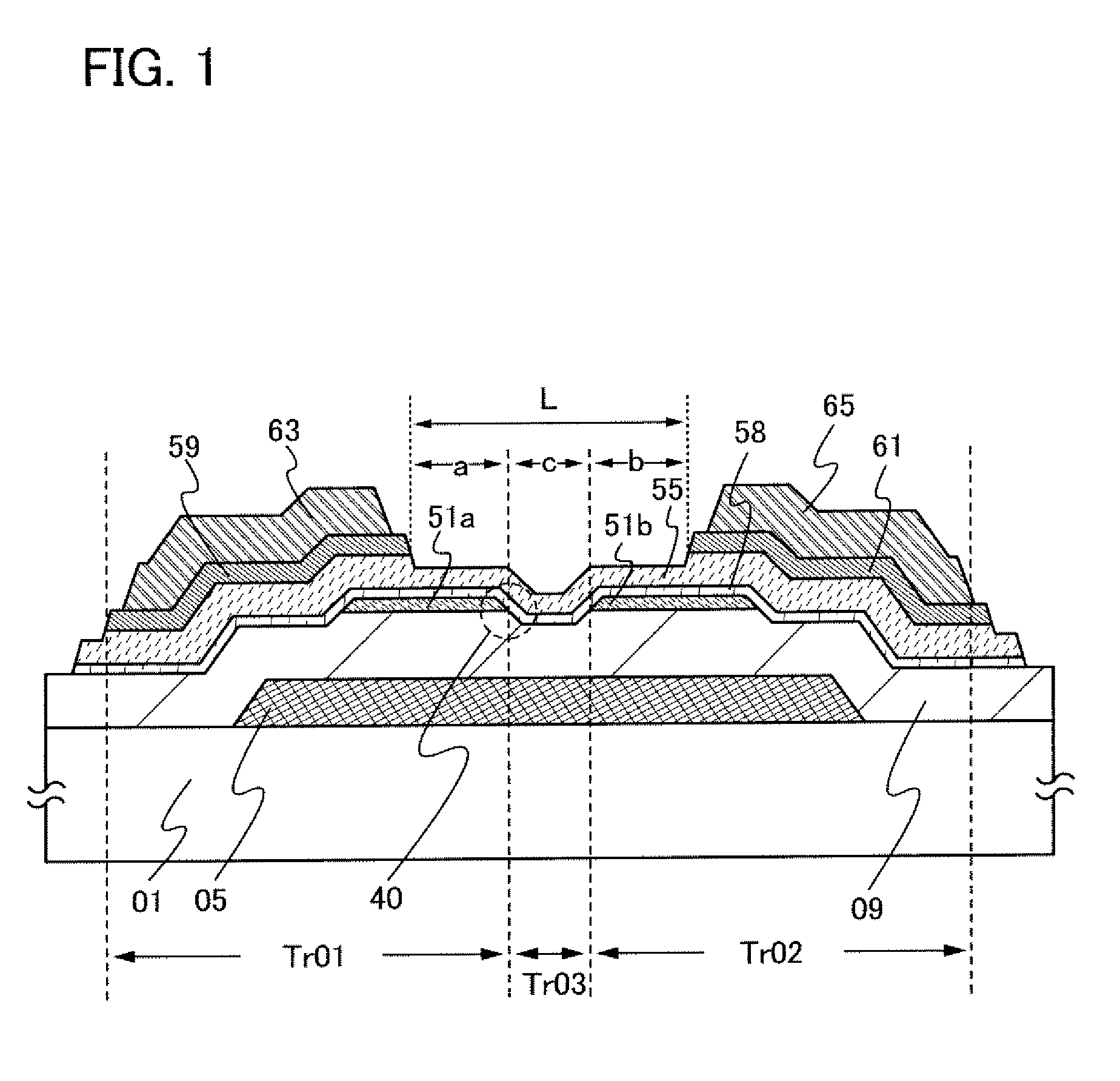

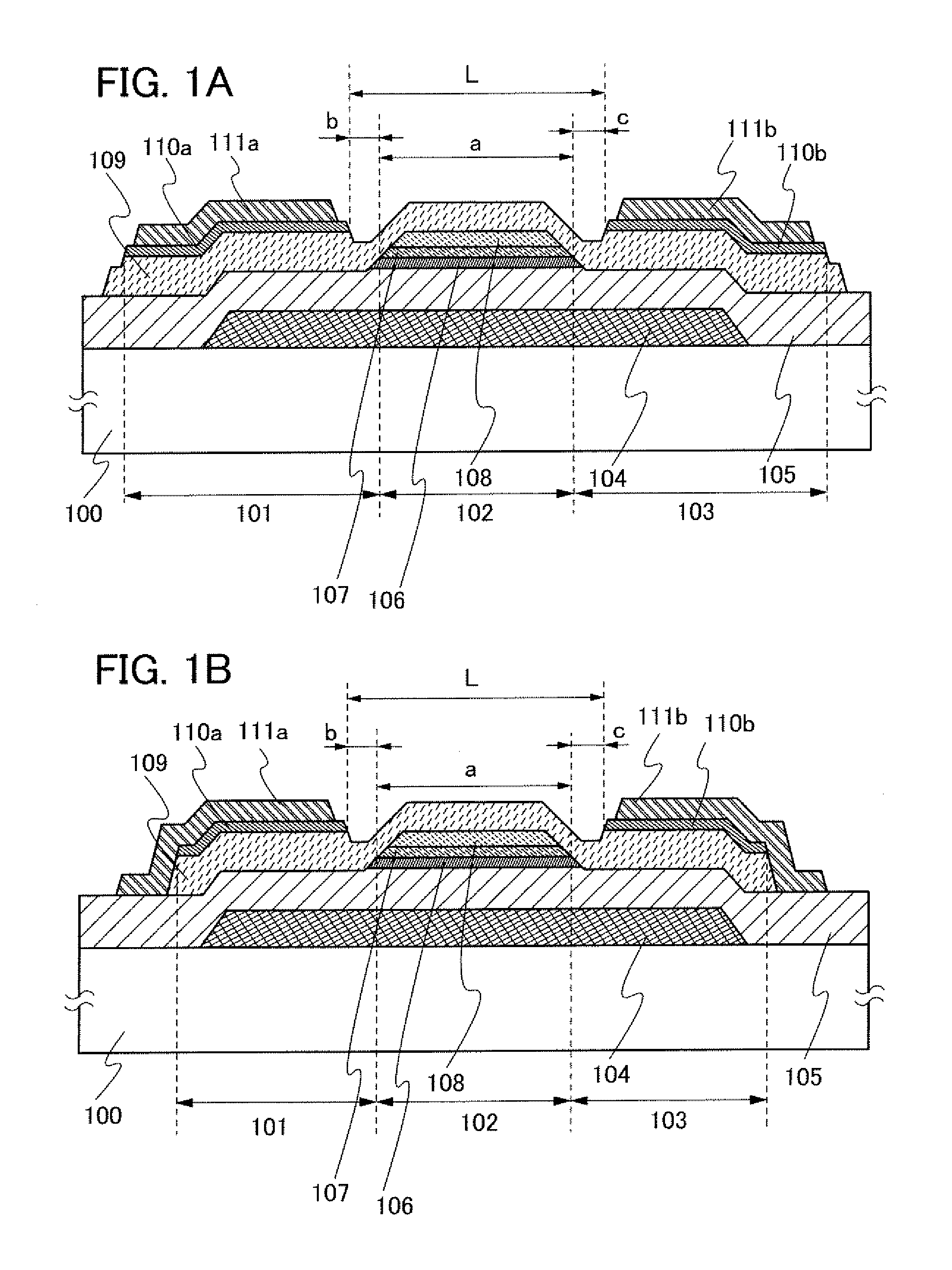

Thin-film transistor and display device

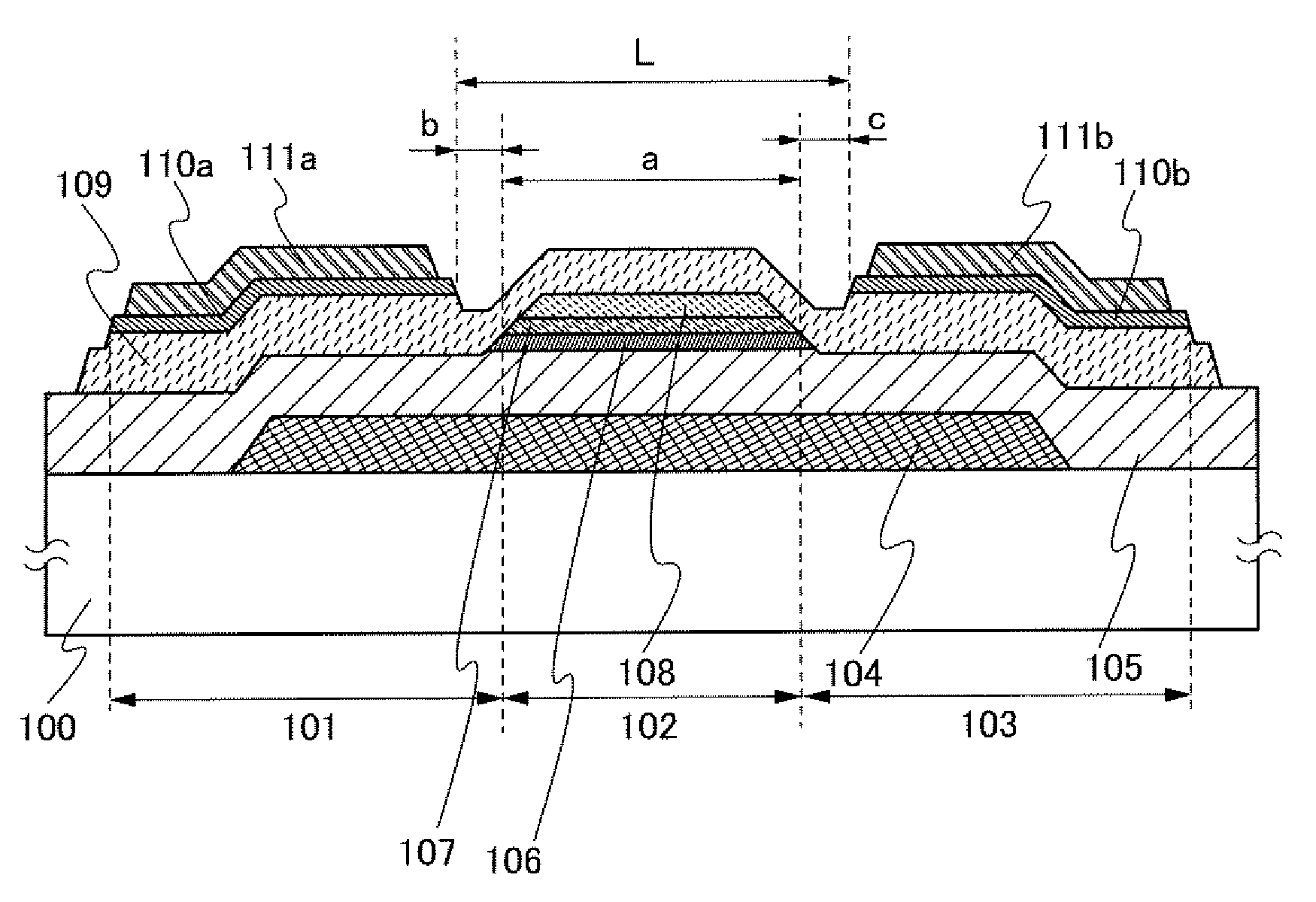

InactiveUS20090218572A1Increasing field-effect mobilityIncrease speedTransistorDisplay deviceImpurity

A thin-film transistor in which problems with ON-state current and OFF-state current are solved, and a thin-film transistor capable of high-speed operation. The thin-film transistor includes a pair of impurity semiconductor layers in which an impurity element imparting one conductivity type is added to form a source and drain regions, provided with a space therebetween so as to be overlapped with a gate electrode with a gate insulating layer interposed between the gate electrode and the impurity semiconductor layers; a pair of semiconductor layers in which an impurity element which serves as an acceptor is added, overlapped over the gate insulating layers with the gate electrode and the impurity semiconductor layers, and disposed with a space therebetween in a channel length direction; and an amorphous semiconductor layer being in contact with the gate insulating layer and the pair of semiconductor layers and extended between the pair of semiconductor layers.

Owner:SEMICON ENERGY LAB CO LTD

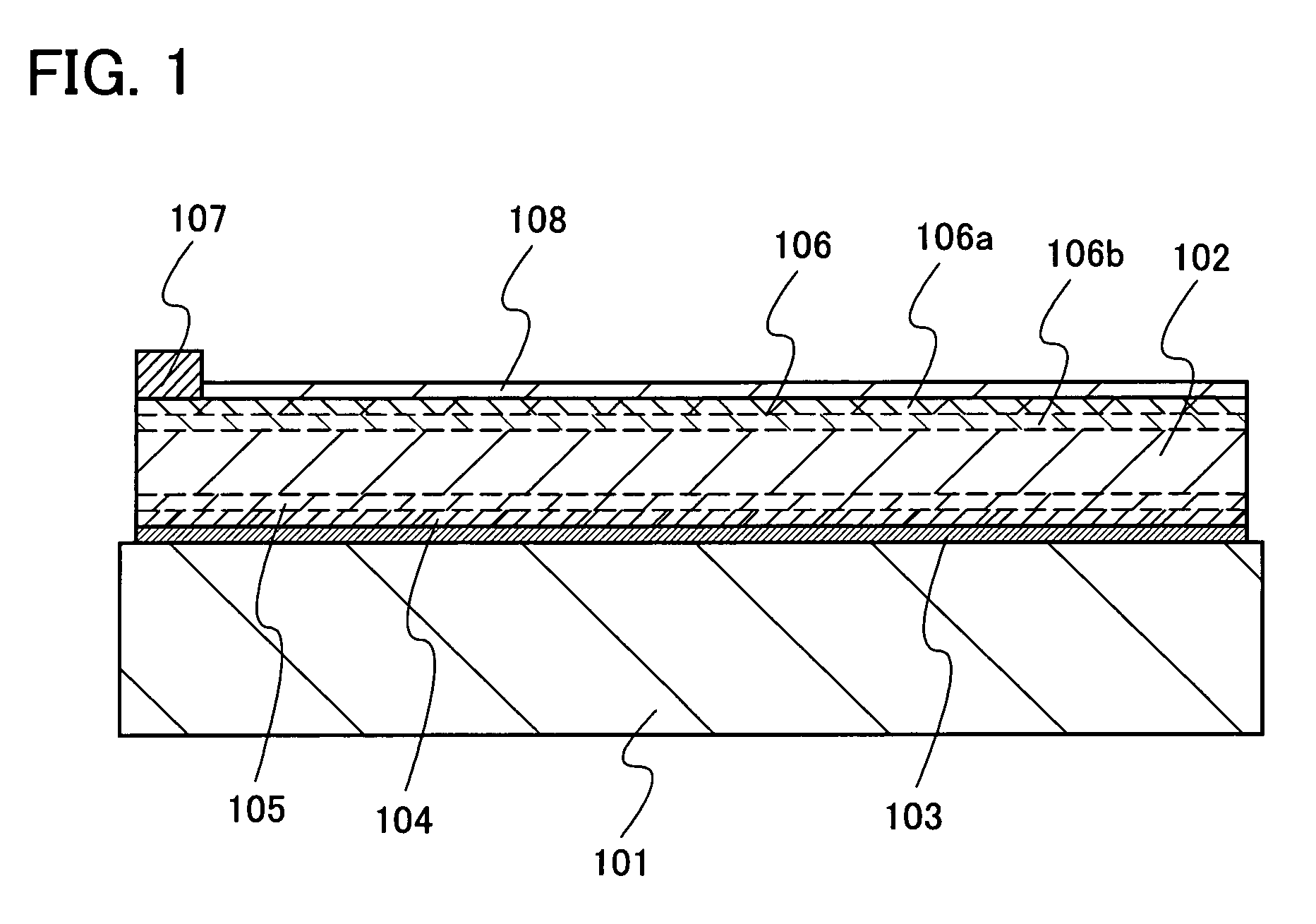

Photovoltaic device and method for manufacturing the same

InactiveUS20080251126A1Easy to useExcellent characteristicsPV power plantsSemiconductor/solid-state device manufacturingSurface layerSingle crystal

A photovoltaic device uses a single crystal or polycrystalline semiconductor layer which is separated from a single crystal or polycrystalline semiconductor substrate as a photoelectric conversion layer and has a SOI structure in which the semiconductor layer is bonded to a substrate having an insulating surface or an insulating substrate. A single crystal semiconductor layer which is a separated surface layer part of a single crystal semiconductor substrate and is transferred is used as a photoelectric conversion layer and includes an impurity semiconductor layer to which hydrogen or halogen is added on a light incidence surface or on an opposite surface. The semiconductor layer is fixed to a substrate having an insulating surface or an insulating substrate.

Owner:SEMICON ENERGY LAB CO LTD

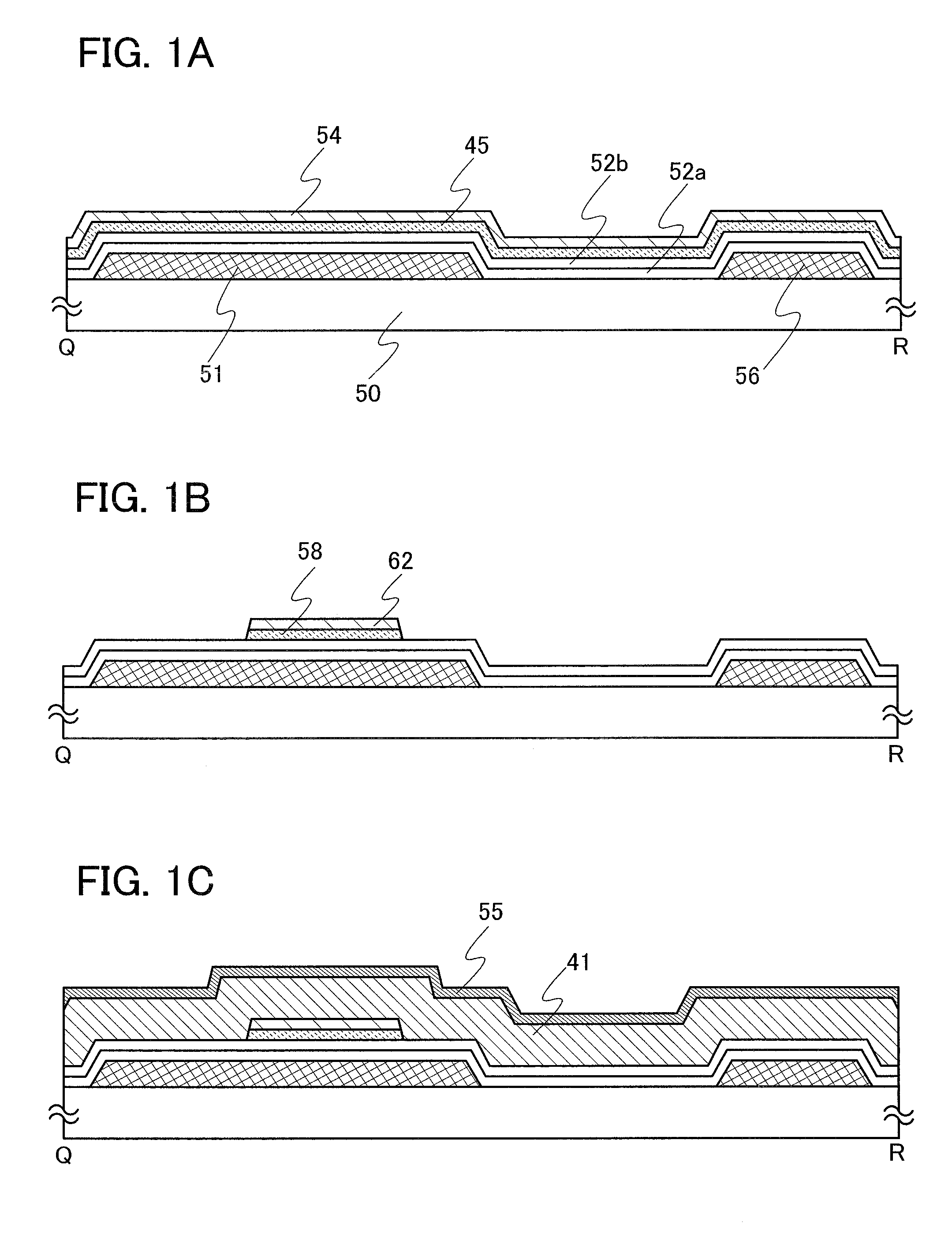

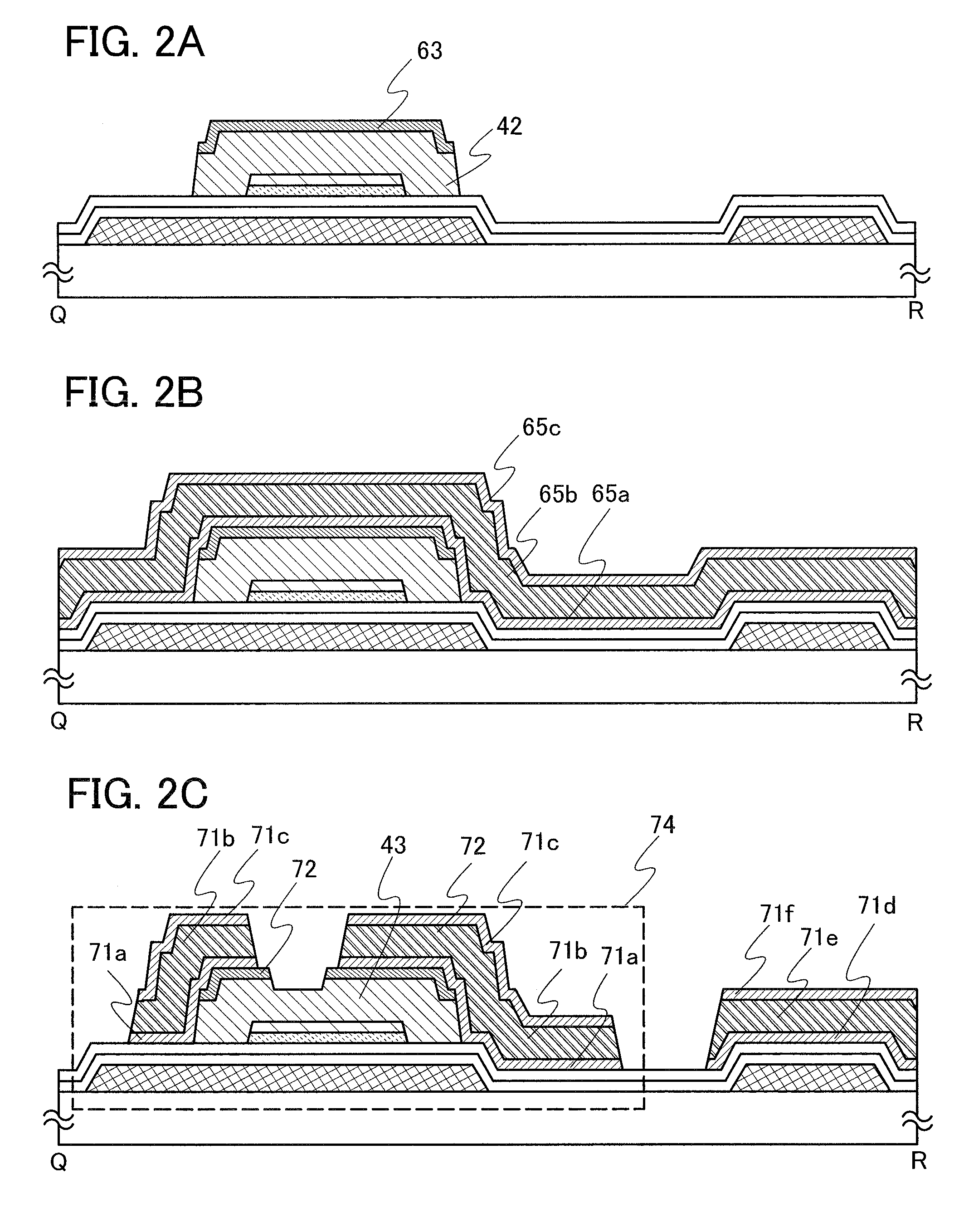

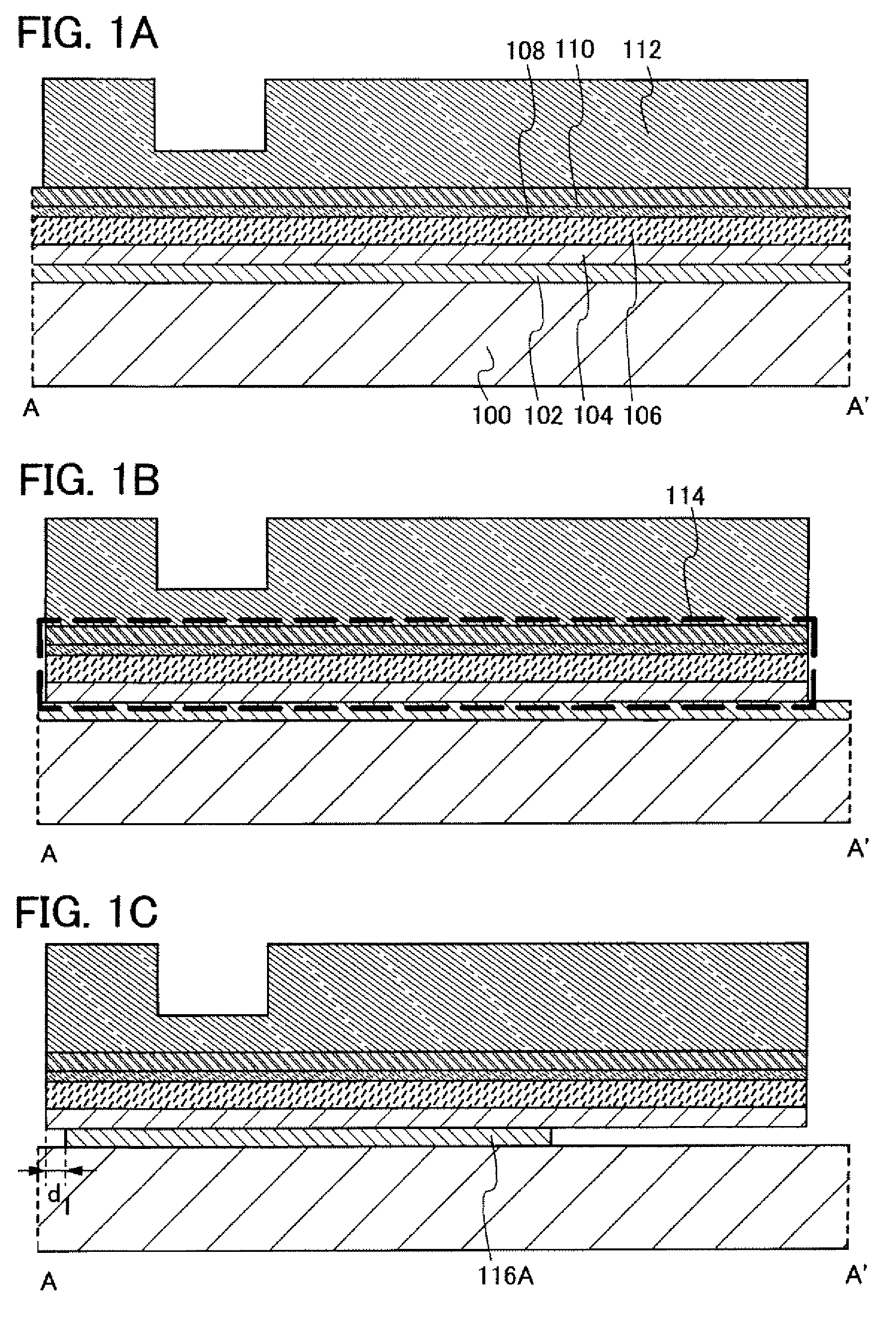

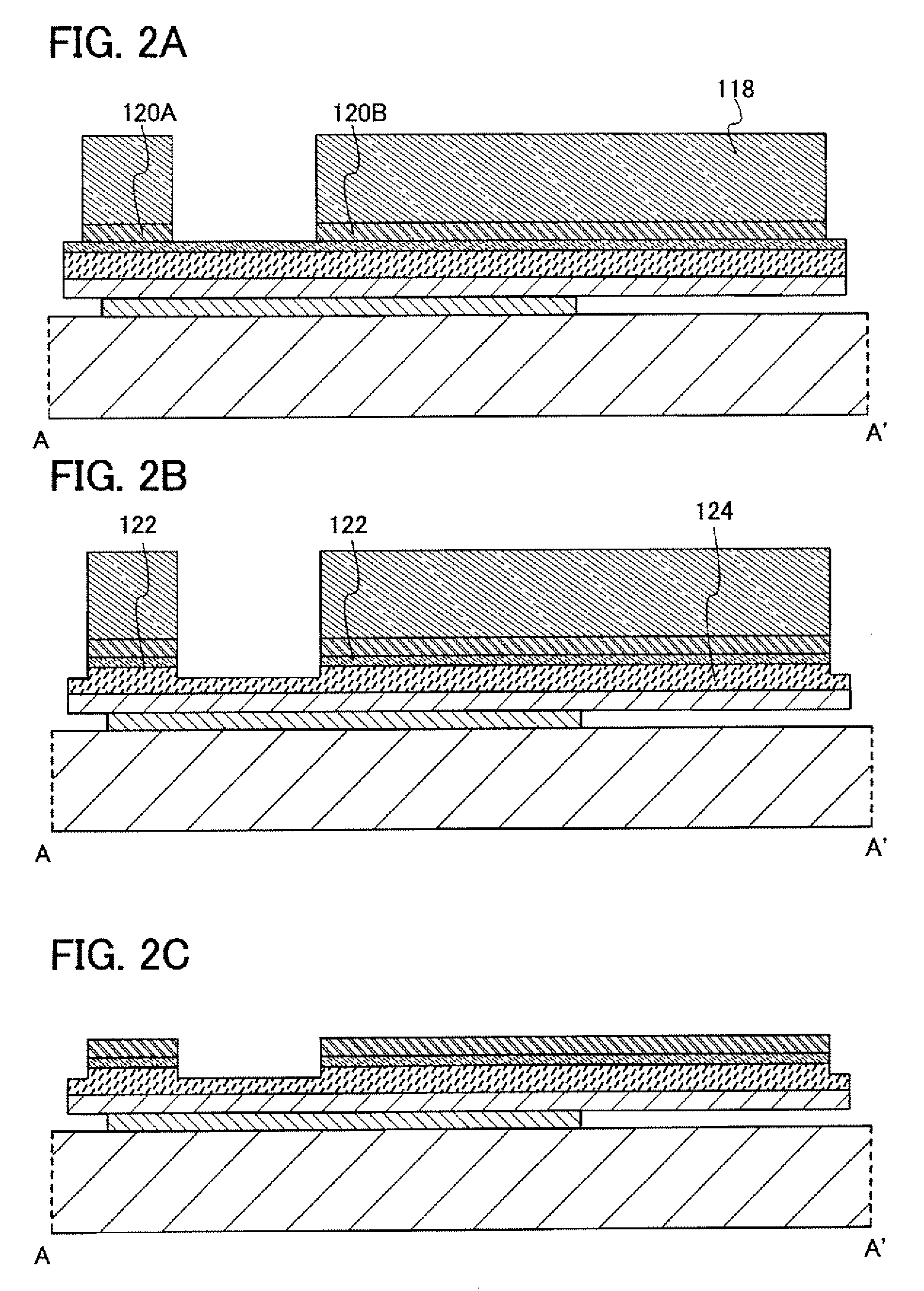

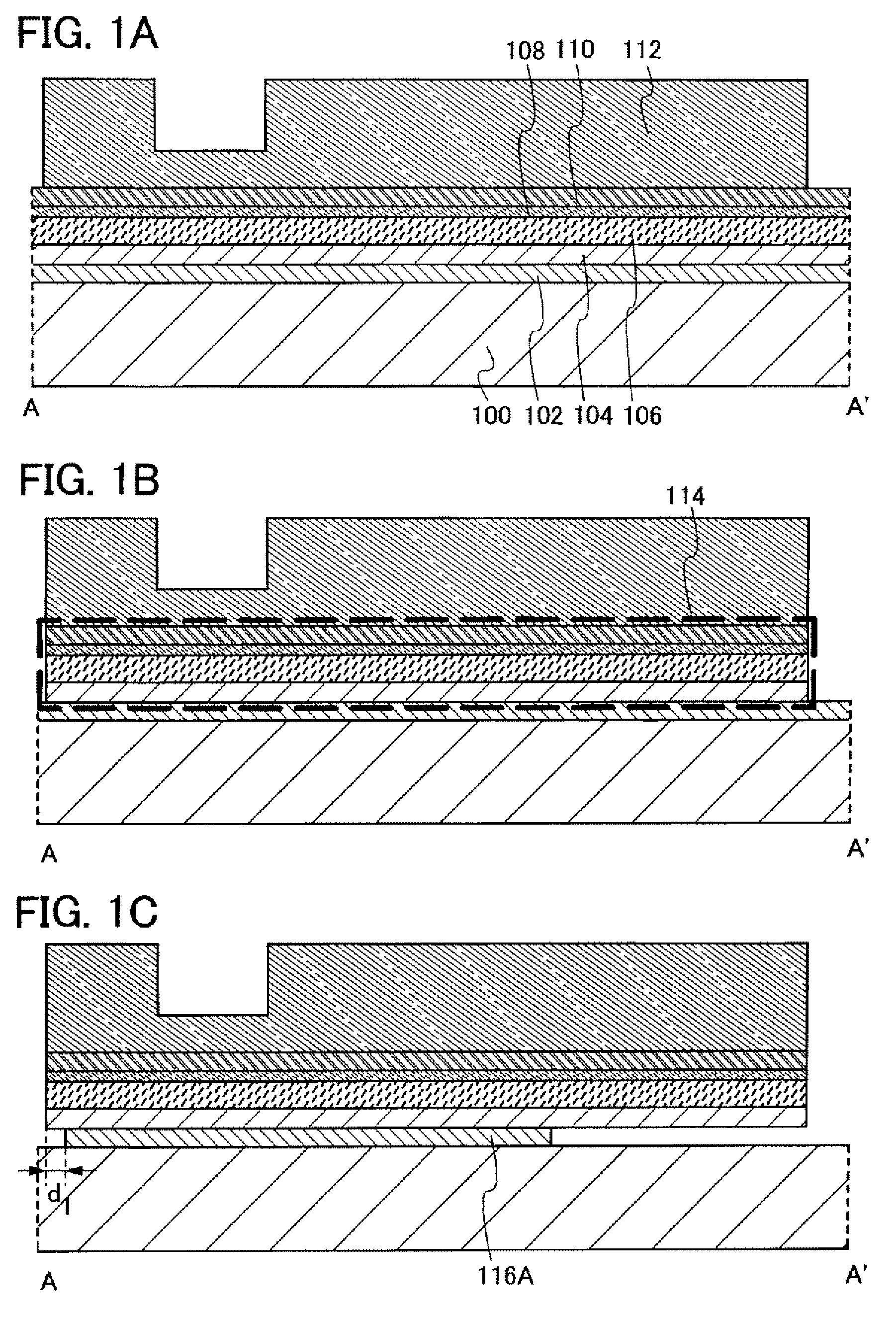

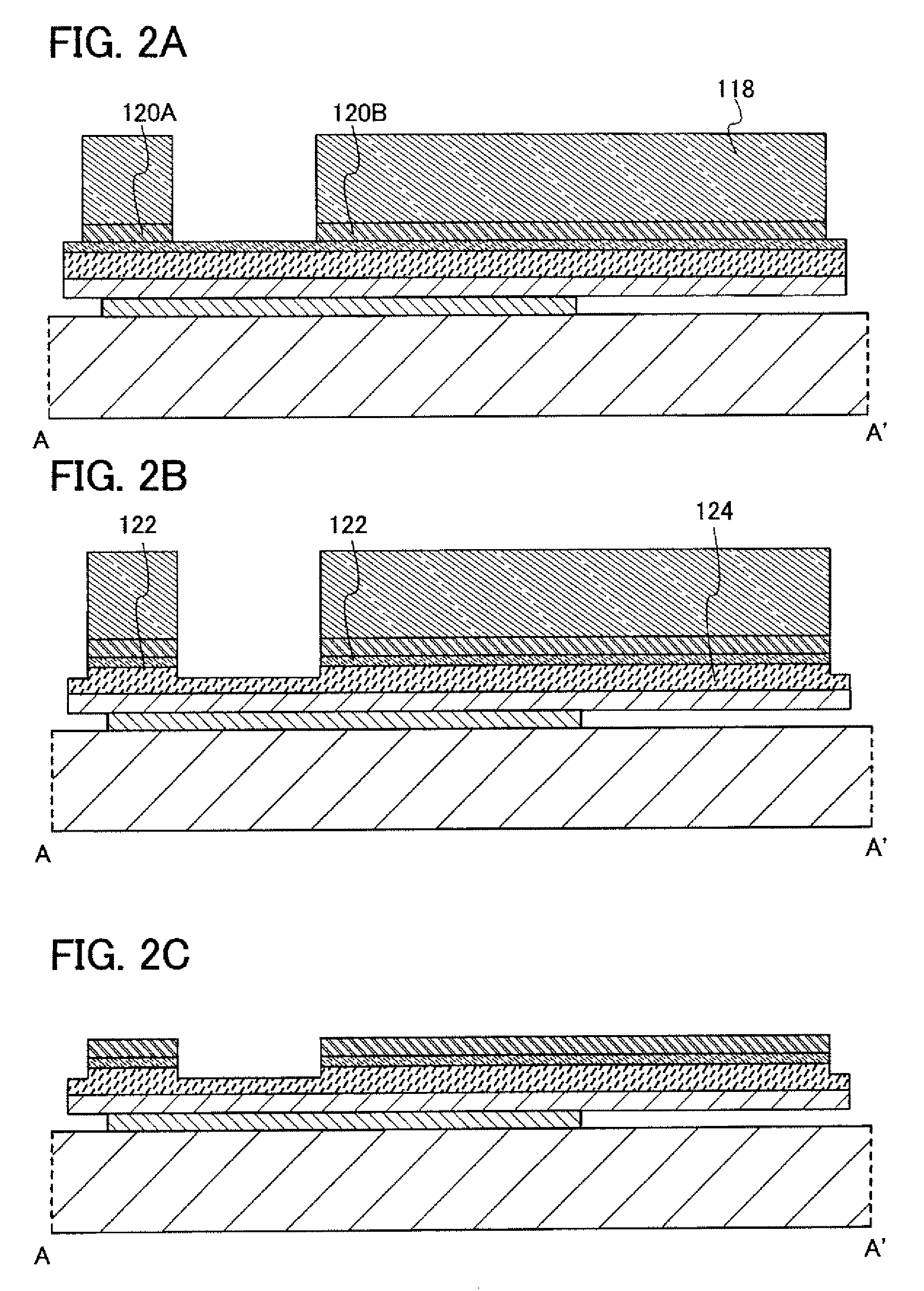

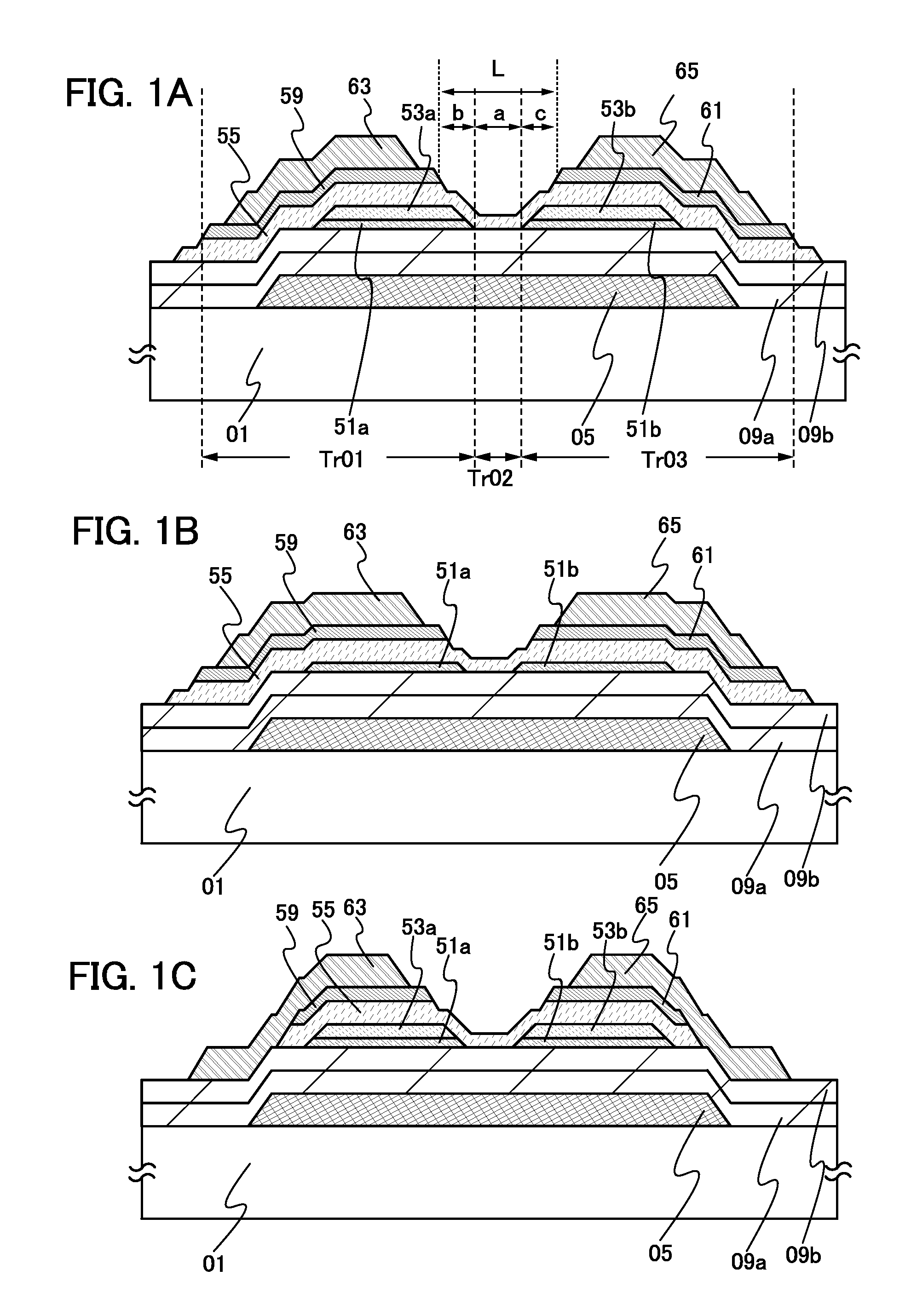

Thin film transistor and manufacturing method thereof

InactiveUS20110147754A1High currentLower average currentTransistorSolid-state devicesMicrocrystalline siliconImpurity

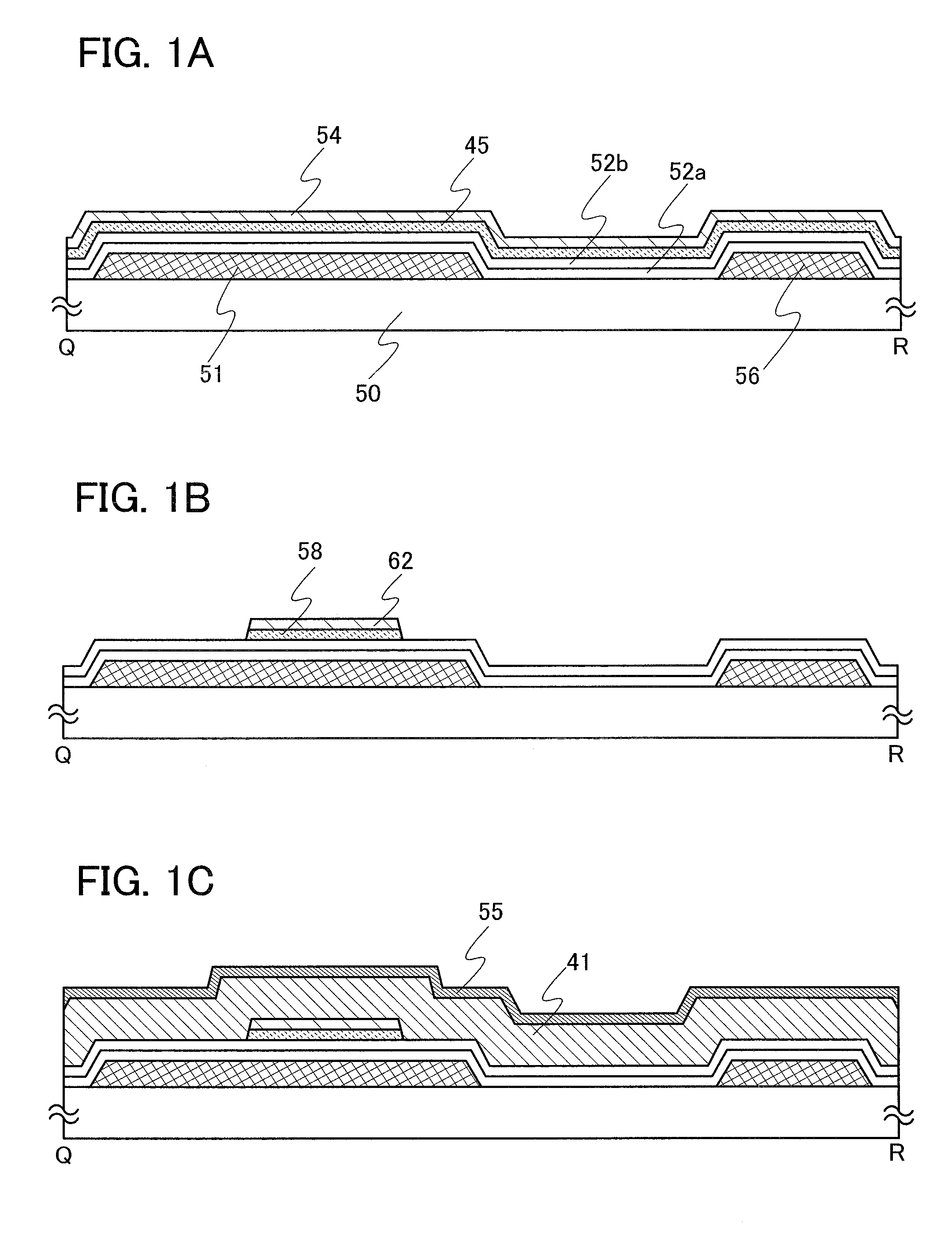

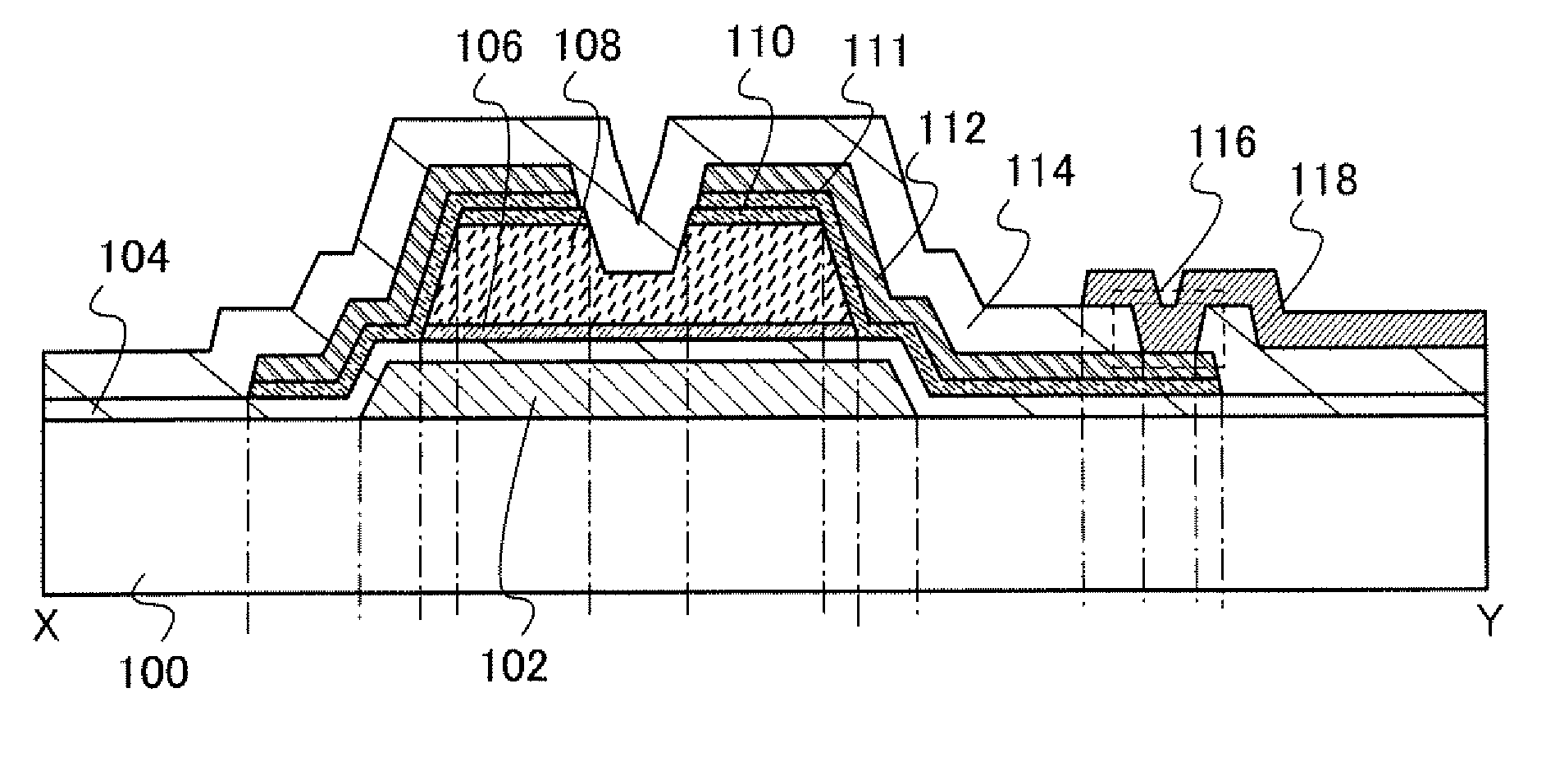

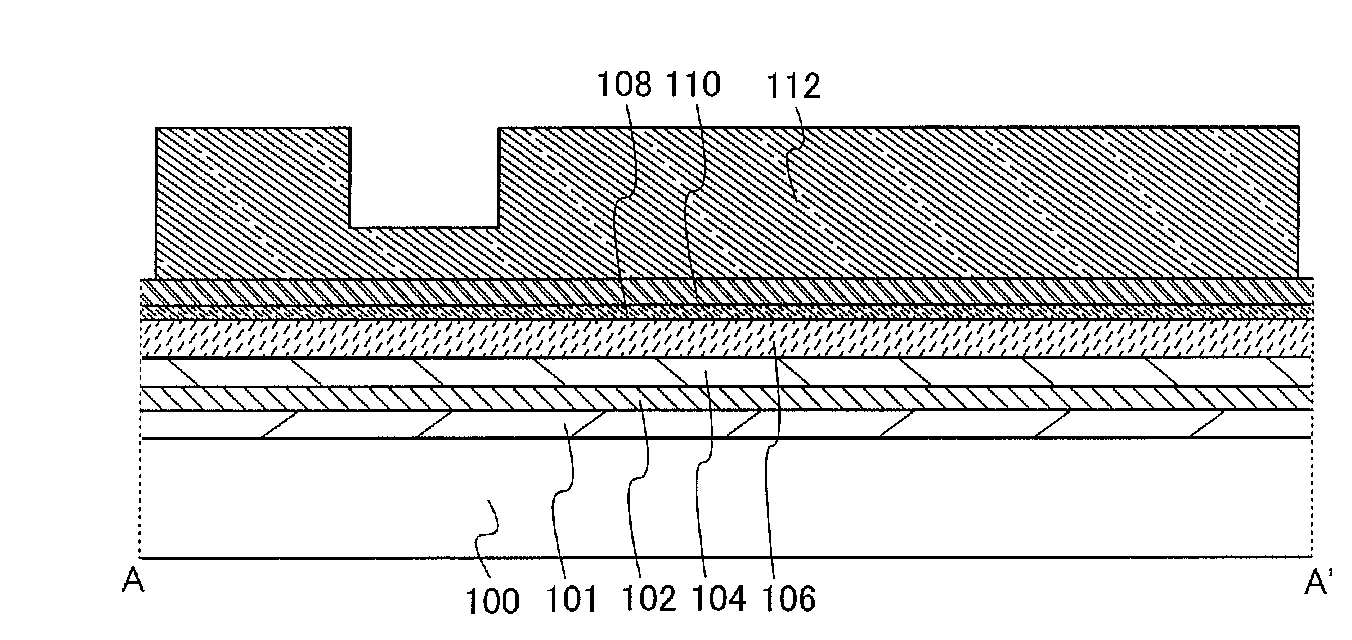

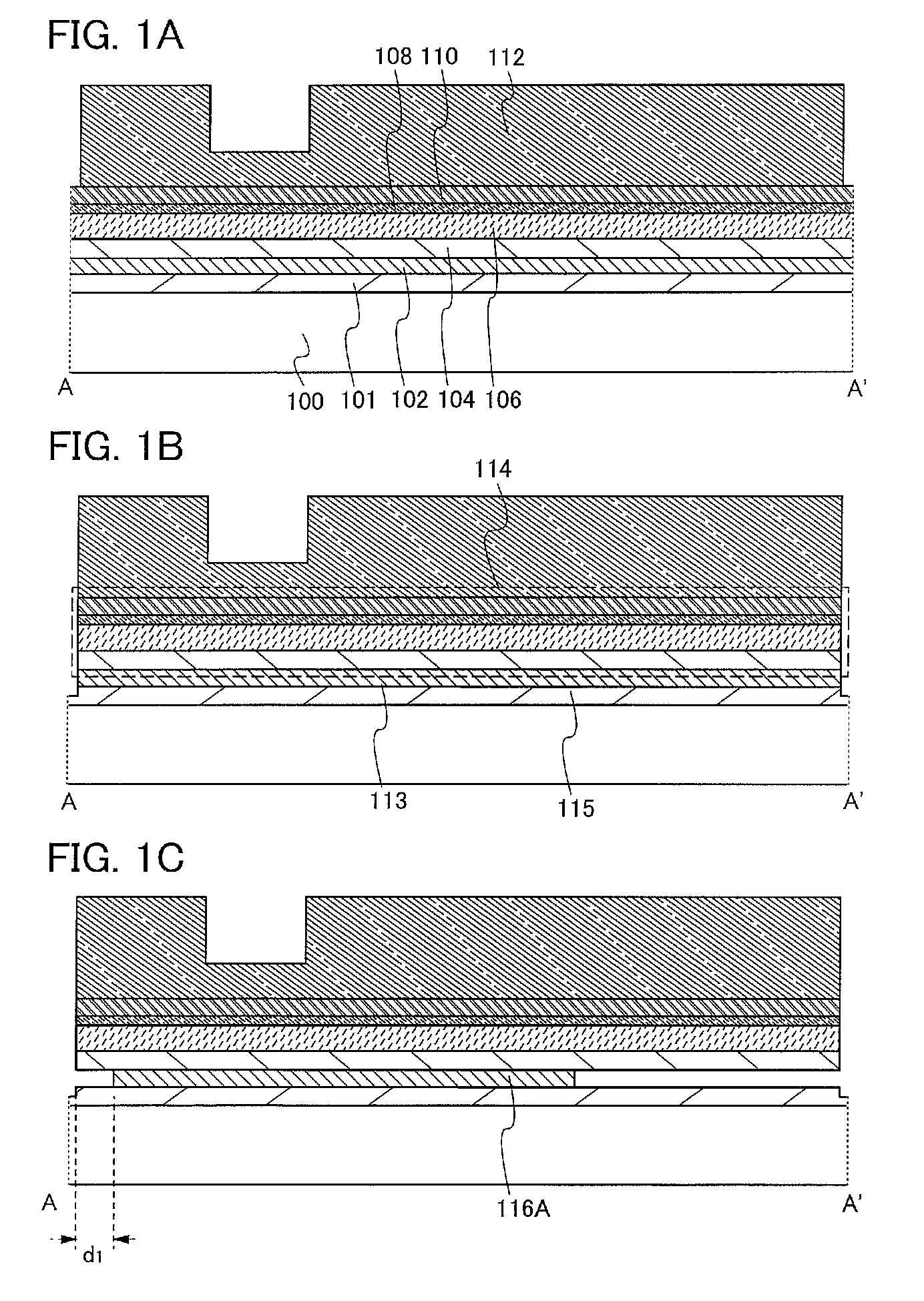

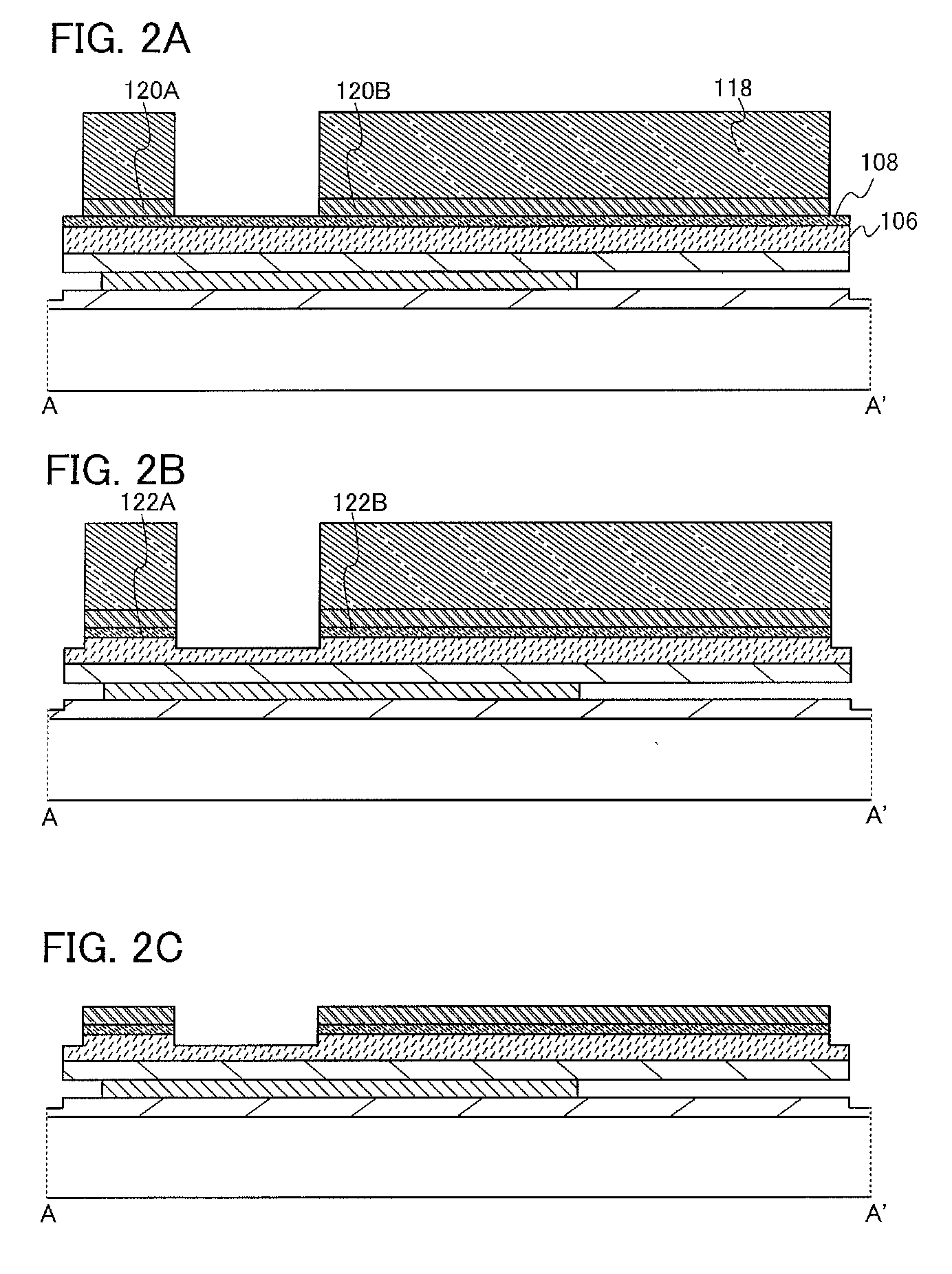

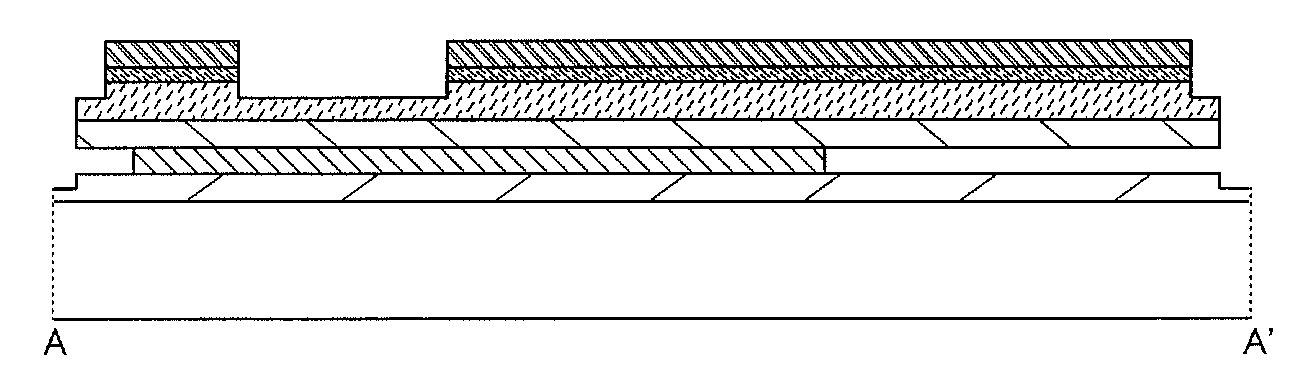

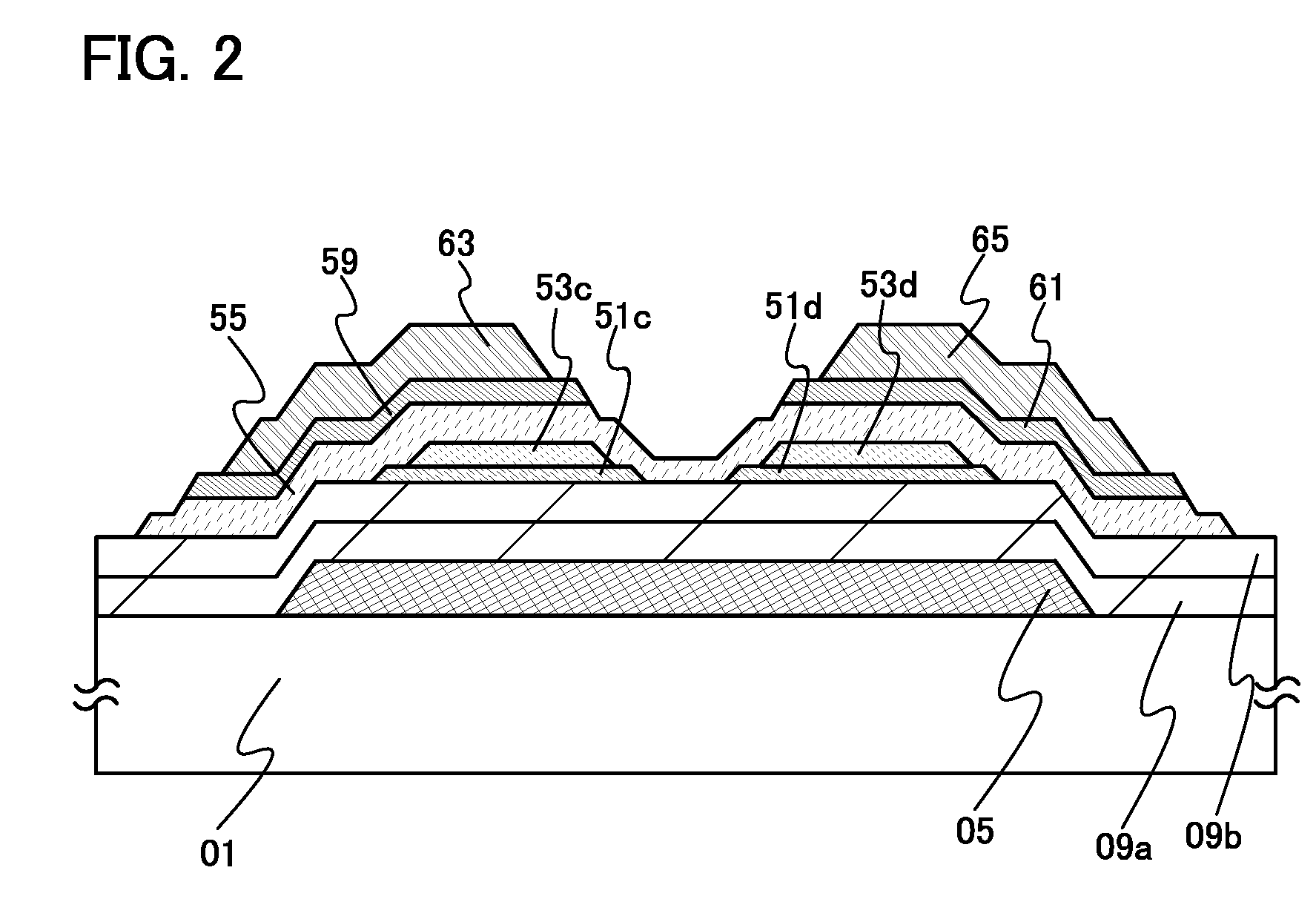

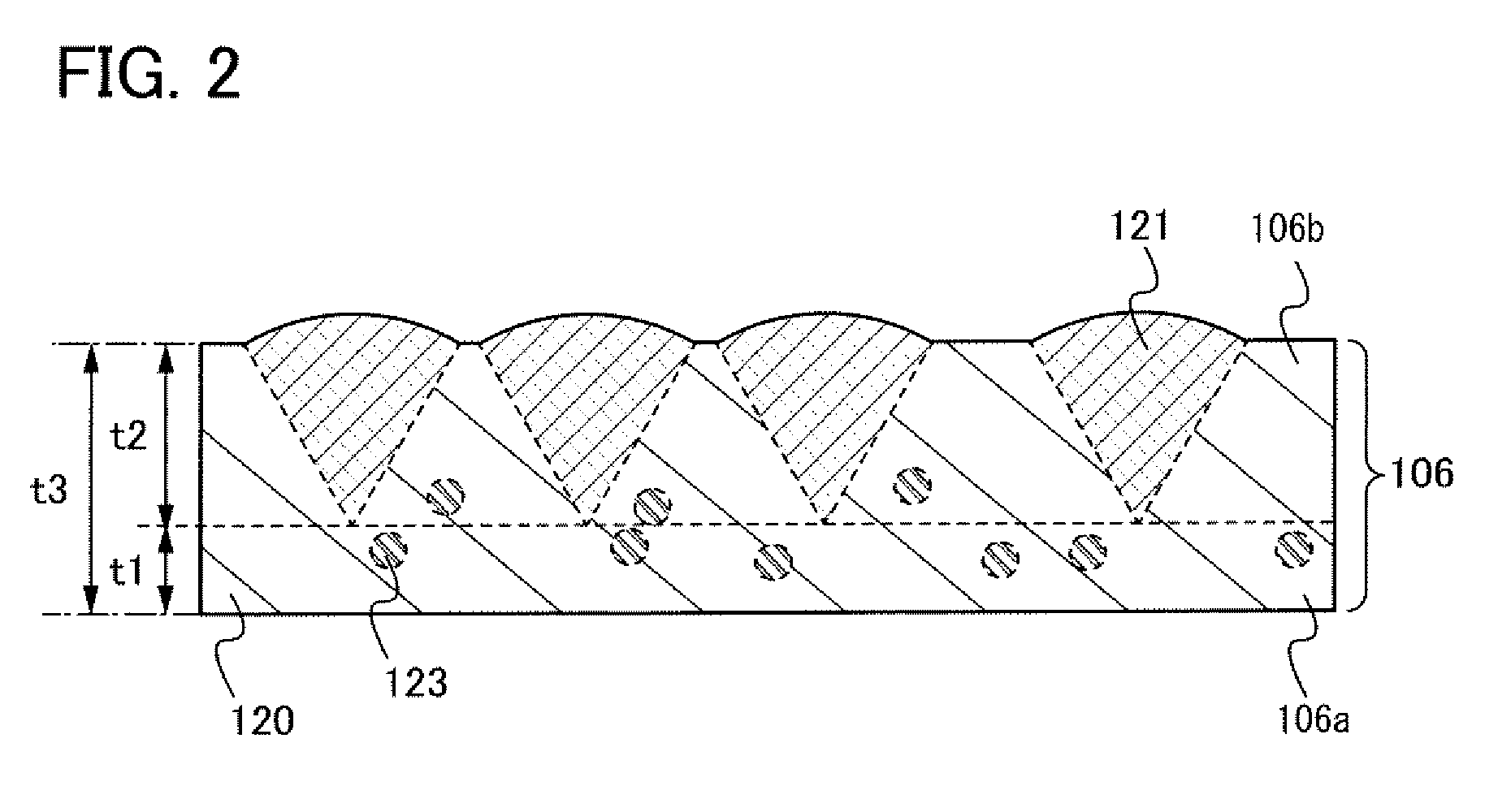

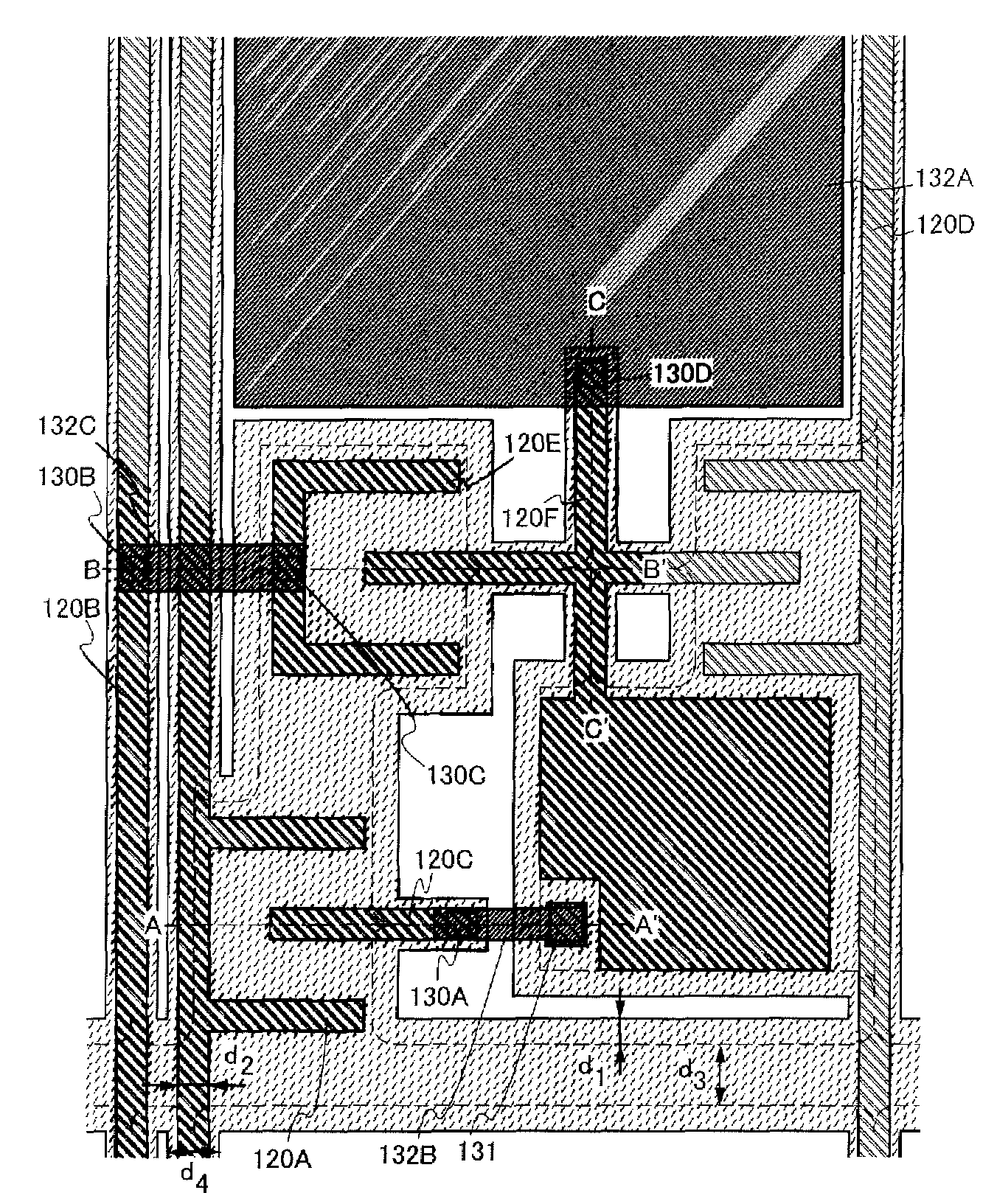

Disclosed is a thin film transistor including: a gate insulating layer covering a gate electrode; a microcrystalline semiconductor region over the gate insulating layer; a pair of amorphous semiconductor region over the microcrystalline semiconductor; a pair of impurity semiconductor layers over the amorphous semiconductor regions; and wirings over the impurity semiconductor layers. The microcrystalline semiconductor region has a surface having a projection and depression on the gate insulating layer side. The microcrystalline semiconductor region includes a first microcrystalline semiconductor region which is not covered with the amorphous regions and a second microcrystalline semiconductor region which is in contact with the amorphous semiconductor regions. A thickness d1 of the first microcrystalline semiconductor region is smaller than a thickness d2 of the second microcrystalline semiconductor region and d1 is greater than or equal to 30 nm.

Owner:SEMICON ENERGY LAB CO LTD

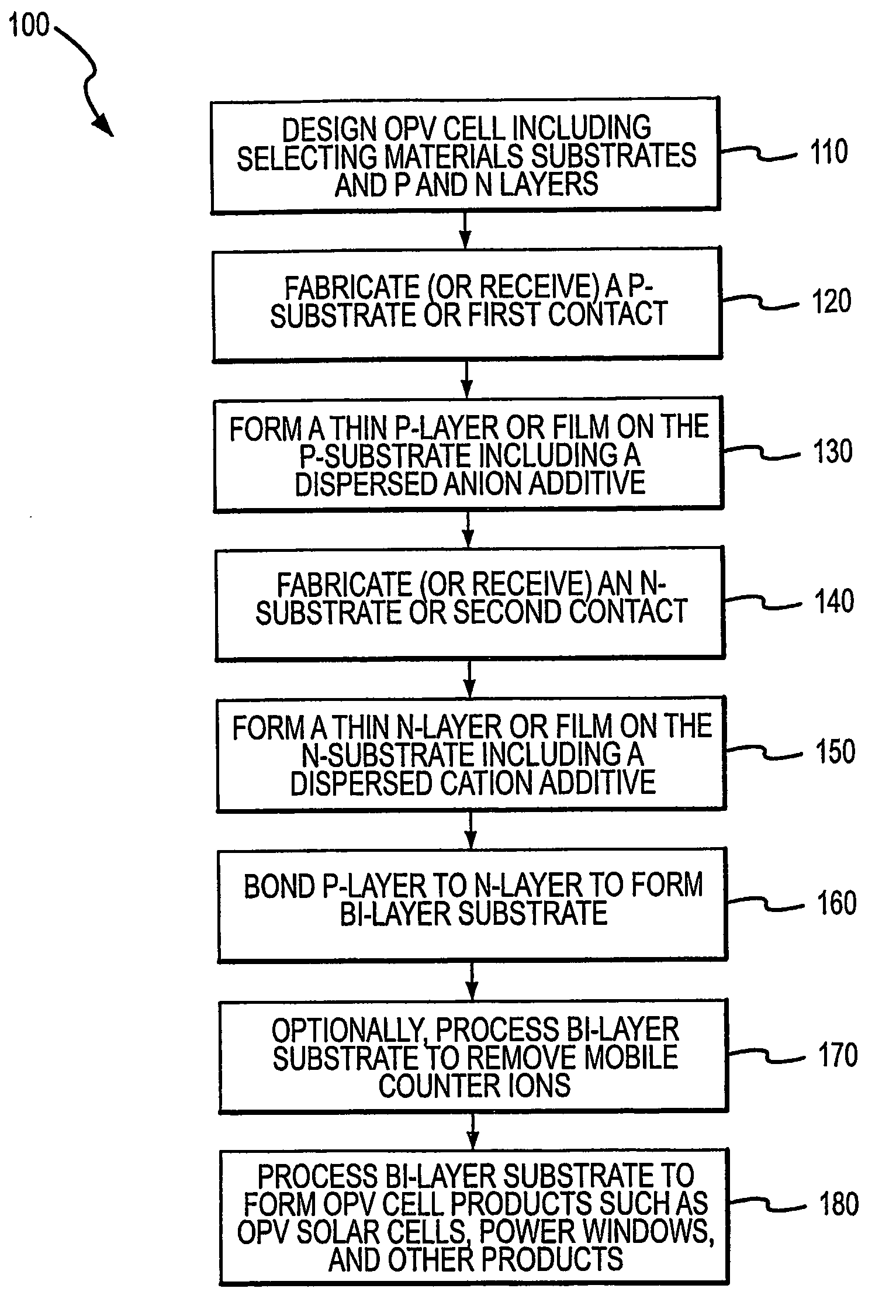

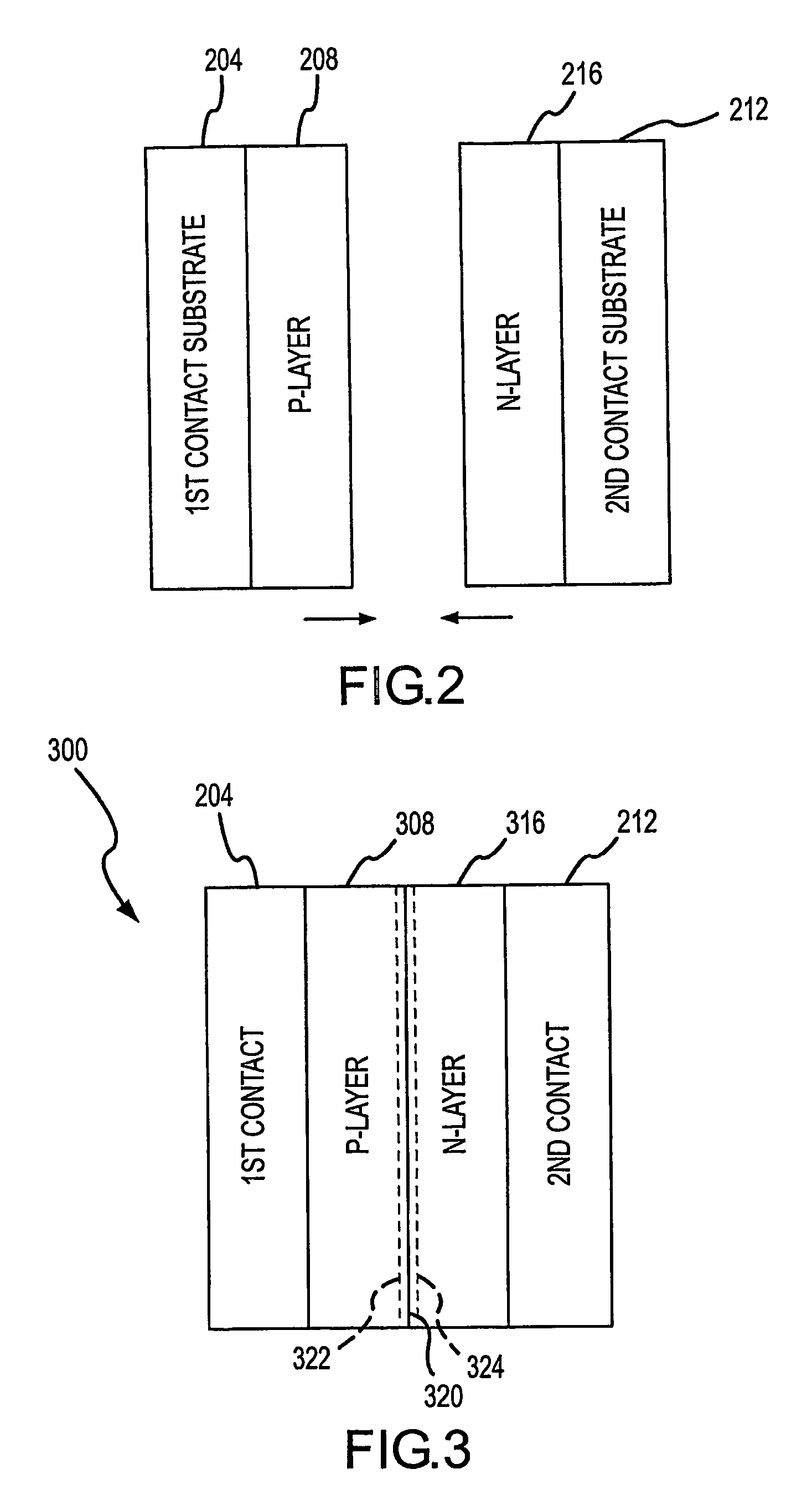

Organic photovoltaic cells with an electric field integrally-formed at the heterojunction interface

InactiveUS7157641B2Superior mobility and exciton diffusion lengthEasy to processPV power plantsFinal product manufactureHeterojunctionEpoxy

A bi-layer photovoltaic cell, and method (100) of making same, with an electric field applied at the p-n heterojunction interface. The cell includes a first semiconductor layer including a binder, nanocrystals of an n-type semiconductor, and spatially bound cations and a second semiconductor layer contacting the first semiconductor layer that includes a binder, nanocrystals of a p-type semiconductor, and spatially bound anions. The cell further includes a p-n heterojunction at the contacting interface between the first and second semiconductor layers. An electric field is created by the spatially bound cations and anions that are located in the layers proximal to the p-n heterojunction. The nanocrystals are single crystals of organic semiconductors that are less than 50 nanometers in size and that comprise a majority of the volume of their respective layers. The binder is a polymer matrix, such as an epoxy. The cell includes electrical contacts abutting the semiconductor layers.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY

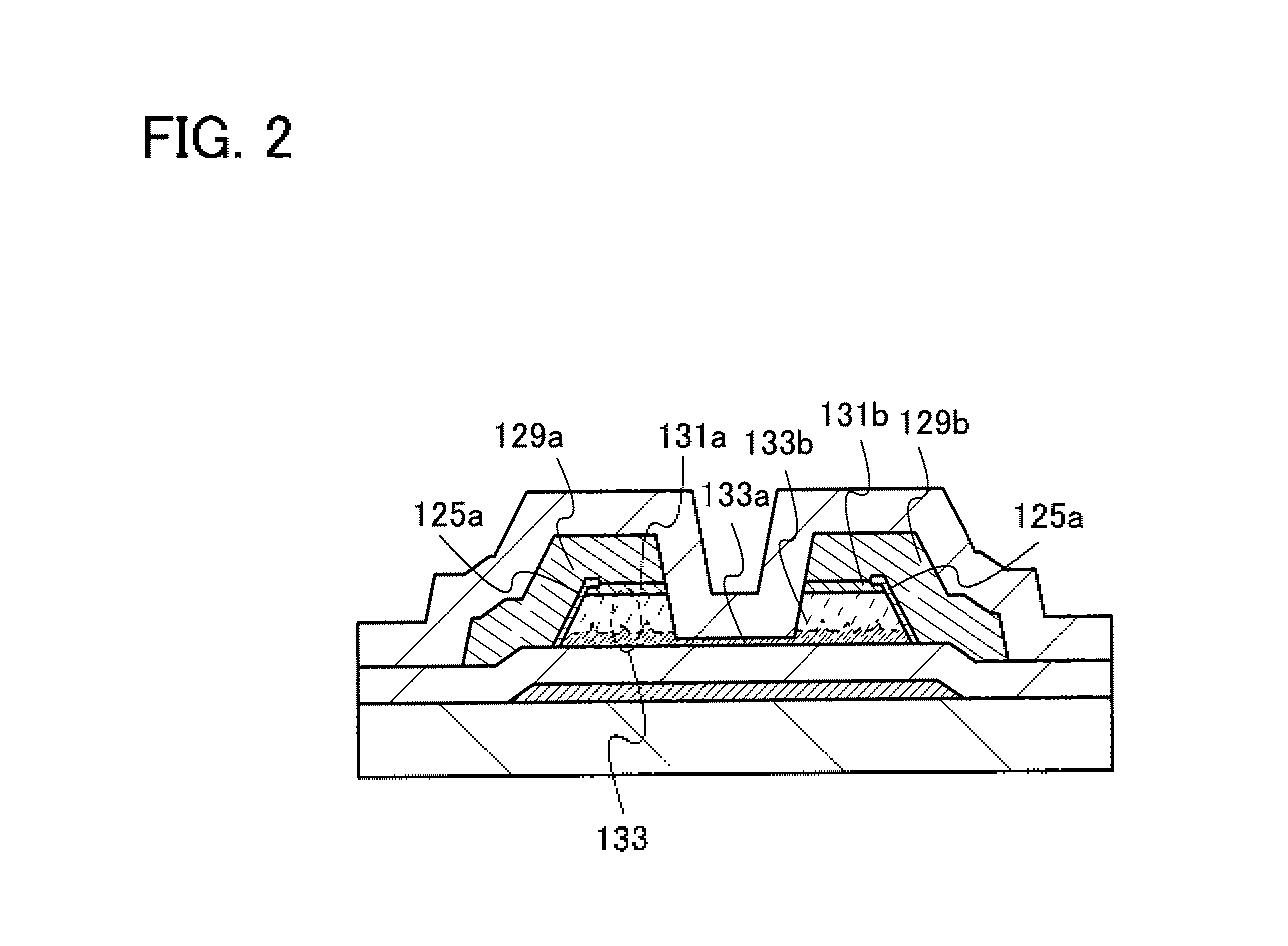

Diode and display device including diode

InactiveUS7786482B2Reduce contrastIncreased power consumptionSolid-state devicesDiodeImaging qualityDisplay device

A thin film transistor which includes a microcrystalline semiconductor film over a gate electrode with a gate insulating film interposed therebetween to be in an inner region in which end portions of microcrystalline semiconductor film are in an inside of end portions of the gate electrode, an amorphous semiconductor film which covers top and side surfaces of the microcrystalline semiconductor film, and an impurity semiconductor film to which an impurity element imparting one conductivity is added, and which forms a source region and a drain region, wherein the microcrystalline semiconductor film includes an impurity element serving as a donor is provided to reduce off current of a thin film transistor, to reduce reverse bias current of a diode, and to improve an image quality of a display device using a thin film transistor.

Owner:SEMICON ENERGY LAB CO LTD

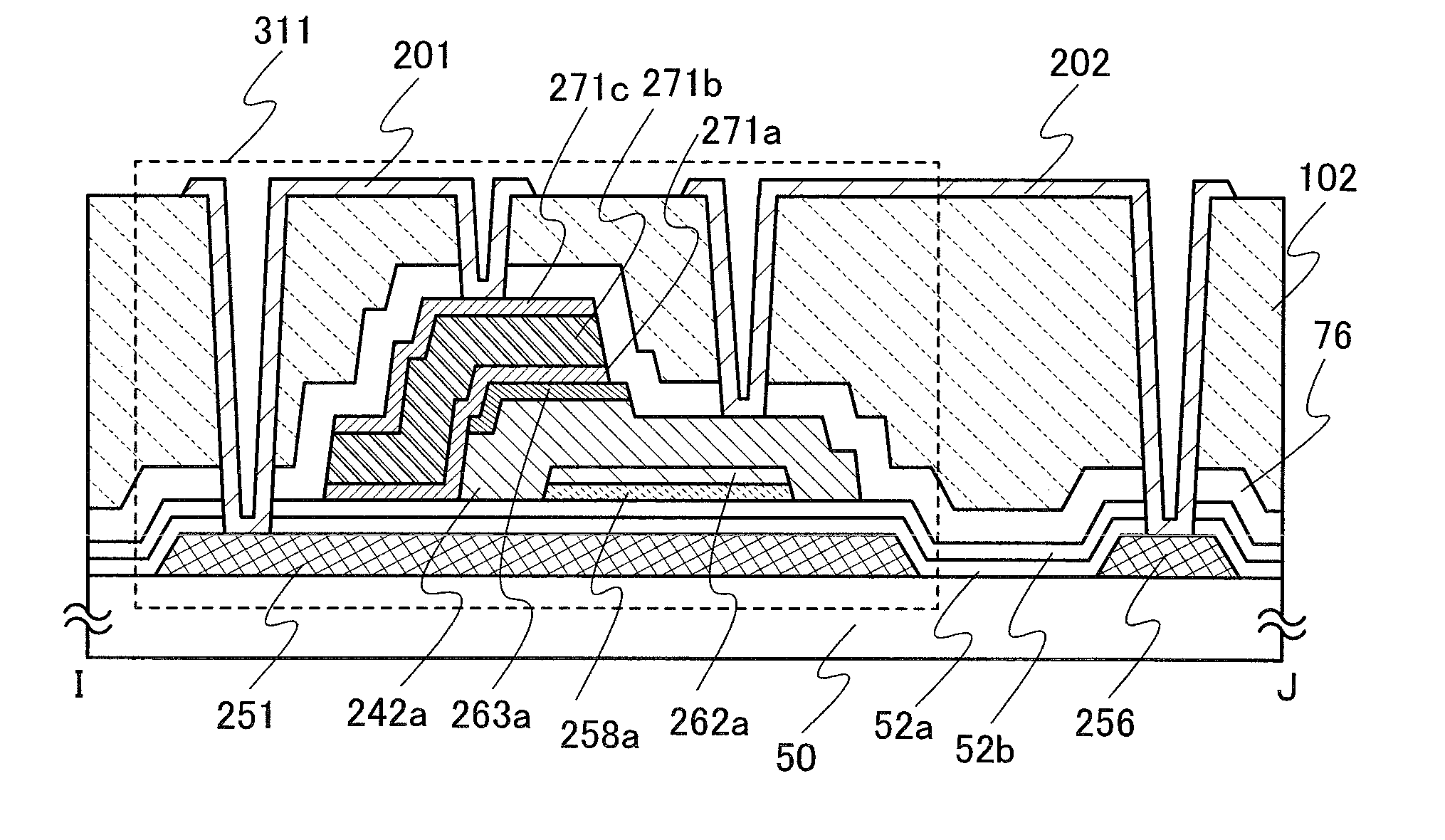

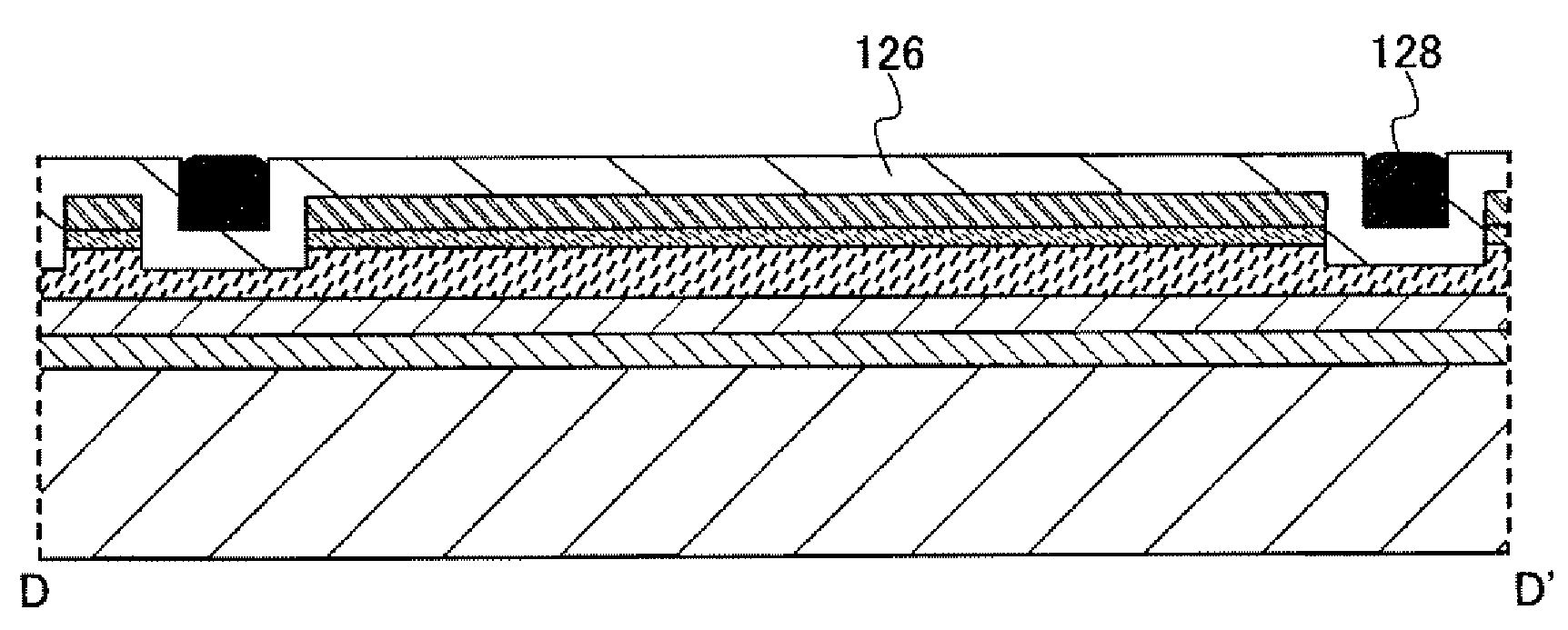

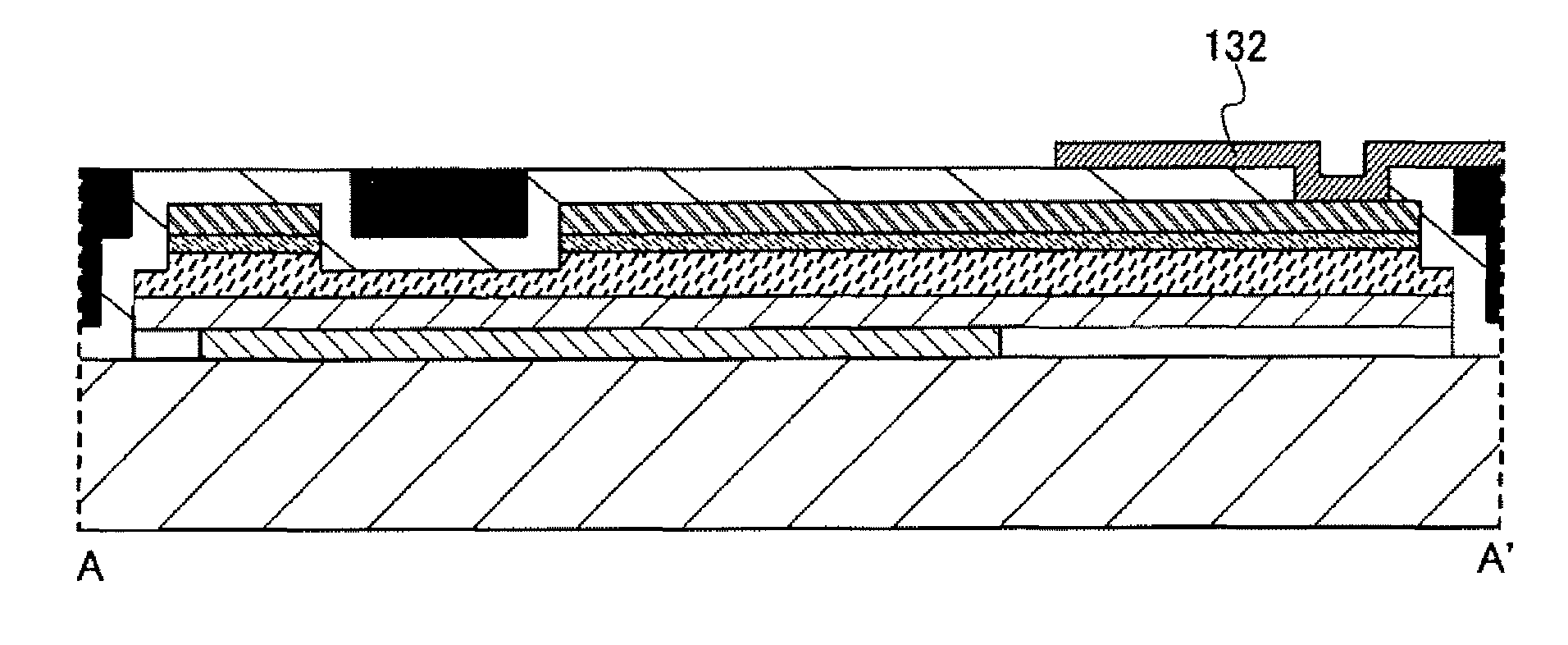

Liquid crystal display device and manufacturing method thereof, and electronic device

InactiveUS20090212300A1Reduce the number of stepsSimple manufacturing processSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEtching

An objective is simplification of a manufacturing method of a liquid crystal display device or the like. In a manufacturing method of a thin film transistor, a stack in which a first conductive film, an insulating film, a semiconductor film, an impurity semiconductor film, and a second conductive film are stacked in this order is formed, and the first conductive film is exposed by first etching and a pattern of the second conductive film is formed by second etching. Further, after thin film transistors are formed, a color filter layer is formed so that unevenness caused by the thin film transistors or the like is relieved; thus, the level difference of the surface where the pixel electrode layer is formed is reduced. Alternatively, a color filter layer is selectively formed utilizing the unevenness caused by thin film transistors or the like.

Owner:SEMICON ENERGY LAB CO LTD

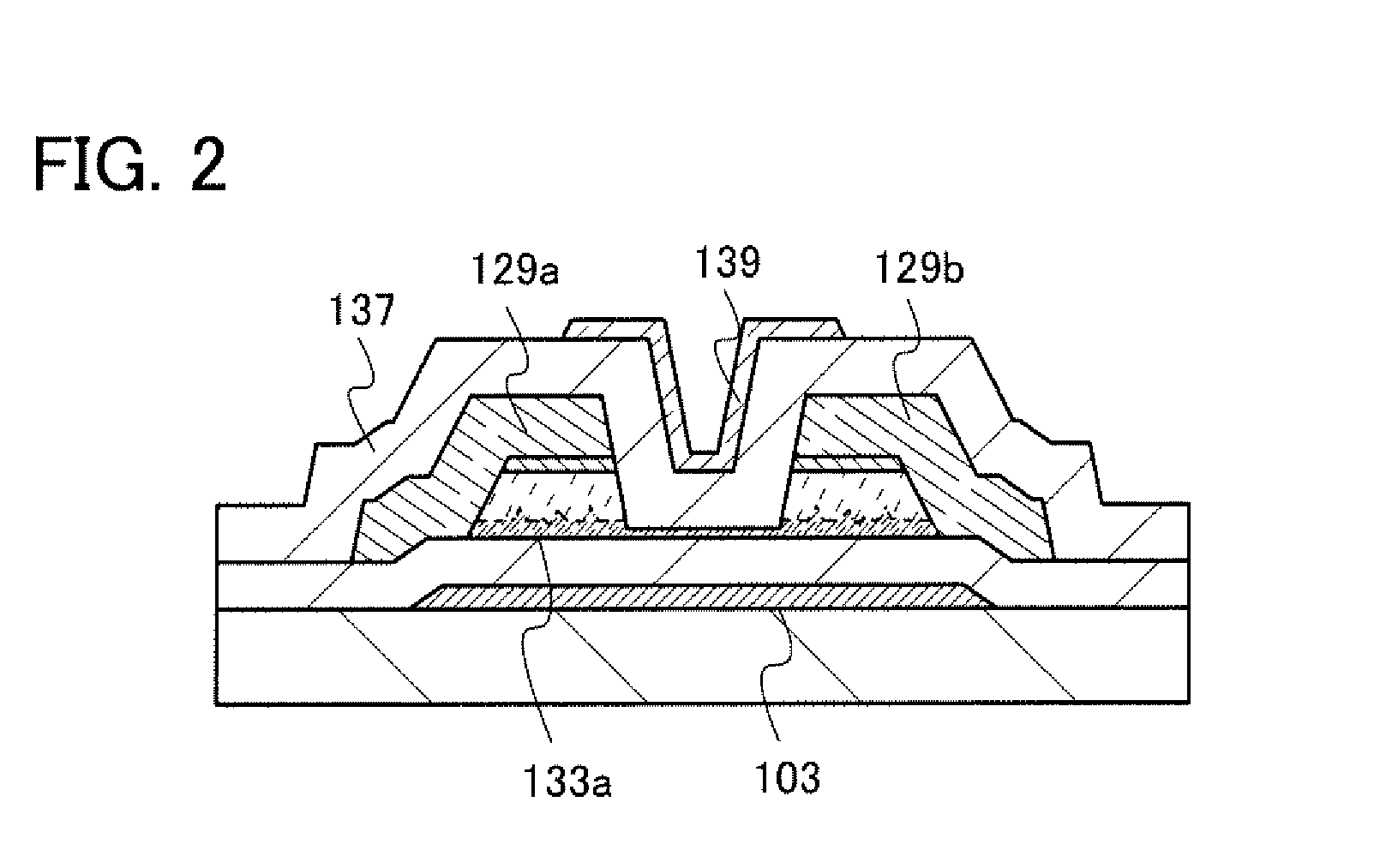

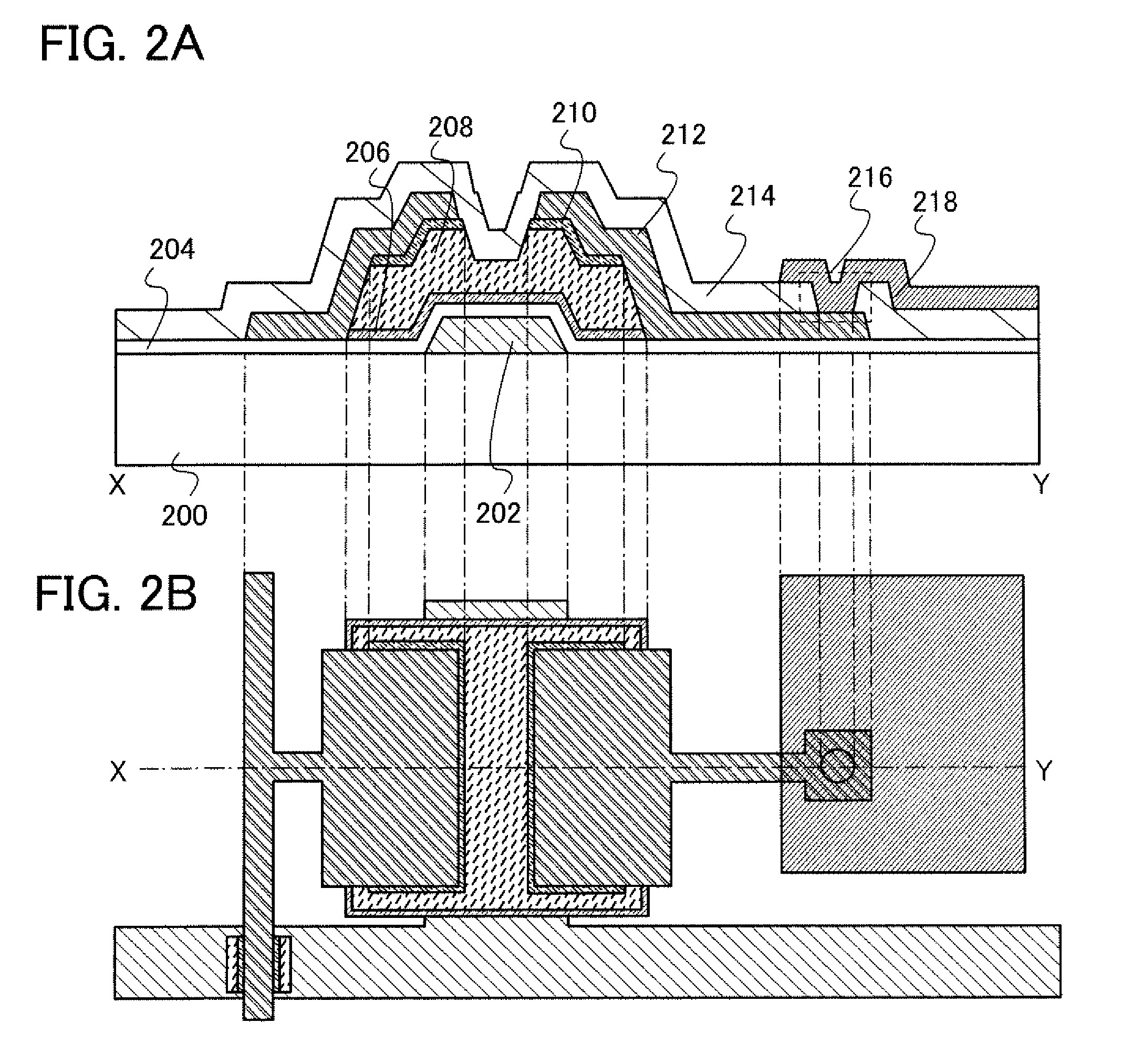

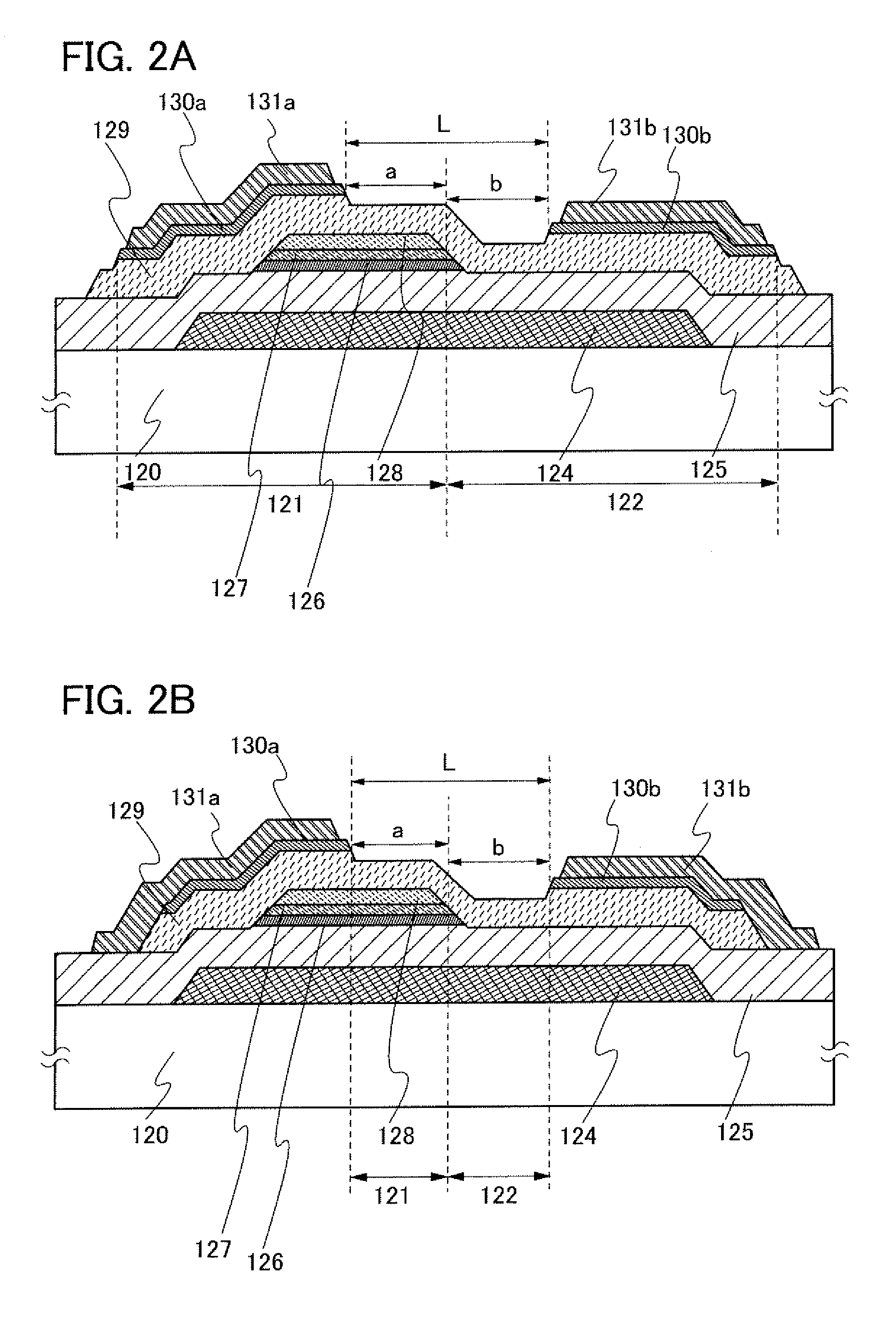

Thin film transisotr and display device

InactiveUS20090218568A1Run at high speedImprove mobilityTransistorSemiconductor/solid-state device manufacturingDisplay deviceImpurity

To improve problems with on-state current and off-state current of thin film transistors, a thin film transistor includes a pair of impurity semiconductor layers to which an impurity element imparting one conductivity type is added, provided with a space therebetween; a conductive layer which is overlapped, over the gate insulating layer, with the gate electrode and one of the pair of impurity semiconductor layers to which an impurity element imparting one conductivity type is added; and an amorphous semiconductor layer which is provided successively between the pair of impurity semiconductor layers to which an impurity element imparting one conductivity type is added in such a manner that the amorphous semiconductor layer extends over the gate insulating layer from the conductive layer and is in contact with both of the pair of impurity semiconductor layers to which an impurity element imparting one conductivity type is added.

Owner:SEMICON ENERGY LAB CO LTD

Thin film transistor

A thin film transistor having favorable electric characteristics with high productively is provided. The thin film transistor includes a gate insulating layer covering a gate electrode, a semiconductor layer in contact with the gate insulating layer, an impurity semiconductor layer which is in contact with part of the semiconductor layer and functions as a source region and a drain region, and a wiring in contact with the impurity semiconductor layer. The semiconductor layer includes a microcrystalline semiconductor region having a concave-convex shape, which is formed on the gate insulating layer side, and an amorphous semiconductor region in contact with the microcrystalline semiconductor region. A barrier region is provided between the semiconductor layer and the wiring.

Owner:SEMICON ENERGY LAB CO LTD

Liquid crystal display device

InactiveUS8049221B2Reduce in quantitySimple processSolid-state devicesSemiconductor/solid-state device manufacturingLiquid-crystal displayEtching

An objective is simplification of a manufacturing method of a liquid crystal display device or the like. In a manufacturing method of a thin film transistor, a stack in which a first conductive film, an insulating film, a semiconductor film, an impurity semiconductor film, and a second conductive film are stacked in this order is formed, and the first conductive film is exposed by first etching and a pattern of the second conductive film is formed by second etching. Further, after thin film transistors are formed, a color filter layer is formed so that unevenness caused by the thin film transistors or the like is relieved; thus, the level difference of the surface where the pixel electrode layer is formed is reduced. Alternatively, a color filter layer is selectively formed utilizing the unevenness caused by thin film transistors or the like.

Owner:SEMICON ENERGY LAB CO LTD

Thin film transistor and display device

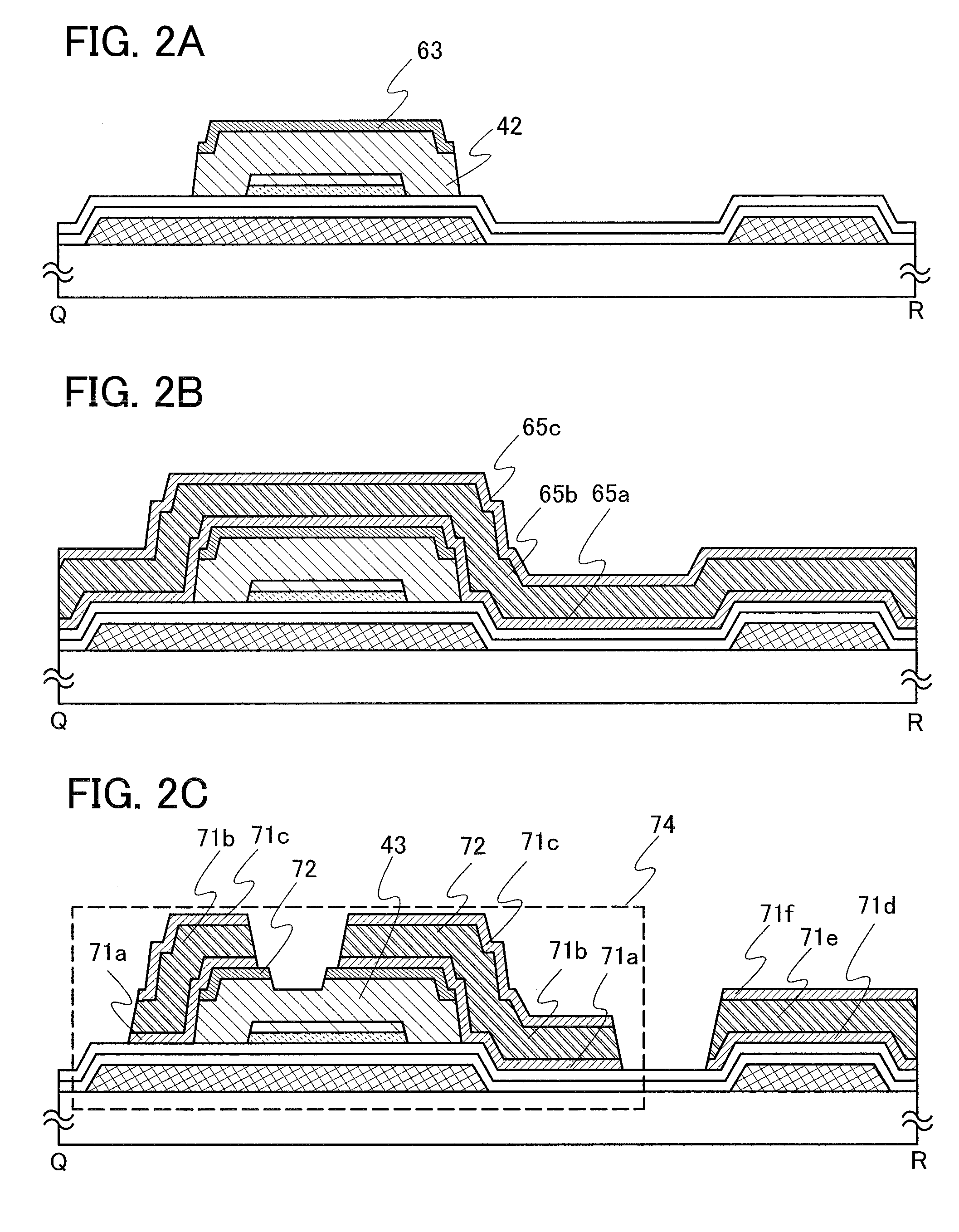

ActiveUS20100148178A1Small currentHigh on-off ratioTransistorSolid-state devicesElectrical conductorDisplay device

A thin film transistor includes: a gate electrode layer; a first semiconductor layer; a second semiconductor layer having lower carrier mobility than the first semiconductor layer, which is provided over and in contact with the first semiconductor layer; a gate insulating layer which is provided between and in contact with the gate electrode layer and the first semiconductor layer; first impurity semiconductor layers which are provided so as to be in contact with the second semiconductor layer; second impurity semiconductor layers which are provided so as to be partially in contact with the first impurity semiconductor layers and the first and second semiconductor layers; and source and drain electrode layers which are provided so as to be in contact with entire surfaces of the second impurity semiconductor layers, in which an entire surface of the first semiconductor layer on the gate electrode layer side overlaps with the gate electrode layer.

Owner:SEMICON ENERGY LAB CO LTD

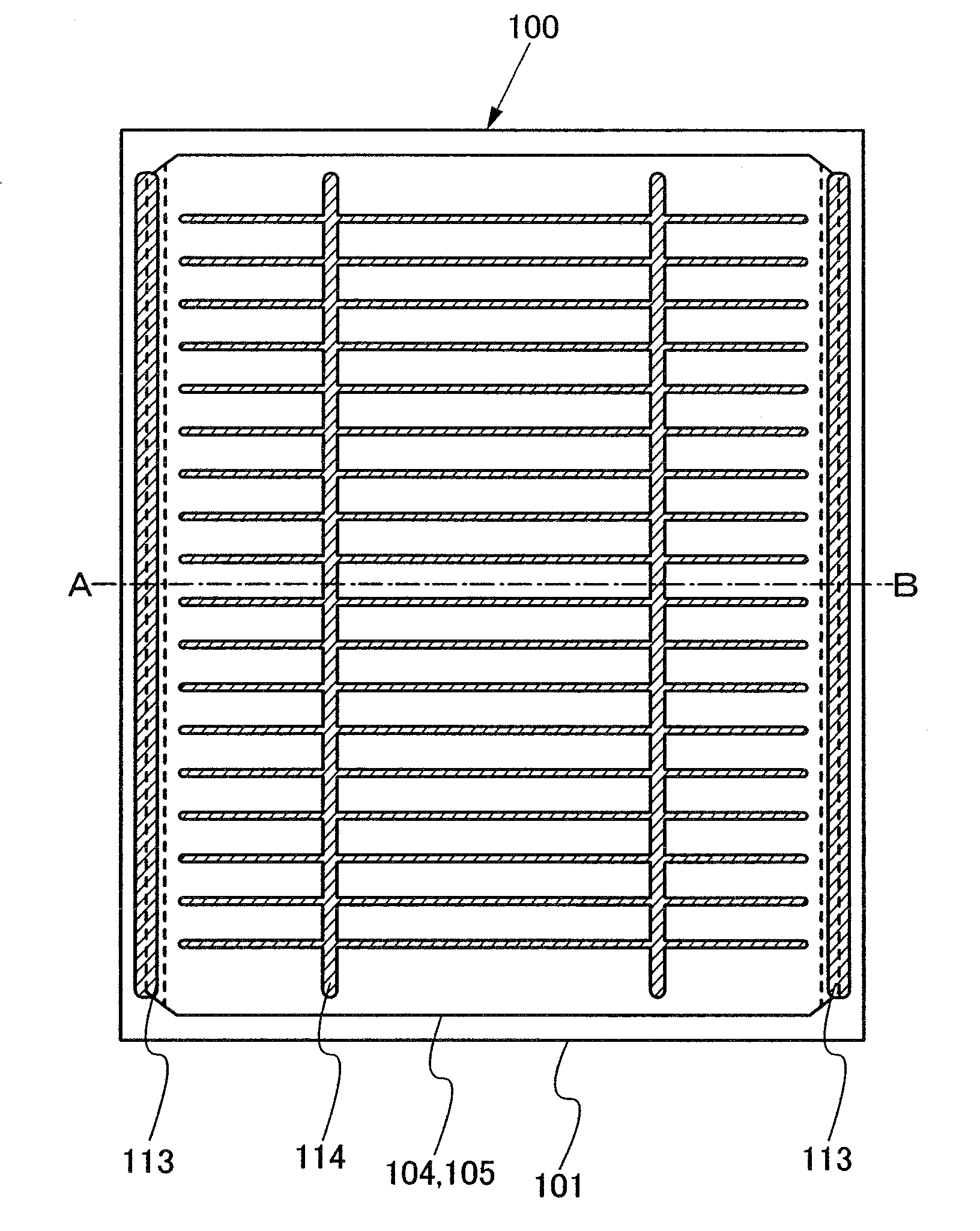

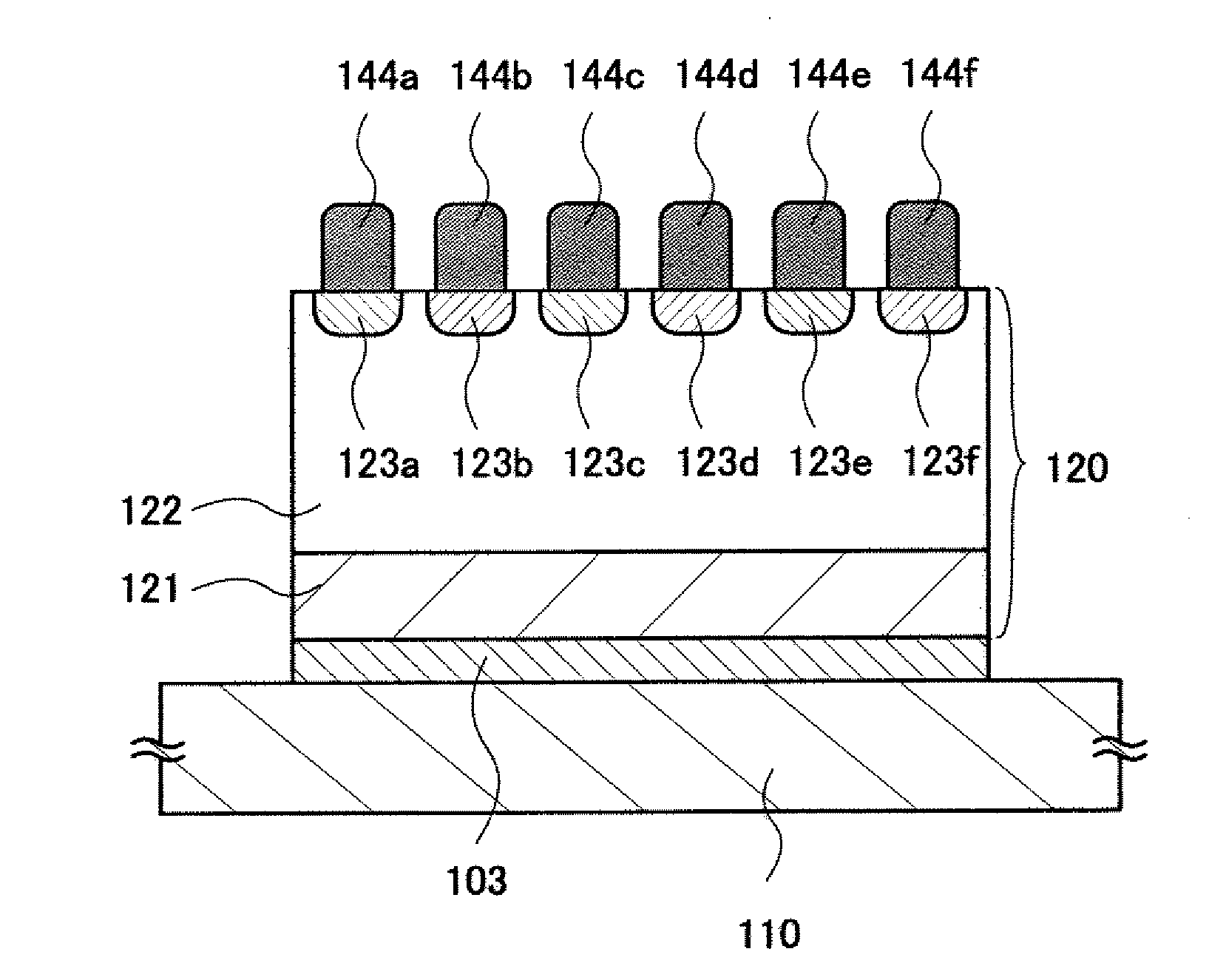

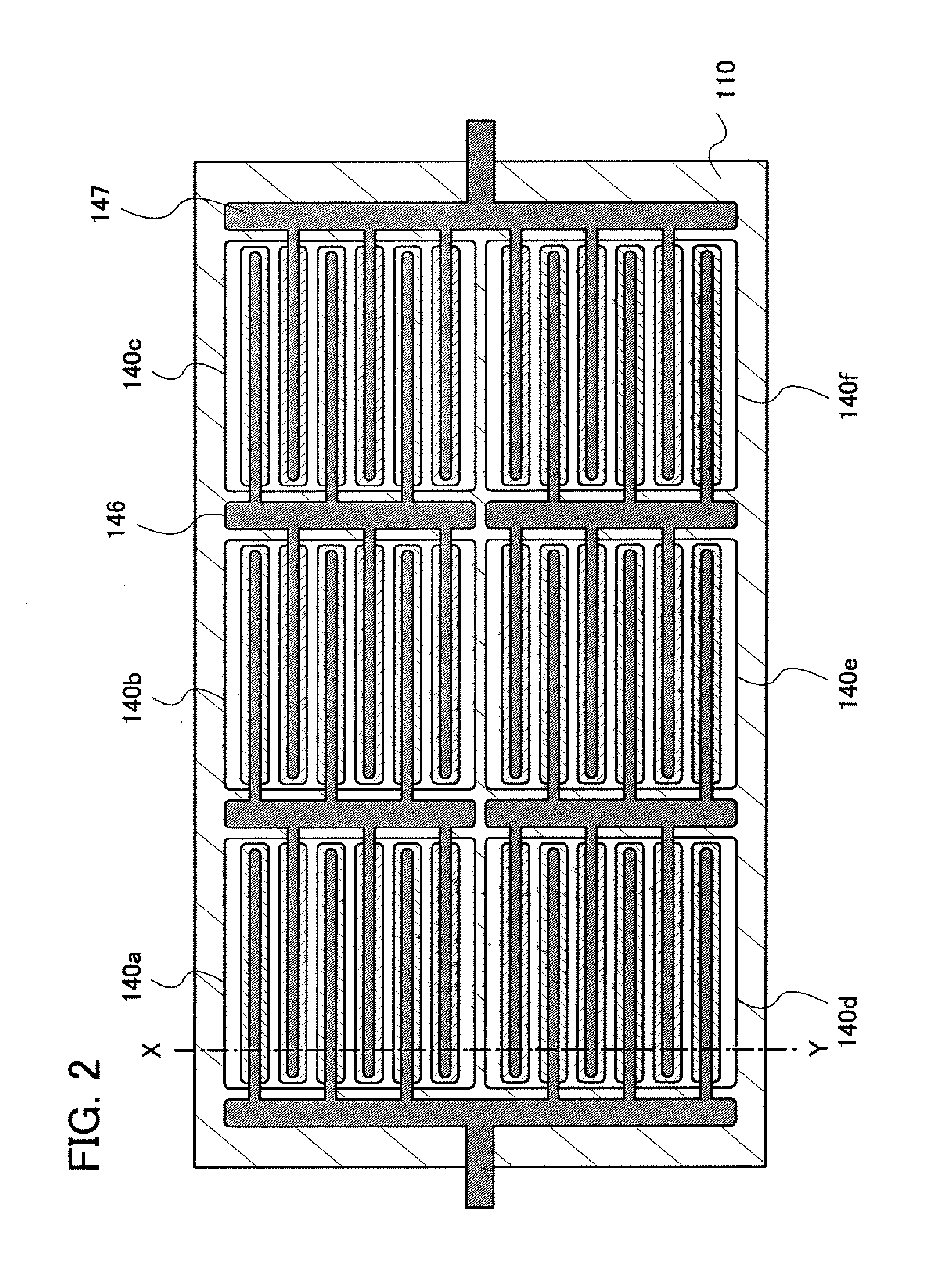

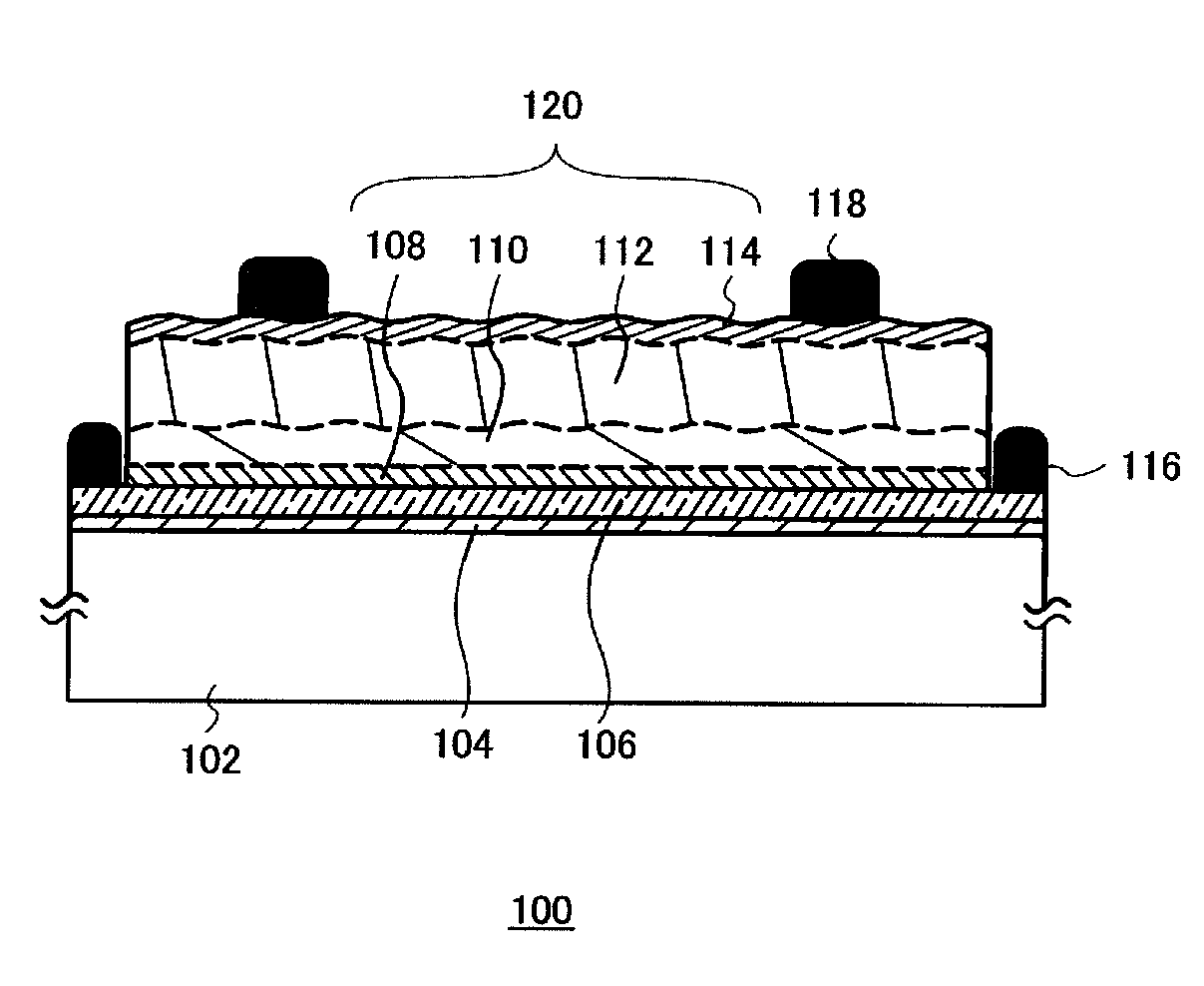

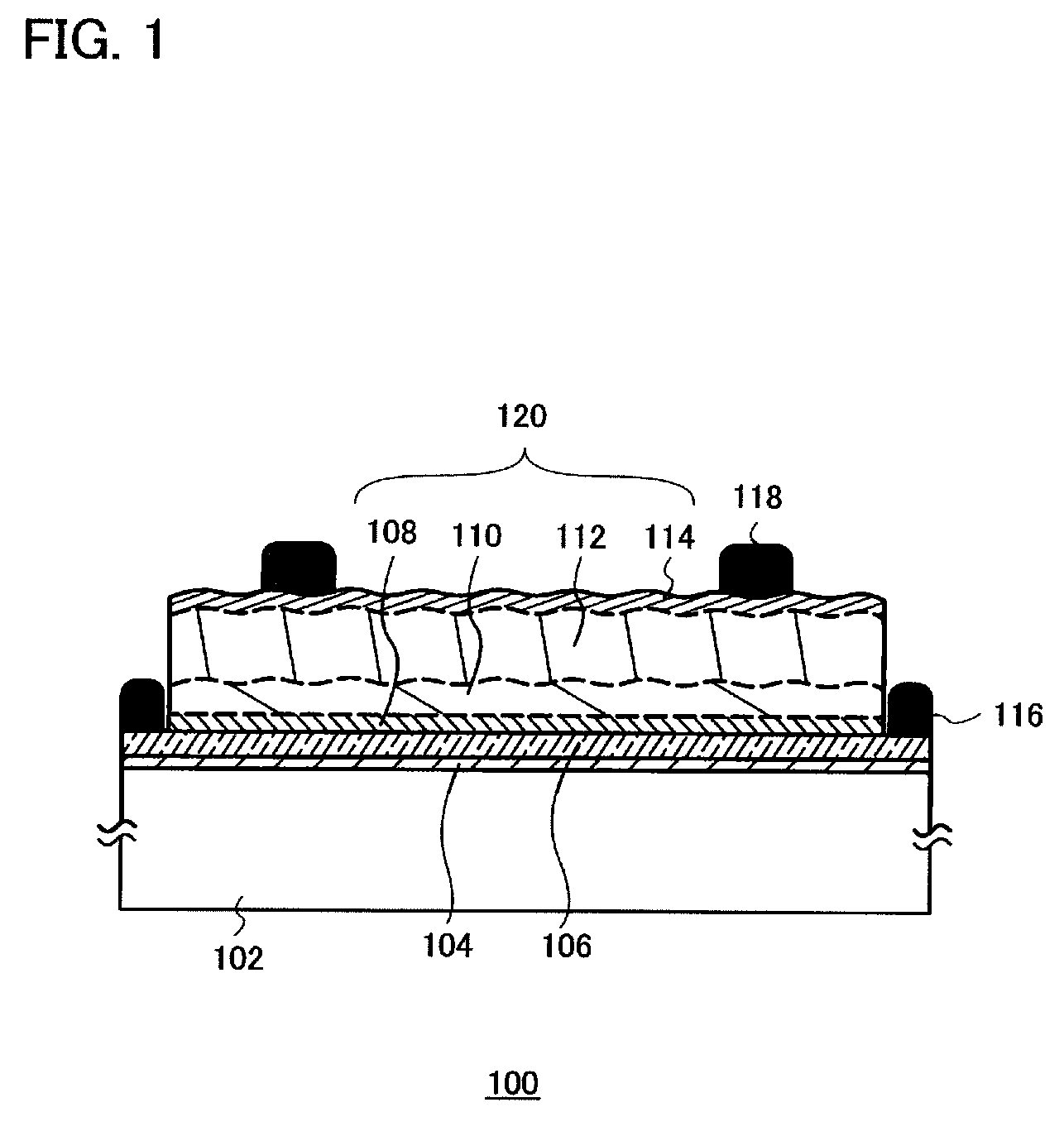

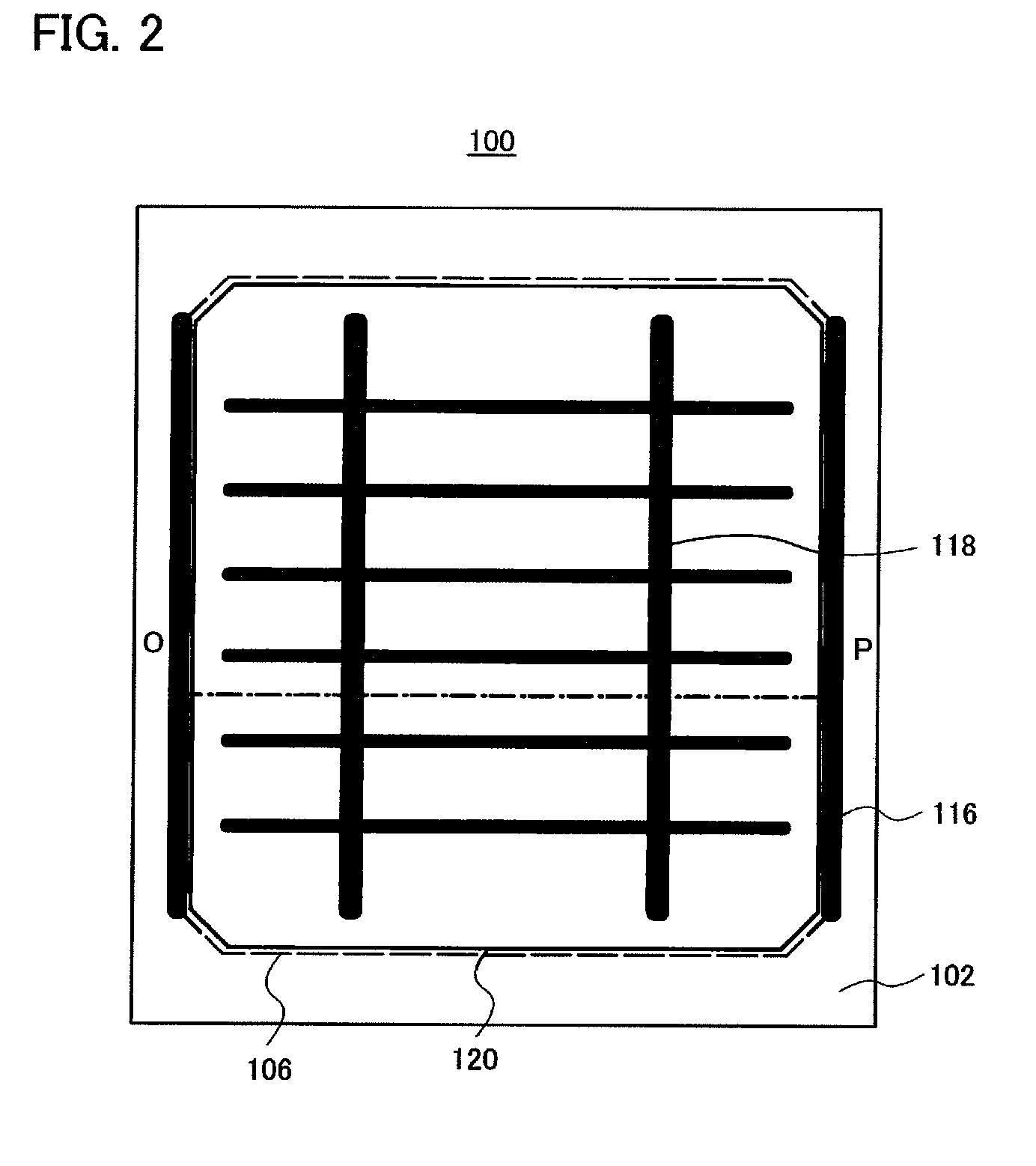

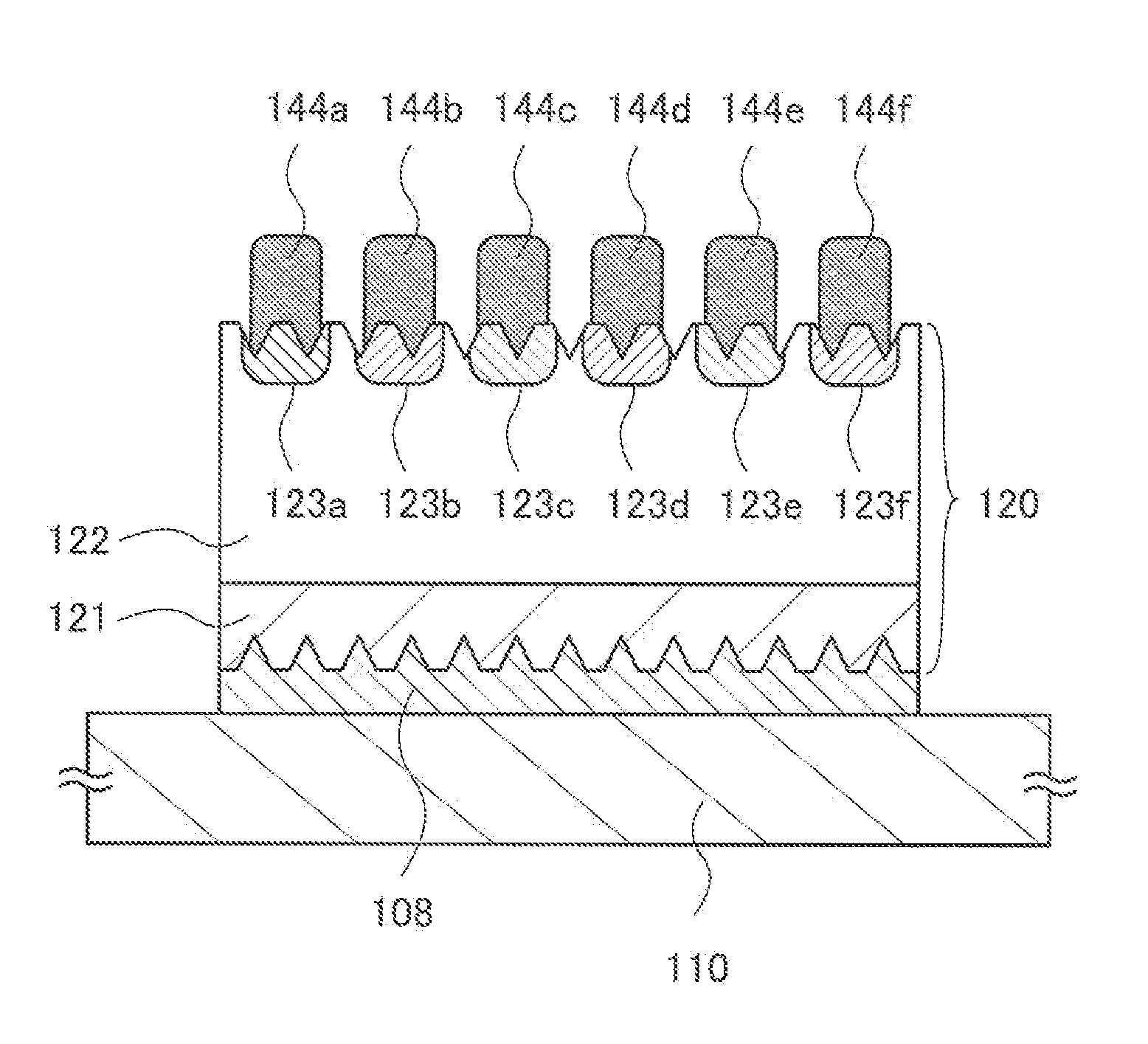

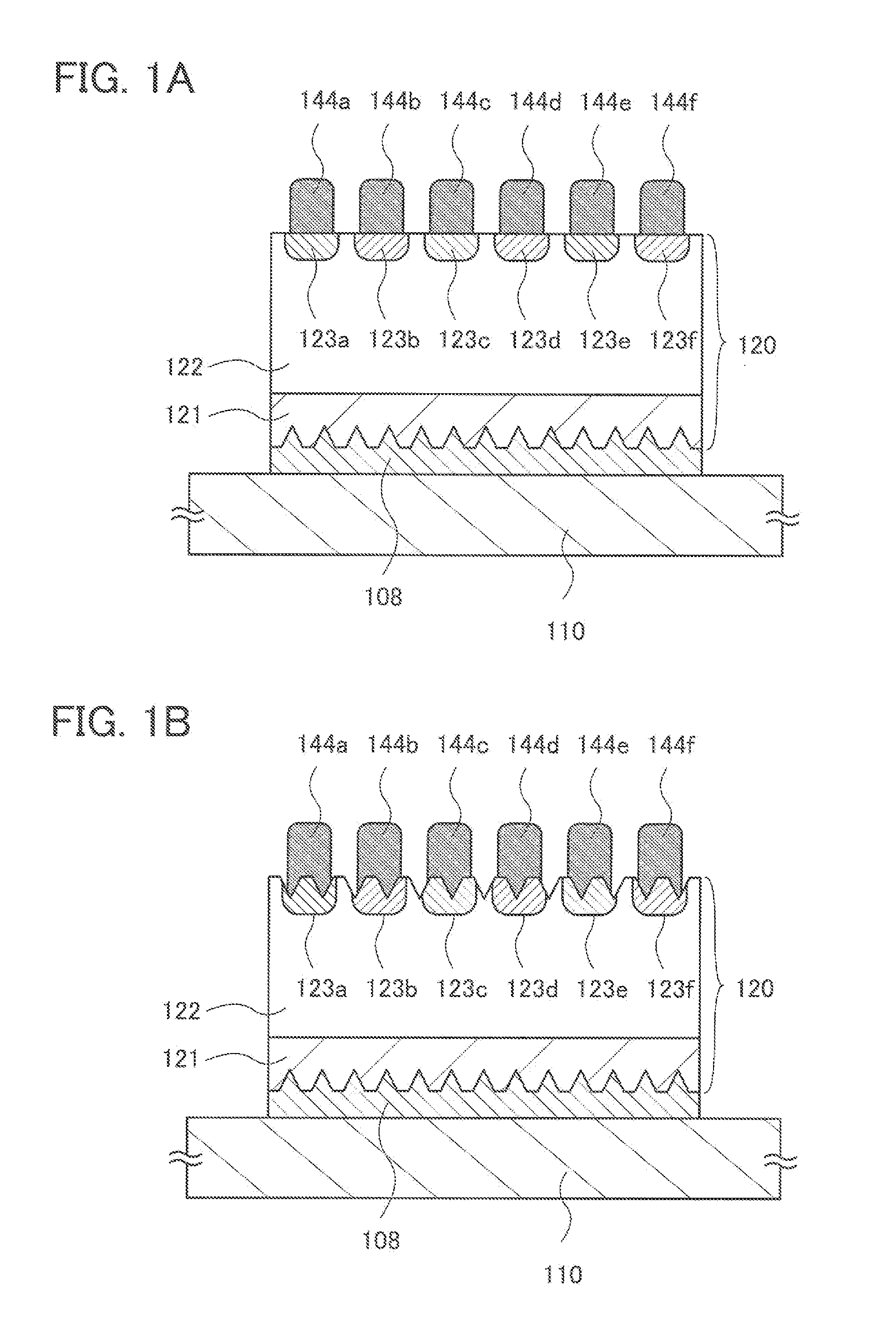

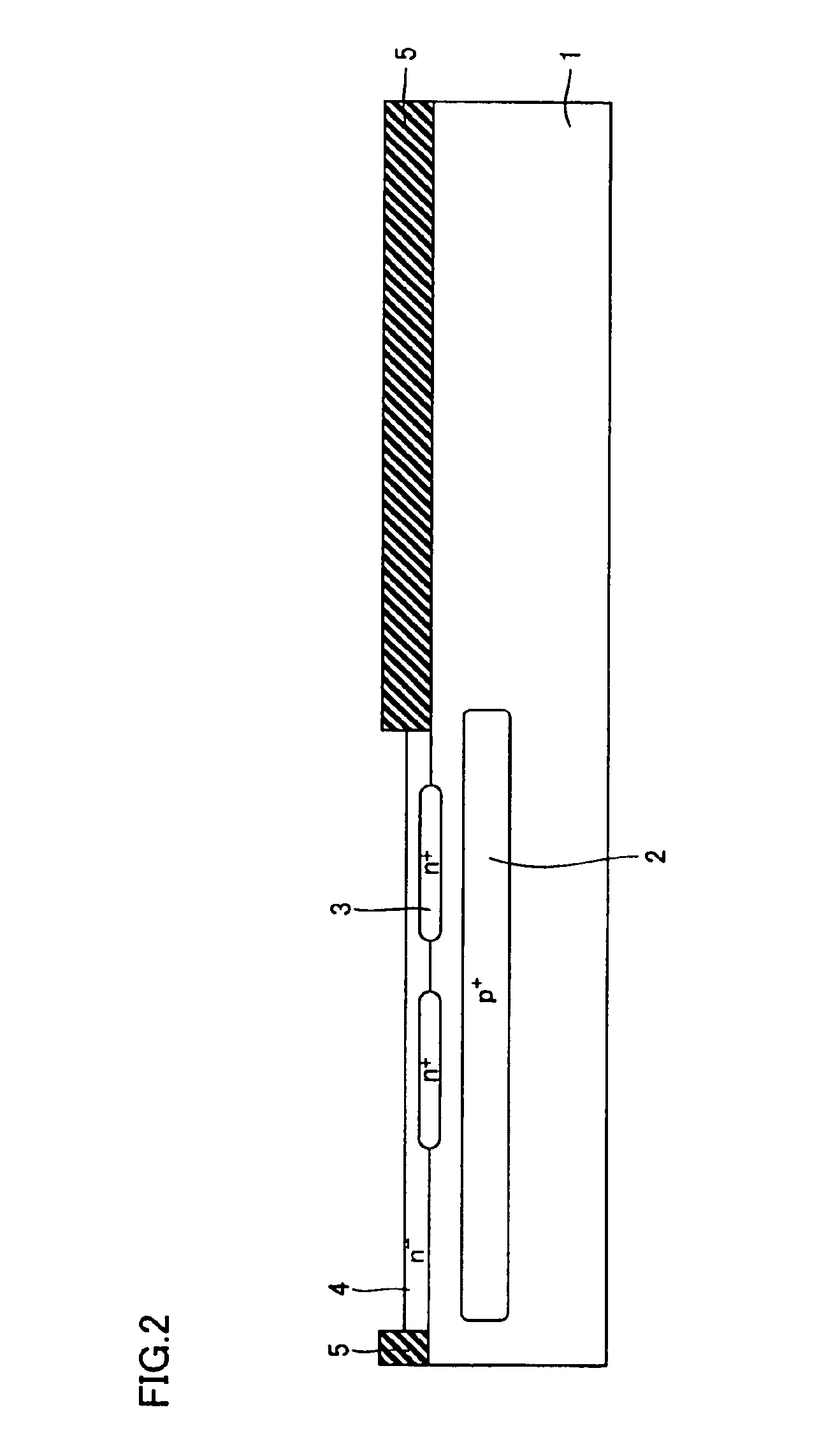

Photoelectric conversion device and manufacturing method thereof

InactiveUS20100275990A1Improve efficiencyHigh resource savingFinal product manufactureSemiconductor/solid-state device manufacturingSurface layerBand shape

To provide a novel photoelectric conversion device and a manufacturing method thereof. Over a base substrate having a light-transmitting property, a light-transmitting insulating layer and a single crystal semiconductor layer over the insulating layer are formed. A plurality of first impurity semiconductor layers each having one conductivity type is provided in a band shape in a surface layer of the single crystal semiconductor layer or on a surface of the single crystal semiconductor layer, and a plurality of second impurity semiconductor layers each having a conductivity type which is opposite to the one conductivity type is provided in a band shape in such a manner that the first impurity semiconductor layers and the second impurity semiconductor layers are alternately provided and do not overlap with each other. First electrodes in contact with the first impurity semiconductor layers and second electrodes in contact with the second impurity semiconductor layers are provided, and a back contact cell is formed, whereby a photoelectric conversion device provided with a photo acceptance surface on the base substrate side is formed.

Owner:SEMICON ENERGY LAB CO LTD

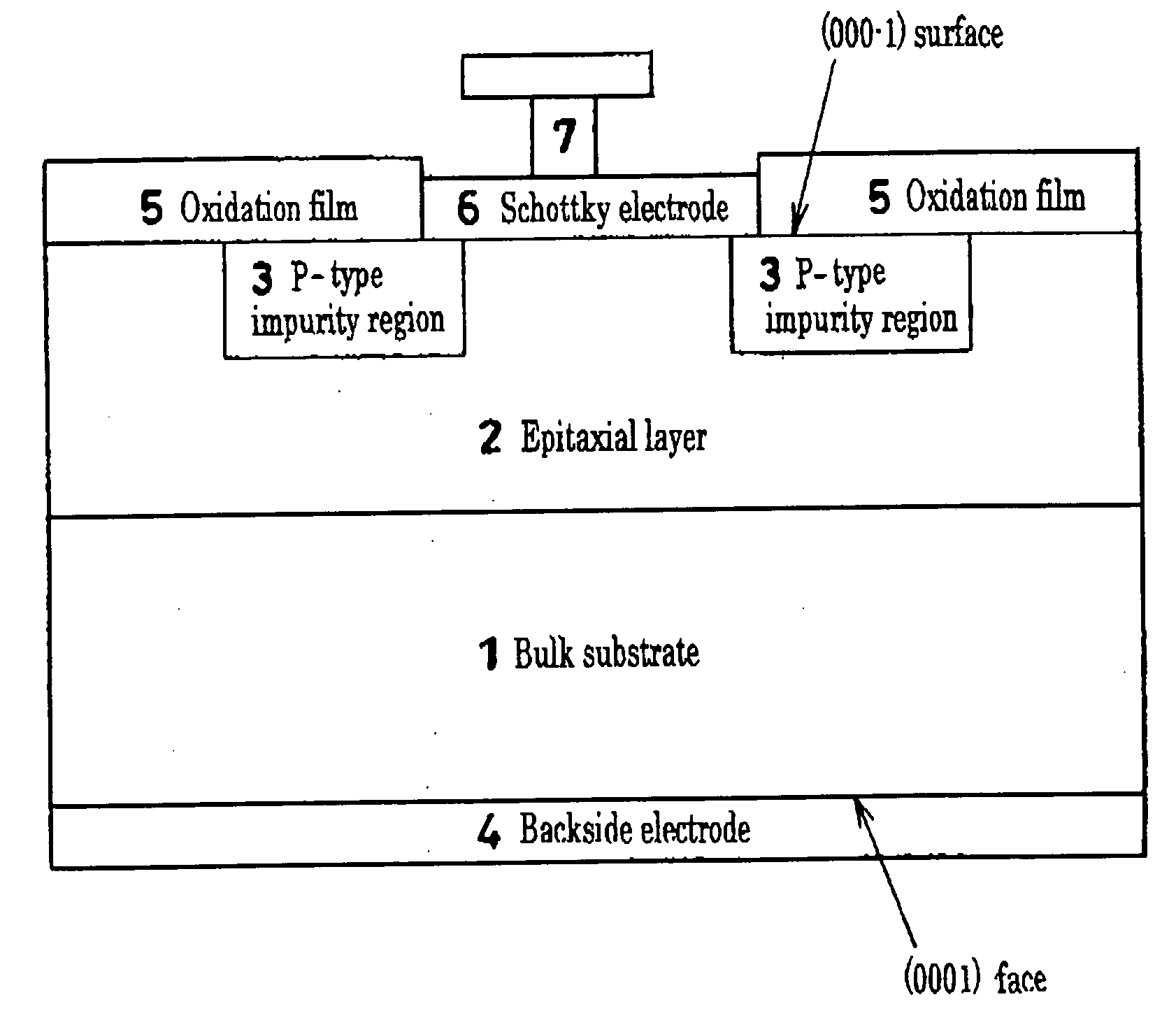

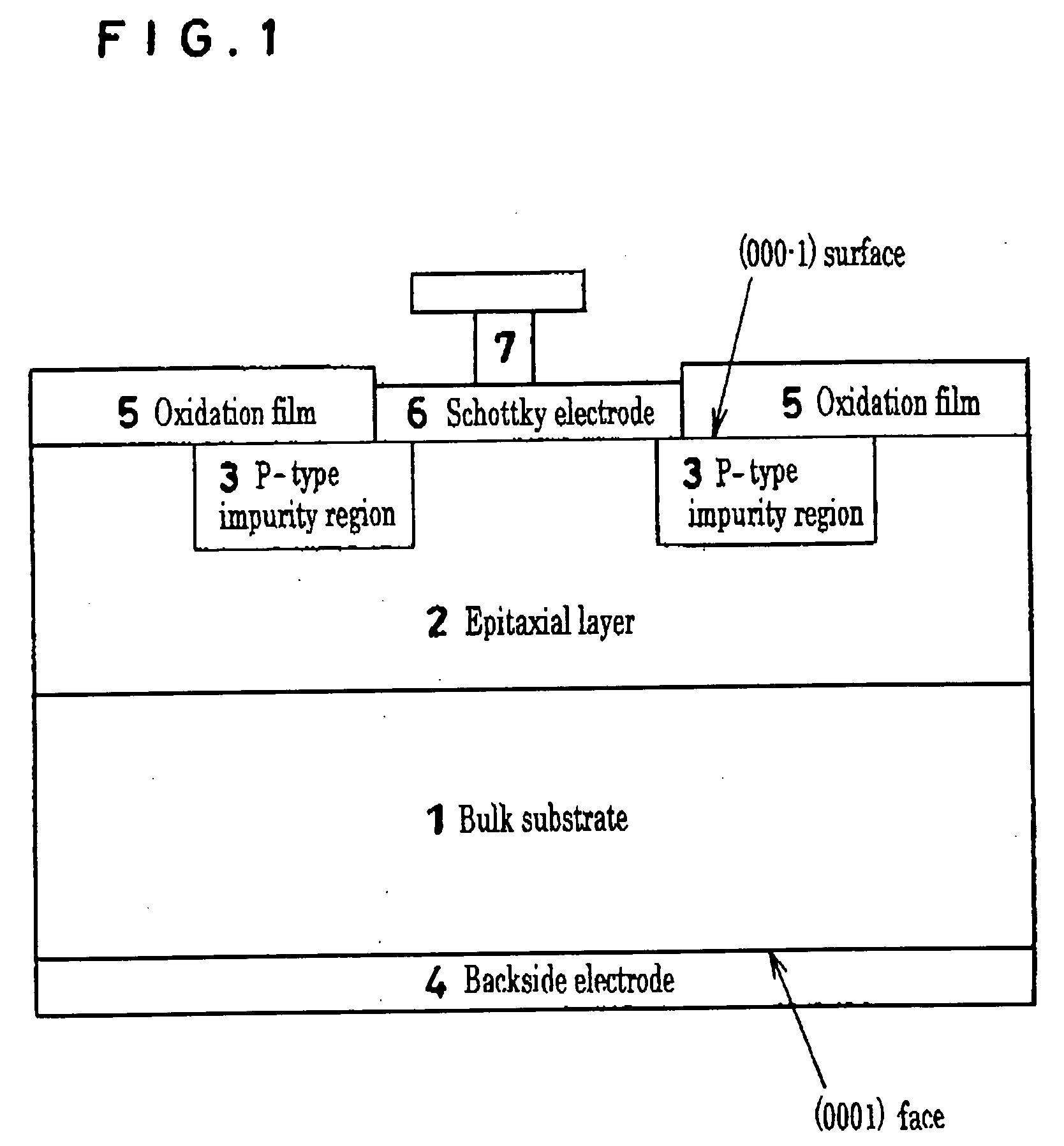

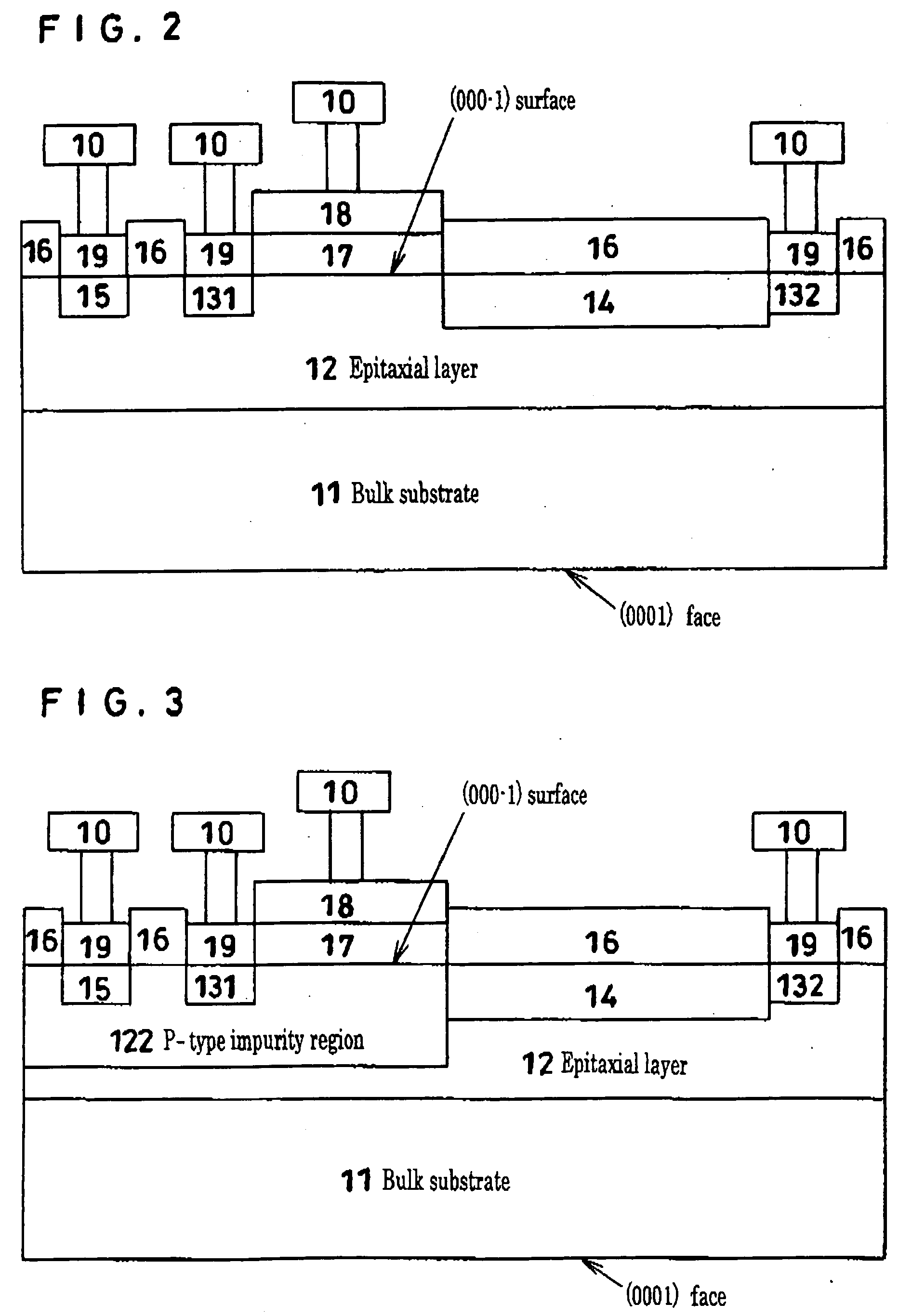

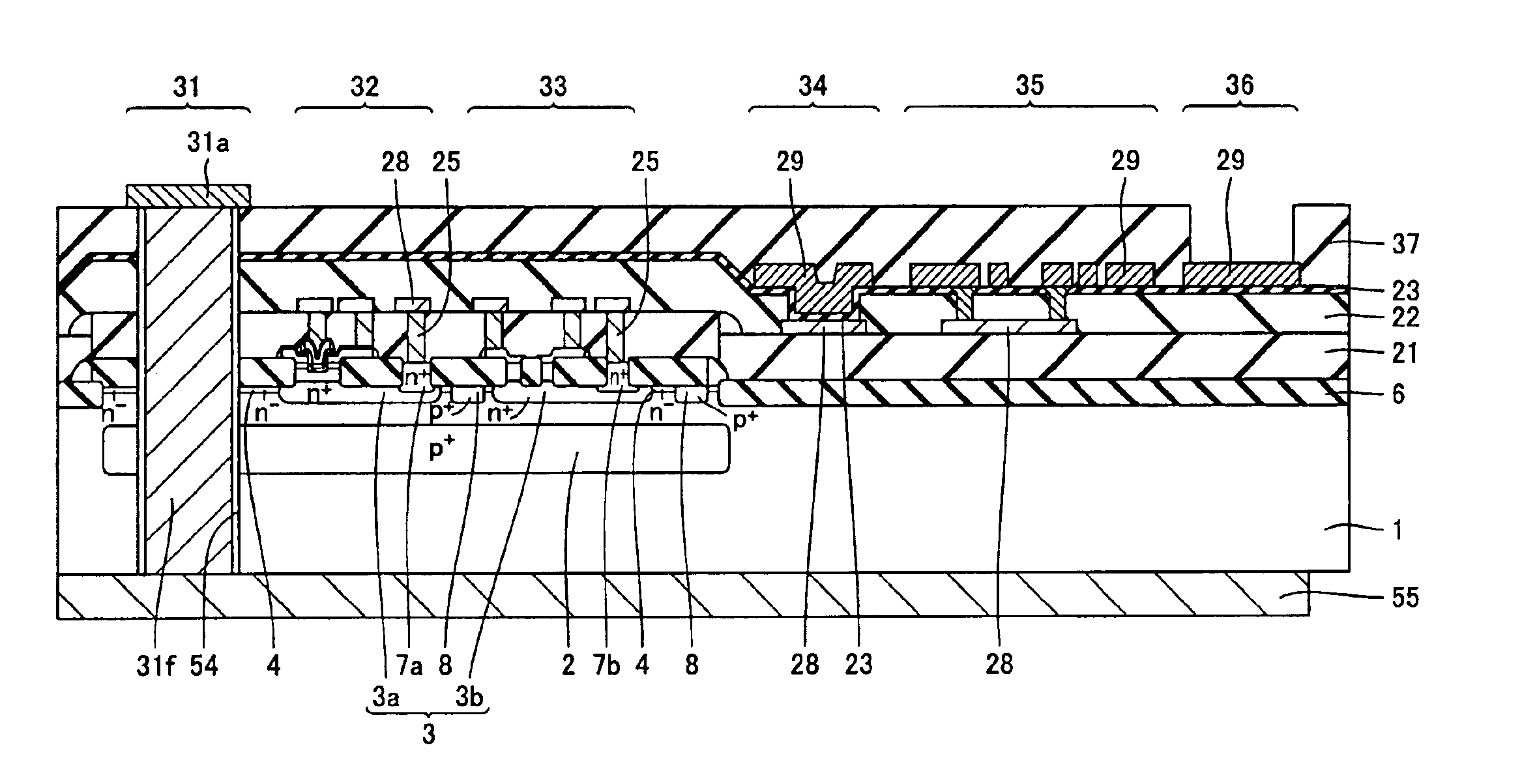

Semiconductor device and power converter, driving inverter, general-purpose inverter and high-power high-frequency communication device using same

InactiveUS20060151806A1Excellent electrical propertiesSuppress roughnessThyristorSemiconductor/solid-state device manufacturingSchottky barrierDevice material

In a semiconductor device that uses a silicon carbide semiconductor substrate having p type, n type impurity semiconductor regions formed by ion implantation, the electrical characteristics of the end semiconductor device can be improved by decreasing the roughness of the silicon carbide semiconductor substrate surface. The semiconductor device of this invention is a Schottky barrier diode or a p-n type diode comprising at least one of a p type semiconductor region and n type semiconductor region selectively formed in a silicon carbide semiconductor region having an outermost surface layer surface that is a (000-1) surface or a surface inclined at an angle to the (000-1) surface, and a metal electrode formed on the outermost surface layer surface, that controls a direction in which electric current flows in a direction perpendicular to the outermost surface layer surface from application of a voltage to the metal electrode.

Owner:NAT INST OF ADVANCED IND SCI & TECH

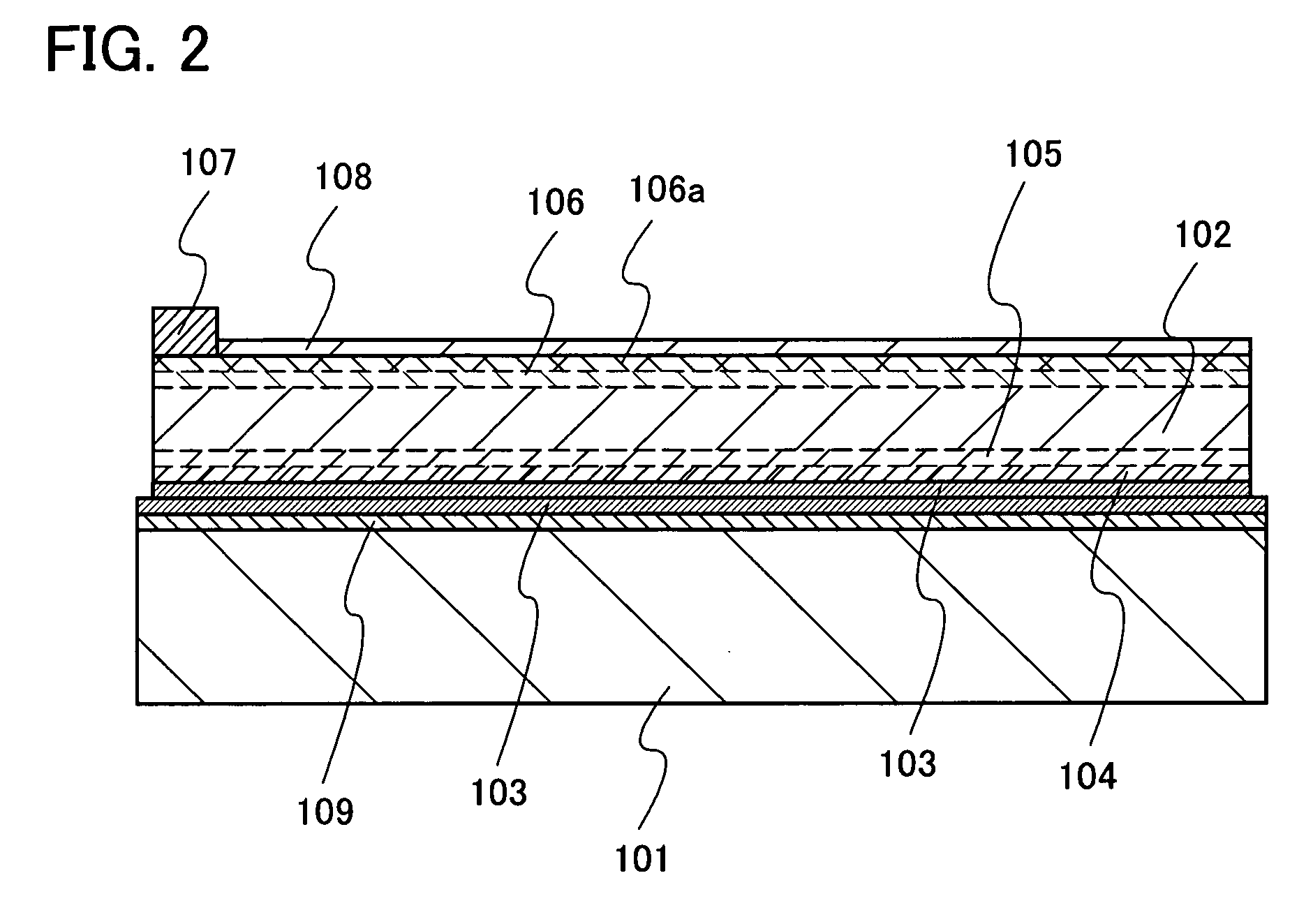

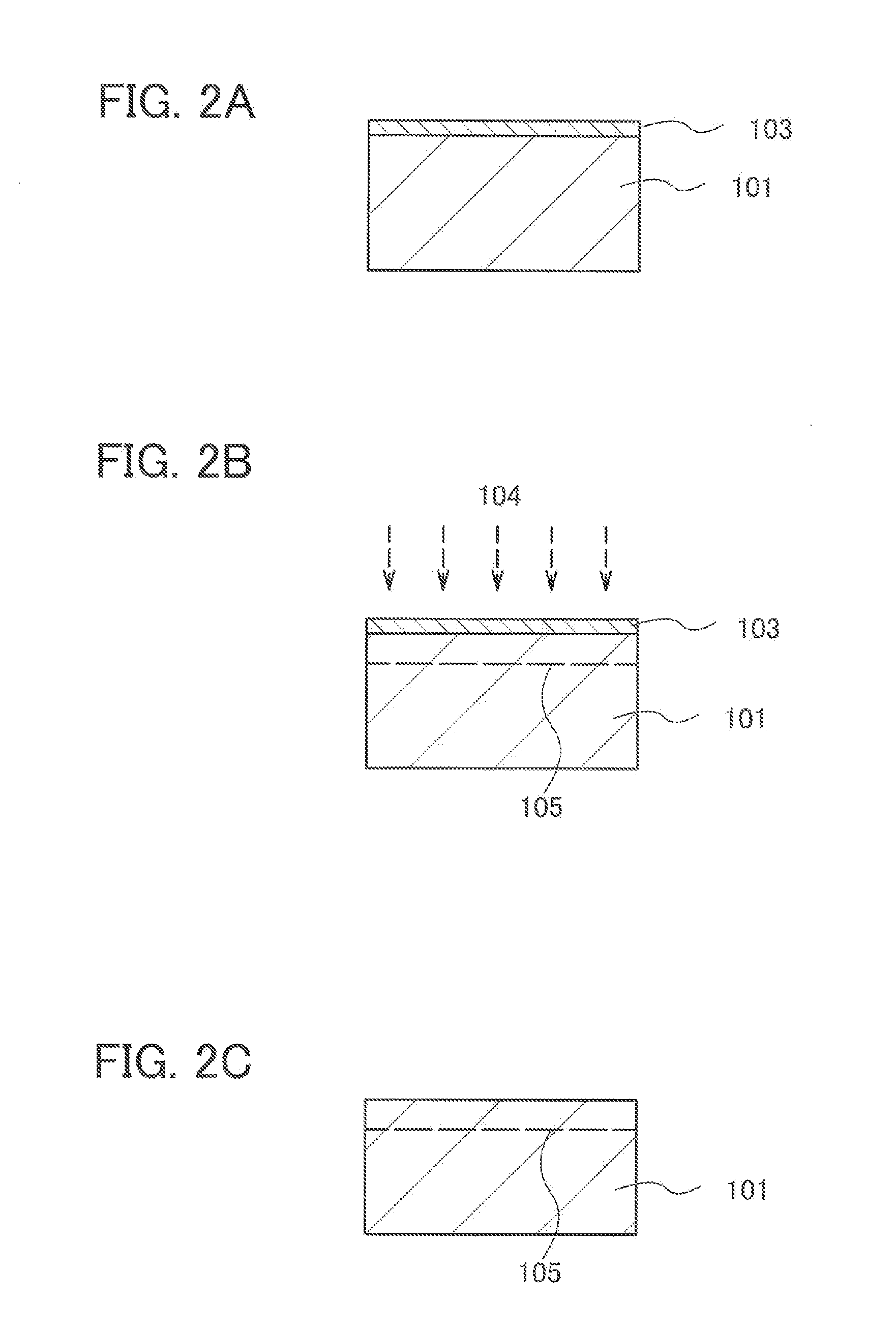

Method of manufacturing photoelectric conversion device

InactiveUS7858431B2Efficient use of resourcesEasily made thickFinal product manufactureSemiconductor/solid-state device manufacturingSingle crystalPhotoelectric conversion

A fragile layer is formed in a region at a depth of less than 1000 nm from one surface of a single crystal semiconductor substrate, and a first impurity semiconductor layer and a first electrode are formed at the one surface side. After bonding the first electrode and a supporting substrate, the single crystal semiconductor substrate is separated using the fragile layer or the vicinity as a separation plane, thereby forming a first single crystal semiconductor layer over the supporting substrate. An amorphous semiconductor layer is formed on the first single crystal semiconductor layer, and a second single crystal semiconductor layer is formed by heat treatment for solid phase growth of the amorphous semiconductor layer. A second impurity semiconductor layer having a conductivity type opposite to that of the first impurity semiconductor layer and a second electrode are formed over the second single crystal semiconductor layer.

Owner:SEMICON ENERGY LAB CO LTD

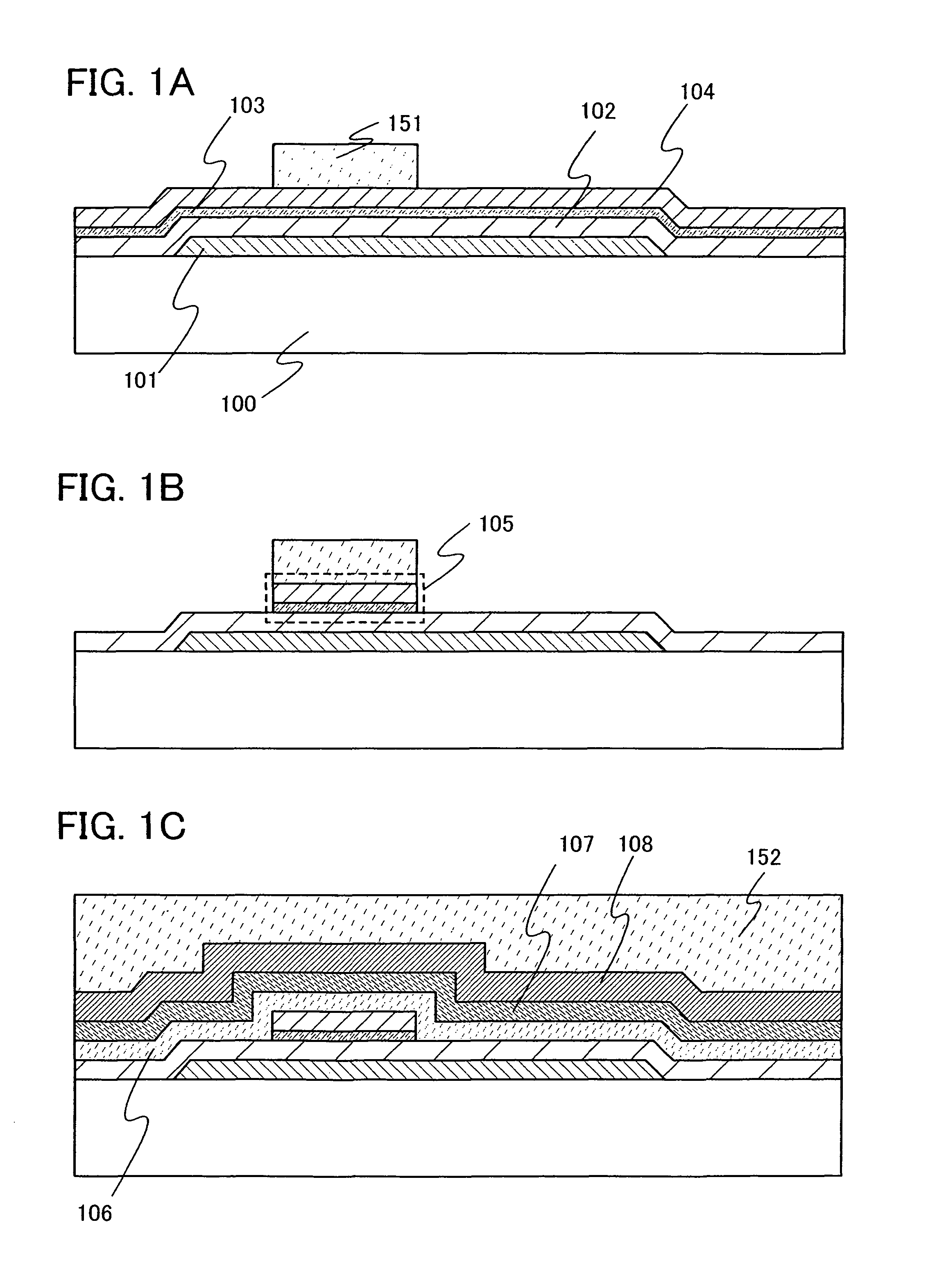

Display device and electronic device having the display device, and method for manufacturing thereof

InactiveUS20090039352A1Reduce yieldTransistorSemiconductor/solid-state device manufacturingDisplay deviceEngineering

To provide a display device including a thin film transistor in which high electric characteristics and reduction in off-current can be achieved. The display device having a thin film transistor includes a substrate, a gate electrode provided over the substrate, a gate insulating film provided over the gate electrode, a microcrystalline semiconductor film provided over the gate electrode with the gate insulating film interposed therebetween, a channel protection layer which is provided over and in contact with the microcrystalline semiconductor film, an amorphous semiconductor film provided over the gate insulating film and on a side surface of the microcrystalline semiconductor film and the channel protection layer, an impurity semiconductor layer provided over the amorphous semiconductor film, and a source electrode and a drain electrode provided over and in contact with the impurity semiconductor layer. The thickness of the amorphous semiconductor film is larger than that of the microcrystalline semiconductor film.

Owner:SEMICON ENERGY LAB CO LTD

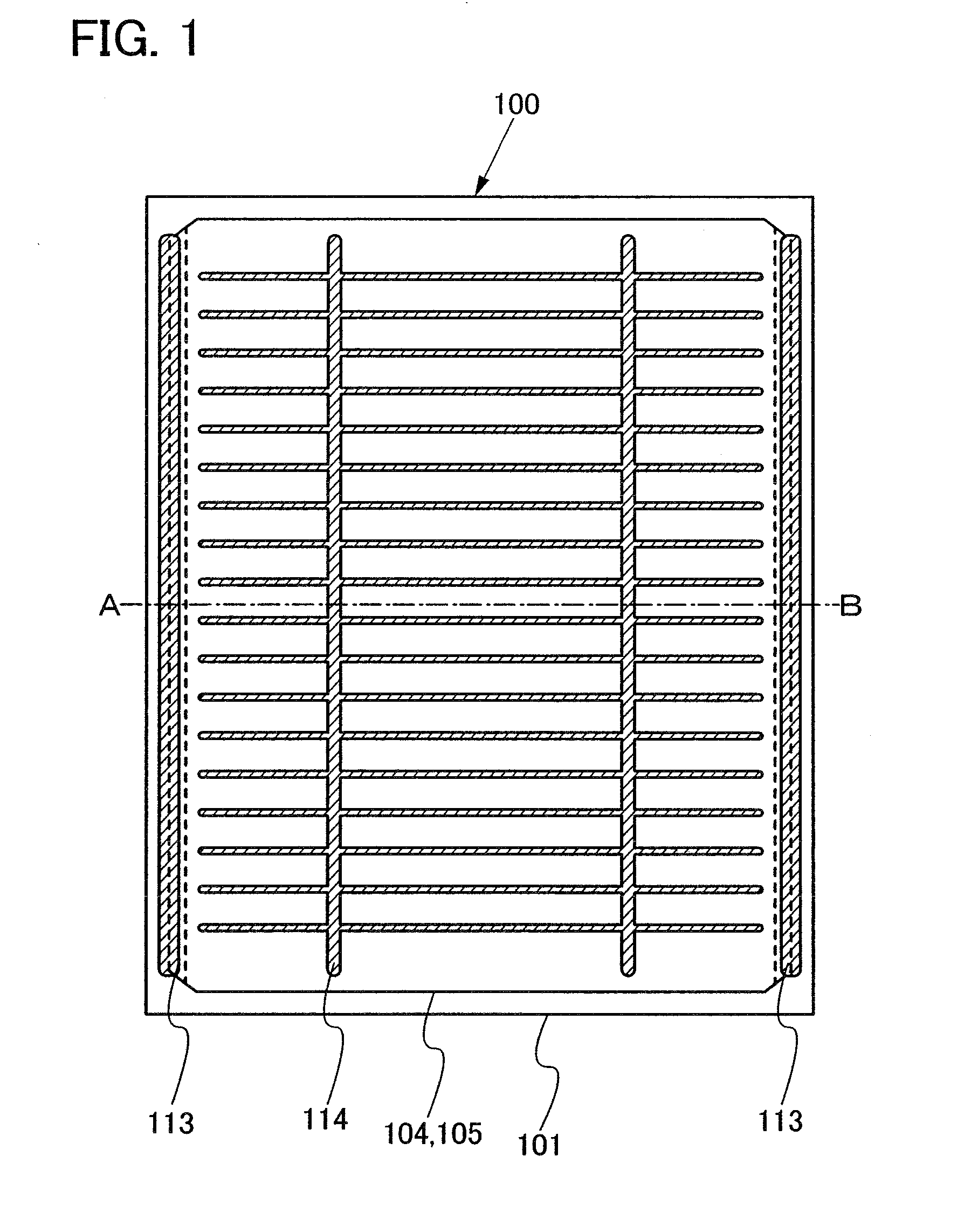

Photoelectric conversion device and manufacturing method thereof

InactiveUS20110041910A1High mechanical strengthImprove photoelectric conversion efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingSurface layerSingle crystal

A novel photoelectric conversion device and a manufacturing method thereof are provided. The photoelectric conversion device includes an insulating layer over a light-transmitting base substrate; a single crystal semiconductor layer provided with a plurality of depressions which are filled with the insulating layer; a plurality of first impurity semiconductor layers formed in stripes having one conductivity type and a plurality of second impurity semiconductor layers formed in stripes having a conductivity type which is opposite to the one conductivity type, which are arranged alternately and do not overlap with each other, in a surface layer or over a surface of the single crystal semiconductor layer; first electrodes which are in contact with the first impurity semiconductor layers; and second electrodes which are in contact with the second impurity semiconductor layers.

Owner:SEMICON ENERGY LAB CO LTD

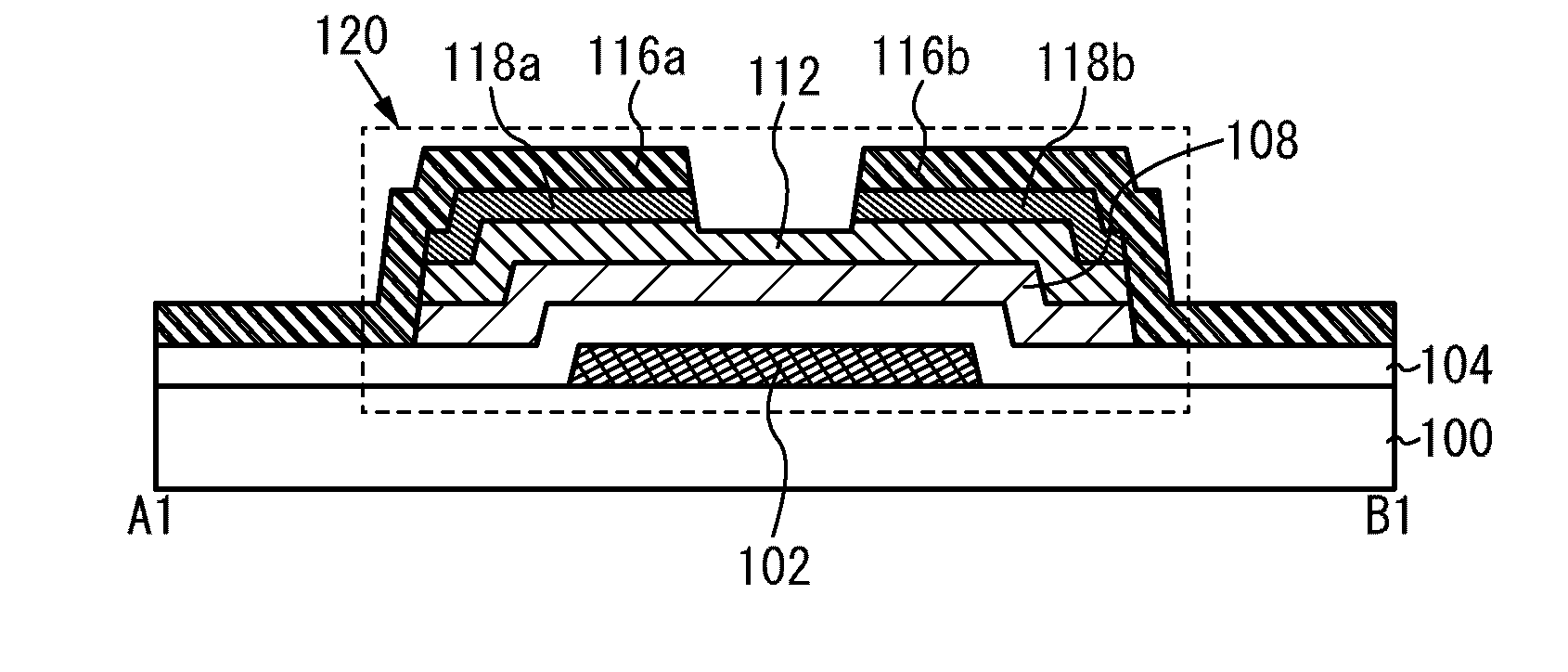

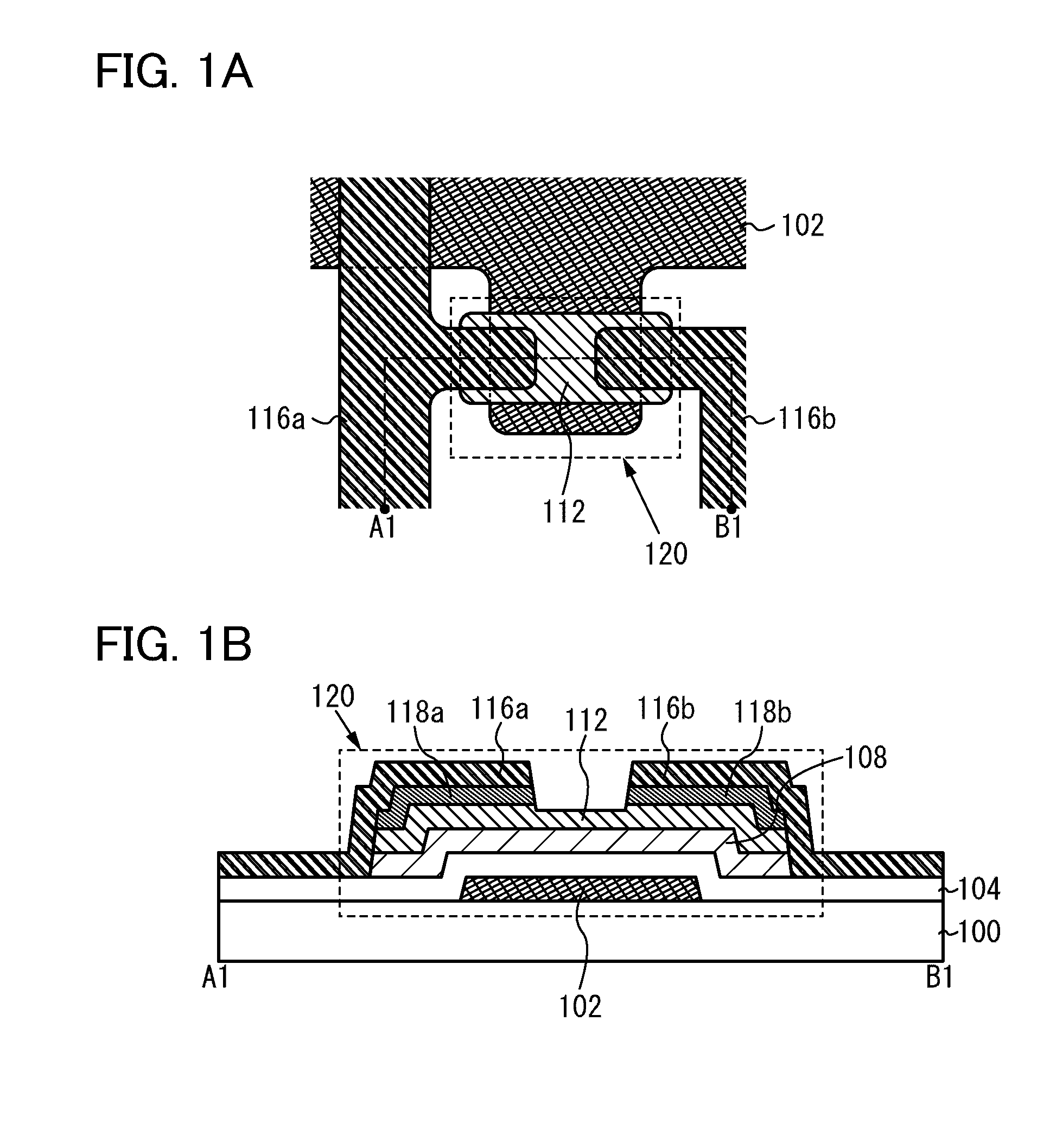

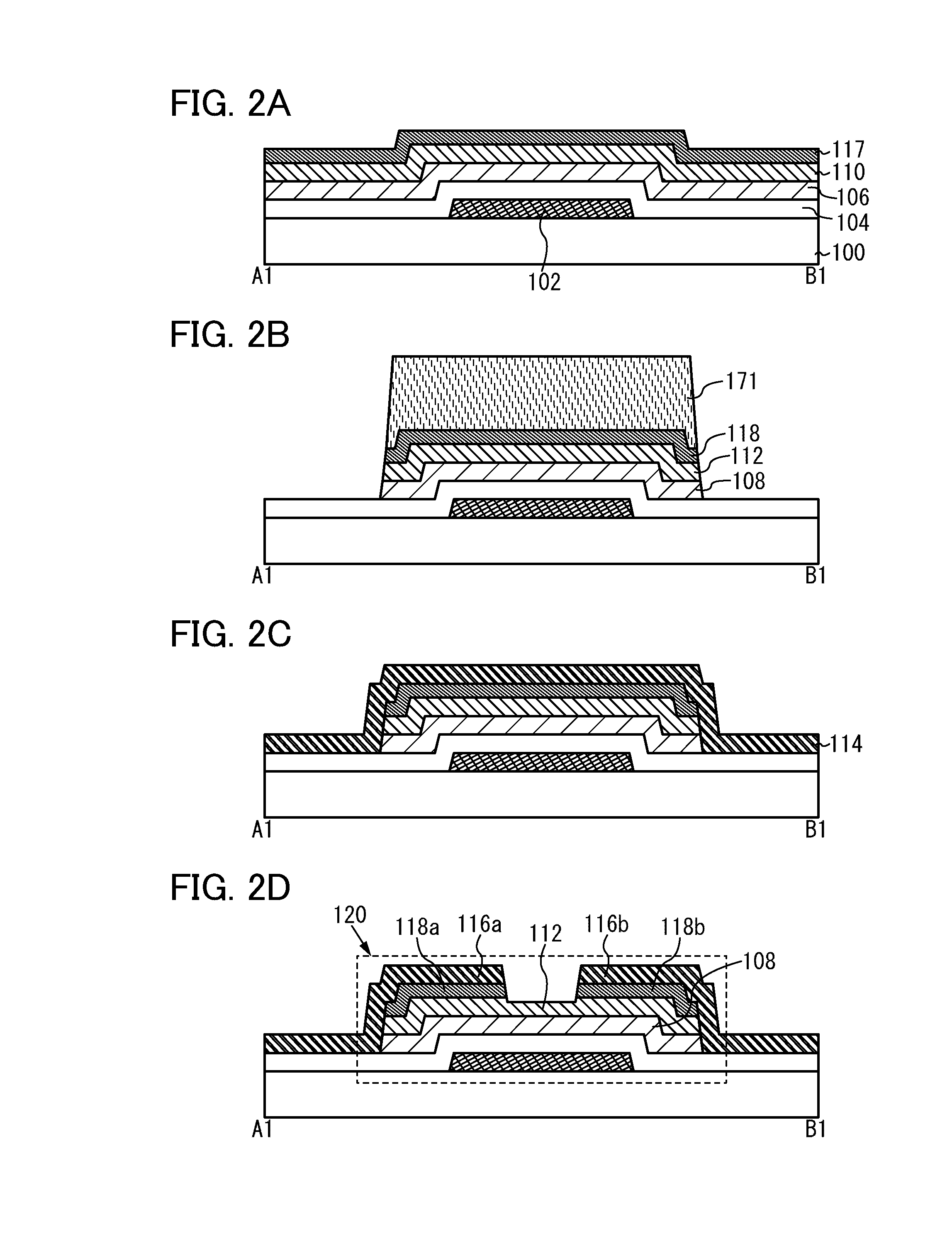

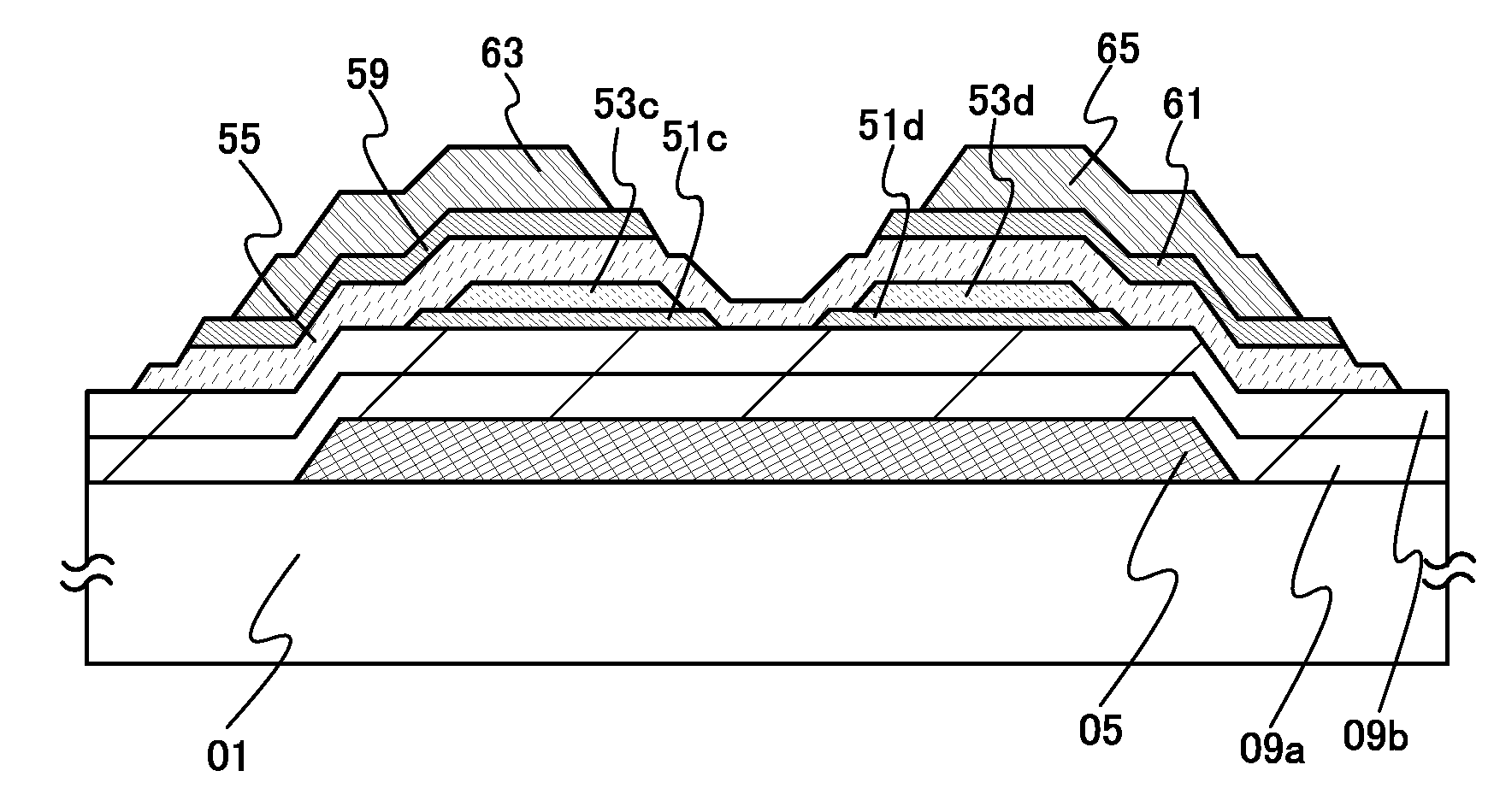

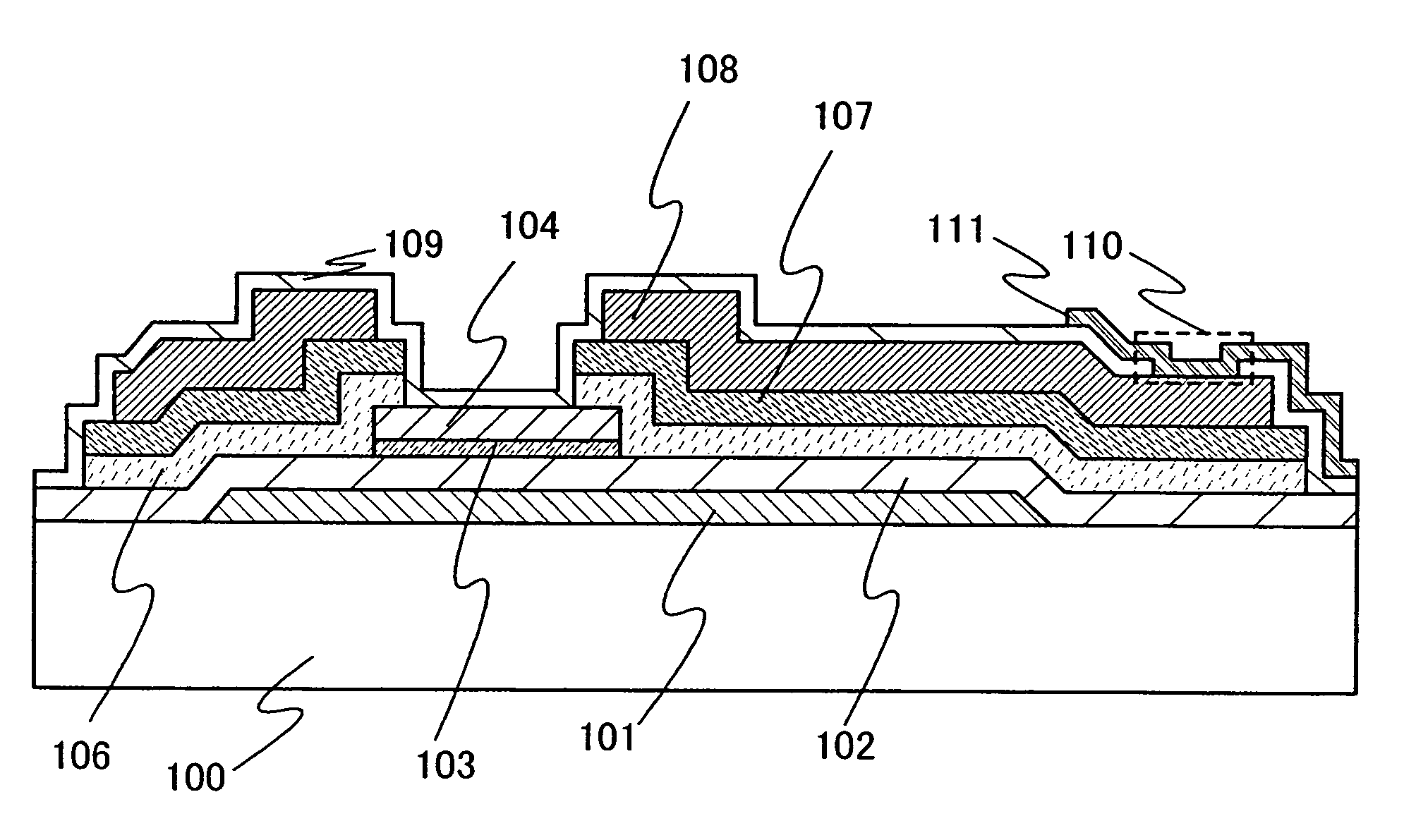

Thin film transistor and display device

InactiveUS20090236600A1Improve mobilityLarge on-state currentSemiconductor devicesDisplay deviceImpurity

A thin film transistor is provided, which includes a gate insulating layer covering a gate electrode, a microcrystalline semiconductor layer provided over the gate insulating layer, an amorphous semiconductor layer overlapping the microcrystalline semiconductor layer and the gate insulating layer, and a pair of impurity semiconductor layers which are provided over the amorphous semiconductor layer and to which an impurity element imparting one conductivity type is added to form a source region and a drain region. The gate insulating layer has a step adjacent to a portion in contact with an end portion of the microcrystalline semiconductor layer. A second thickness of the gate insulating layer in a portion outside the microcrystalline semiconductor layer is smaller than a first thickness thereof in a portion in contact with the microcrystalline semiconductor layer.

Owner:SEMICON ENERGY LAB CO LTD

Transistor, semiconductor device including the transistor, and manufacturing method of the transistor and the semiconductor device

ActiveUS20100207117A1Variation in characteristicSuppress deterioration in electrical characteristicTransistorSolid-state devicesDevice materialImpurity

An object is to suppress deterioration in electric characteristics in a transistor including an oxide semiconductor layer or a semiconductor device including the transistor. In a transistor in which a channel layer is formed using an oxide semiconductor, a silicon layer is provided in contact with a surface of the oxide semiconductor layer, an impurity semiconductor layer is provided over the silicon layer, and a source electrode layer and a drain electrode layer are provided to be electrically connected to the impurity semiconductor layer.

Owner:SEMICON ENERGY LAB CO LTD

Thin film transistor, manufacturing method thereof, display device, and manufacturing method thereof

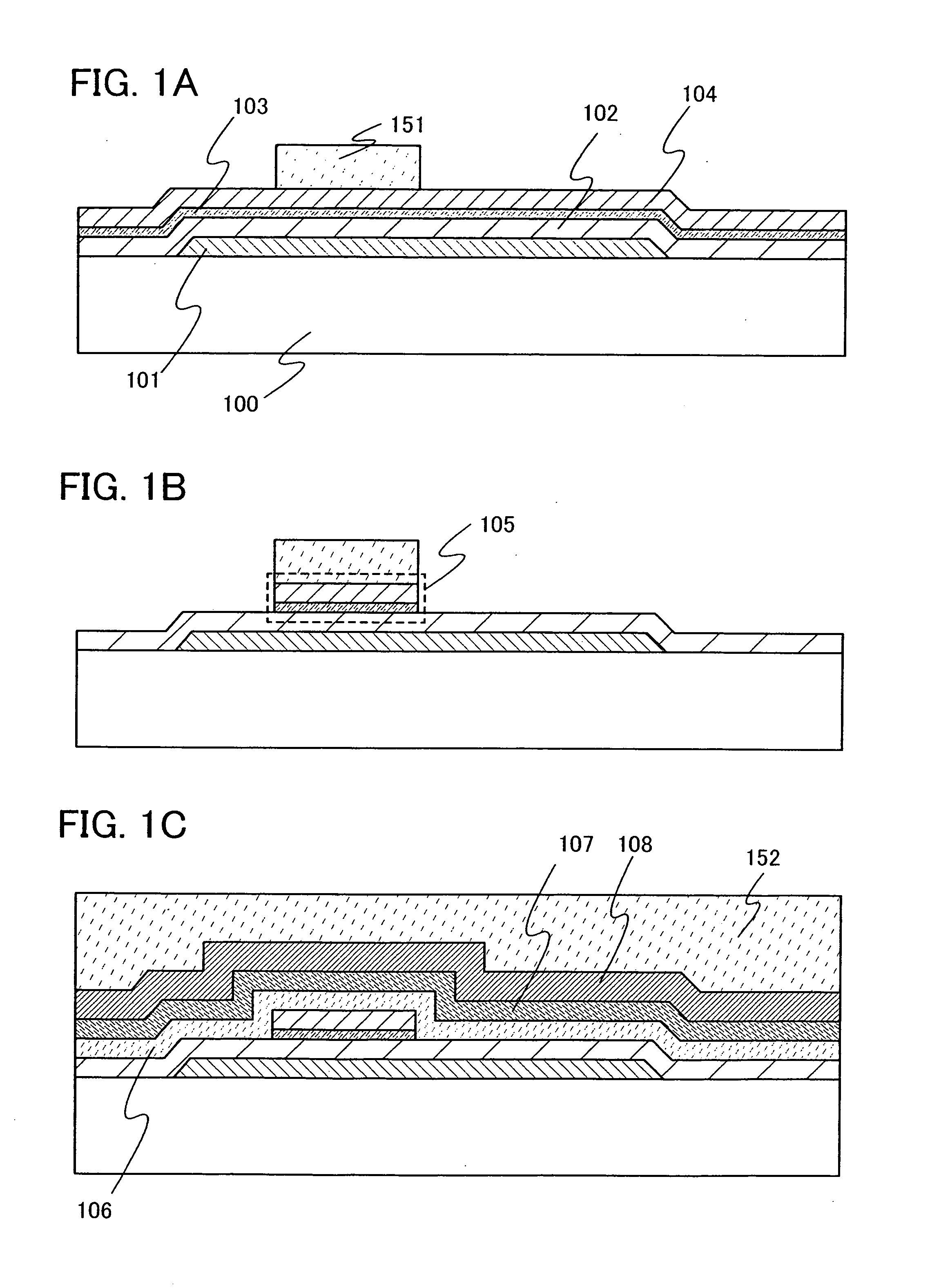

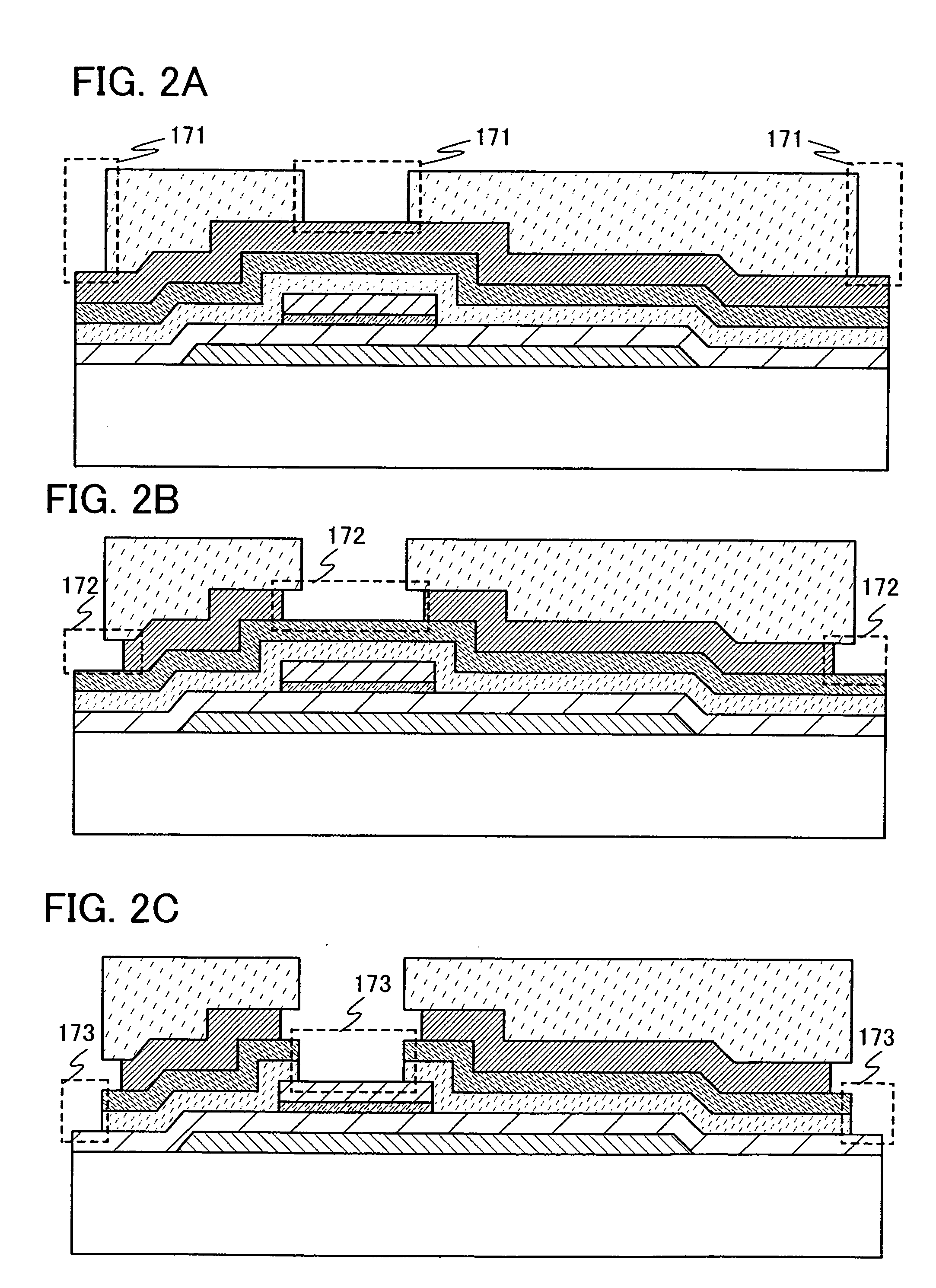

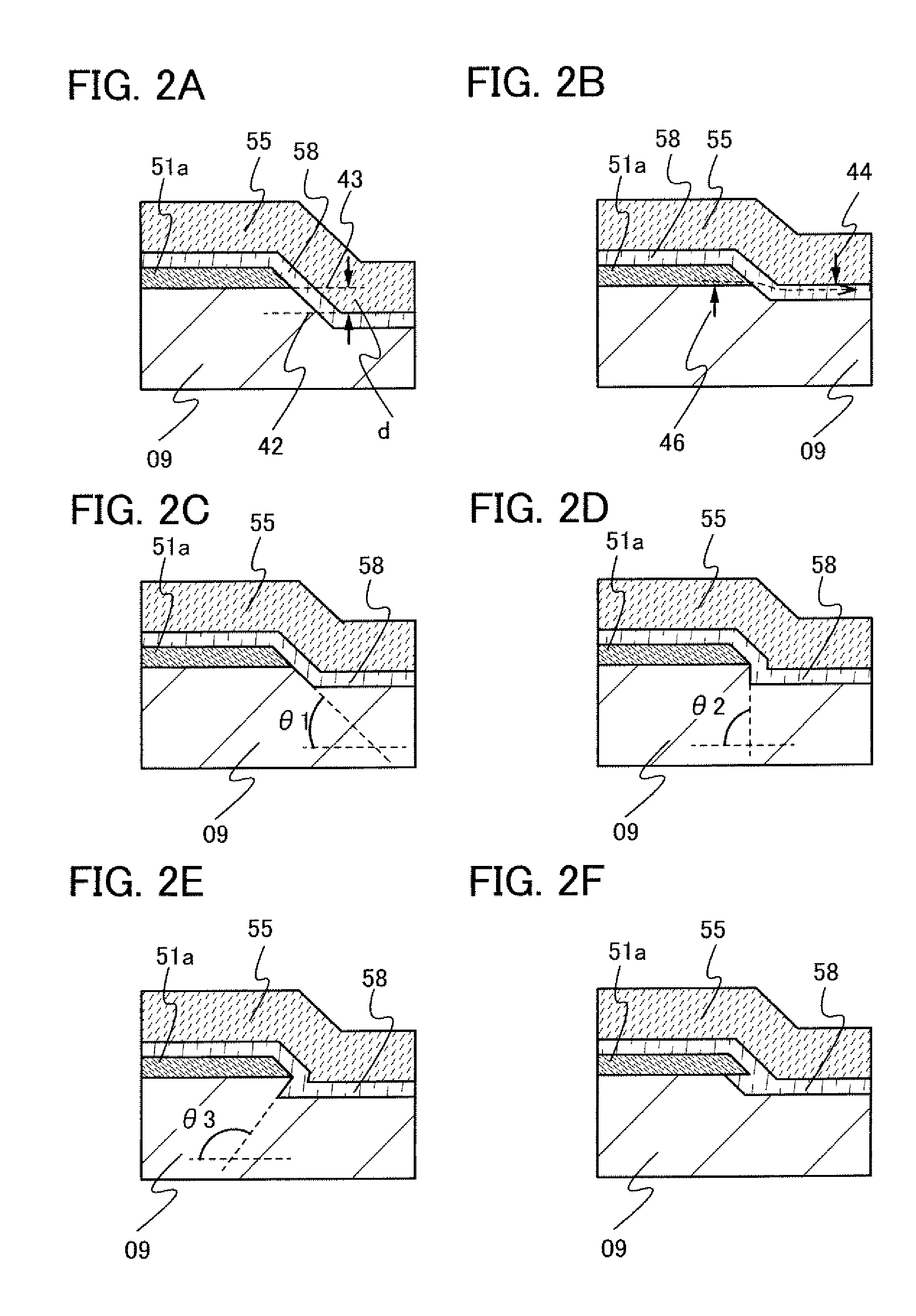

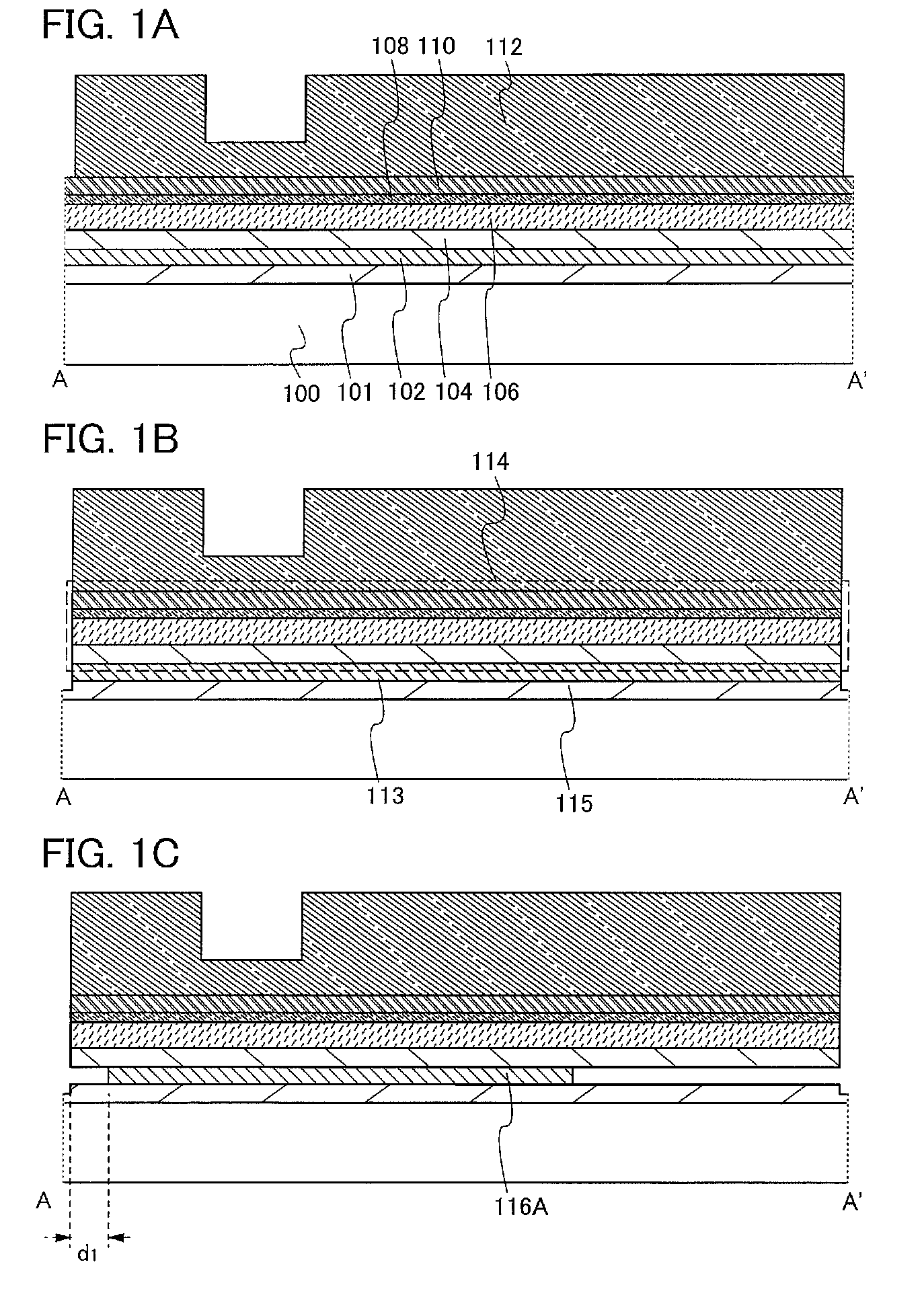

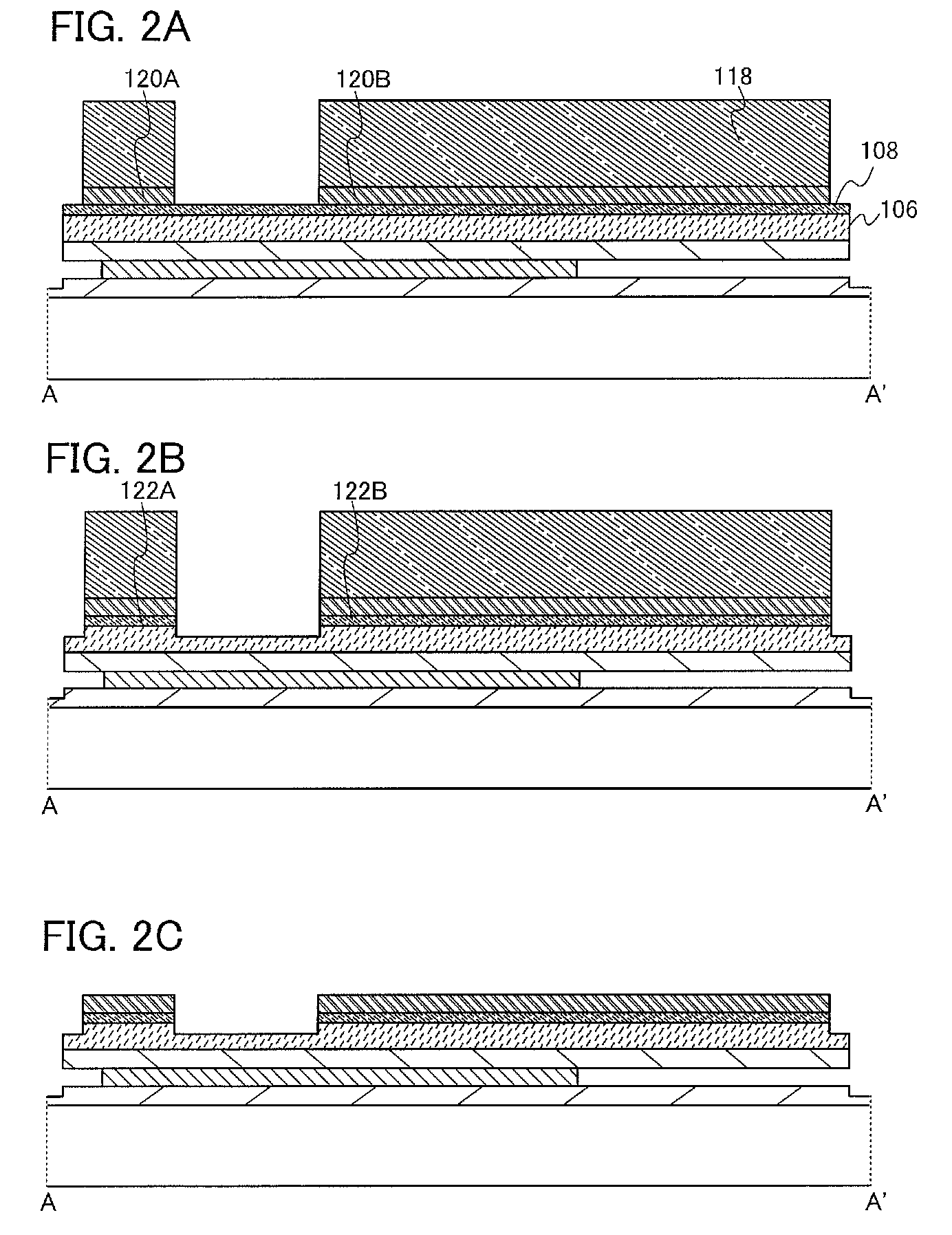

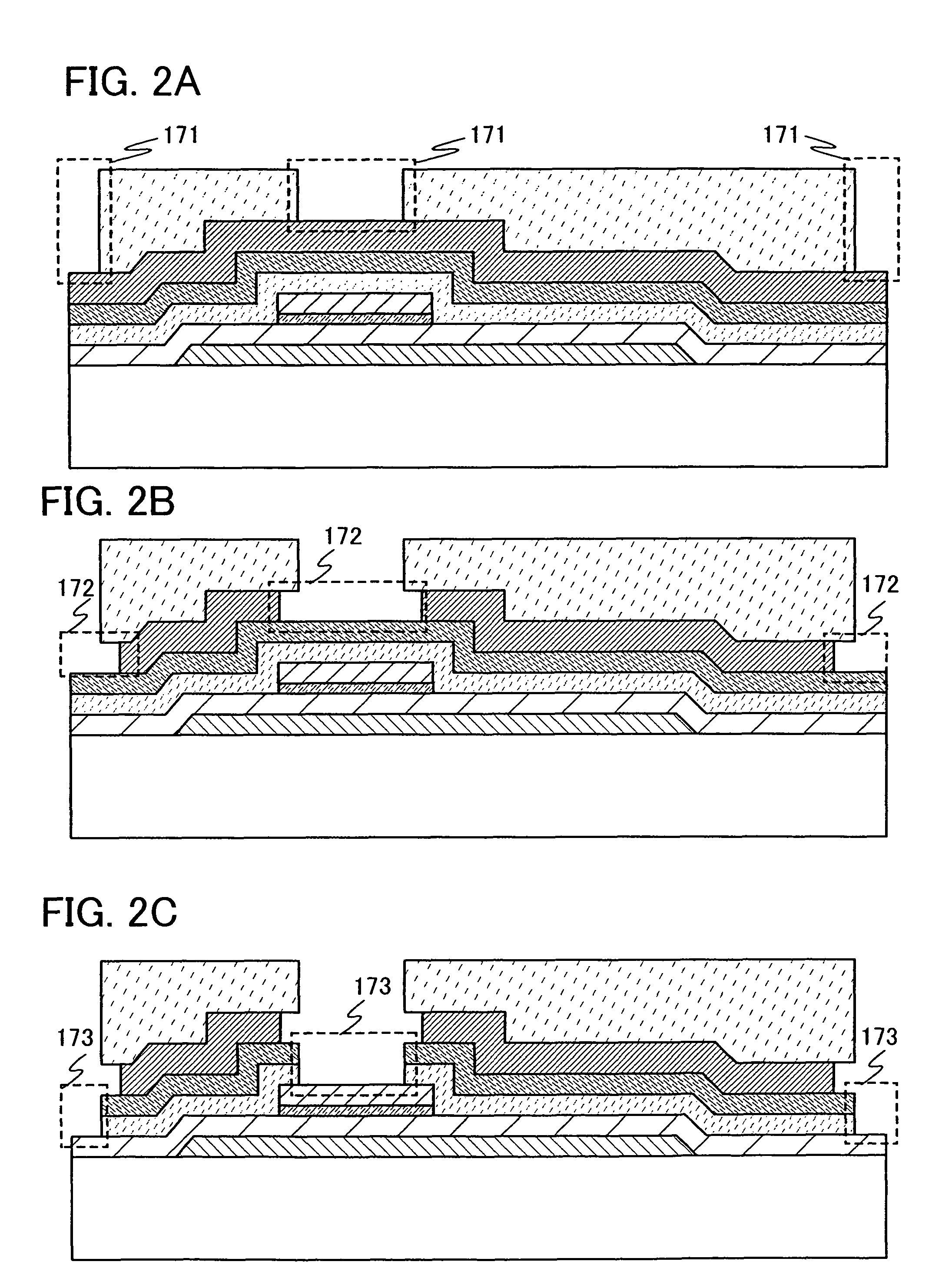

InactiveUS20090227076A1Reduce in quantityReduce manufacturing stepsSolid-state devicesSemiconductor/solid-state device manufacturingResistEtching

Disclosed is a manufacturing method of a thin film transistor, which enables the formation of a thin film transistor by using only one photomask. The method includes: over a substrate sequentially forming a first insulating film, a first conductive film, a second insulating film, a semiconductor film, an impurity semiconductor film, and a second conductive film; forming a resist mask thereover using a first photomask; performing a first etching to allow the side surface of the layers including an upper portion of the first insulating film, the first conductive film, the second insulating film, the semiconductor film, the impurity semiconductor film, and the second conductive film to be coplanar to a side surface of the resist mask; and performing a second etching to selectively etch the first conductive film to allow the side surface of the first conductive film is located inside the side surface of the layers.

Owner:SEMICON ENERGY LAB CO LTD

Thin film transistor, manufacturing method thereof, display device, and manufacturing method thereof

InactiveUS7749820B2Increase contrastImprove display qualitySolid-state devicesSemiconductor/solid-state device manufacturingResistEtching

Owner:SEMICON ENERGY LAB CO LTD

Thin-film transistor and display device

InactiveUS20090218576A1Increasing field-effect mobilityIncrease speedTransistorSolid-state devicesDisplay deviceImpurity

A thin-film transistor includes a pair of impurity semiconductor layers in which an impurity element imparting one conductivity type is added to form a source and drain regions so as to be overlapped at least partly with a gate electrode with a gate insulating layer interposed between the gate electrode and the impurity semiconductor layers; a pair of conductive layers which is overlapped over the gate insulating layers at least partly with the gate electrode and the impurity semiconductor layers, and is disposed with a space therebetween in a channel length direction; and an amorphous semiconductor layer which is in contact with the gate insulating layer and the pair of conductive layers and is extended between the pair of conductive layers.

Owner:SEMICON ENERGY LAB CO LTD

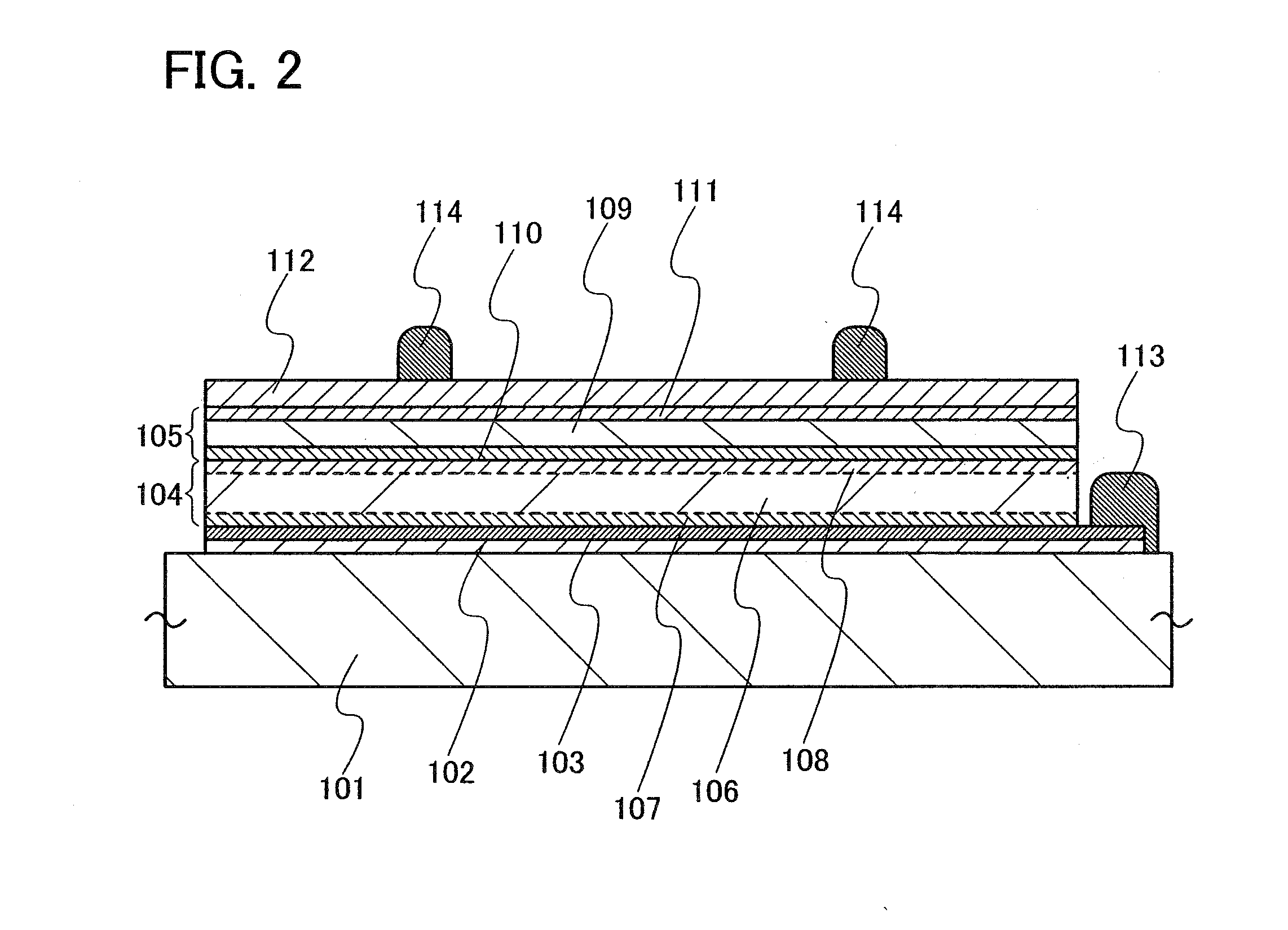

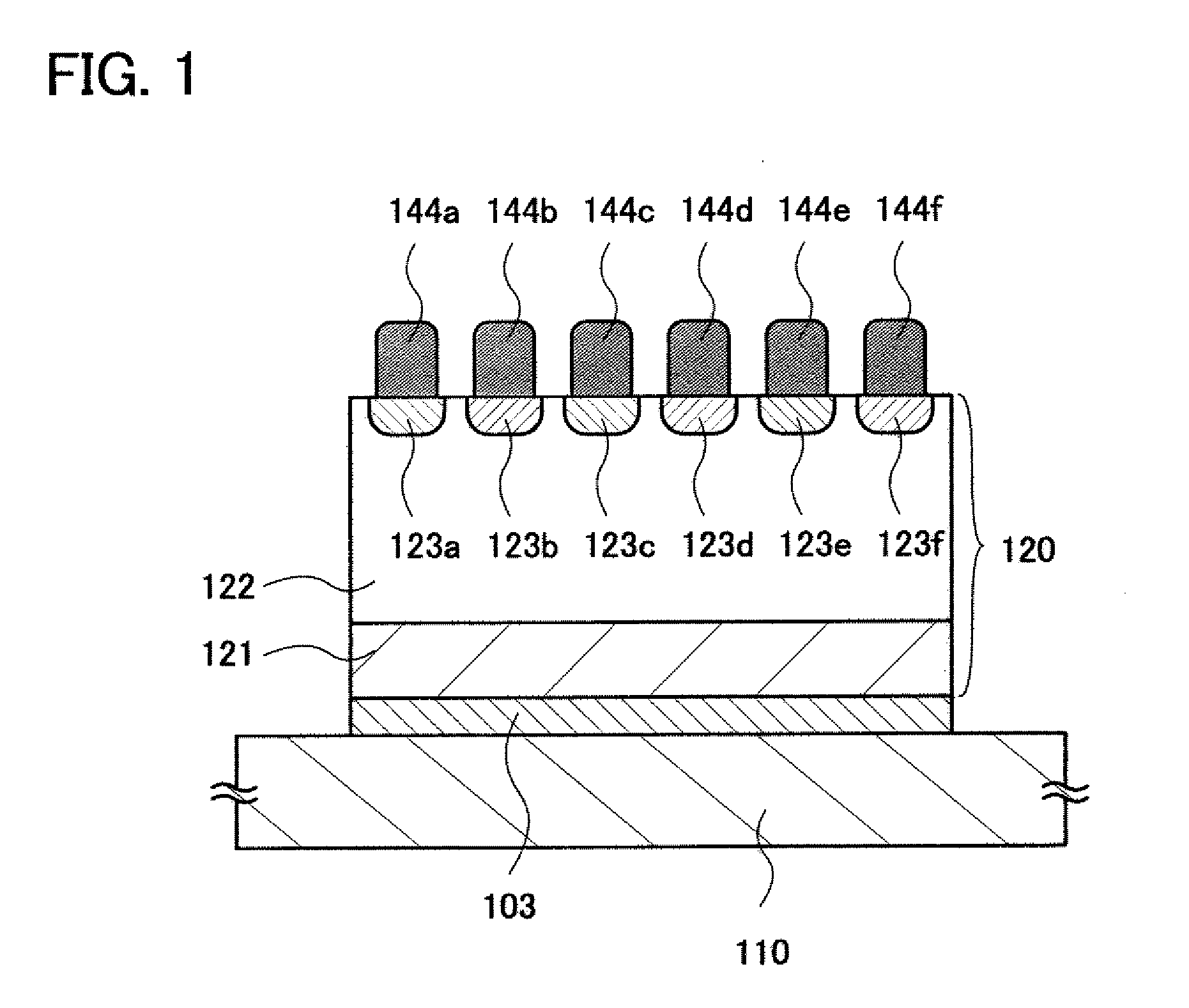

Radiation detection apparatus and radiation detection system

ActiveUS9277896B2Reduce residual chargeEasy to produceRadiation diagnostic clinical applicationsSolid-state devicesElectricitySemiconductor package

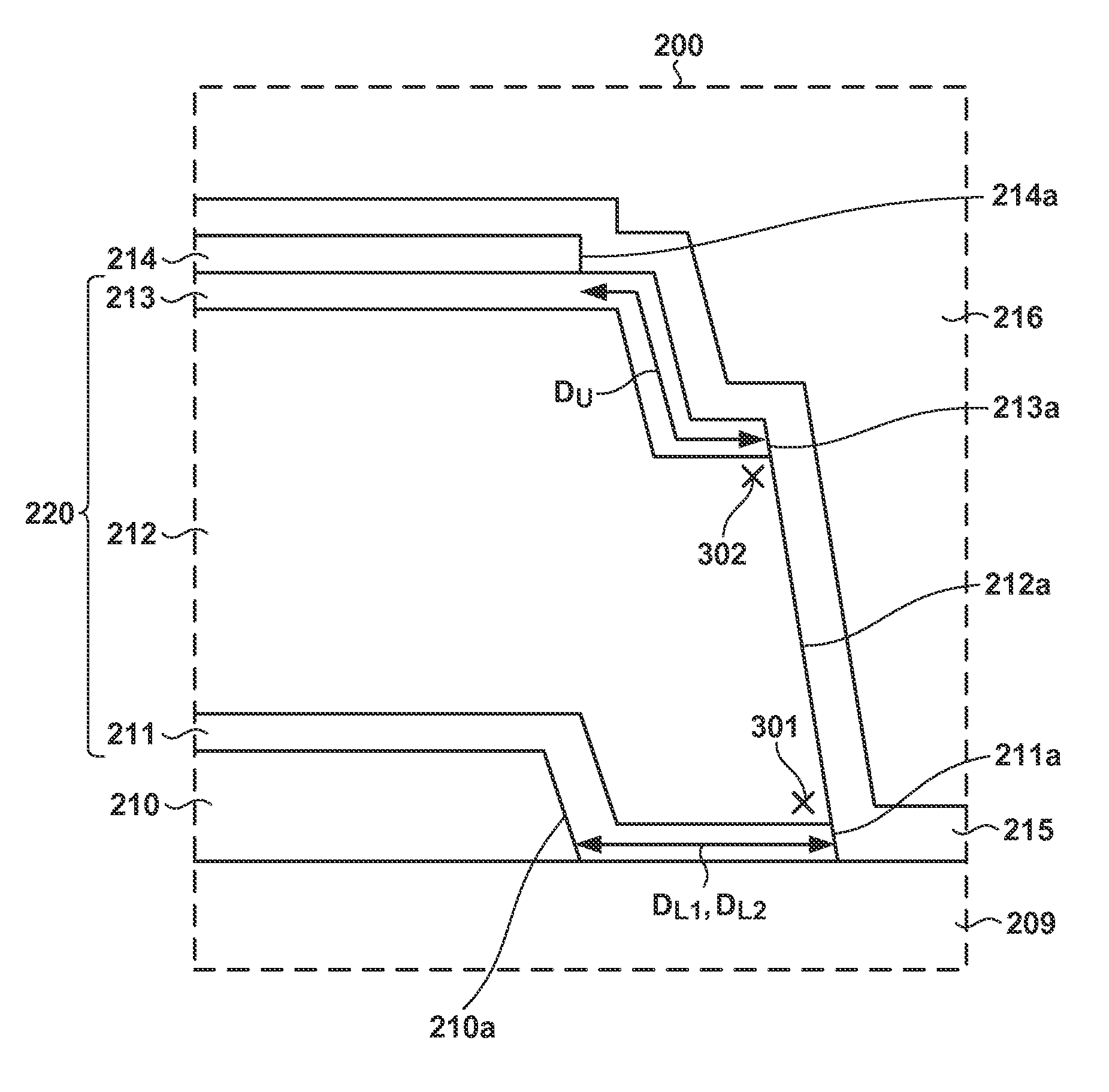

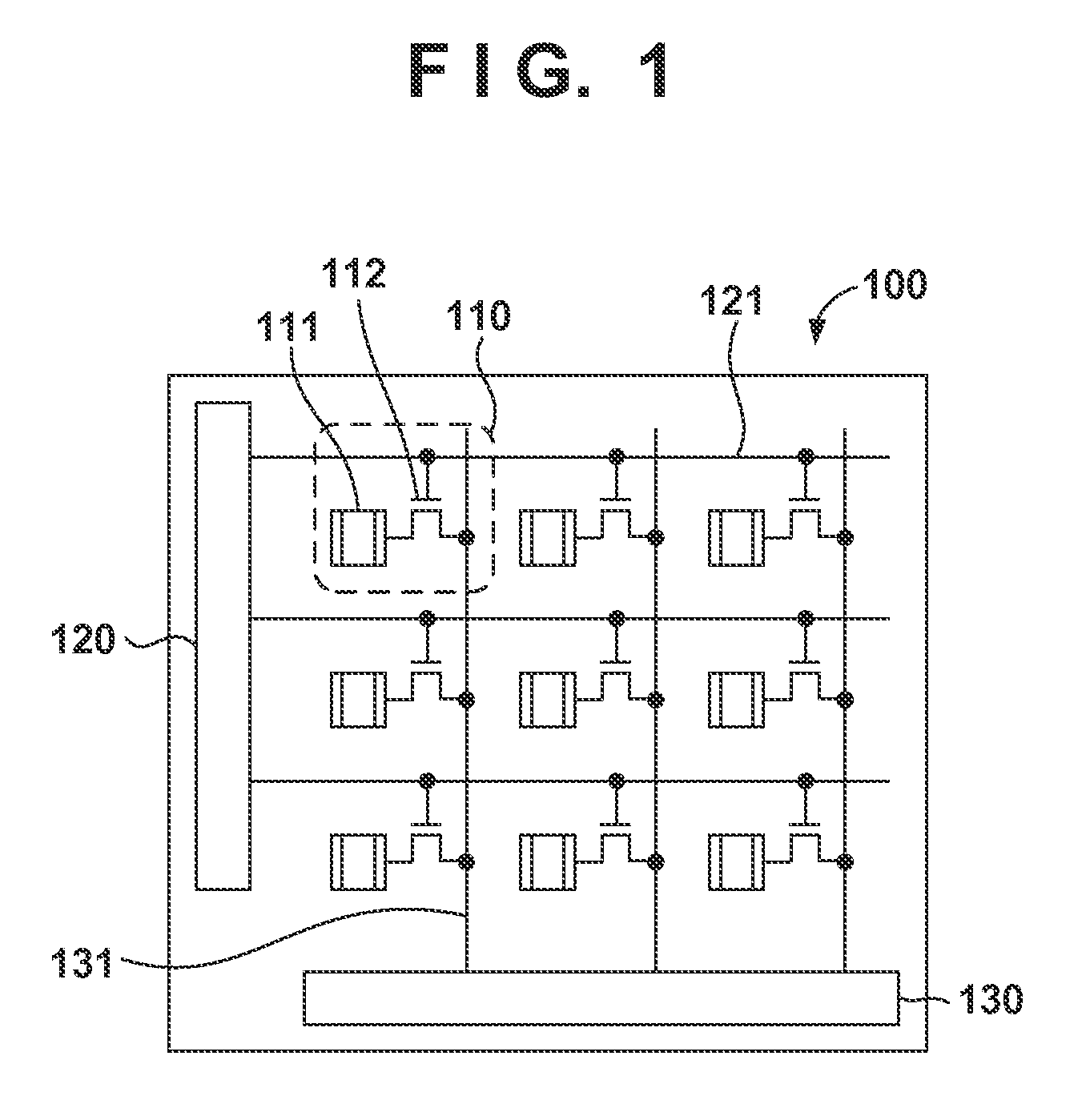

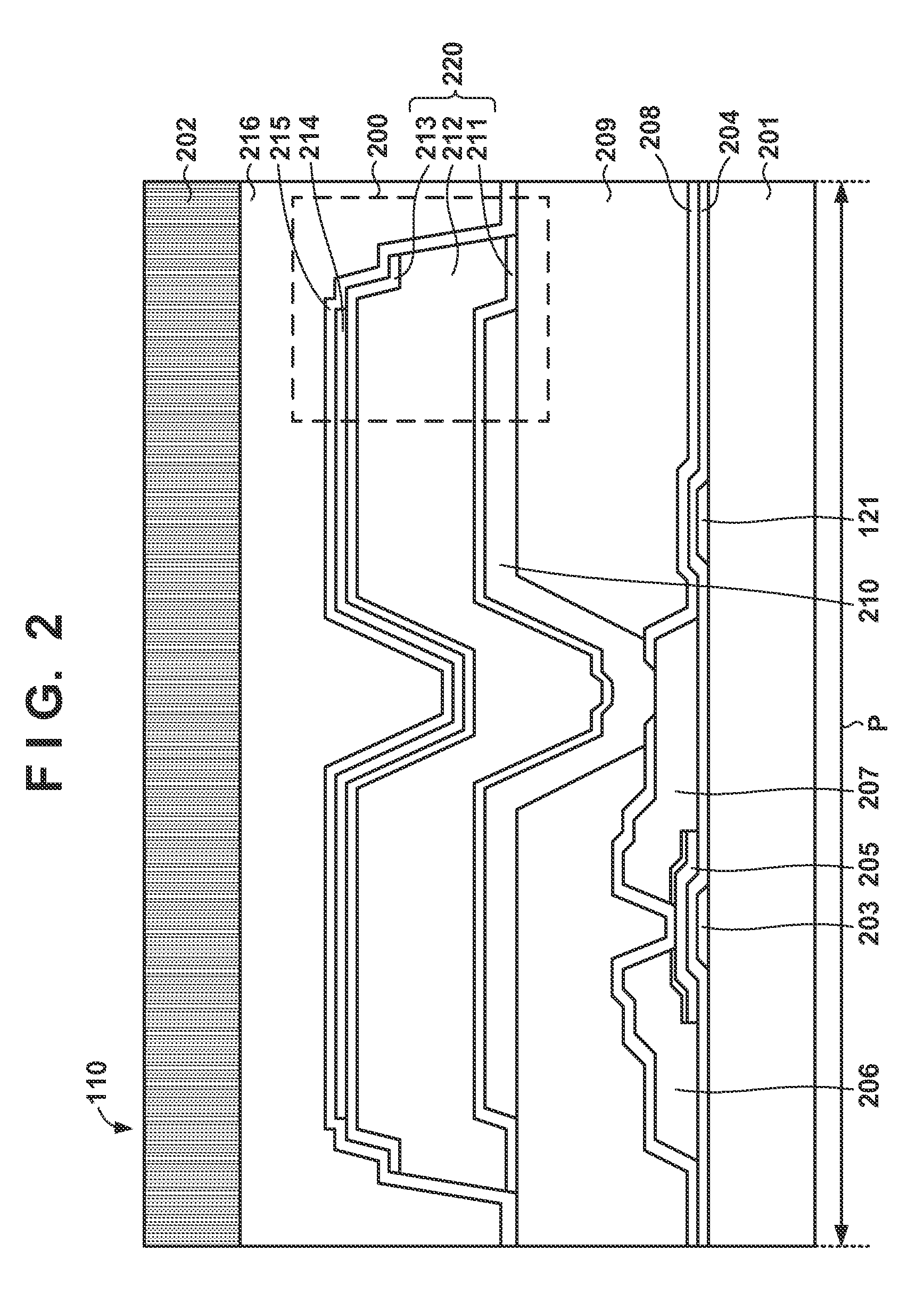

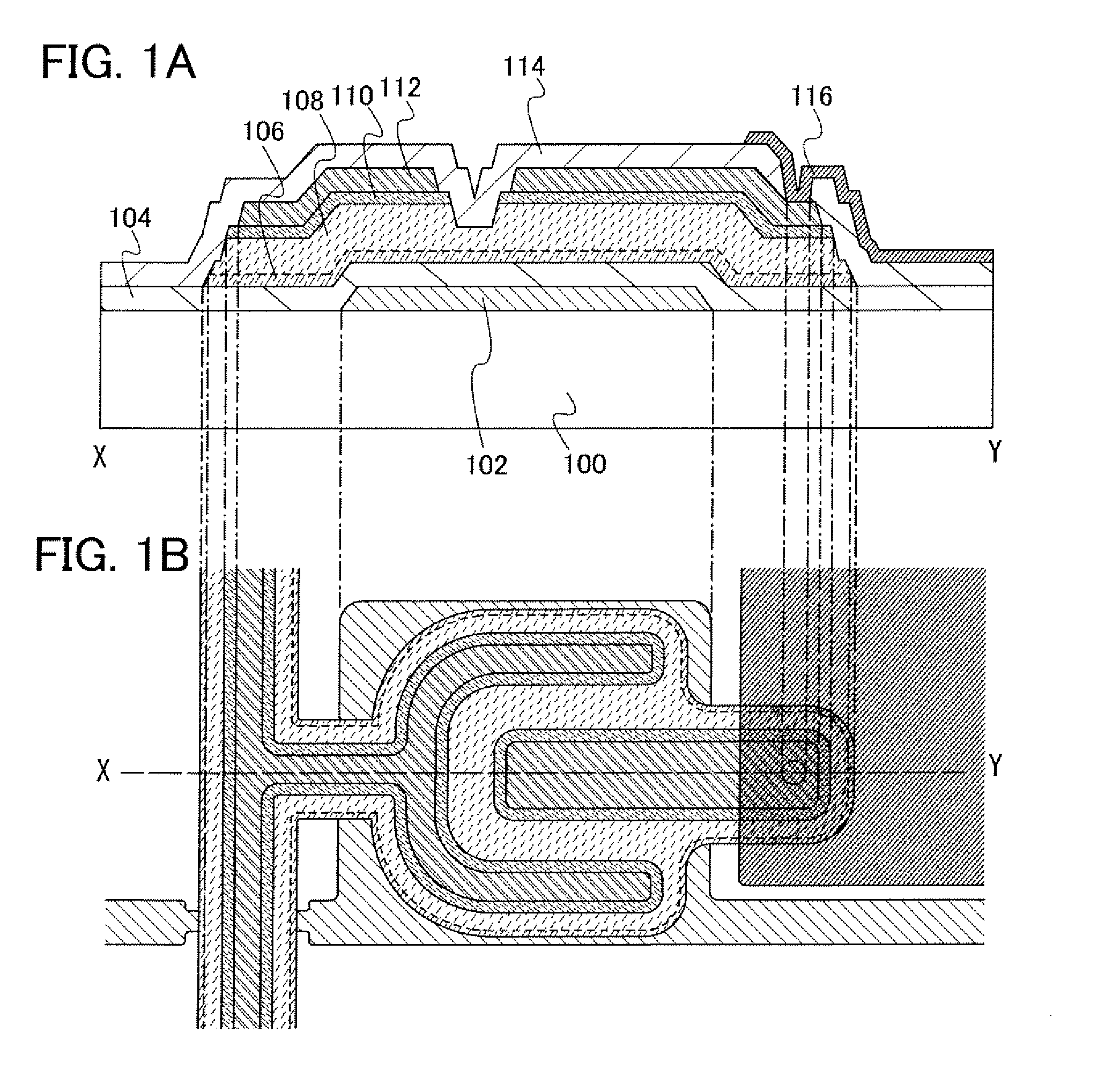

A radiation detection apparatus includes conversion elements including a first electrode, a semiconductor layer, and a second electrode that are divided for each pixel; switching elements electrically connected to the first electrodes; and a first insulating layer that separates the conversion elements of adjacent pixels. The semiconductor layer is located between the first and second electrodes. A periphery of the semiconductor layer is located outside peripheries of the first and second electrodes. The semiconductor layer includes a first impurity semiconductor layer, a second impurity semiconductor layer, and an intrinsic semiconductor layer located between the first and second impurity semiconductor layers. Parameters of the apparatus are defined to set a residual charge 10 μs after the switching element is turned on to be not higher than 2%.

Owner:CANON KK

Thin film transistor

InactiveUS20090267068A1Reduce defect levelIncrease currentTransistorElectric discharge tubesSemiconductor packageImpurity

The thin film transistor includes a gate insulating layer covering a gate electrode, over a substrate having an insulating surface; a semiconductor layer forming a channel formation region, in which a plurality of crystal regions is included in an amorphous structure; an impurity semiconductor layer imparting one conductivity type which forms a source region and a drain region; and a buffer layer formed from an amorphous semiconductor, which is located between the semiconductor layer and the impurity semiconductor layer. The thin film transistor includes the crystal region which includes minute crystal grains and inverted conical or inverted pyramidal grain each of which grows approximately radially from a position away from an interface between the gate insulating layer and the semiconductor layer toward a direction in which the semiconductor layer is deposited in a region which does not reach the impurity semiconductor layer.

Owner:SEMICON ENERGY LAB CO LTD

Thin film transistor and display device including thin film transistor

InactiveUS20090289256A1Improve mobilityImprove switching characteristicsTransistorSolid-state devicesDisplay deviceOxygen

Owner:SEMICON ENERGY LAB CO LTD

Display device and electronic device having the display device, and method for manufacturing thereof

InactiveUS8013338B2Reduce yieldTransistorSemiconductor/solid-state device manufacturingDisplay deviceEngineering

To provide a display device including a thin film transistor in which high electric characteristics and reduction in off-current can be achieved. The display device having a thin film transistor includes a substrate, a gate electrode provided over the substrate, a gate insulating film provided over the gate electrode, a microcrystalline semiconductor film provided over the gate electrode with the gate insulating film interposed therebetween, a channel protection layer which is provided over and in contact with the microcrystalline semiconductor film, an amorphous semiconductor film provided over the gate insulating film and on a side surface of the microcrystalline semiconductor film and the channel protection layer, an impurity semiconductor layer provided over the amorphous semiconductor film, and a source electrode and a drain electrode provided over and in contact with the impurity semiconductor layer. The thickness of the amorphous semiconductor film is larger than that of the microcrystalline semiconductor film.

Owner:SEMICON ENERGY LAB CO LTD

Method For Manufacturing EL Display Device

InactiveUS20090224249A1Reduce manufacturing stepsReduce in quantityElectroluminescent light sourcesSolid-state devicesResistEtching

A manufacture process of a thin film transistor mounted on an EL display device is simplified. A thin film transistor is manufactured by stacking a first conductive film, an insulating film, a semiconductor film, an impurity semiconductor film, and a second conductive film; forming a first resist mask over the stacked films; performing first etching to form a thin-film stack body; performing second etching by side etching is conducted on the thin-film stack body to form a gate electrode layer; and forming a source and drain electrode layer and the like with use of a second resist mask. An EL display device is manufactured using the thin film transistor.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device including bipolar transistor and buried conductive region

InactiveUS6943428B2Increase resistanceIncrease valueTransistorSolid-state devicesElectrical resistance and conductanceHigh resistance

A semiconductor device and a method for manufacturing the device using a semiconductor substrate of a high resistance with improved Q value of a passive circuit element. Leakage current due to an impurity fluctuation, in the high resistance semiconductor substrate and noise resistance of an active element in the high resistance semiconductor substrate are improved. The semiconductor device includes a bipolar transistor at a main surface of and in the semiconductor substrate. The bipolar transistor includes a semiconductor layer of a first conductivity type at a bottom portion of the bipolar transistor and the semiconductor device includes a buried layer of a second conductivity type, located in the semiconductor substrate and facing the semiconductor layer of the first conductivity type.

Owner:MITSUBISHI ELECTRIC CORP

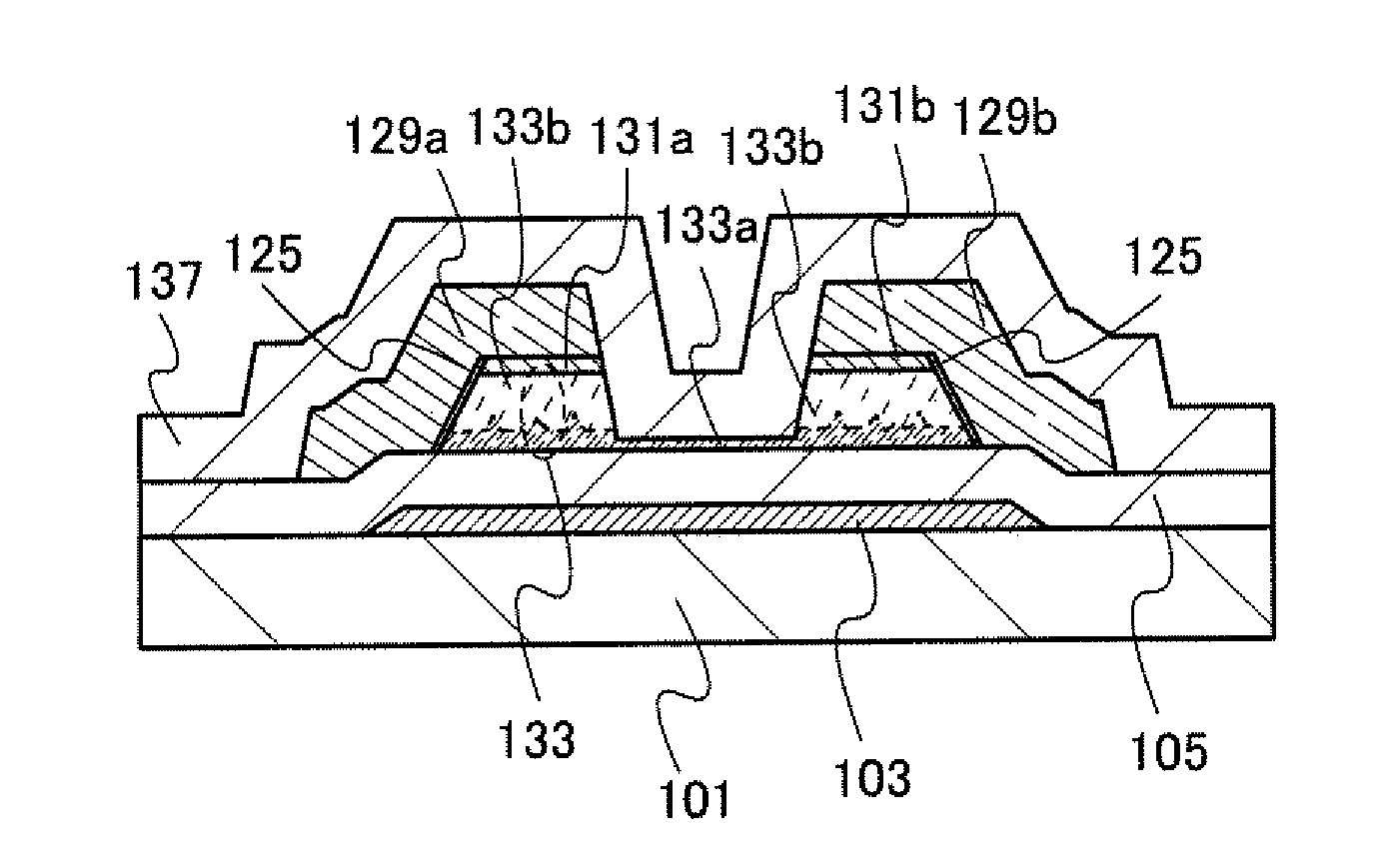

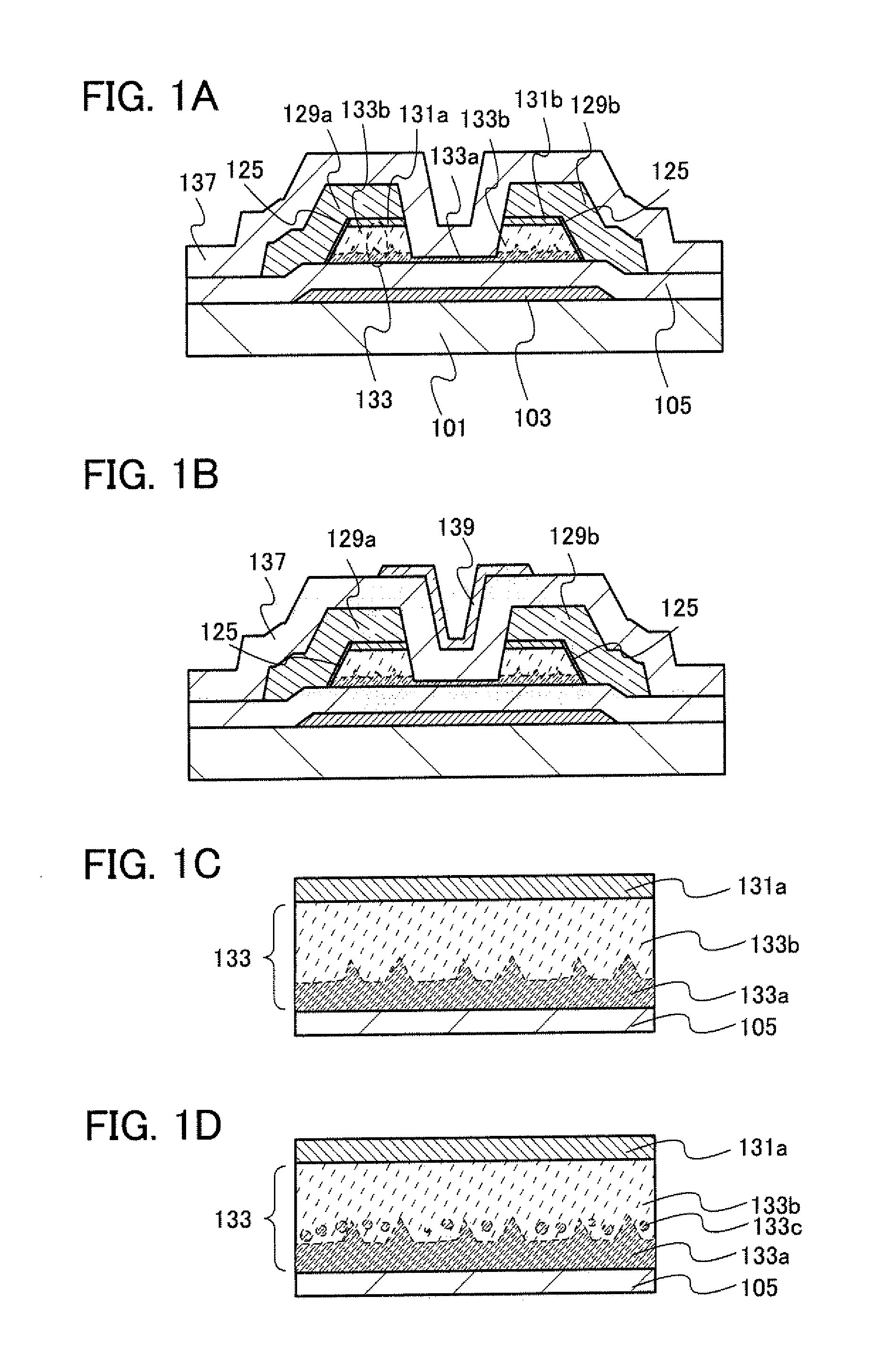

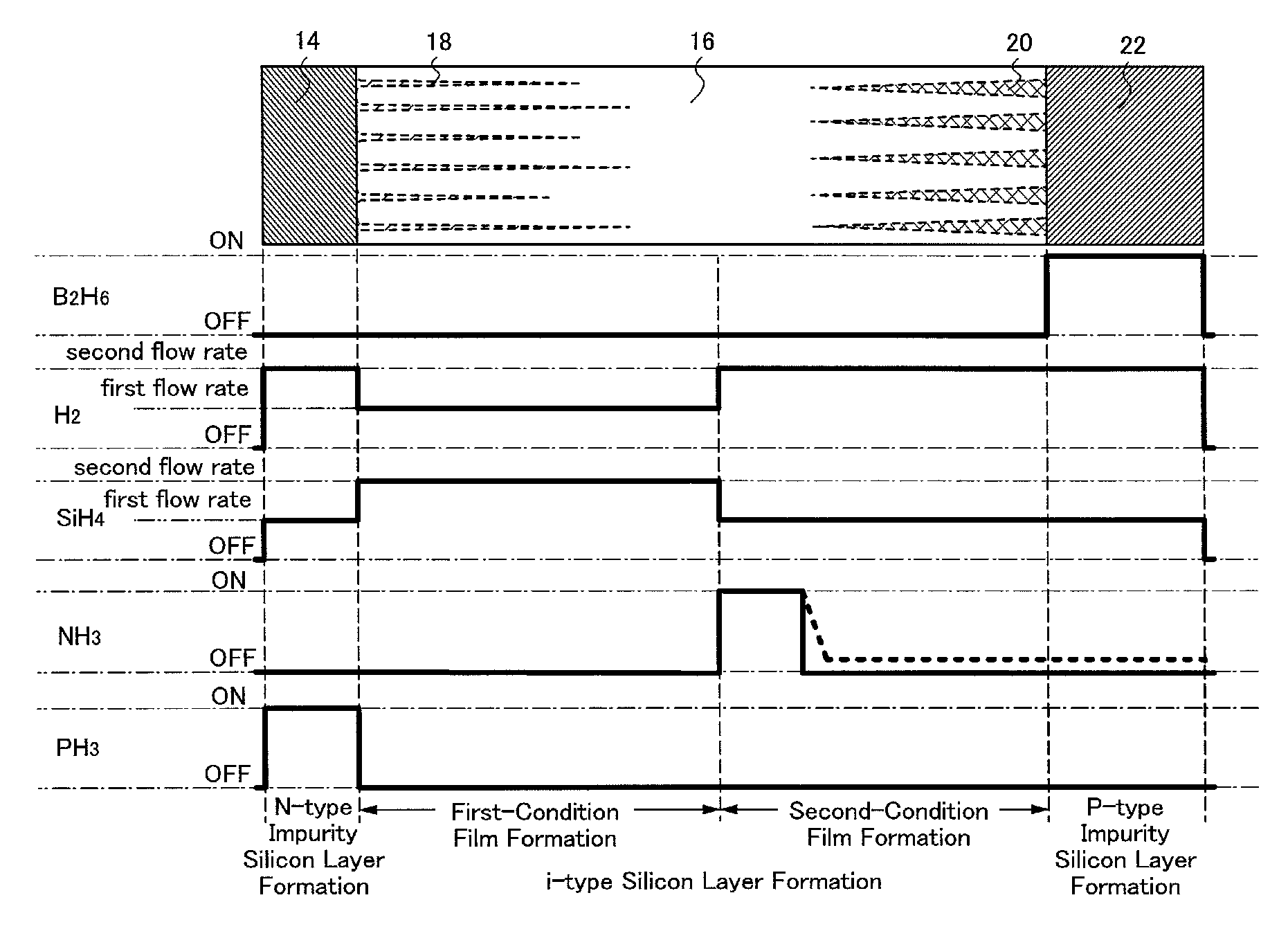

Photoelectric conversion device and manufacturing method thereof

InactiveUS20090277504A1Simple manufacturing processLow costSemiconductor/solid-state device manufacturingPhotovoltaic energy generationProduction ratePhotoelectric conversion

Higher conversion efficiency and productivity of photoelectric conversion devices. A semiconductor layer including a first and second crystal regions grown in the layer-deposition direction is provided between an impurity semiconductor layer containing an impurity element imparting one conductivity type and an impurity semiconductor layer containing an impurity element imparting a conductivity type opposite to the one conductivity type. The first crystal region is grown from the interface between one of the impurity semiconductor layers and the semiconductor layer. The second crystal region is grown toward the interface between the semiconductor layer and the other of the impurity semiconductor layers from a position which is away from the interface between the one of the impurity semiconductor layers and the semiconductor layer. The semiconductor layer including the first and second crystal regions which exist in an amorphous structure forms the main part of a region for photoelectric conversion.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com