Patents

Literature

56results about How to "Suppress roughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

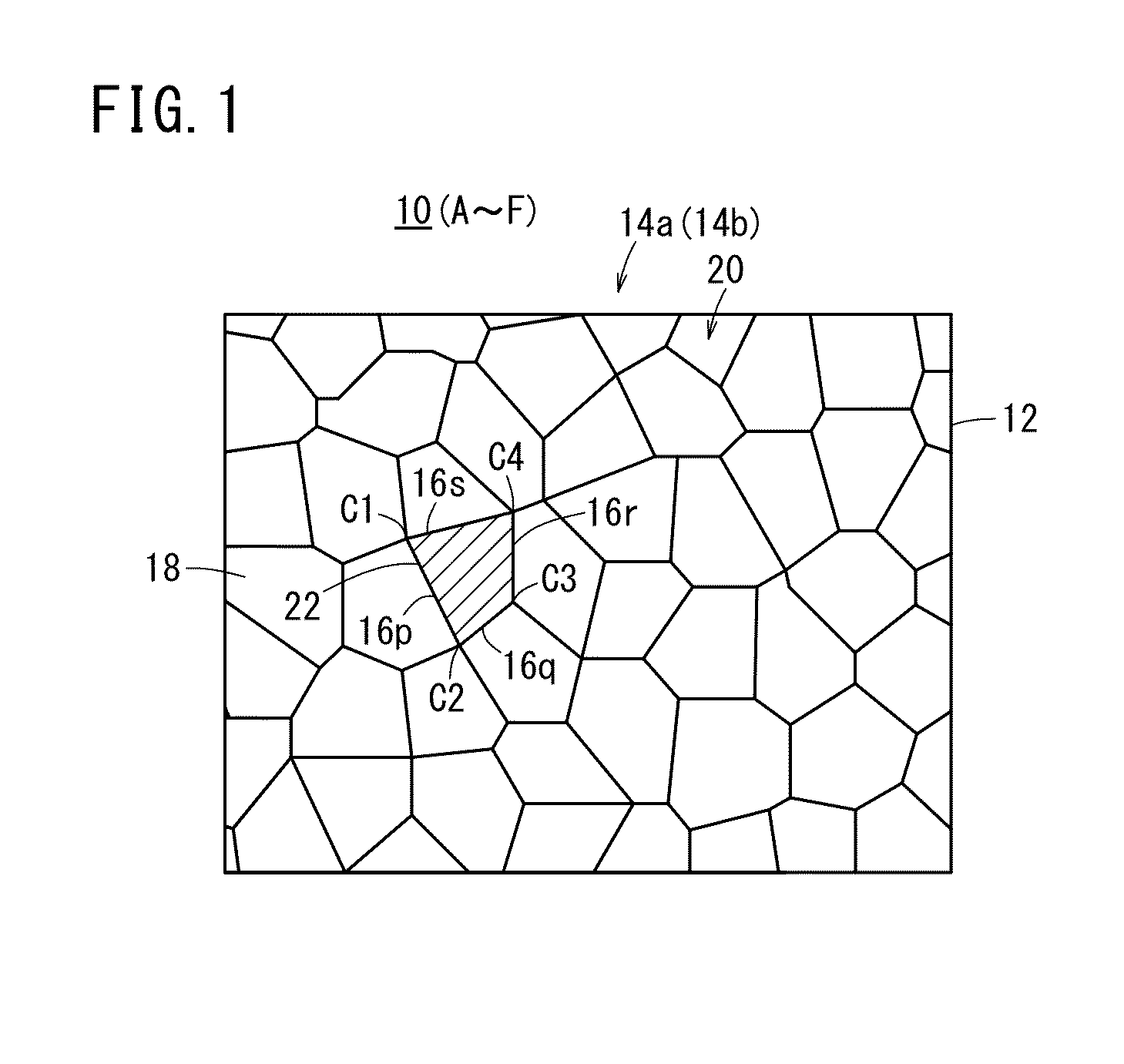

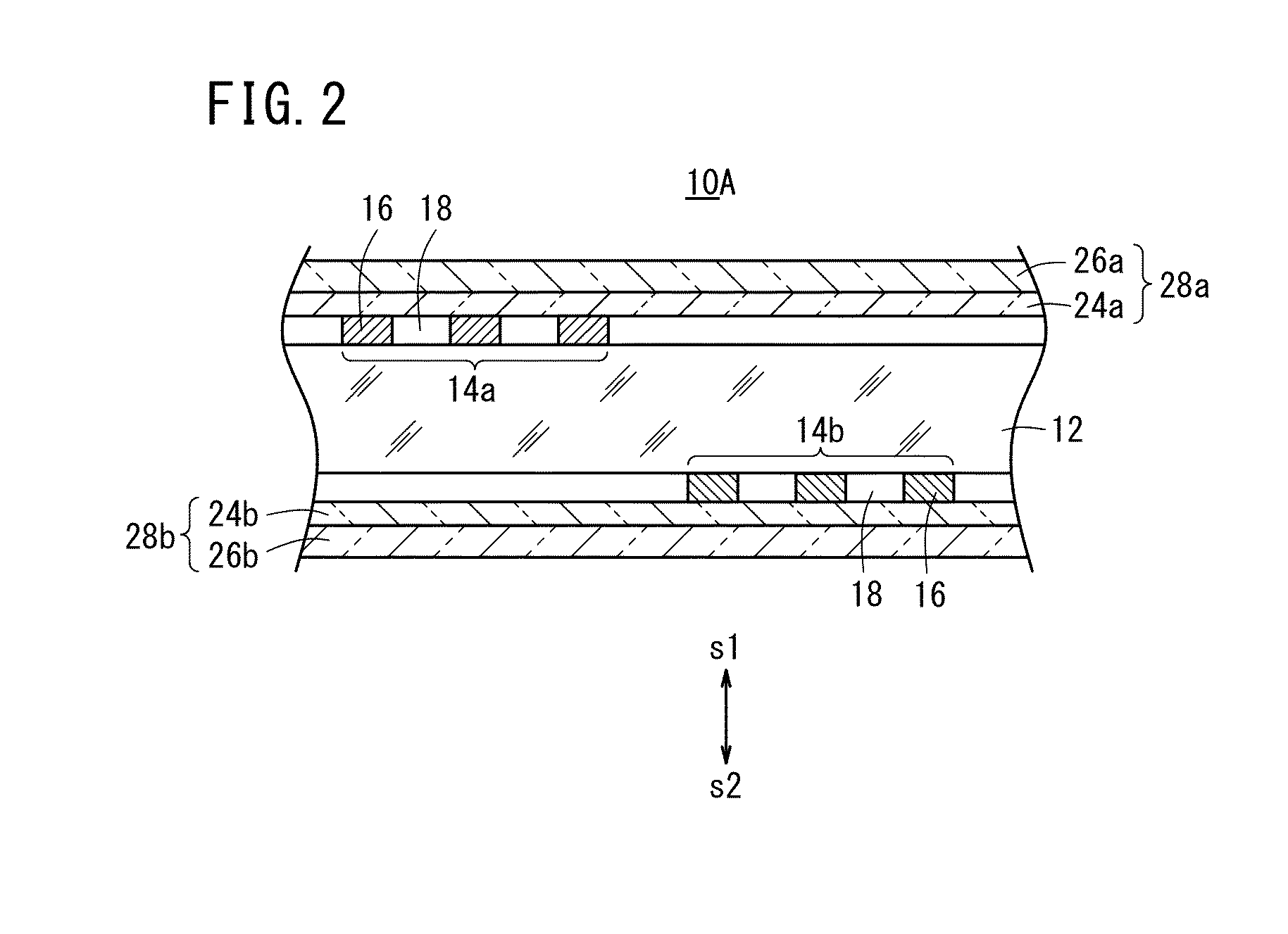

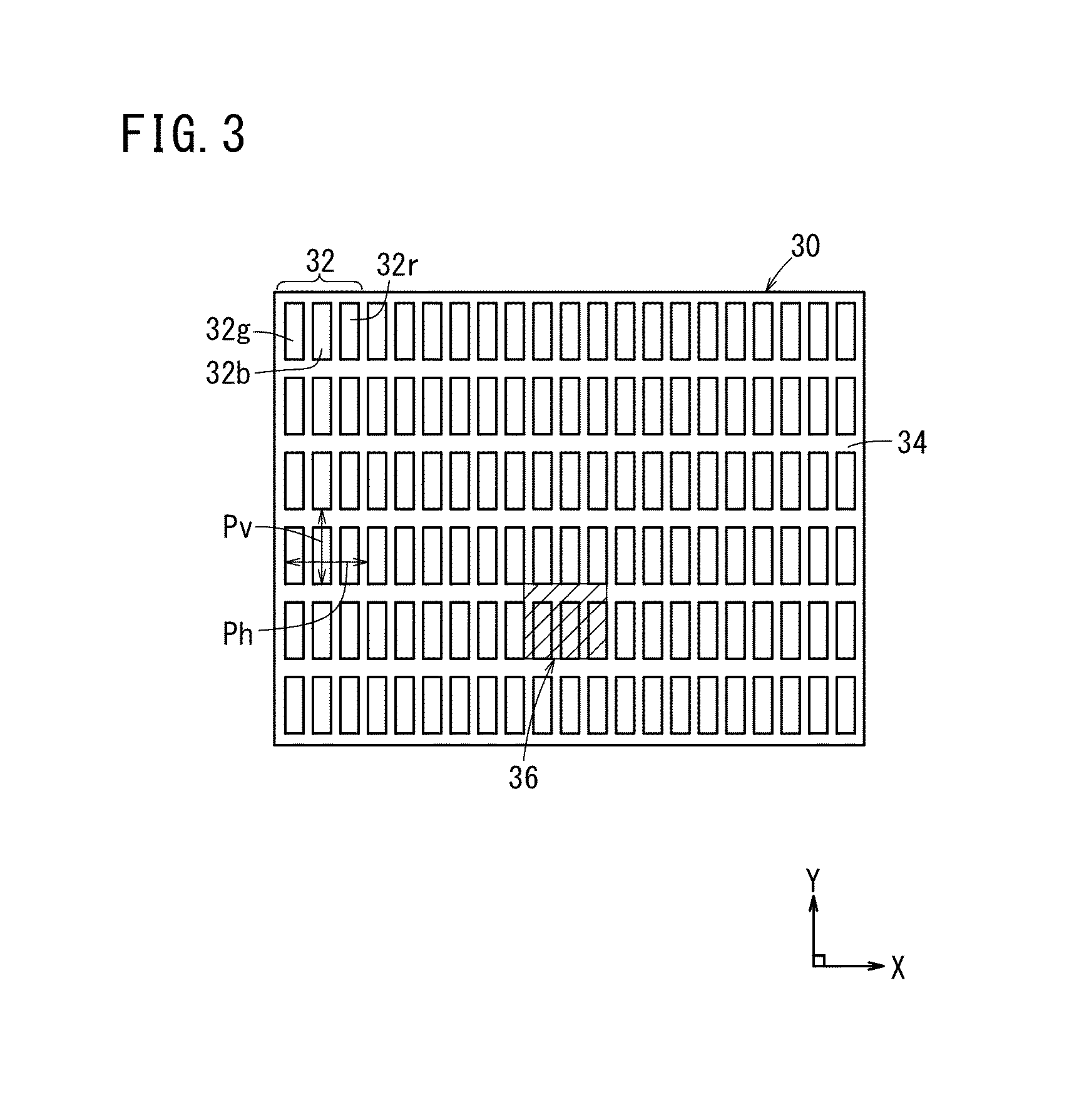

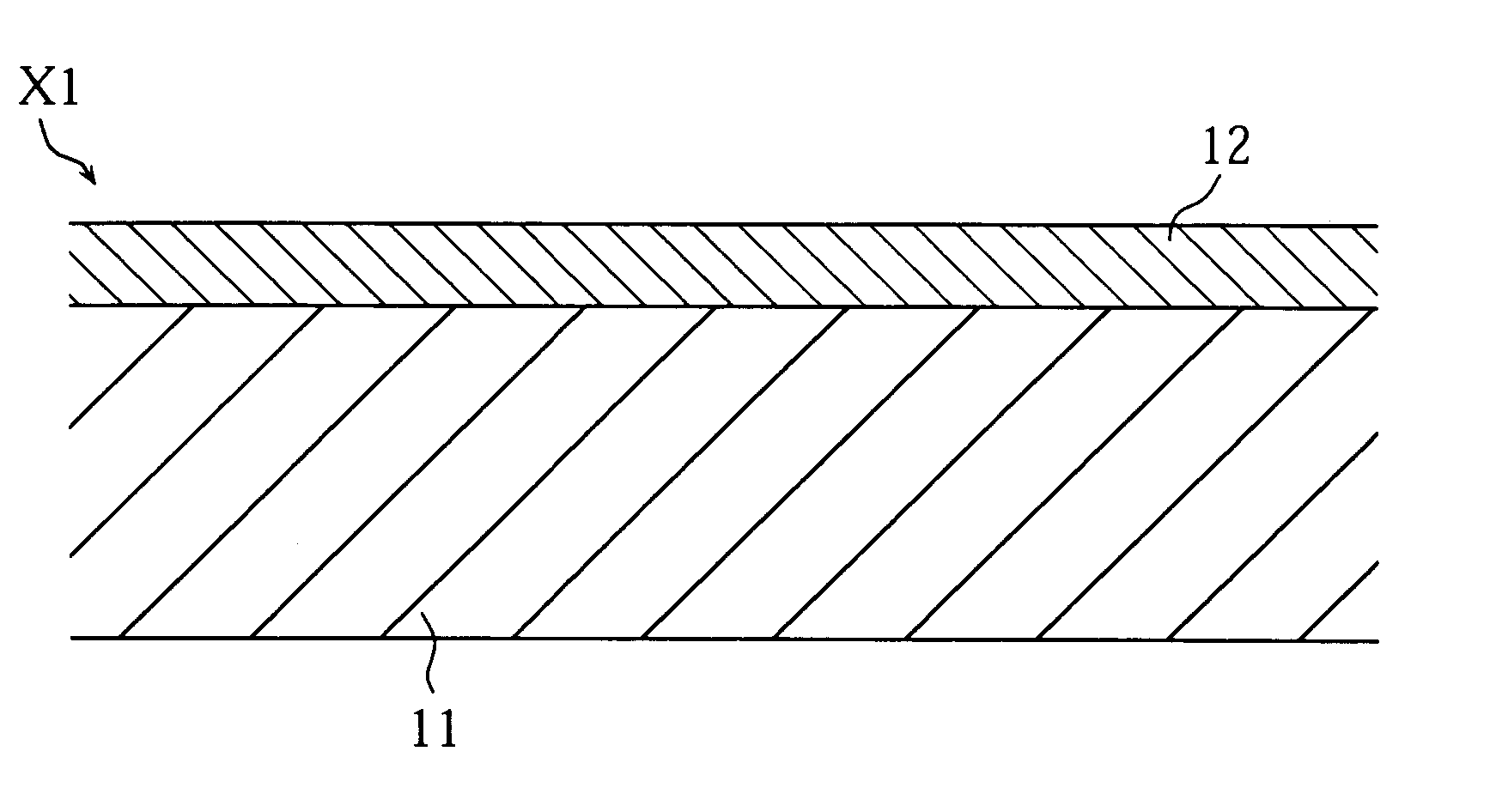

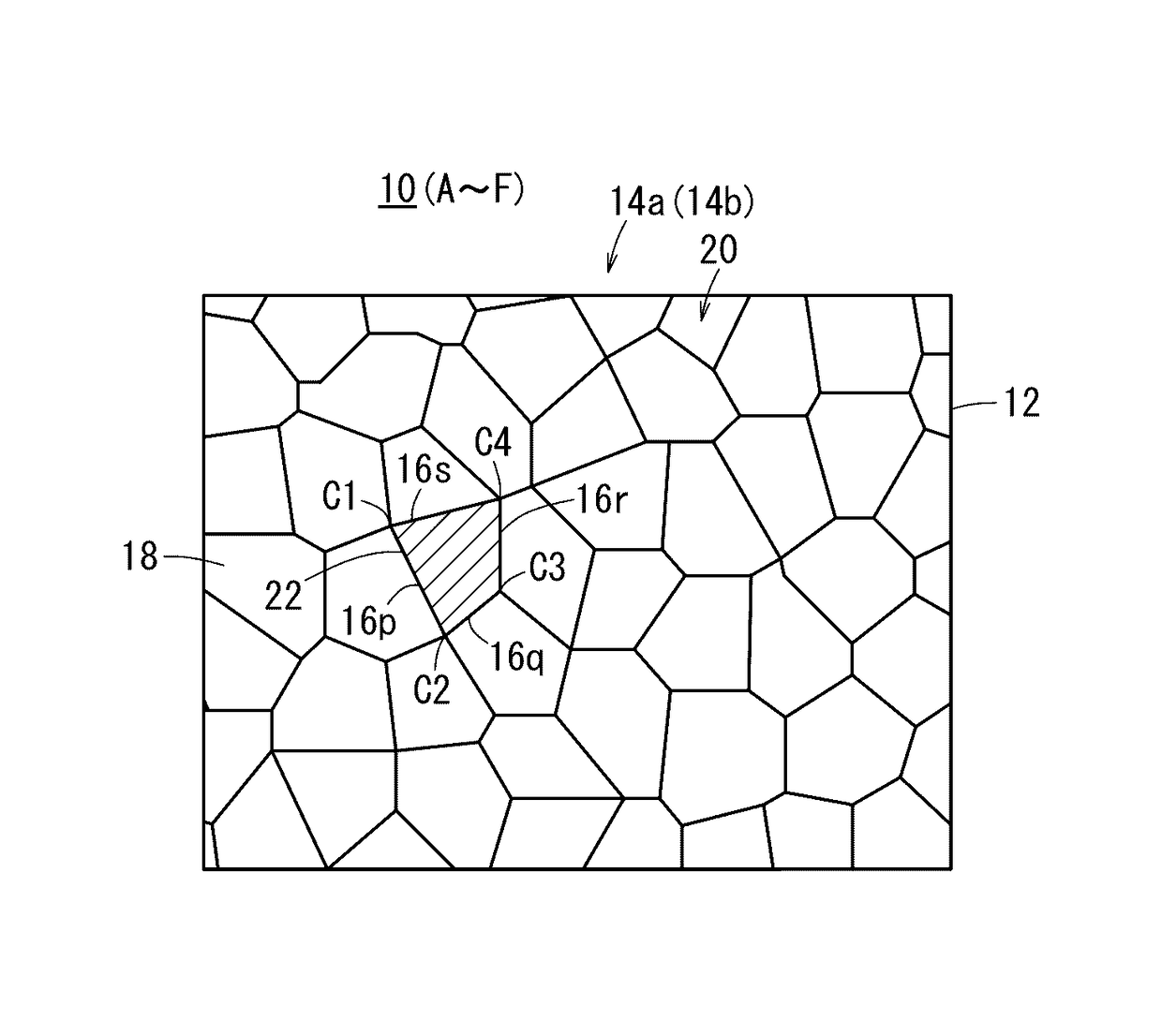

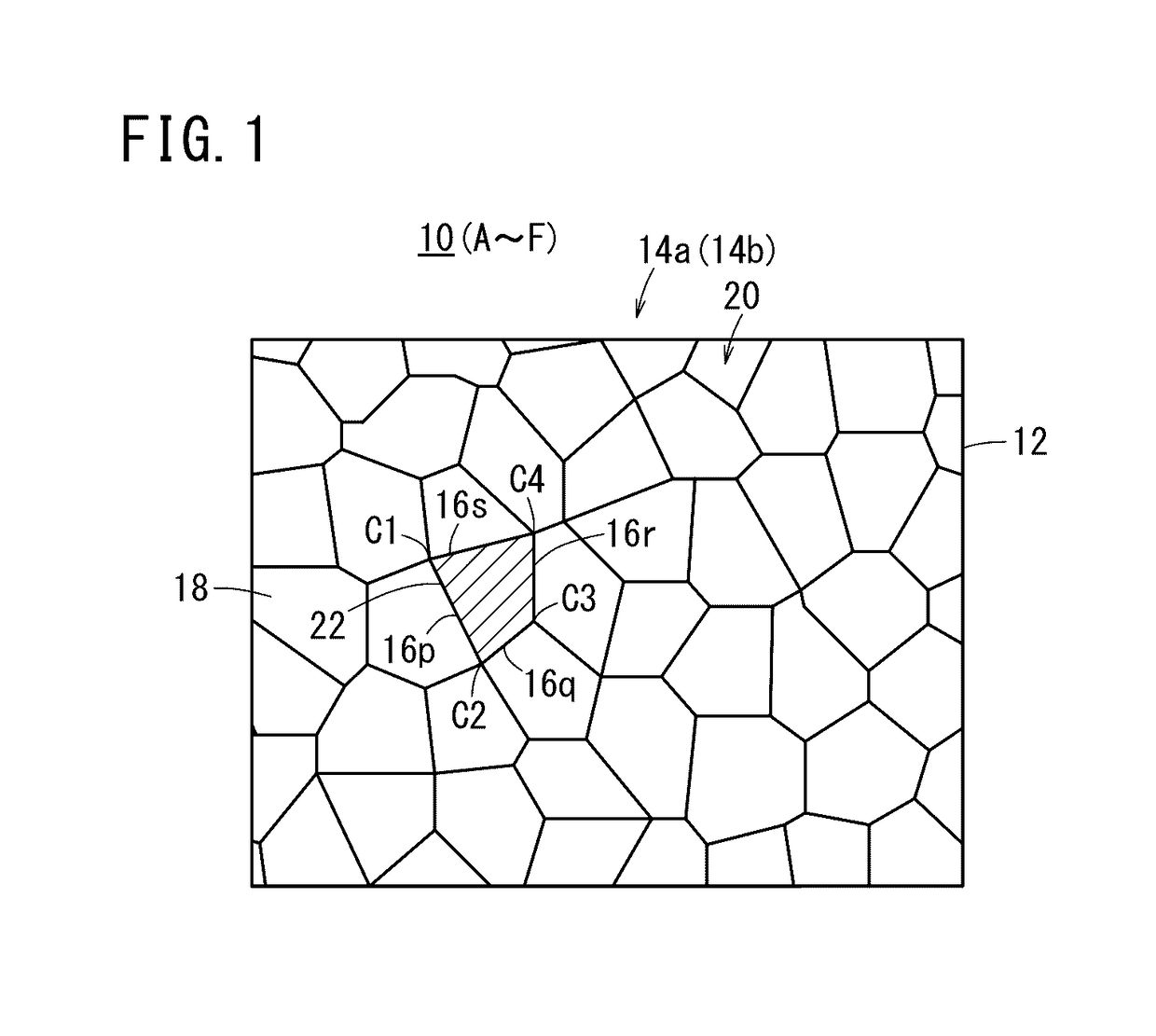

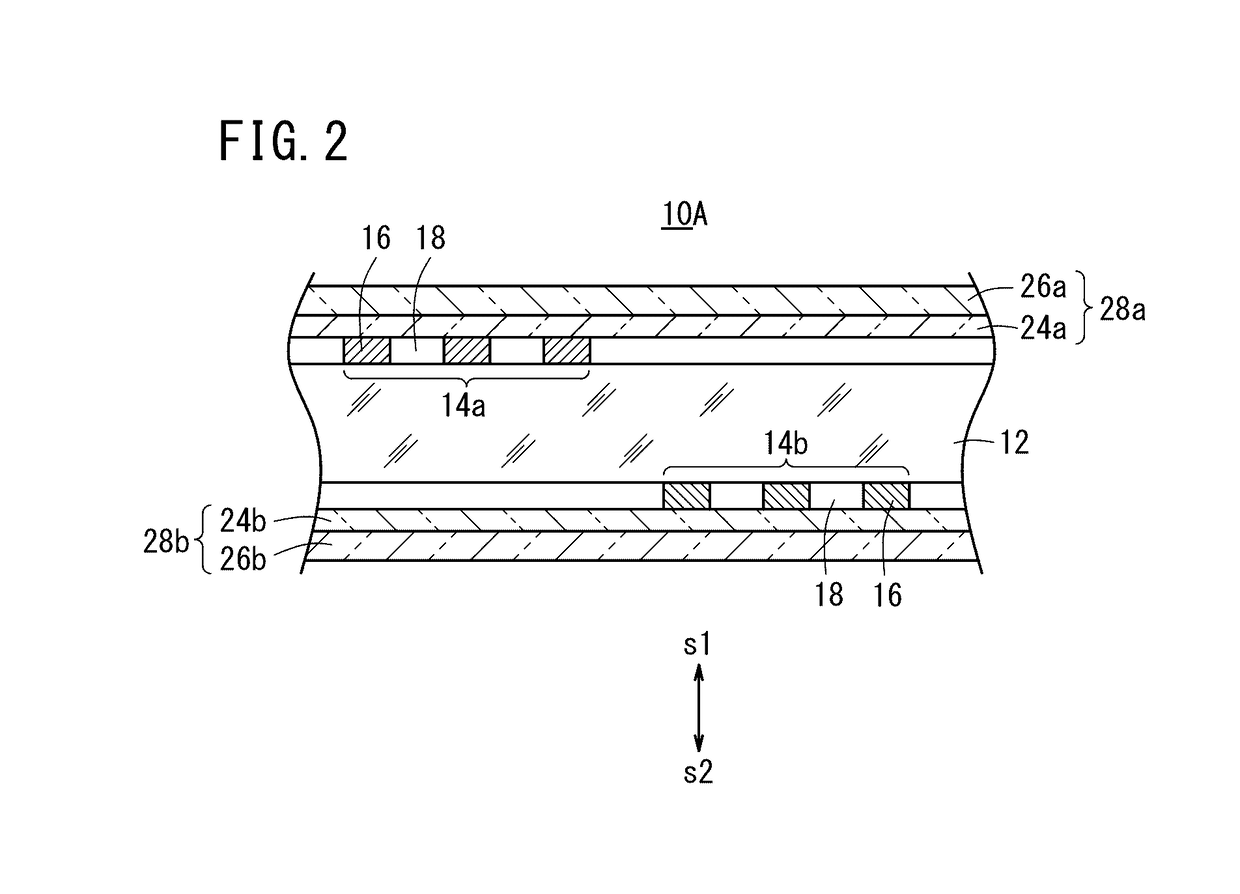

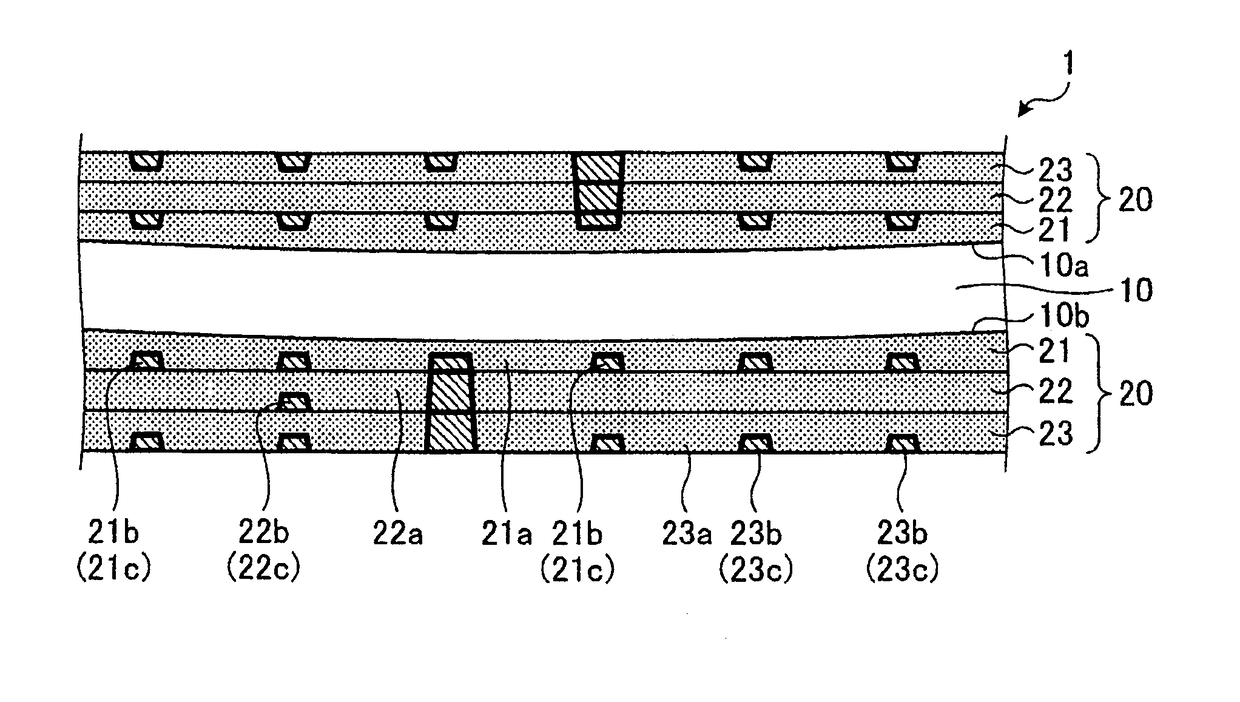

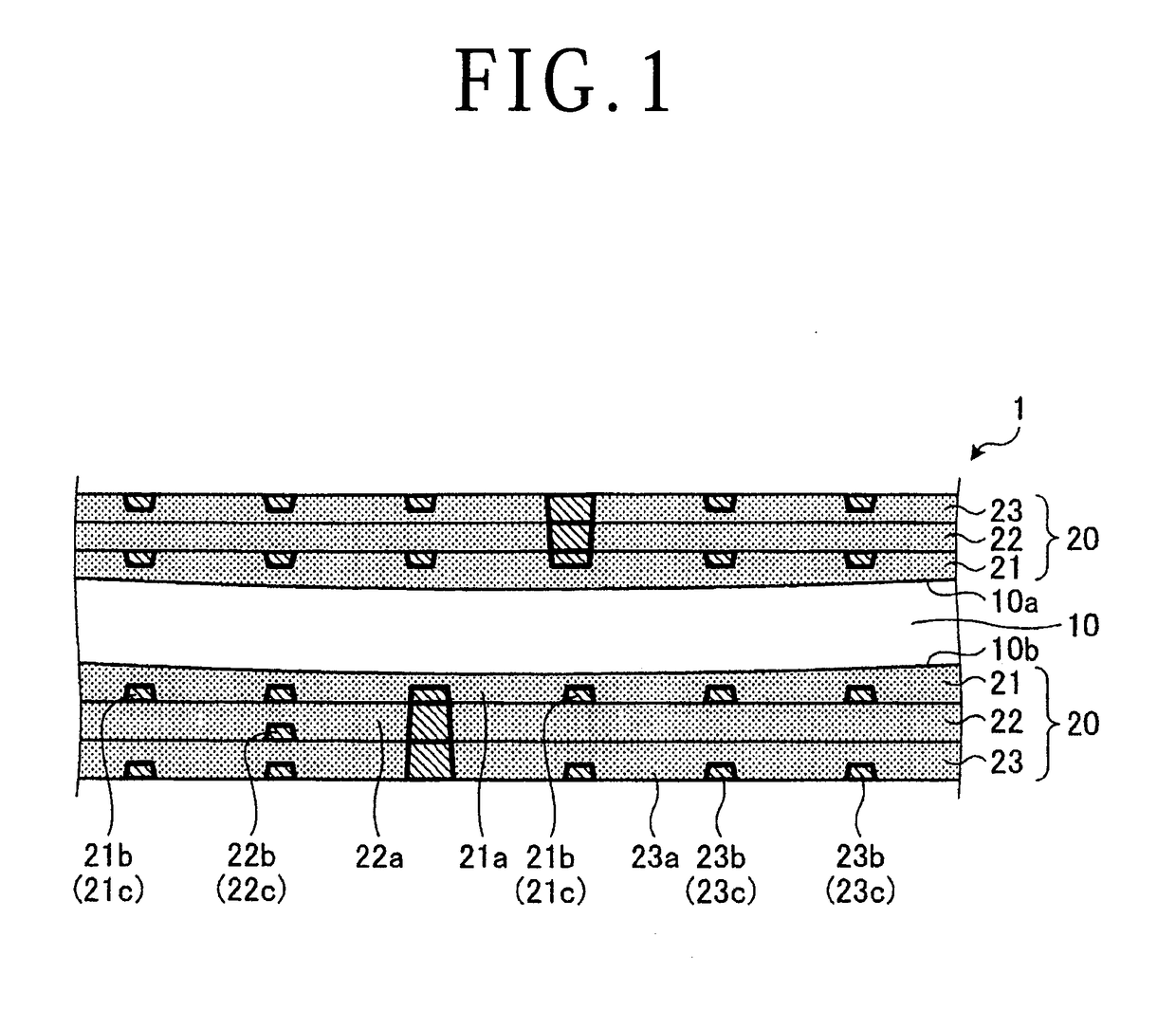

Conductive sheet, touch panel, display device, method for producing said conductive sheet, and non-transitory recording medium

ActiveUS20140111711A1Easy to seeIncrease the differenceConductive layers on insulating-supportsDigital data processing detailsRelative refractive indexDisplay device

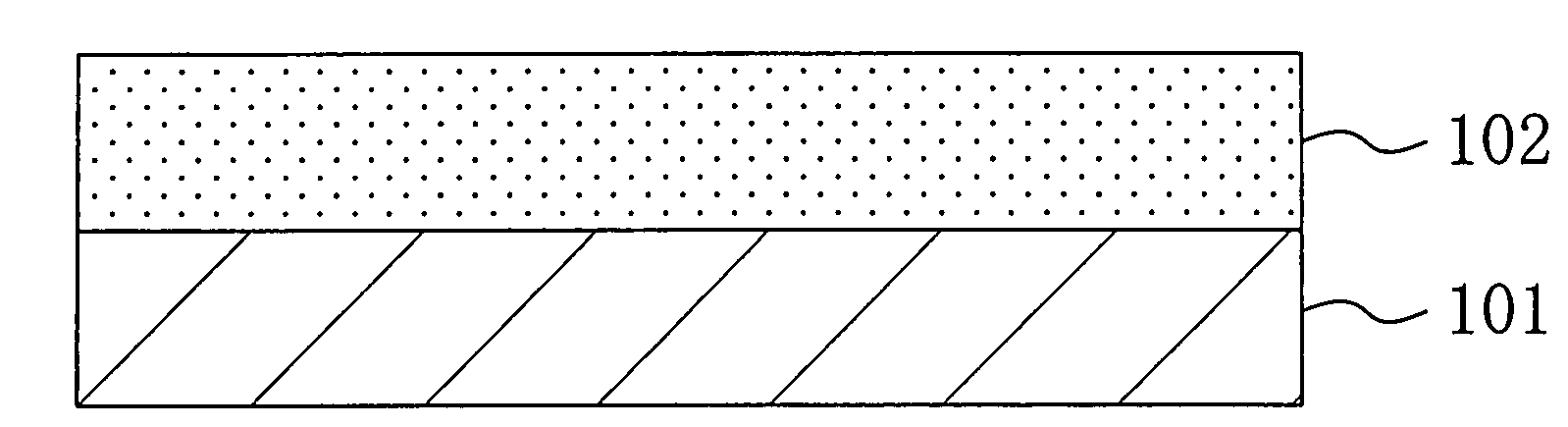

The present invention pertains to: a conductive sheet, a touch panel, a display device, a method for producing the conductive sheet, and a recording medium. In the present invention, the relative refractive index of a substrate with respect to a first protective layer, and / or the relative refractive index of the substrate with respect to a second protective layer is 0.86-1.15. The relative refractive index of a first substrate with respect to the first protective layer, and / or the relative refractive index of a second substrate with respect to the second protective layer is 0.86-1.15.

Owner:FUJIFILM CORP

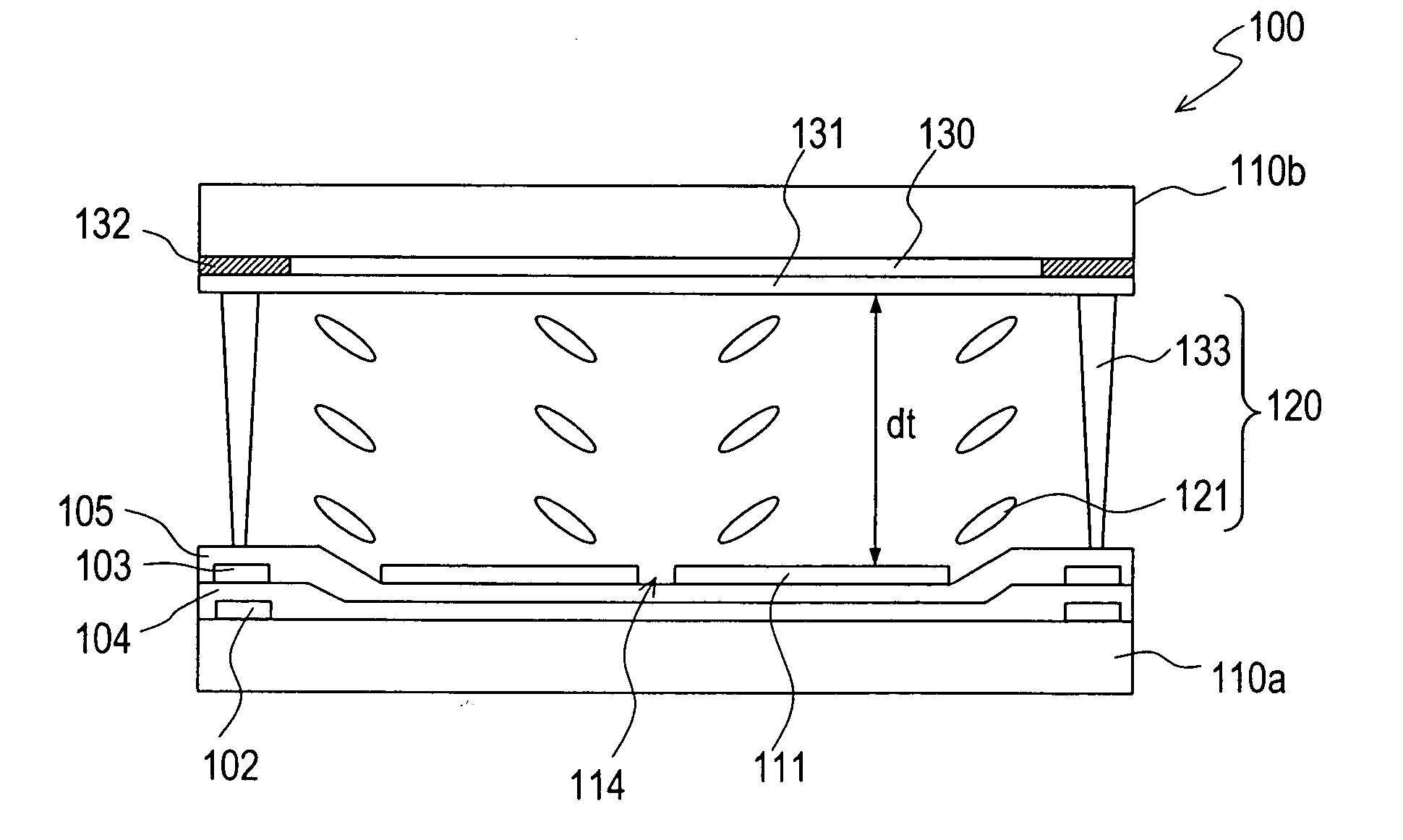

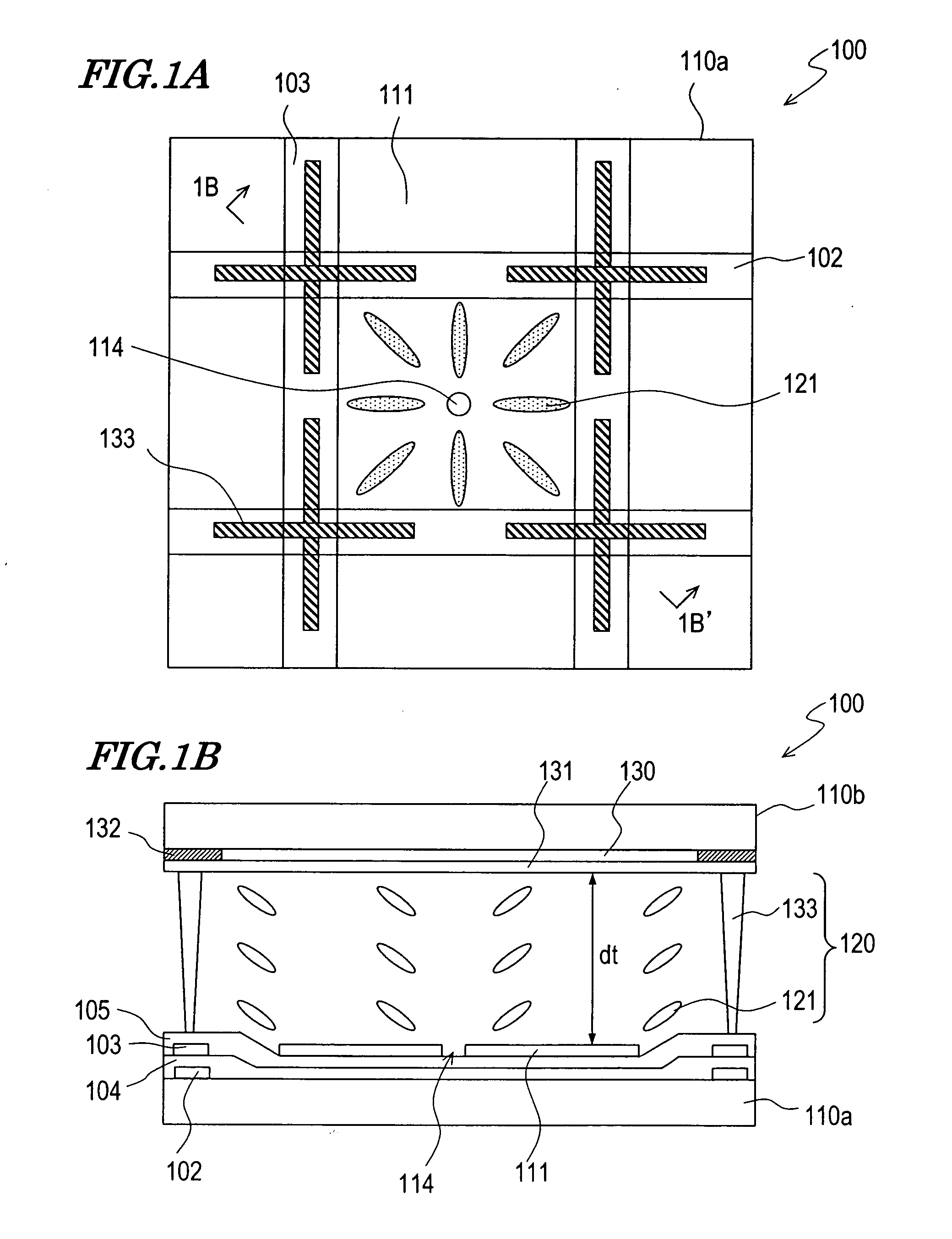

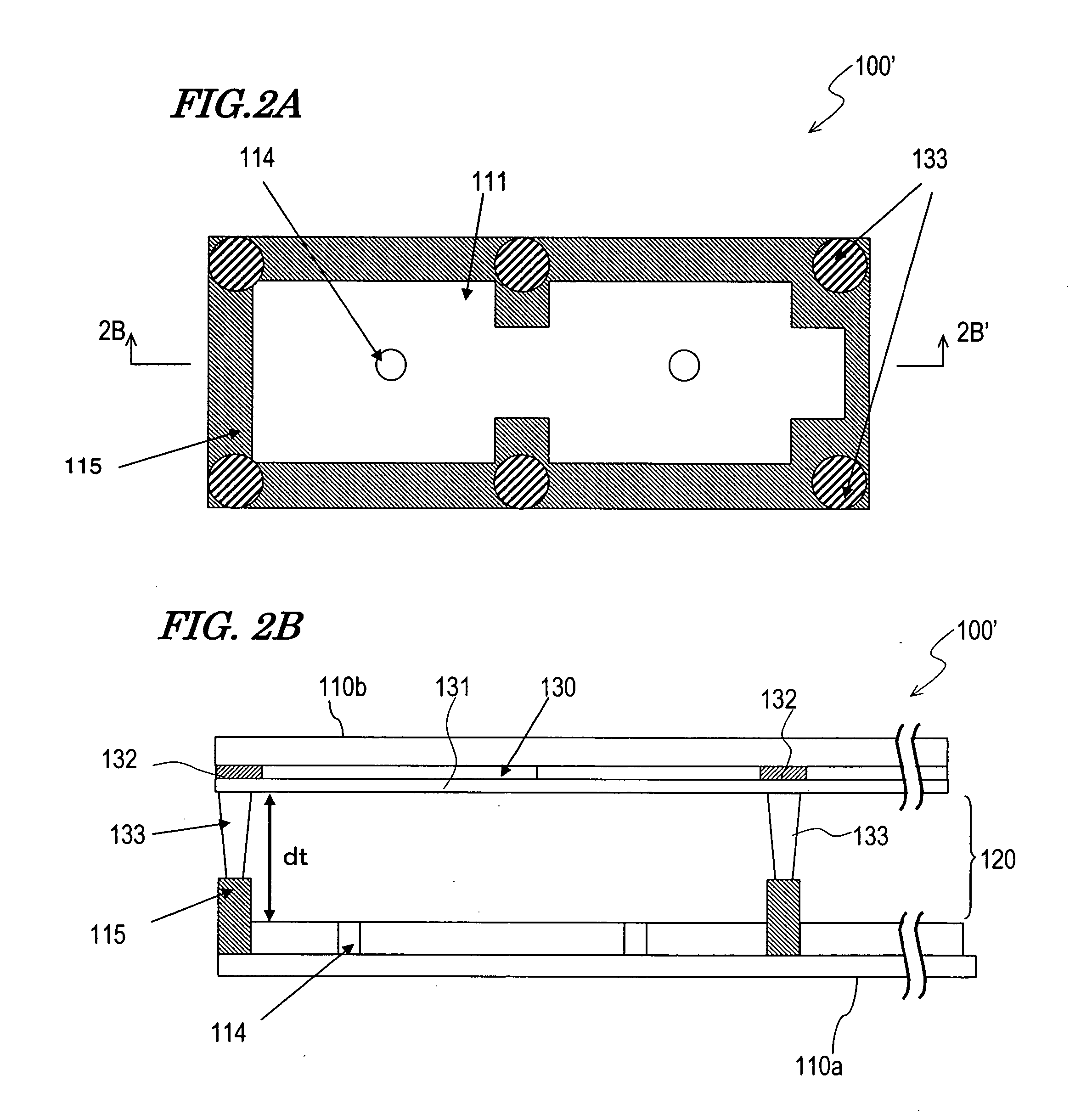

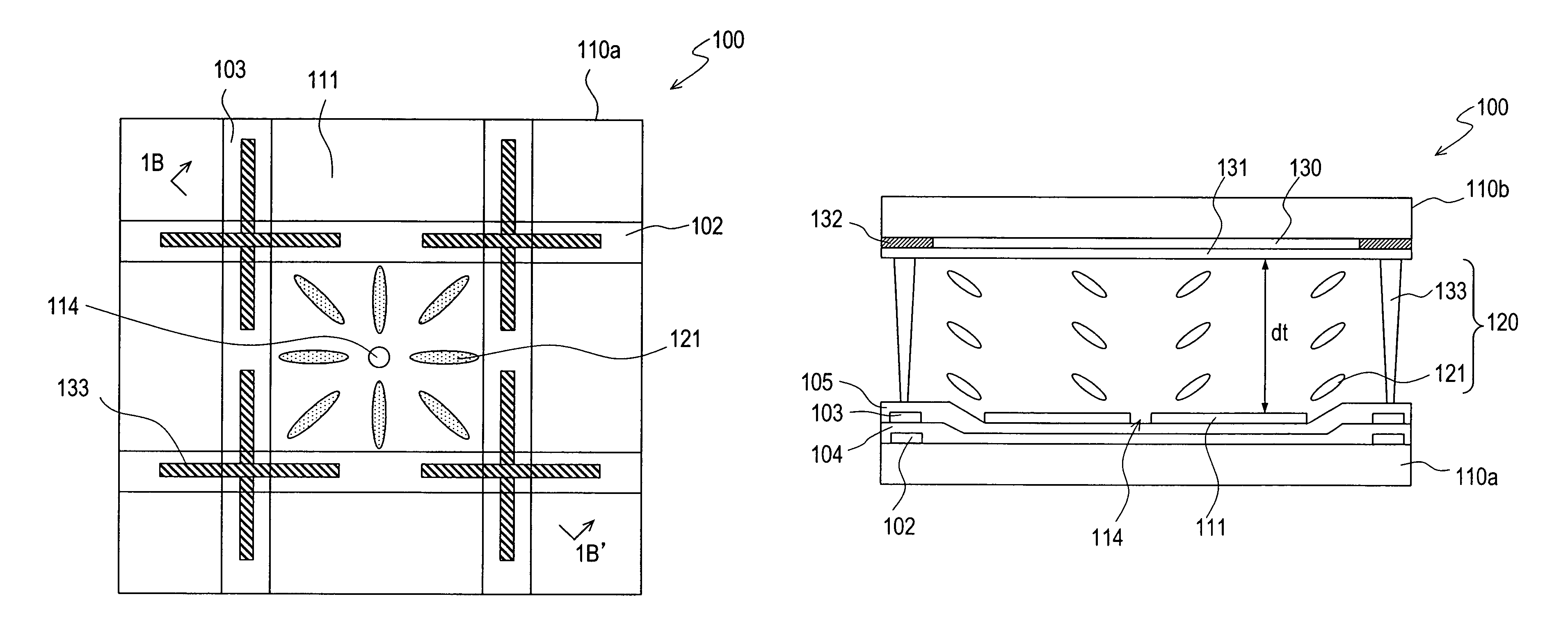

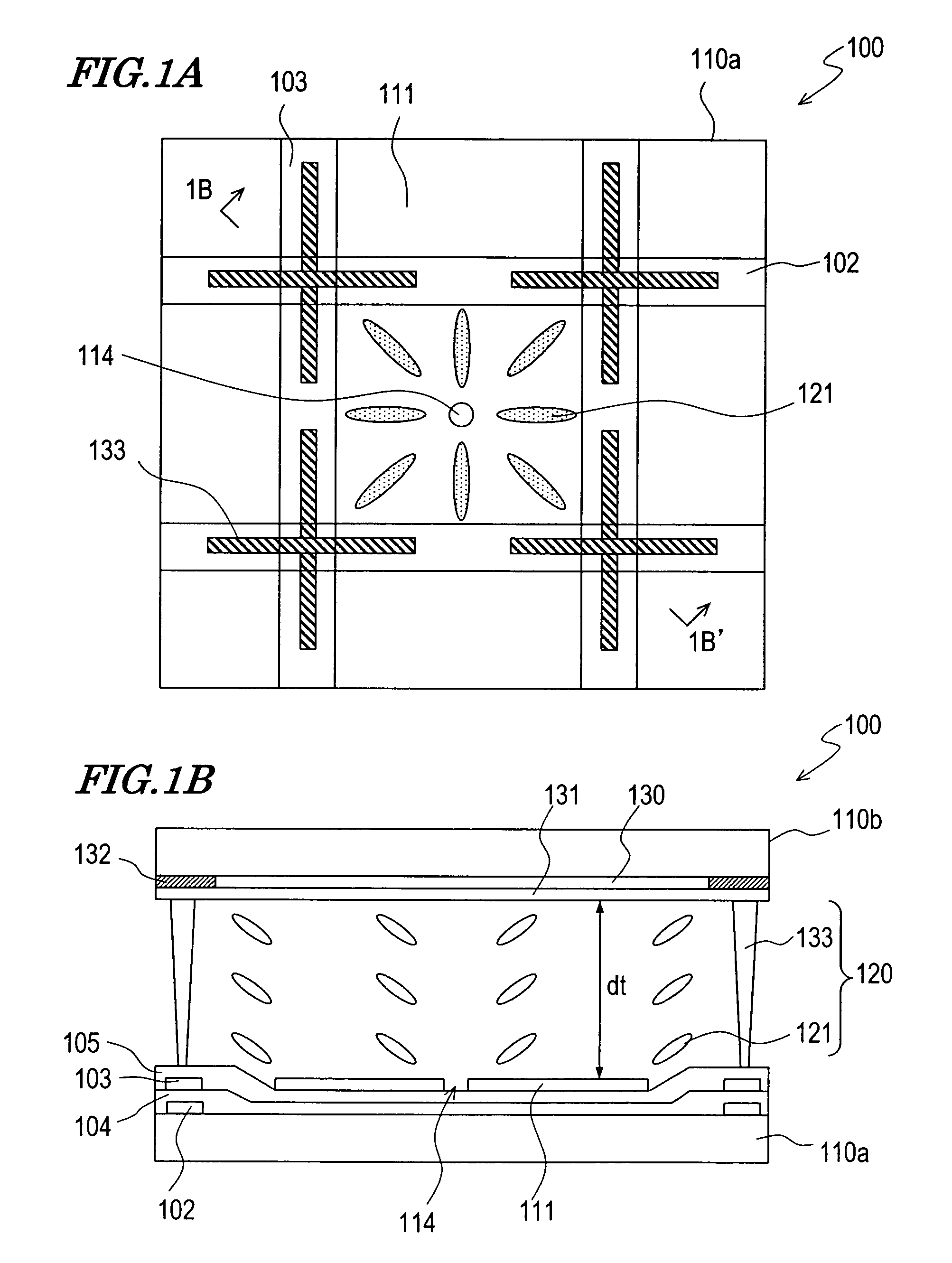

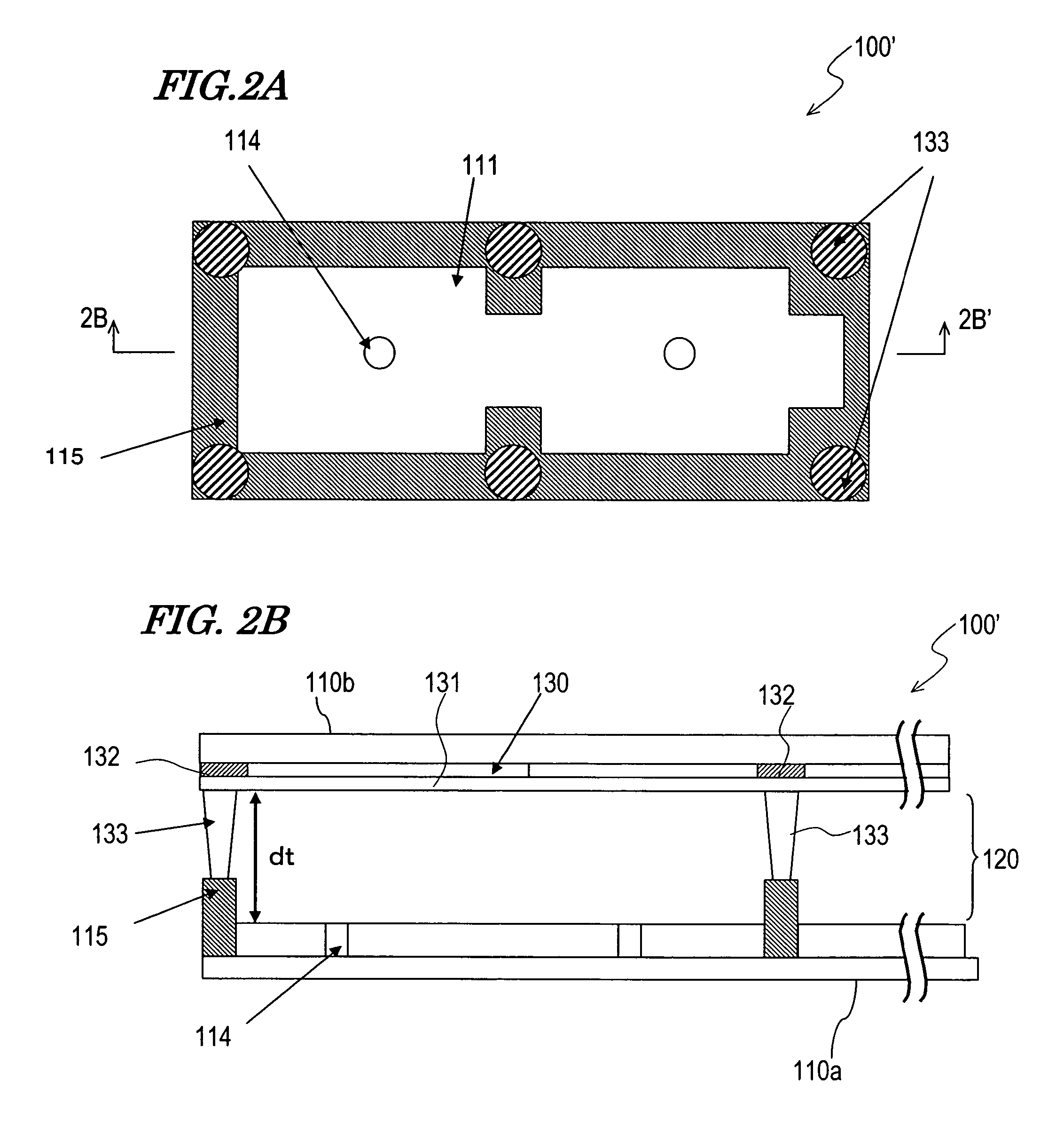

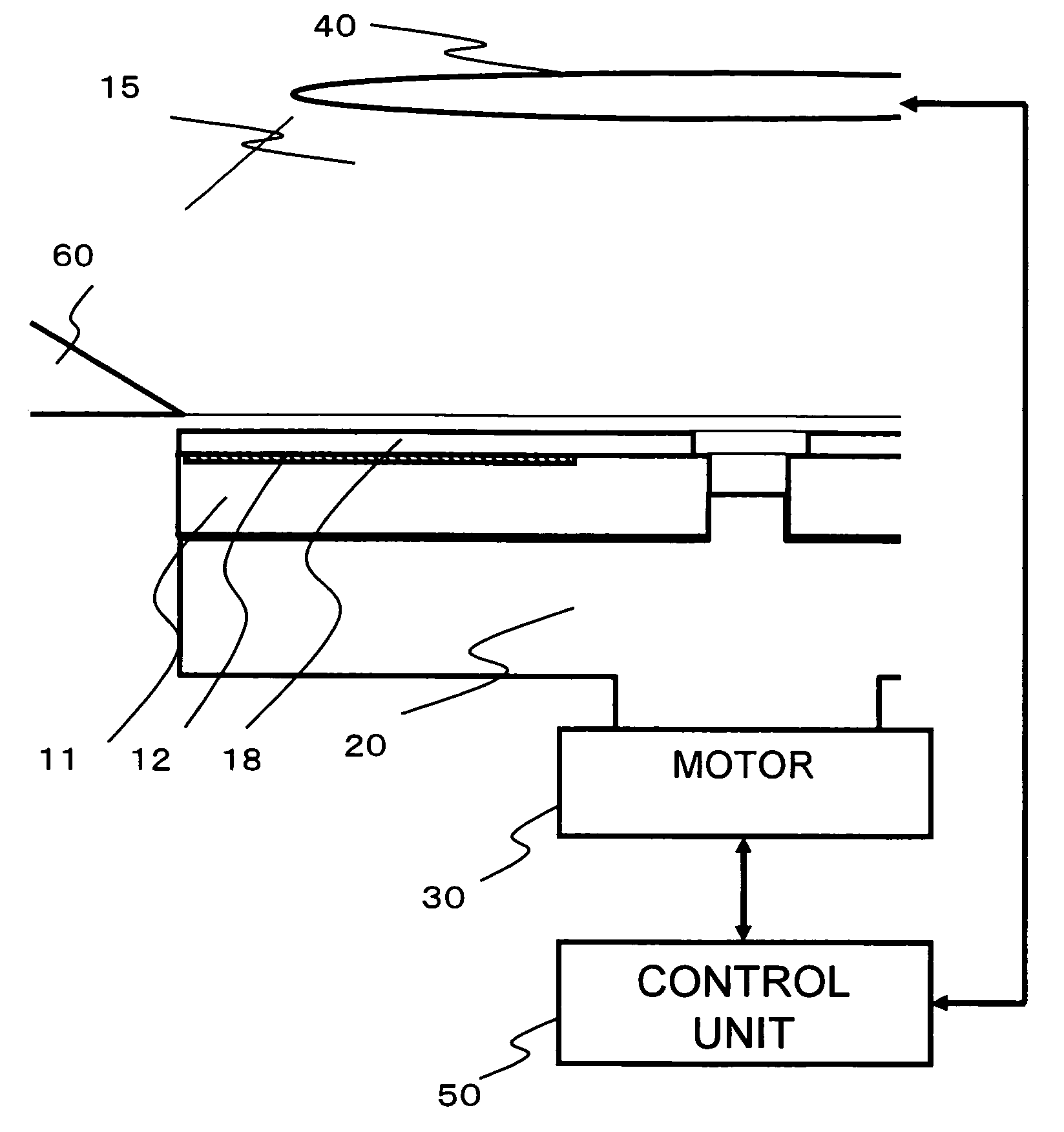

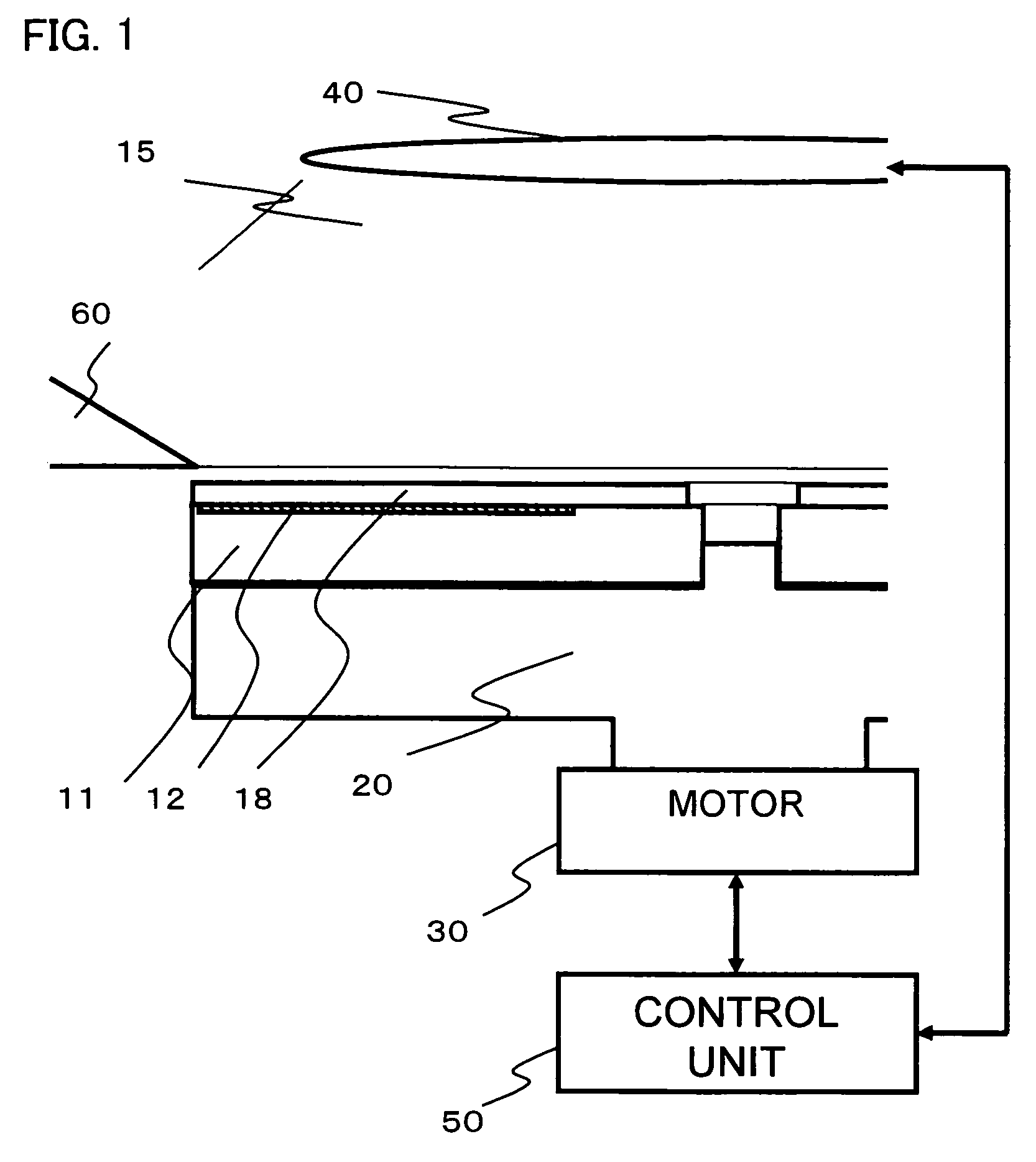

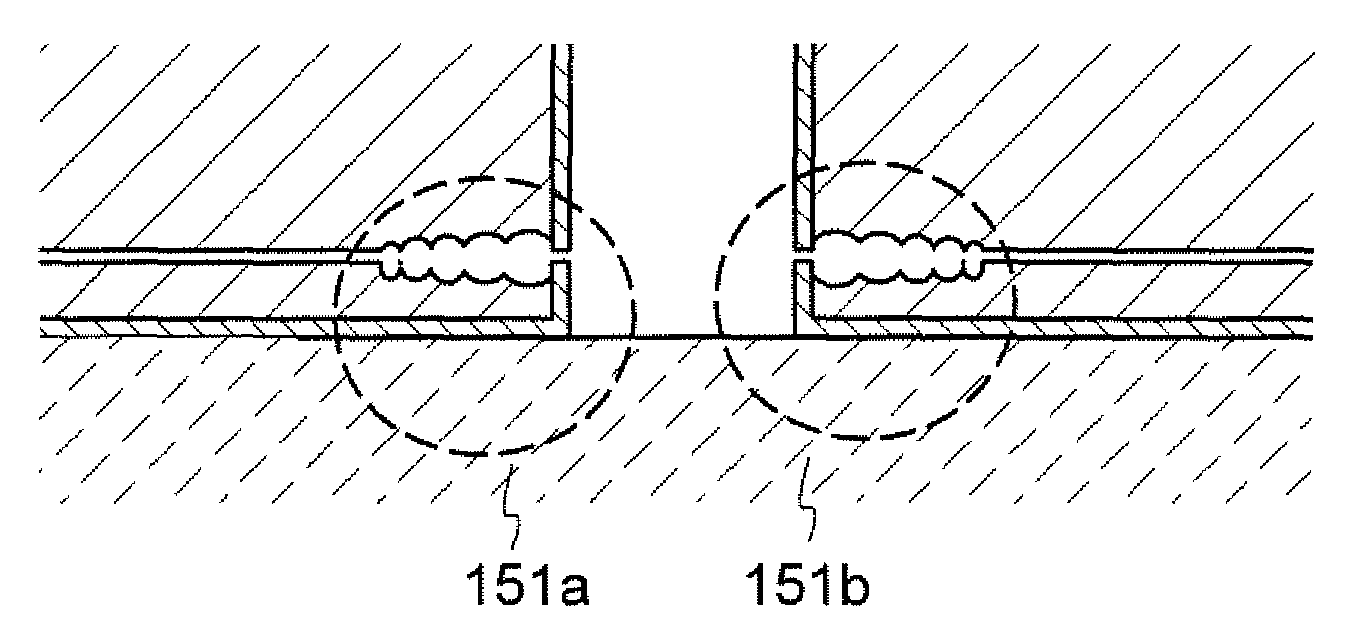

Liquid crystal display device

InactiveUS20050200784A1Effective aperture ratioImprove contrast ratioPolarising elementsNon-linear opticsEngineeringVoltage

The liquid crystal display device of the present invention includes a first substrate, a second substrate and a vertically aligned liquid crystal layer interposed between the first and second substrate. The device has a plurality of pixels each including a first electrode formed on the first substrate, a second electrode formed on the second substrate, and the liquid crystal layer interposed between the first and second electrode, and a shading region provided around the pixels. A plurality of supports for defining the thickness of the liquid crystal layer are placed regularly on the surface of the first or second substrate facing the liquid crystal layer in the shading region. The liquid crystal layer forms at least one liquid crystal domain exhibiting axisymmetric alignment when at least a predetermined voltage is applied, and the tilt direction of liquid crystal molecules in the at least one liquid crystal domain is defined with inclined sides of the plurality of supports.

Owner:SHARP KK

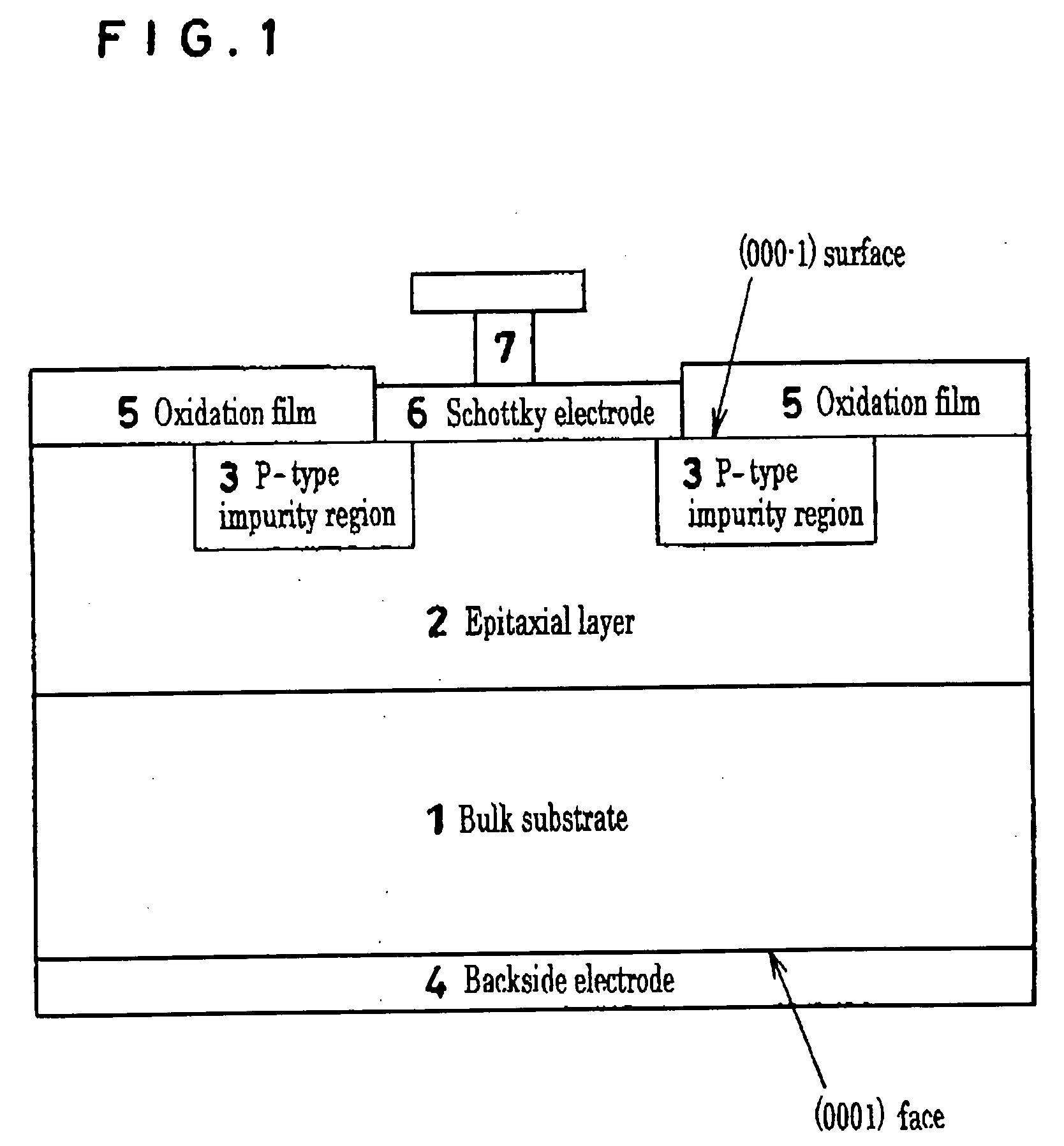

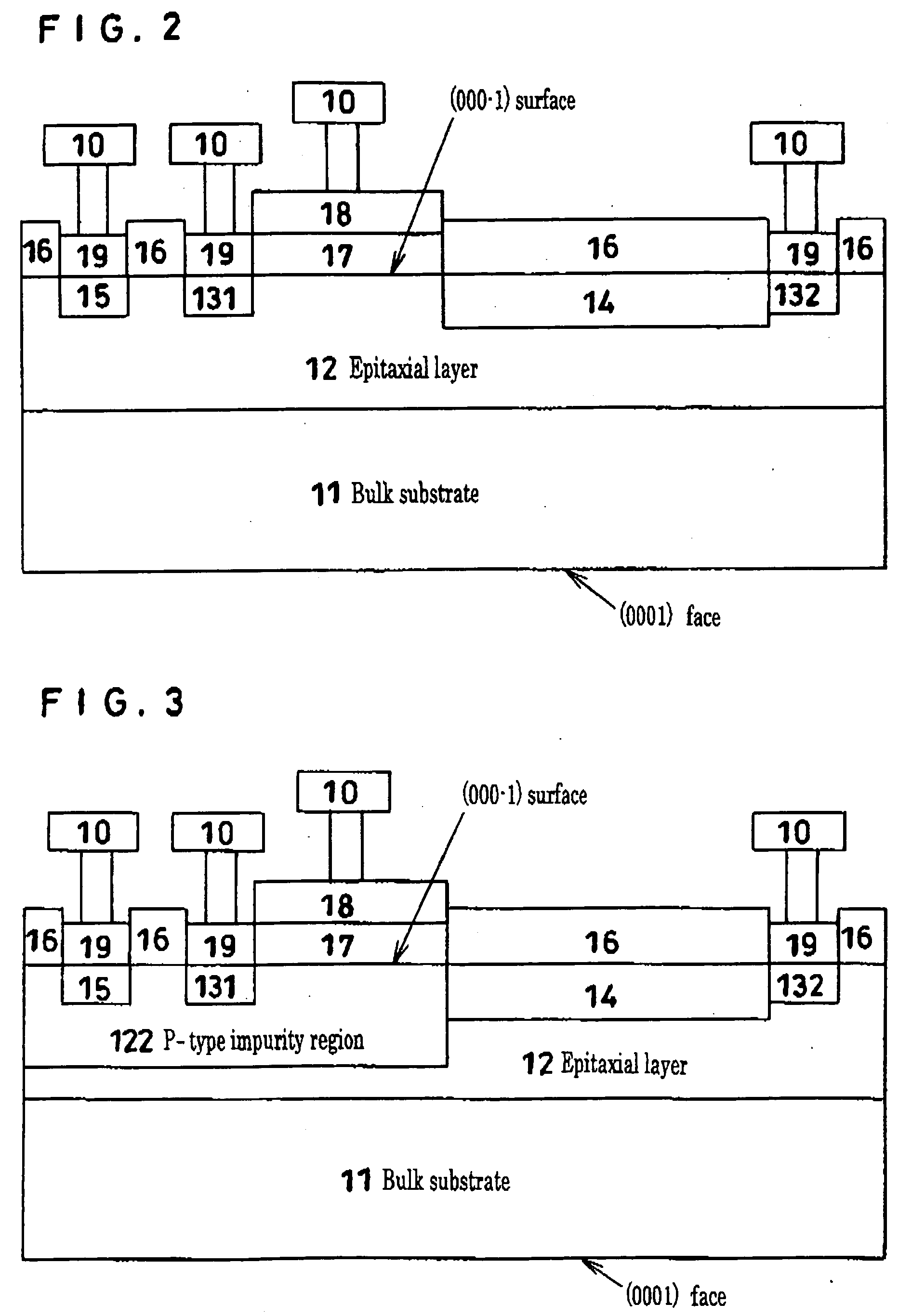

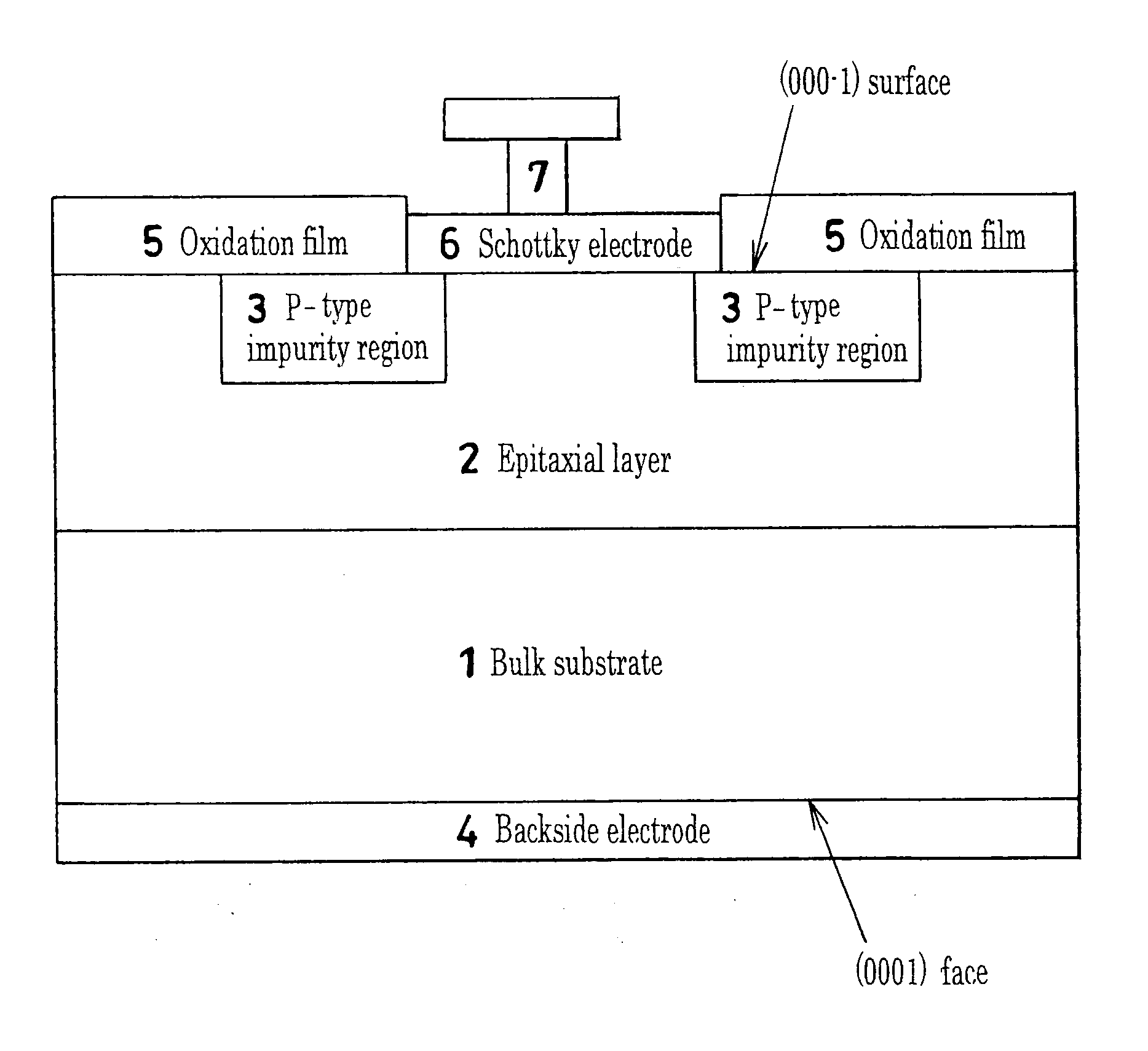

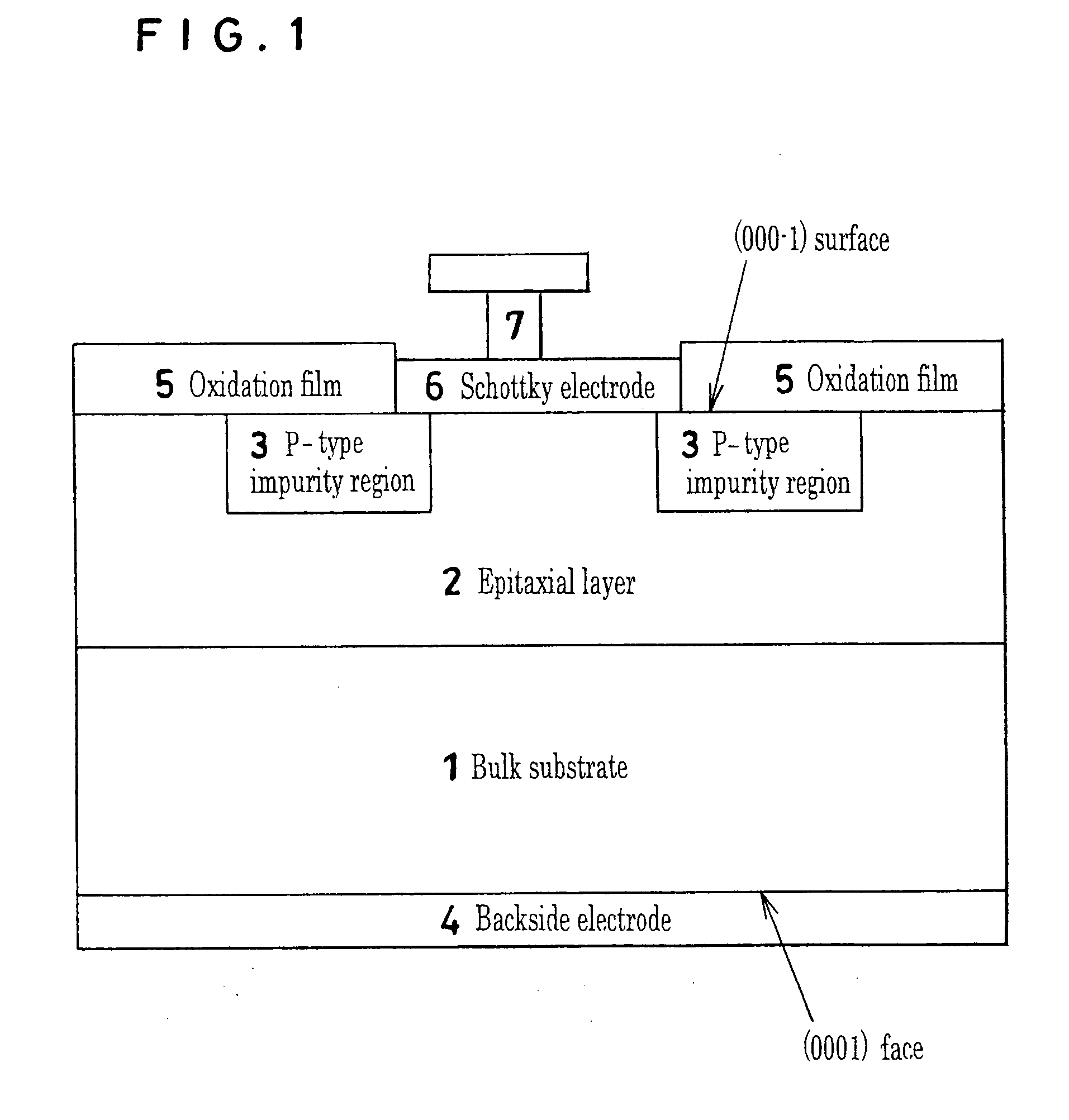

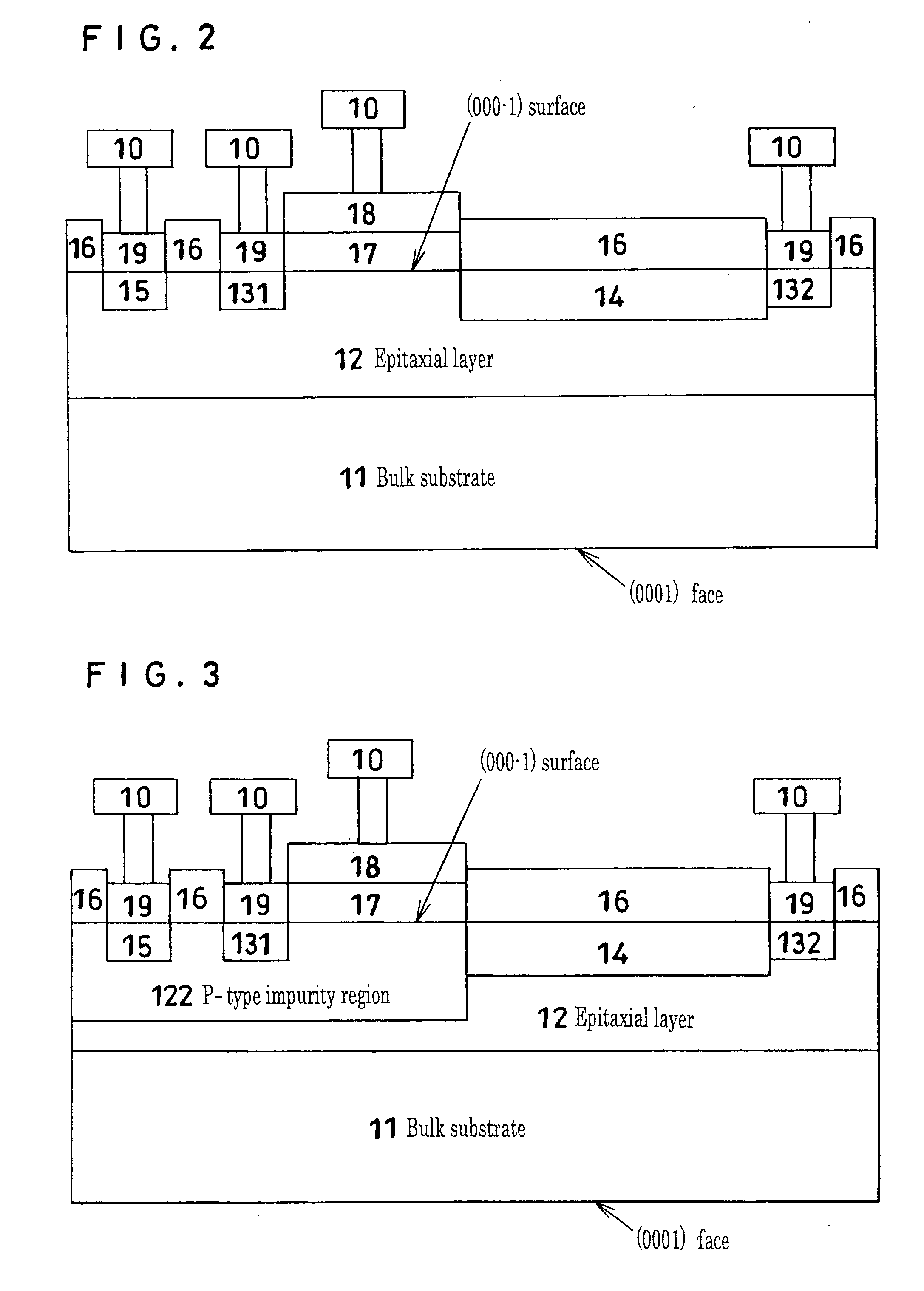

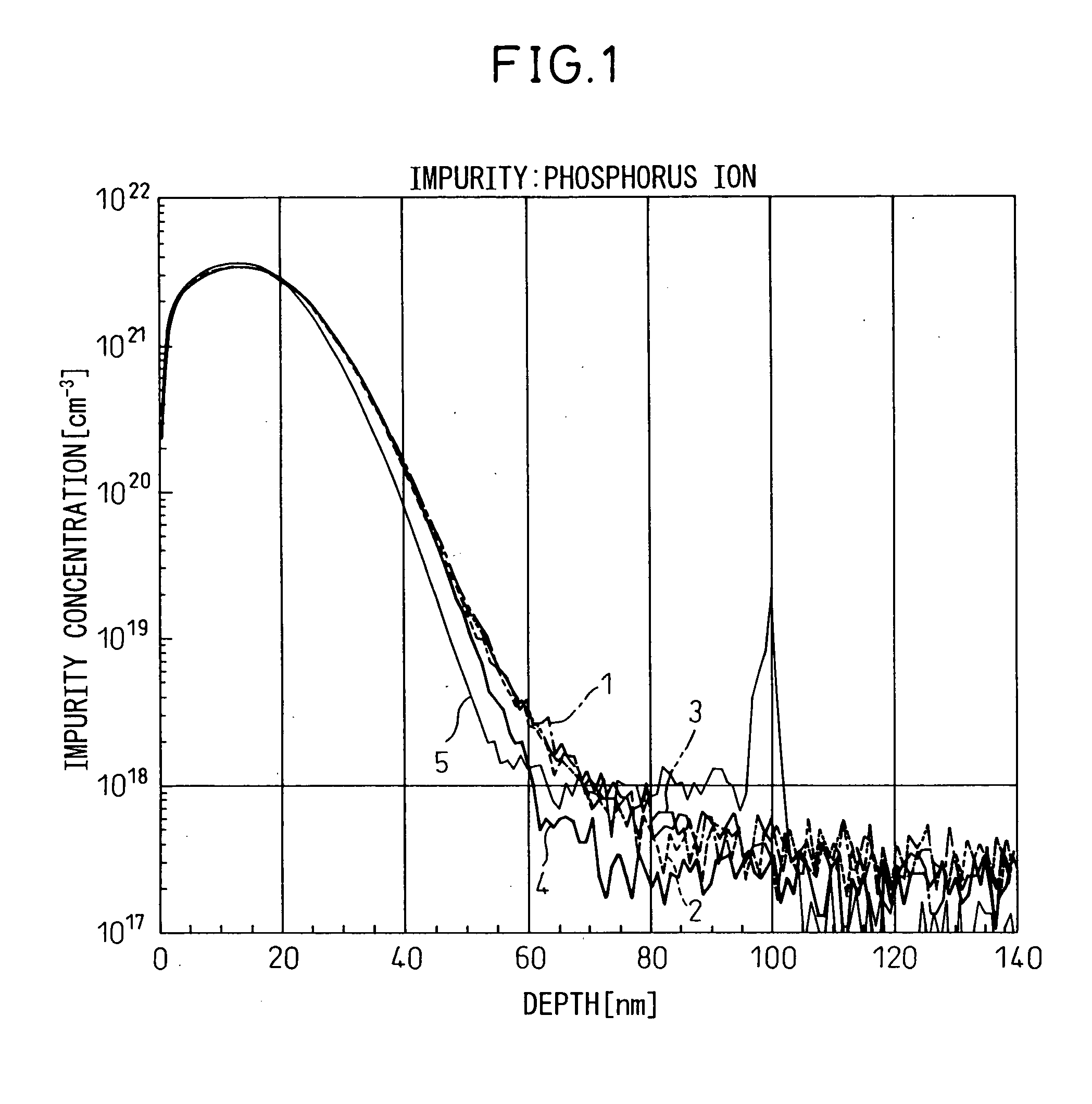

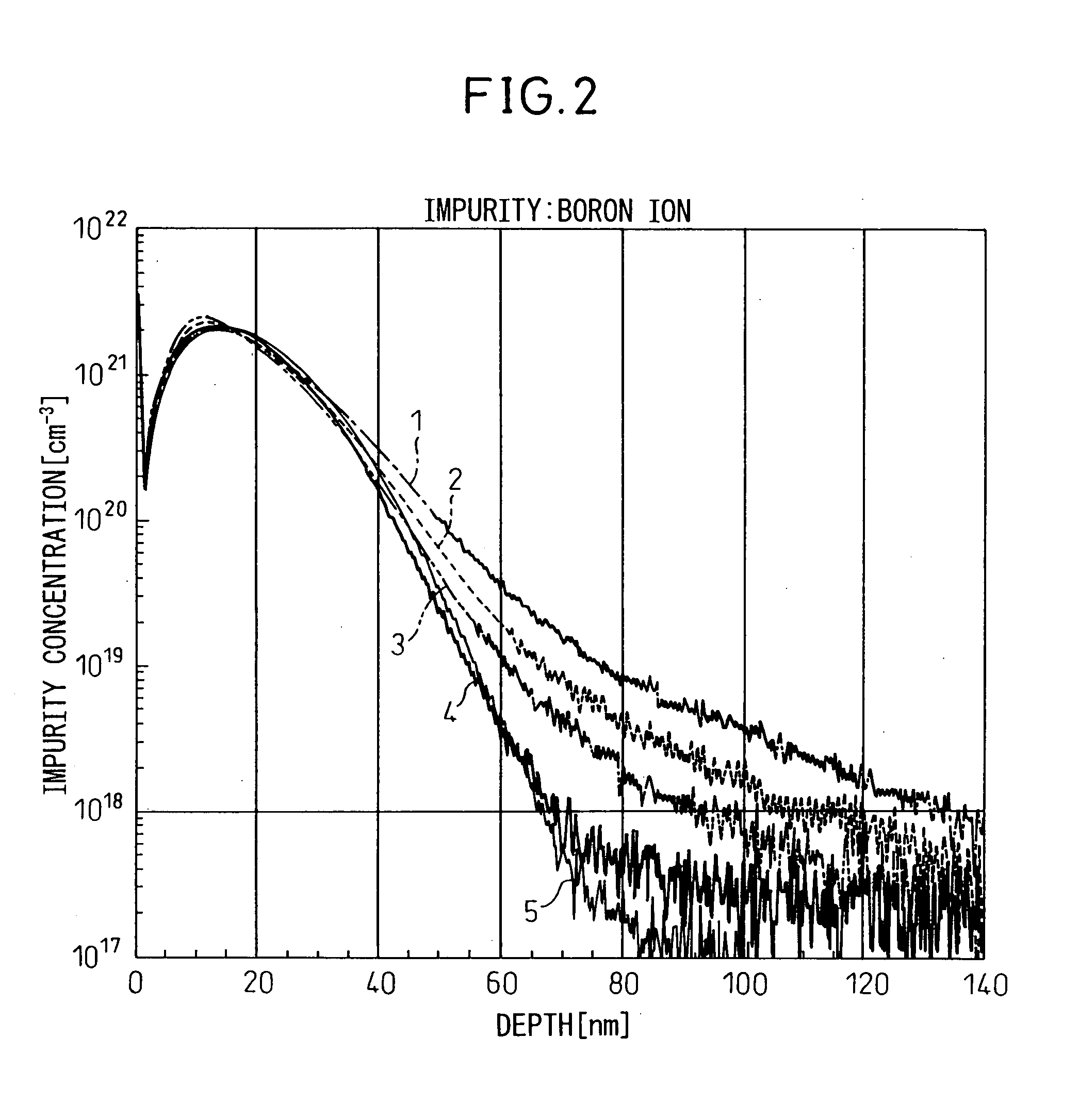

Semiconductor device and power converter, driving inverter, general-purpose inverter and high-power high-frequency communication device using same

InactiveUS20060151806A1Excellent electrical propertiesSuppress roughnessThyristorSemiconductor/solid-state device manufacturingSchottky barrierDevice material

In a semiconductor device that uses a silicon carbide semiconductor substrate having p type, n type impurity semiconductor regions formed by ion implantation, the electrical characteristics of the end semiconductor device can be improved by decreasing the roughness of the silicon carbide semiconductor substrate surface. The semiconductor device of this invention is a Schottky barrier diode or a p-n type diode comprising at least one of a p type semiconductor region and n type semiconductor region selectively formed in a silicon carbide semiconductor region having an outermost surface layer surface that is a (000-1) surface or a surface inclined at an angle to the (000-1) surface, and a metal electrode formed on the outermost surface layer surface, that controls a direction in which electric current flows in a direction perpendicular to the outermost surface layer surface from application of a voltage to the metal electrode.

Owner:NAT INST OF ADVANCED IND SCI & TECH

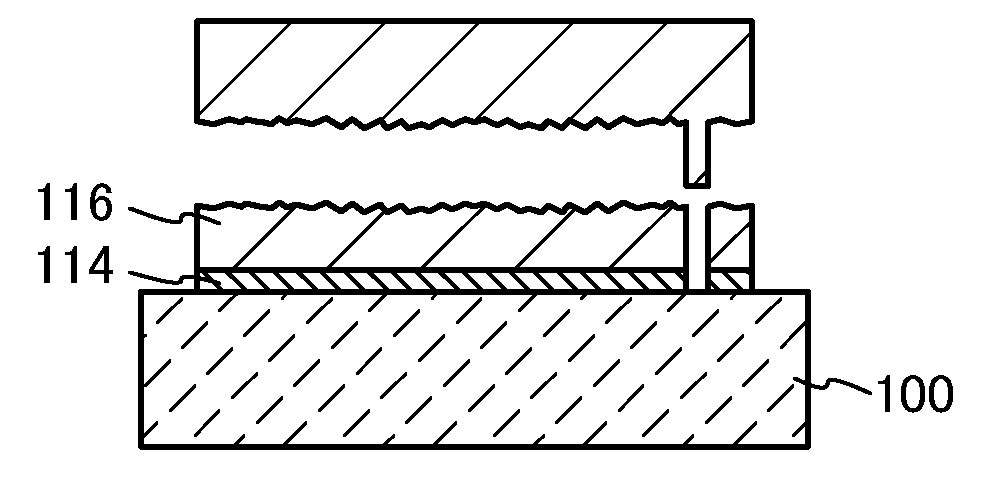

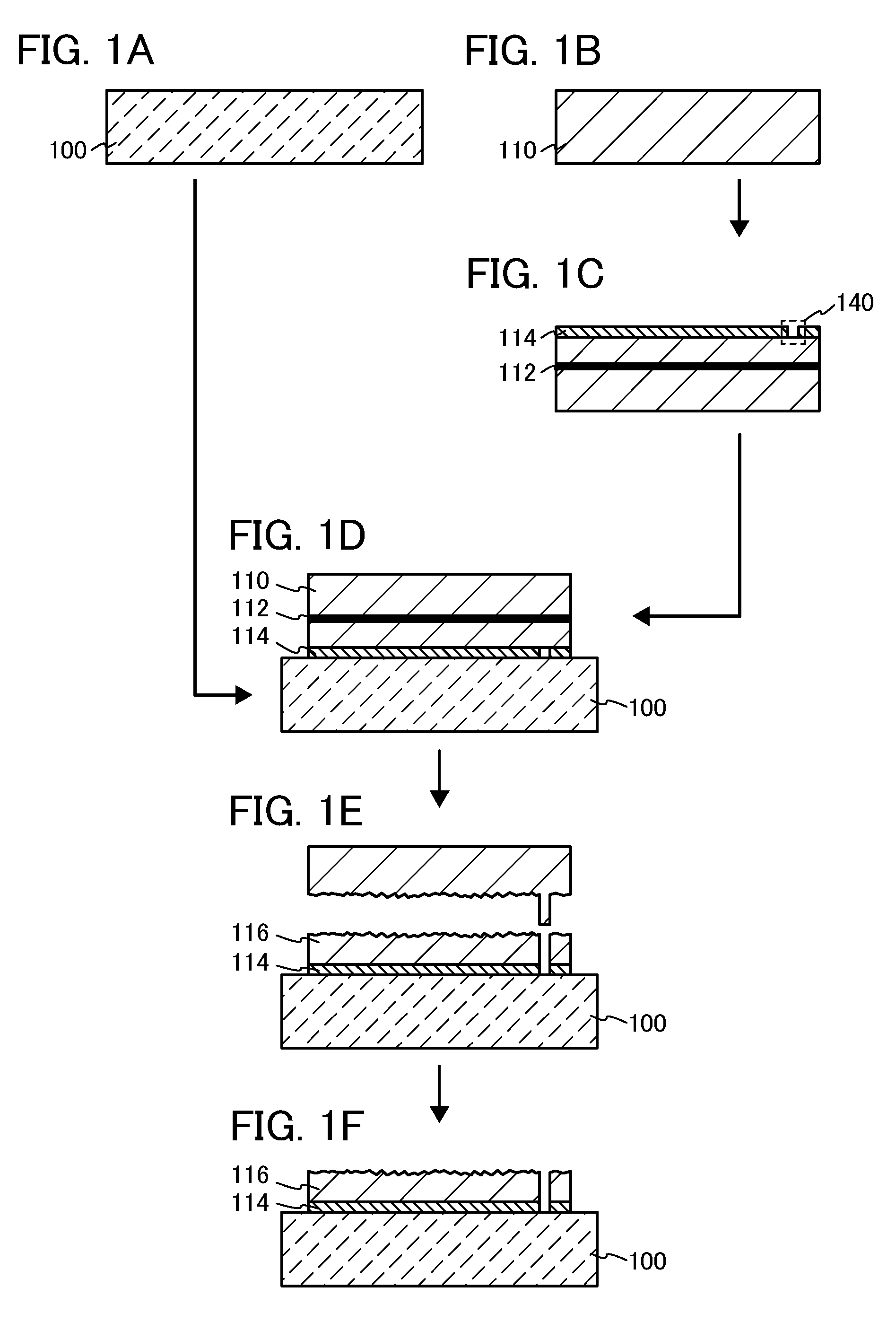

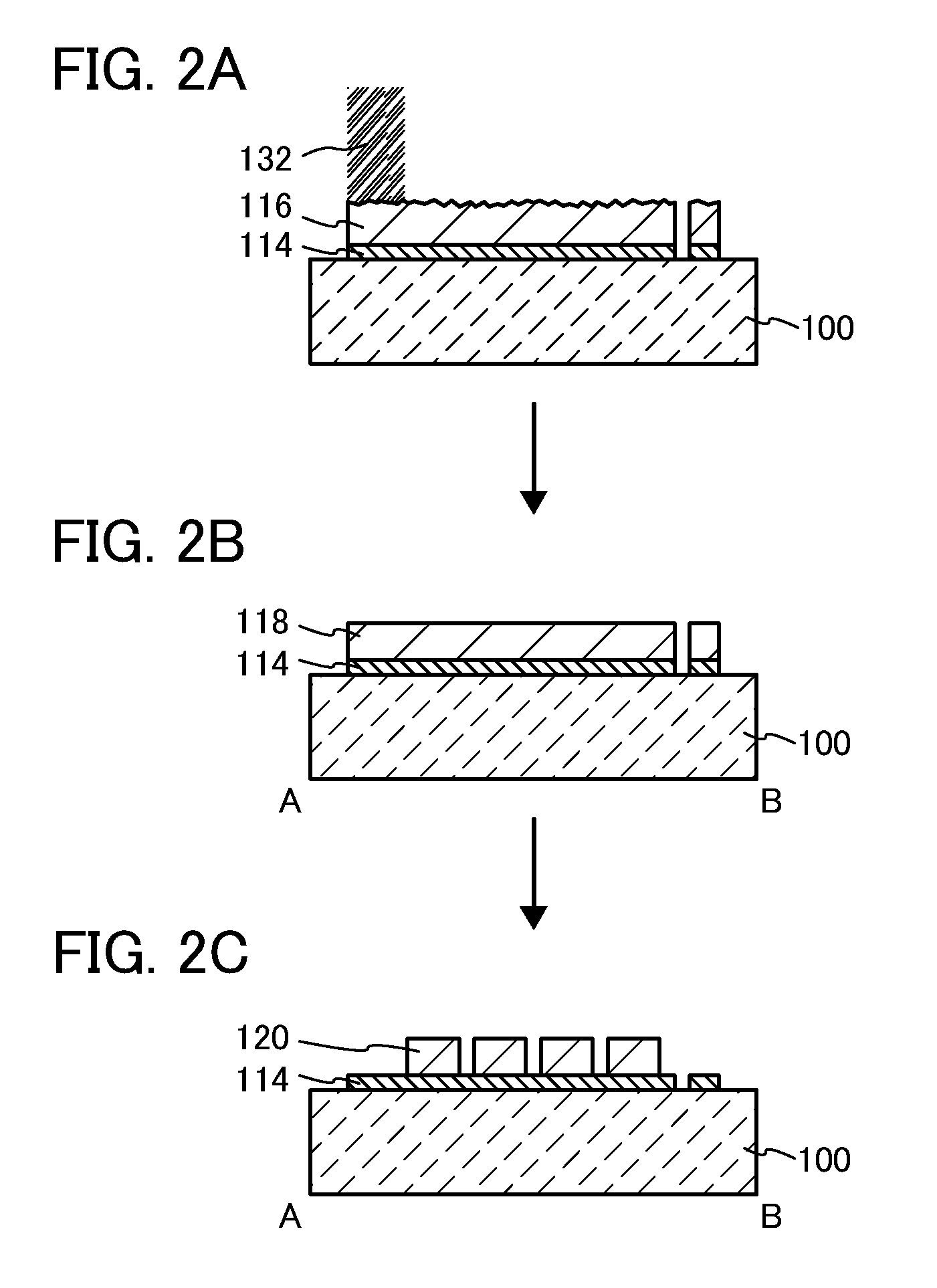

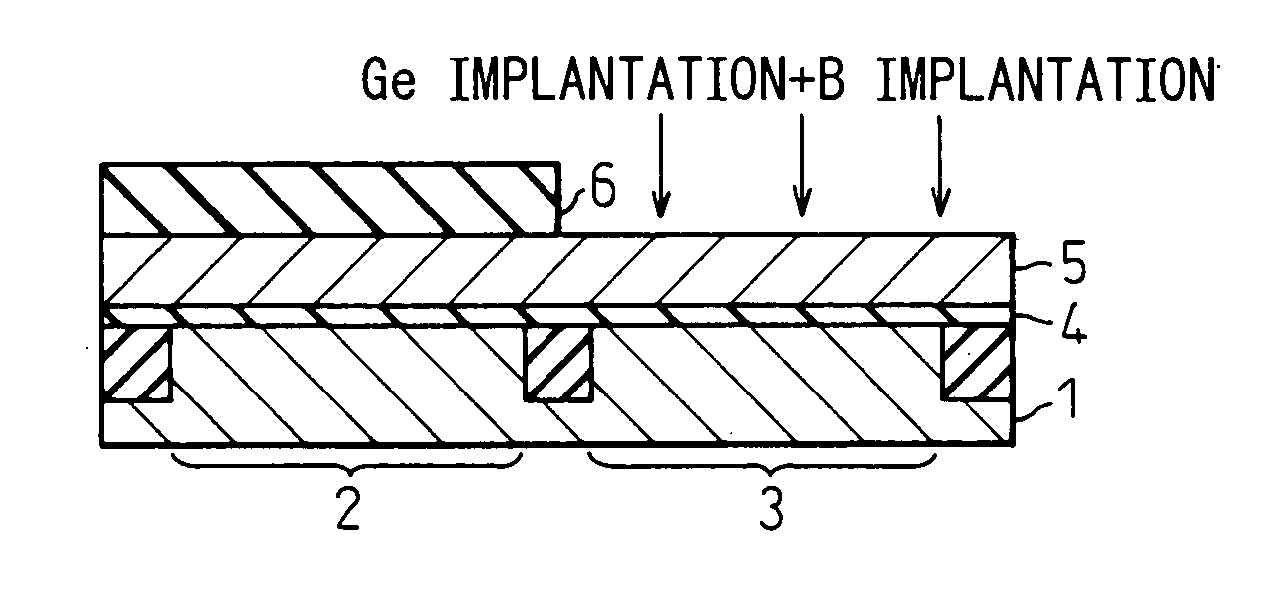

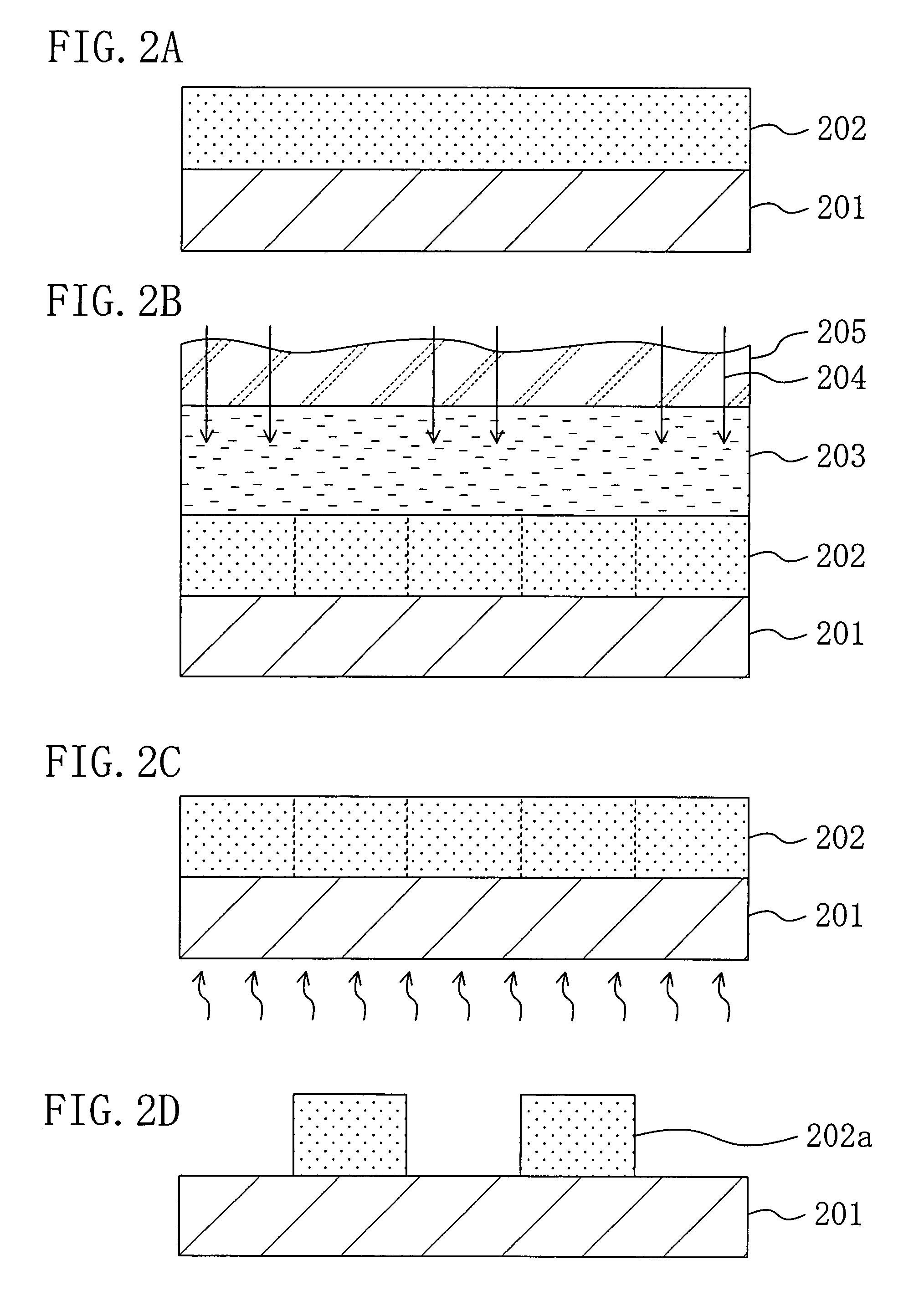

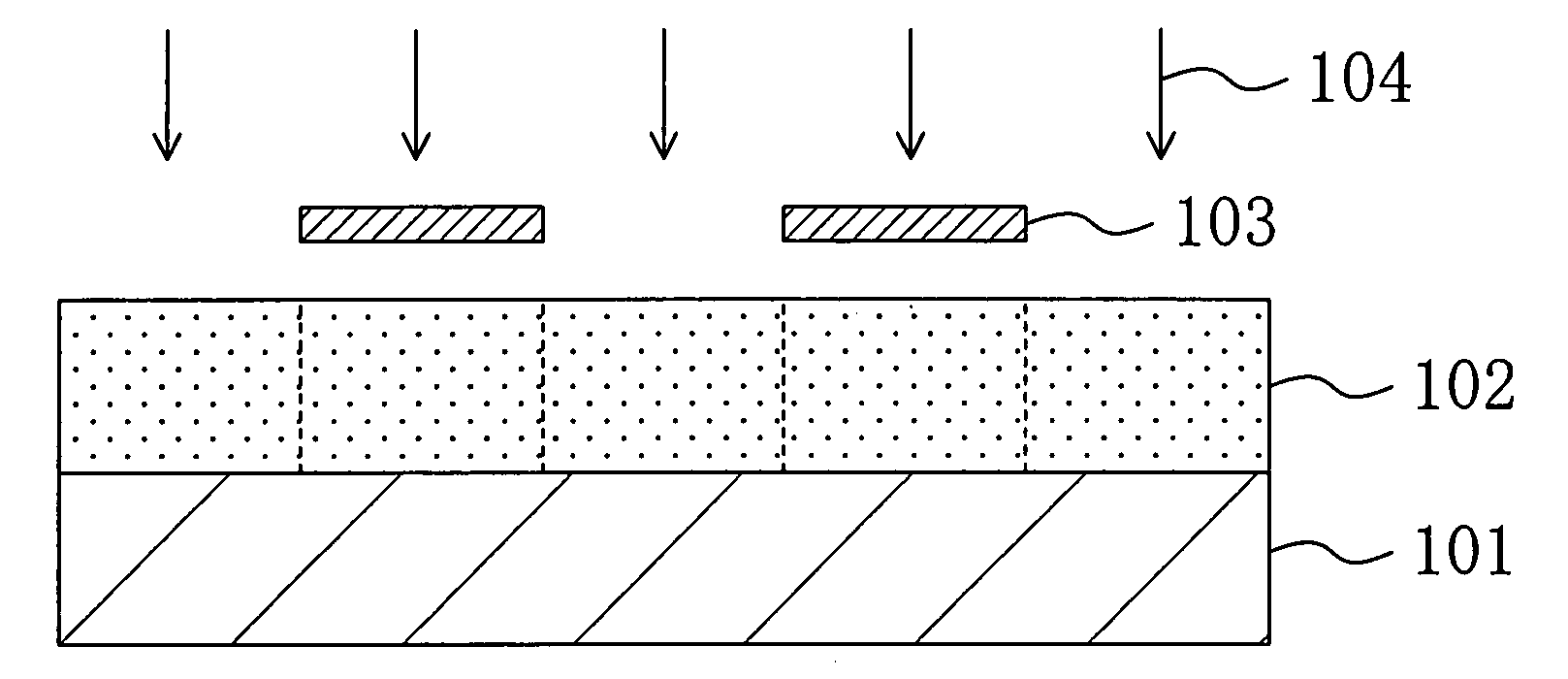

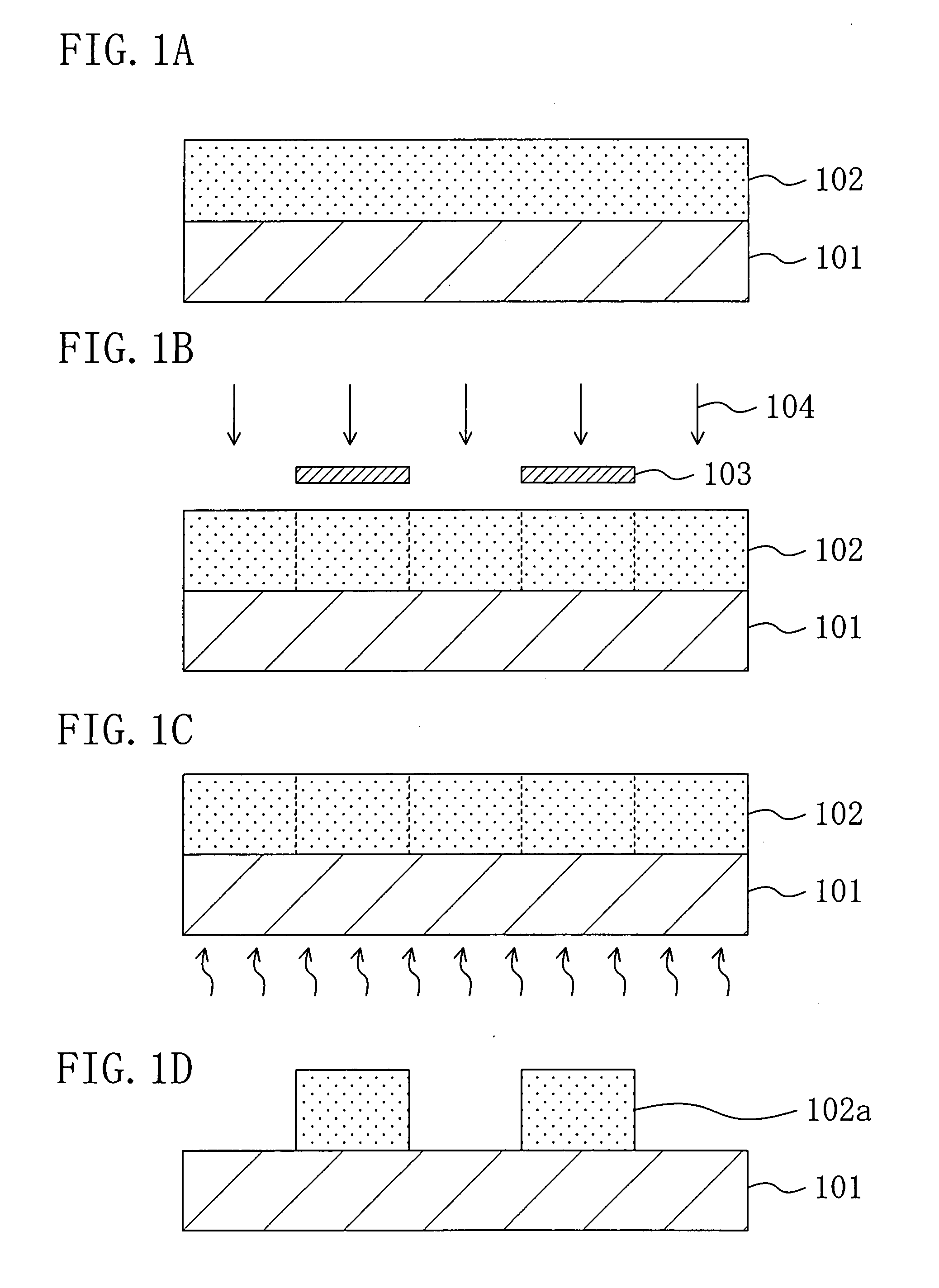

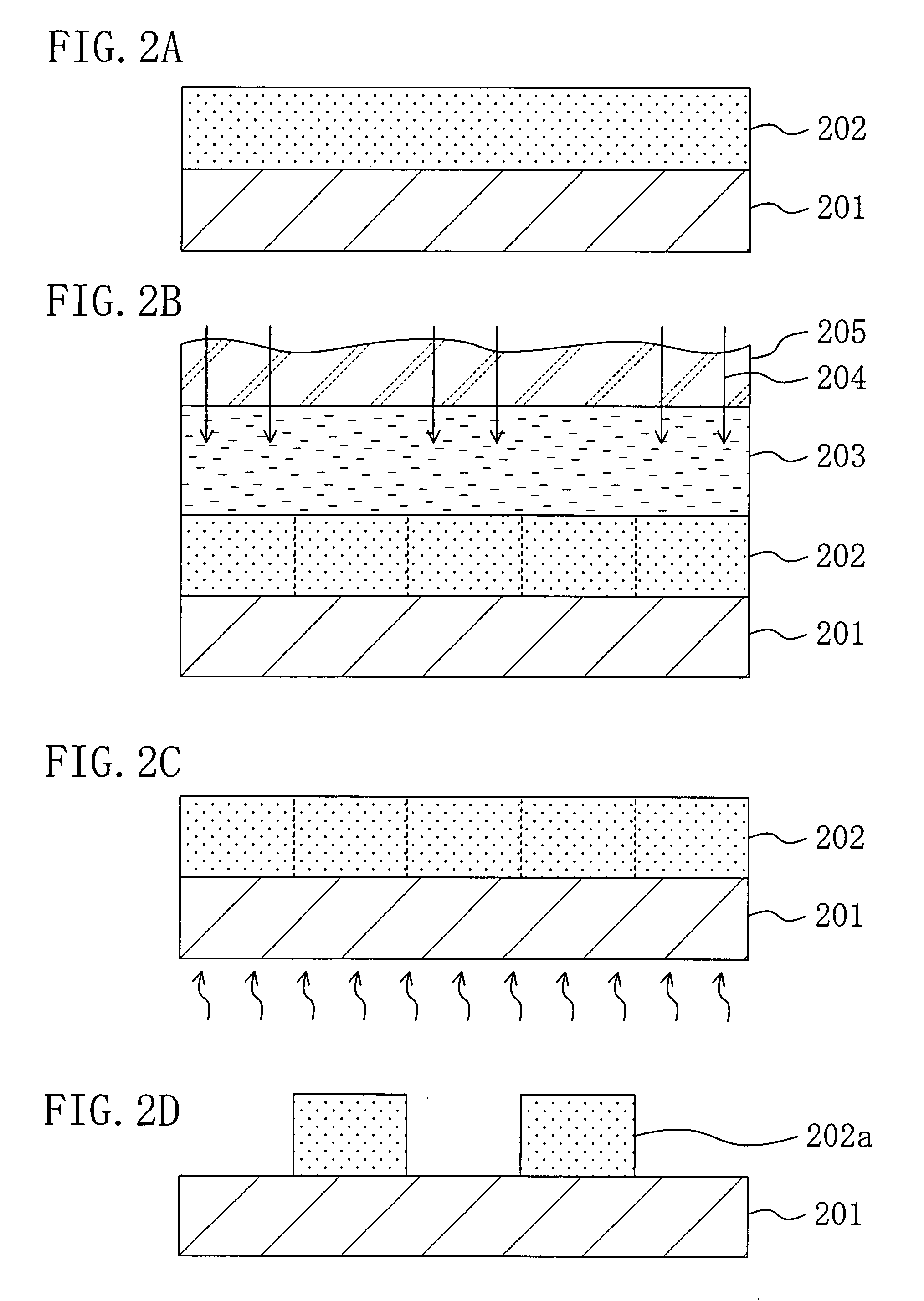

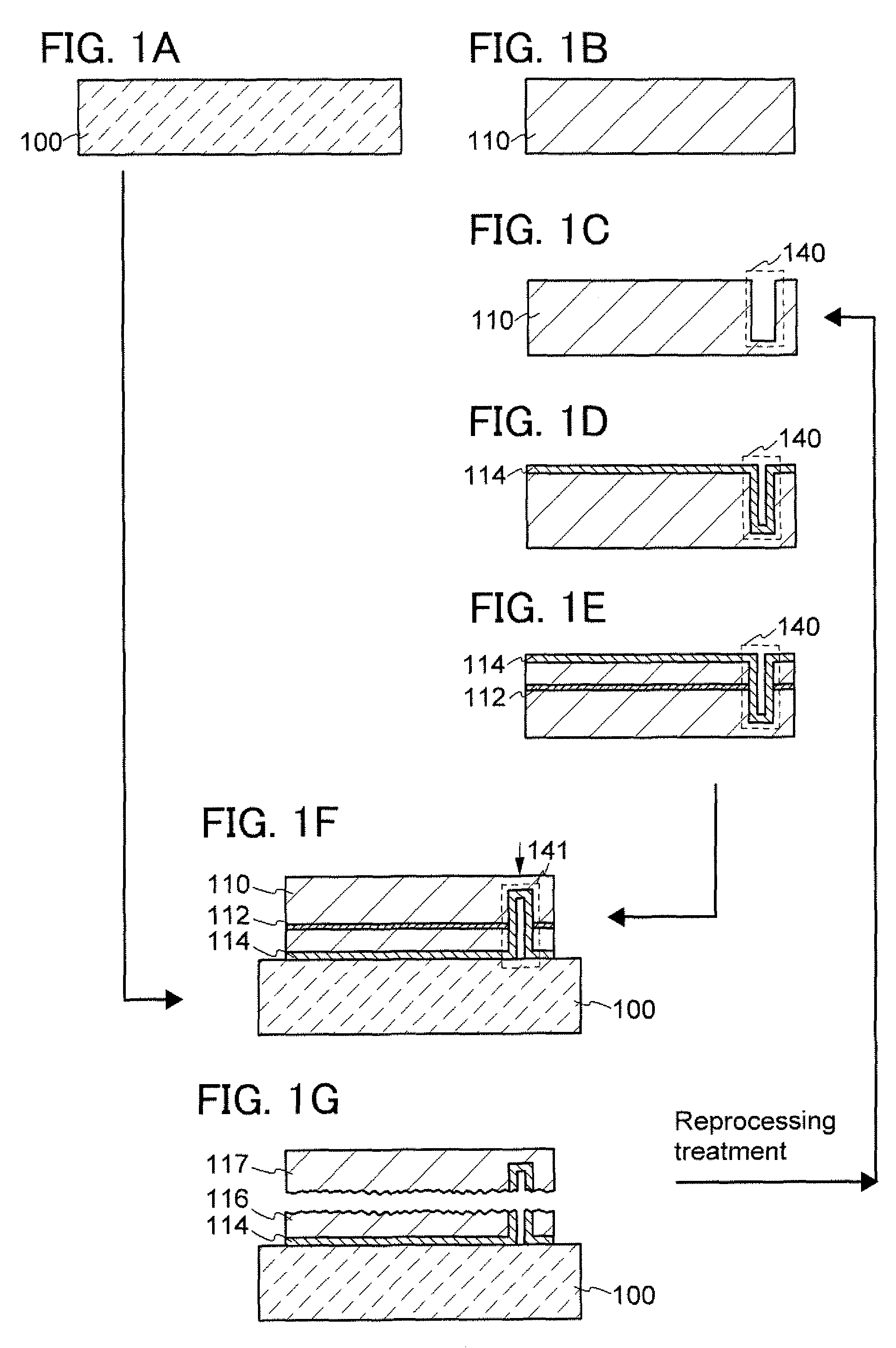

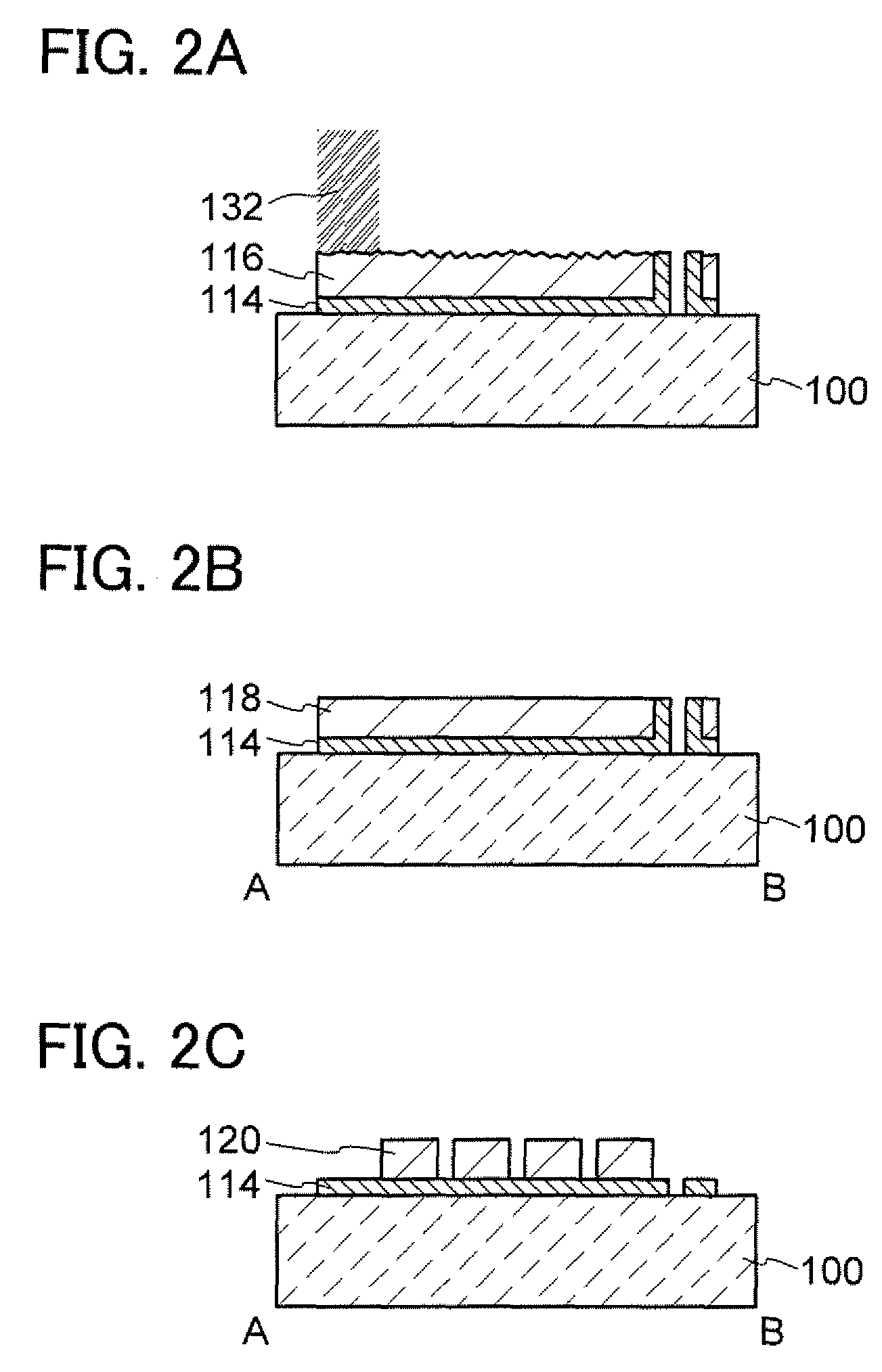

Method for manufacturing soi substrate and soi substrate

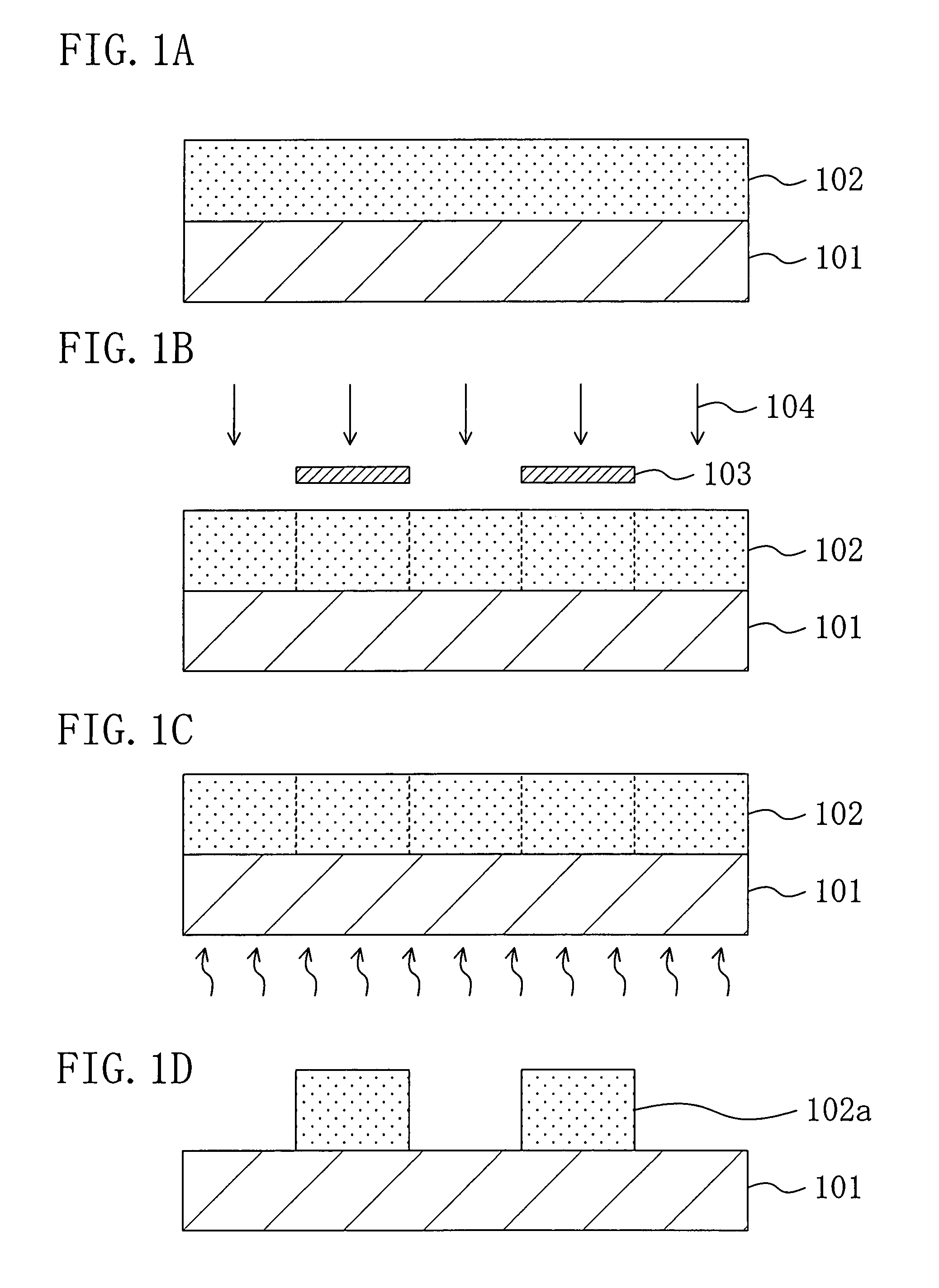

InactiveUS20100330779A1Suppress surface roughnessImprove manufacturing yieldSemiconductor/solid-state device manufacturingSoi substrateSemiconductor

A bond substrate is irradiated with accelerated ions to form an embrittled region in the bond substrate; an insulating layer is formed over a surface of the bond substrate or a base substrate; the bond substrate and the base substrate are bonded to each other with the insulating layer interposed therebetween; a region in which the bond substrate and the base substrate are not bonded to each other and which is closed by the bond substrate and the base substrate is formed in parts of the bond substrate and the base substrate; the bond substrate is separated at the embrittled region by heat treatment; and a semiconductor layer is formed over the base substrate.

Owner:SEMICON ENERGY LAB CO LTD

Liquid crystal display device

InactiveUS7391489B2Effective aperture ratioSuppress contrast dropPolarising elementsNon-linear opticsEngineeringVoltage

Owner:SHARP KK

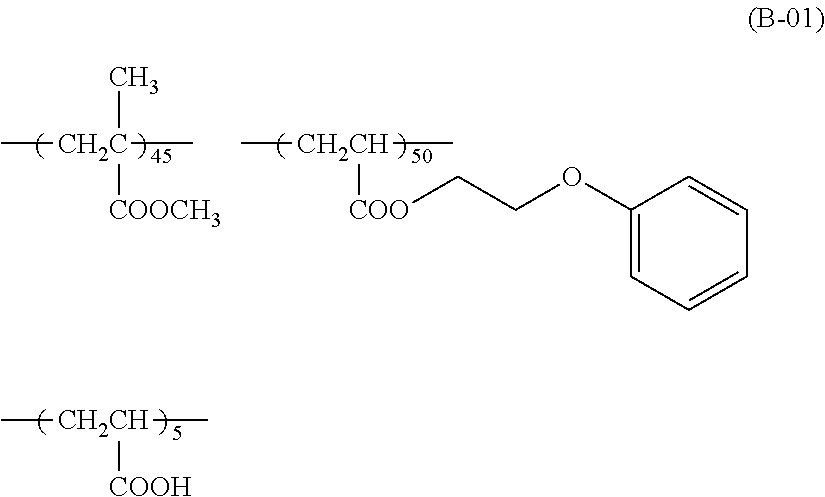

Antistatic hard coat layer forming composition, optical film, optical film manufacturing method, polarization plate, and image display device

InactiveUS20130052434A1Reduce roughnessDamage outer appearanceSynthetic resin layered productsConductive materialSolventBoiling point

Providing is an antistatic hard-coat-layer forming composition including a nonvolatile component containing a conductive polymer (a) a compound (b) and a photo-polymerization initiator (c); and a volatile component containing a solvent (d) having a hydroxyl group, and a solvent (e) having no hydroxyl group where the boiling point is 120° C. or less, wherein the solvent (d) contains a solvent (d2) with 4 or more carbon atoms having a hydroxyl group where the boiling point is 90° C. or more and the SP value is 22.0 to 35.0, the proportion of the polymer (a) in the nonvolatile component is 1 to 20 mass %, the proportion of the solvent (d) in the volatile component is 0.5 to 25 mass %, and the proportion of the component (d2) in the component (d) is 80 to 100 mass %.

Owner:FUJIFILM CORP

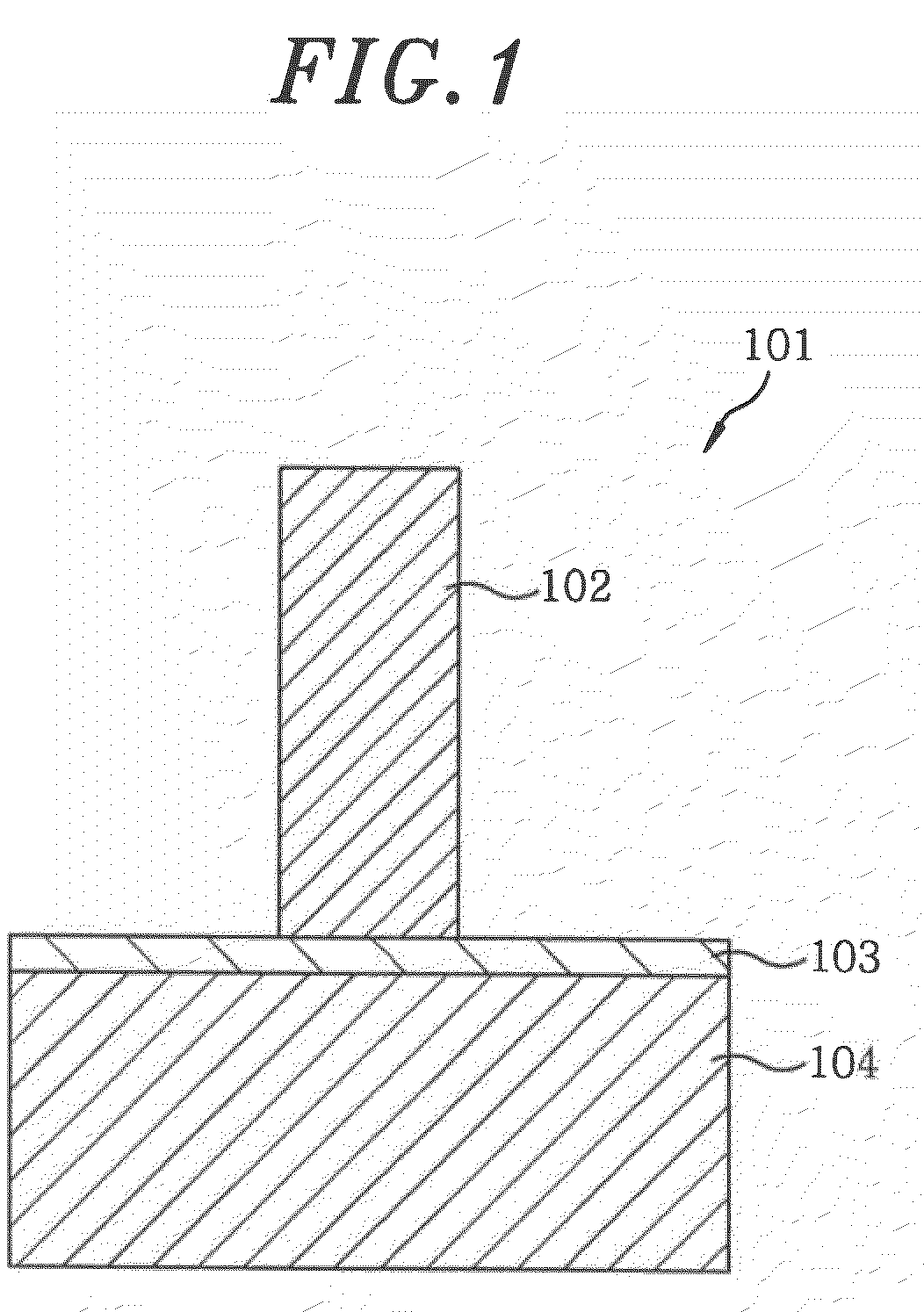

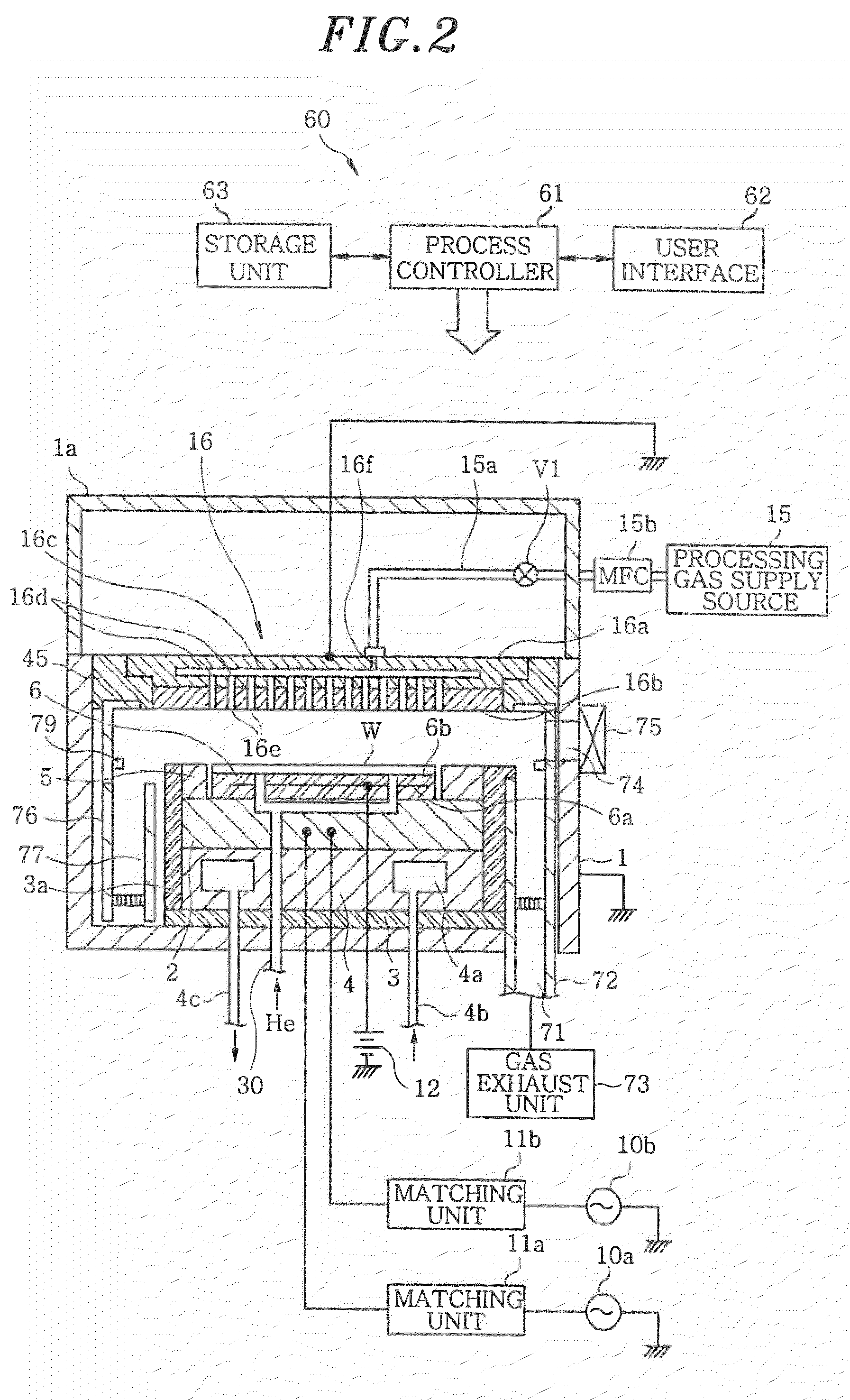

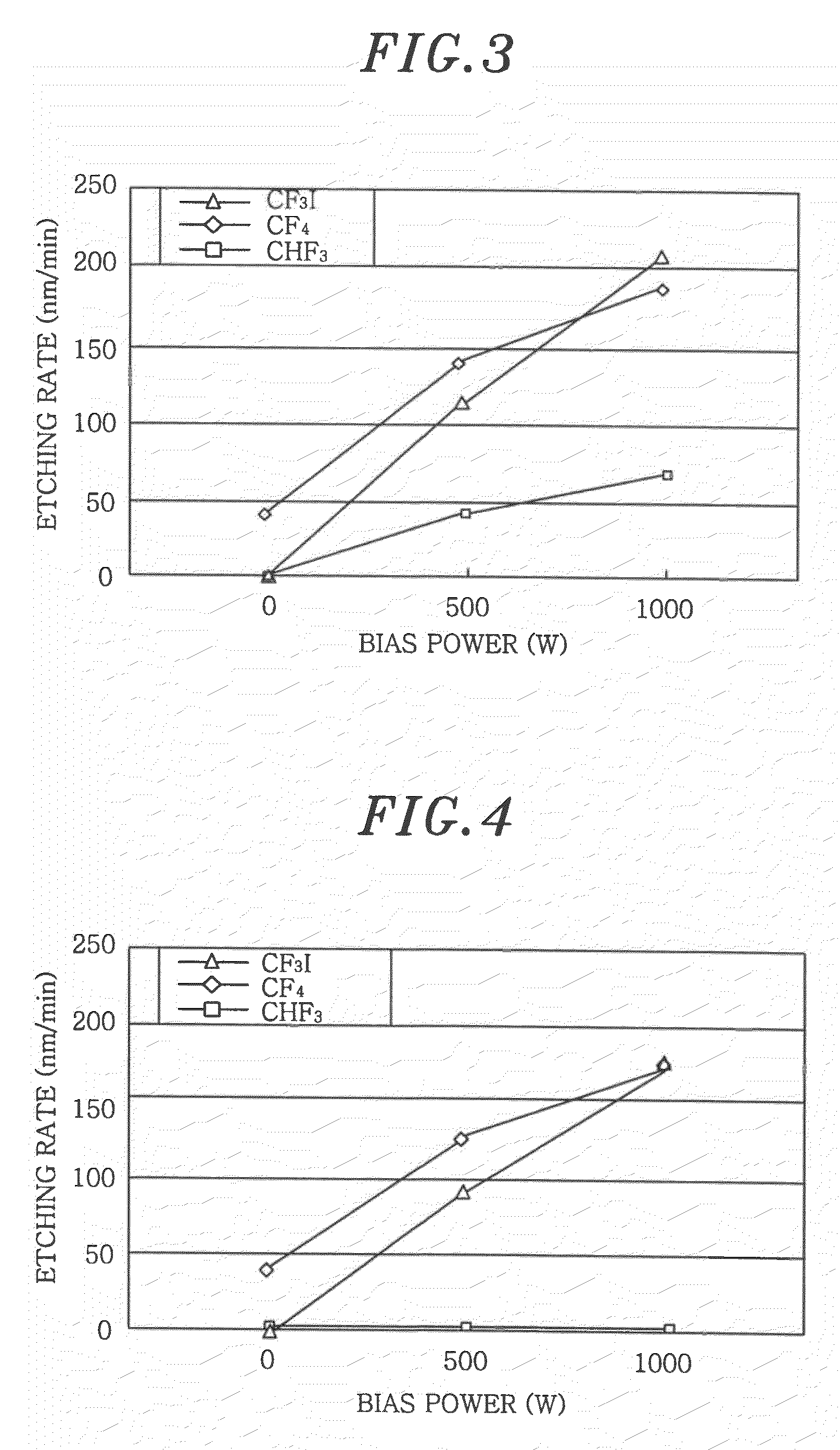

Plasma etching method and computer-readable storage medium

InactiveUS20090203218A1Suppressing roughness of sidewallSuppress surface roughnessSemiconductor/solid-state device manufacturingHigh frequency powerSilicon oxide

A plasma etching method includes etching an etching target layer formed on a substrate to be processed by a plasma of a processing gas by using an ArF photoresist as a mask. The etching target layer is a silicon nitride layer or silicon oxide layer, and the processing gas contains at least a CF3I gas. A high frequency power having a frequency of 13.56 MHz or less is applied to a lower electrode mounting the substrate thereon.

Owner:TOKYO ELECTRON LTD

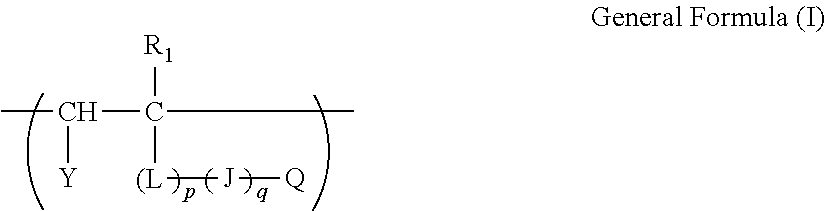

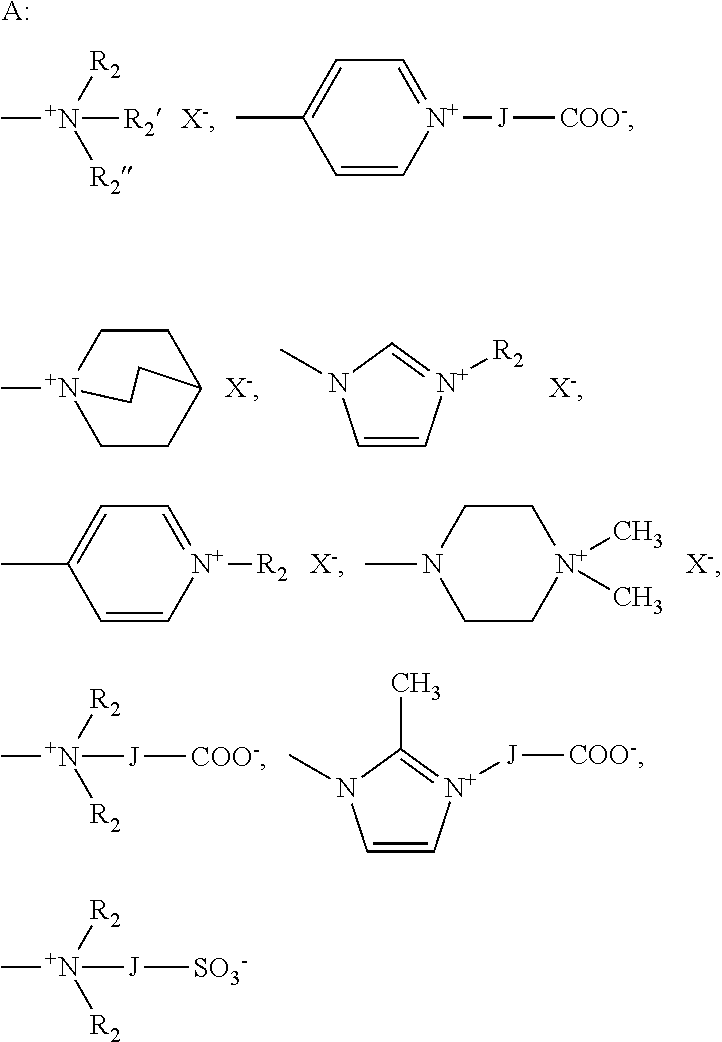

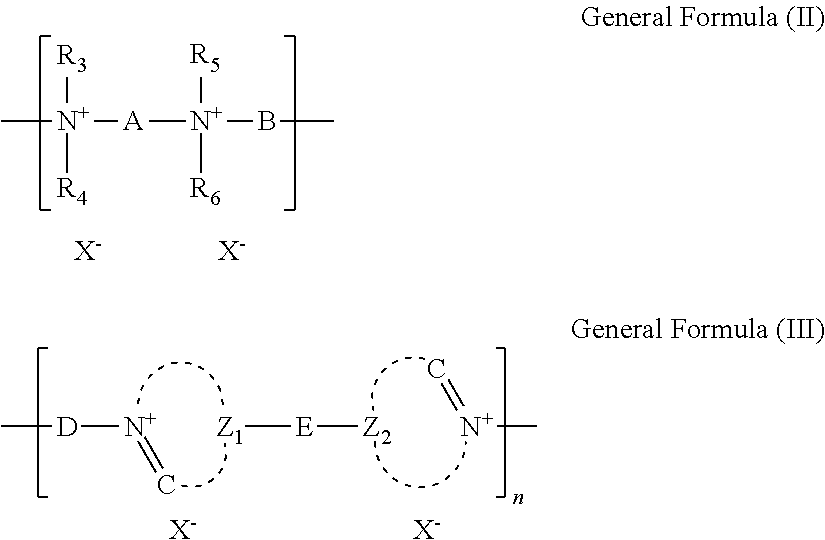

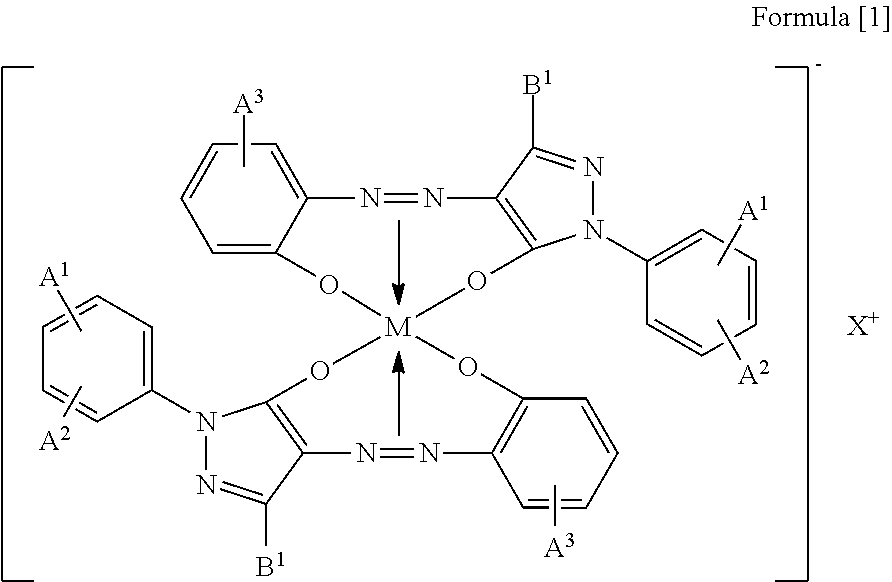

Ink set and image forming method

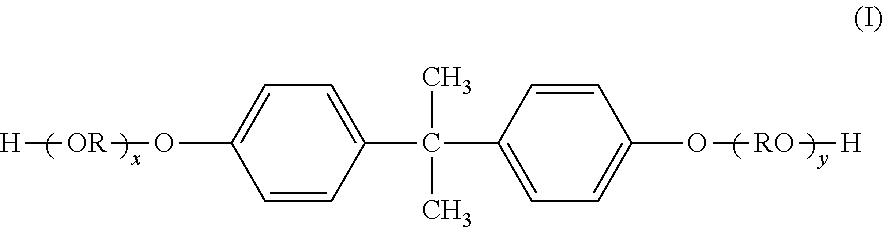

InactiveUS20120320121A1Suppress roughnessIncrease roughnessDuplicating/marking methodsInksPigmentOrganic acid

An ink set is provided in which an image with suppressed roughness may be formed. The ink set includes an ink composition containing resin particles and a pigment, and a process liquid containing an organic acidic compound including a compound represented by General Formula (I).CnH2n+2-m(COOH)m General Formula (I)[wherein, in General Formula (I), n represents an integer of greater than or equal to 2 and m represents an integer of greater than or equal to 3.]

Owner:FUJIFILM CORP

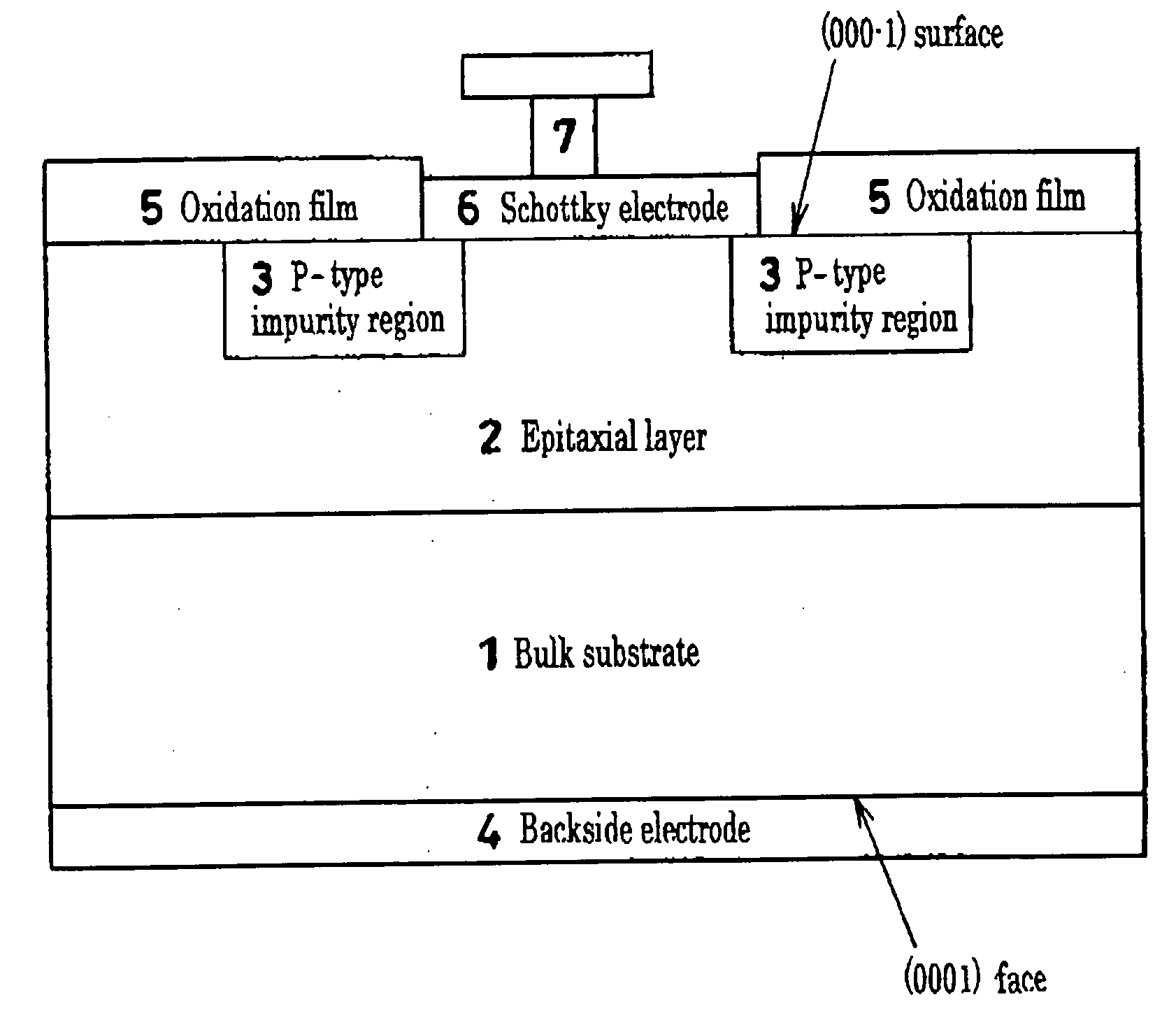

Semiconductor device and electric power converter, drive inverter, general-purpose inverter and super-power high-frequency communication equipment using the semiconductor device

InactiveUS20090057686A1Excellent electrical propertiesSuppress roughnessSemiconductor/solid-state device manufacturingSemiconductor devicesSchottky barrierMetal electrodes

In a semiconductor device that uses a silicon carbide semiconductor substrate having p type, n type impurity semiconductor regions formed by ion implantation, the electrical characteristics of the end semiconductor device can be improved by decreasing the roughness of the silicon carbide semiconductor substrate surface. The semiconductor device of this invention is a Schottky barrier diode or a p-n type diode comprising at least one of a p type semiconductor region and n type semiconductor region selectively formed in a silicon carbide semiconductor region having an outermost surface layer surface that is a (000-1) surface or a surface inclined at an angle to the (000-1) surface, and a metal electrode formed on the outermost surface layer surface, that controls a direction in which electric current flows in a direction perpendicular to the outermost surface layer surface from application of a voltage to the metal electrode.

Owner:NAT INST OF ADVANCED IND SCI & TECH

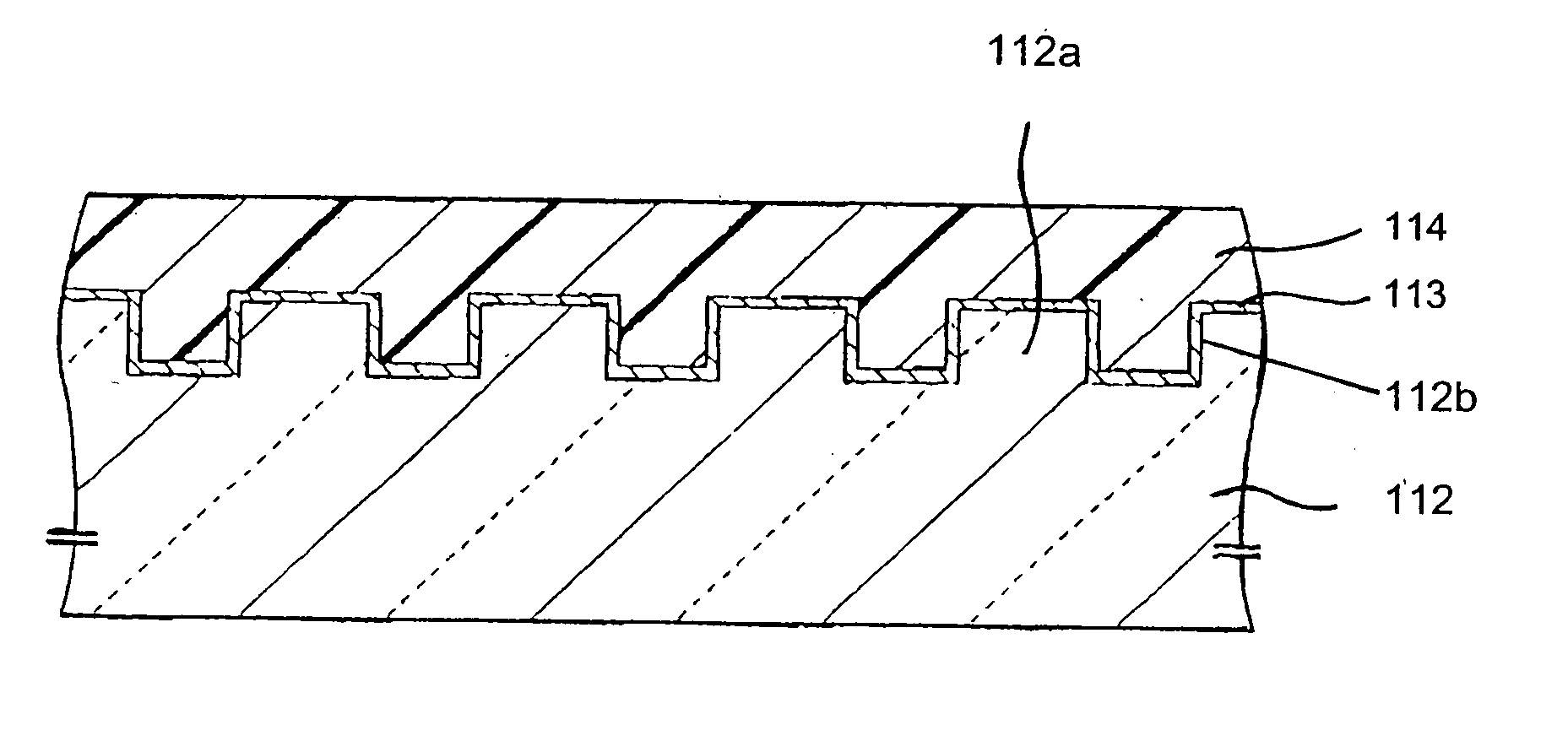

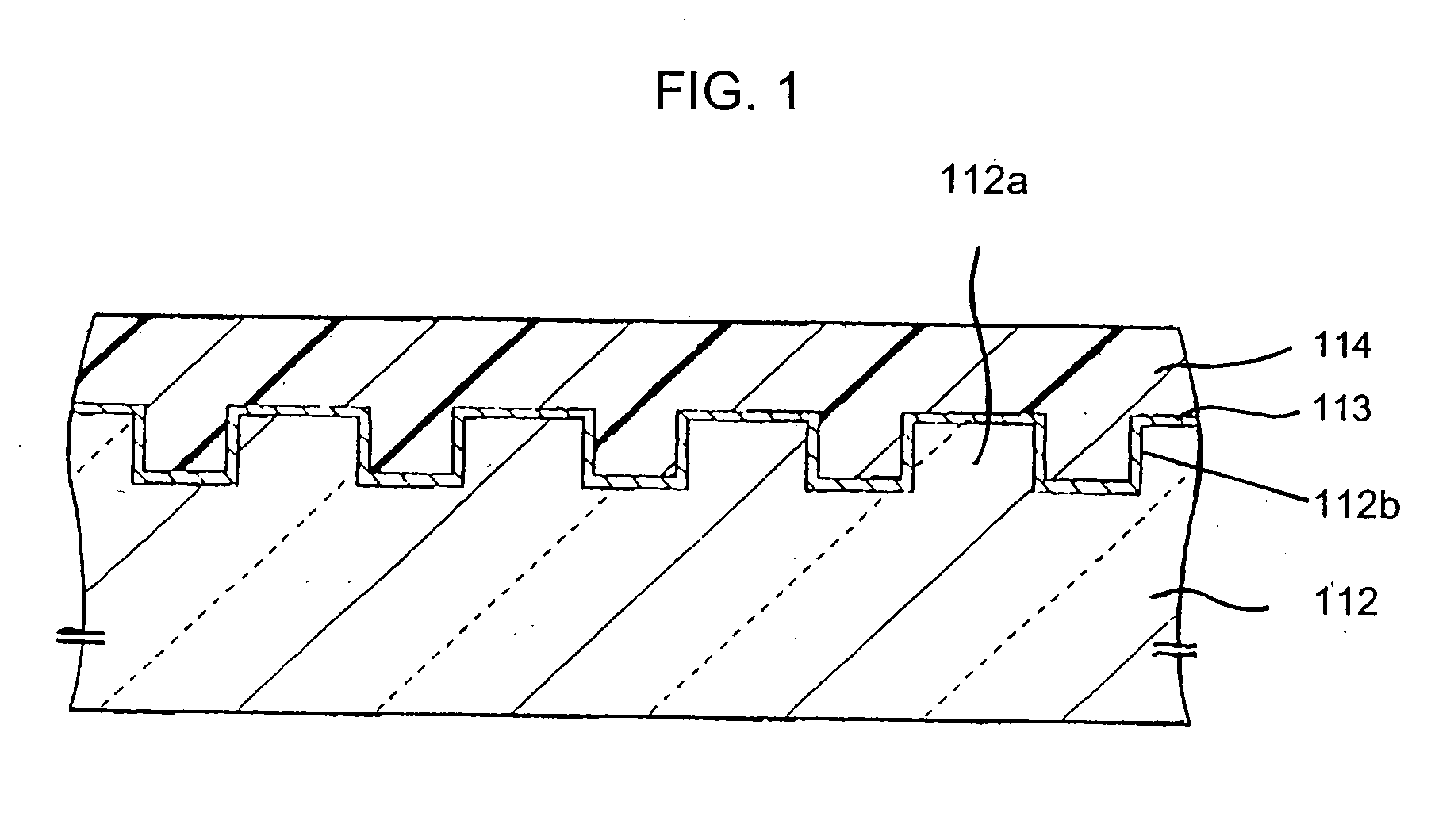

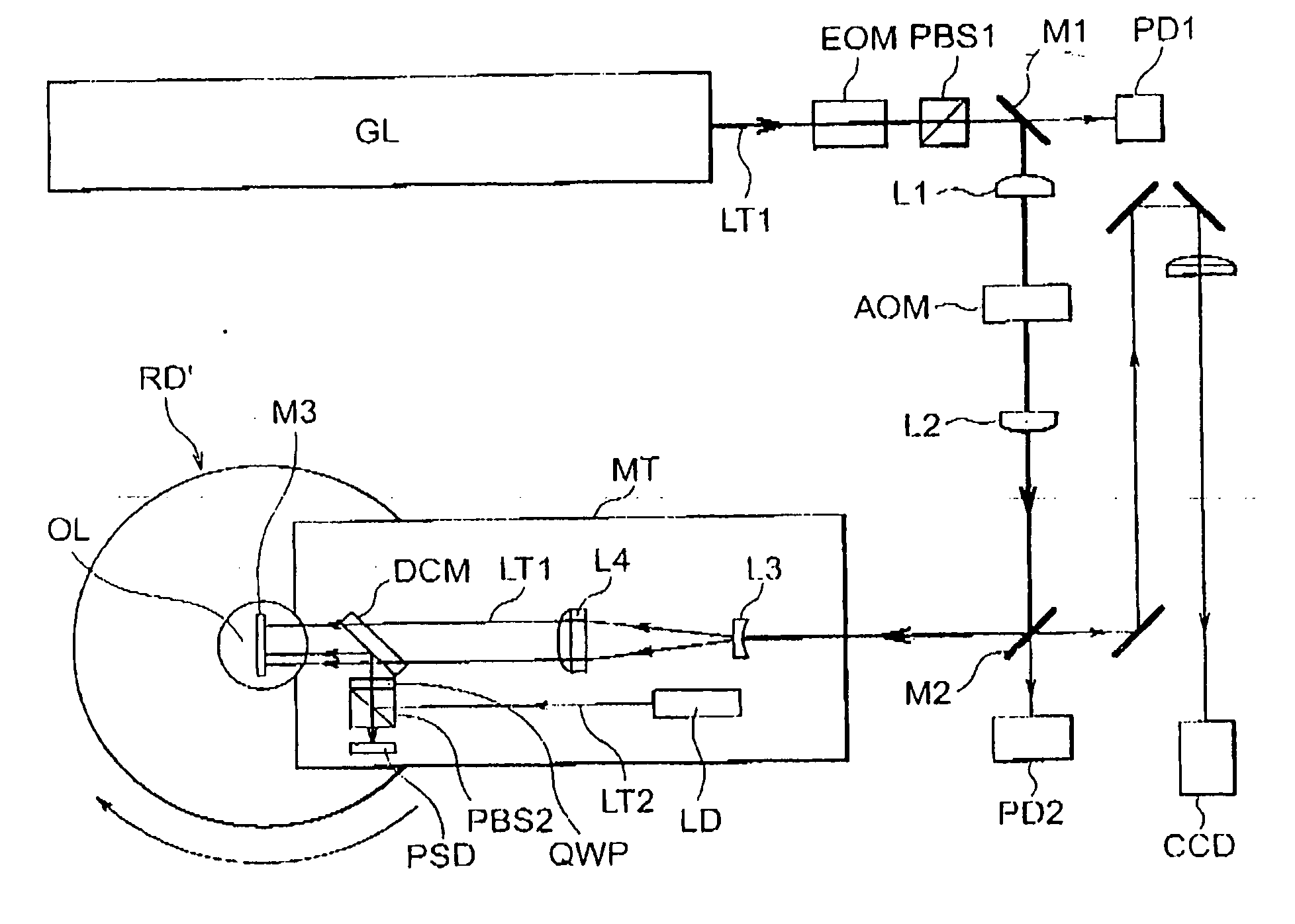

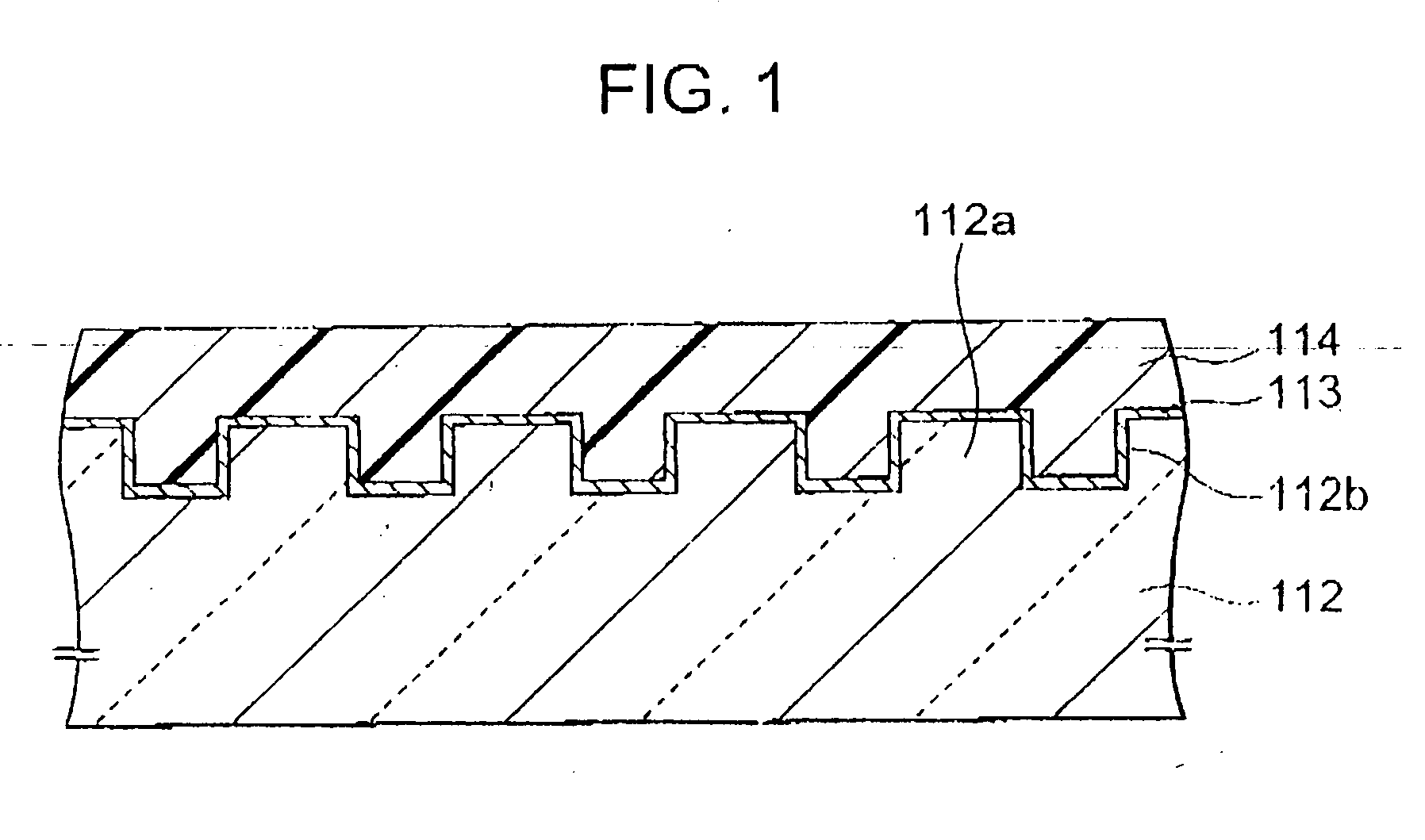

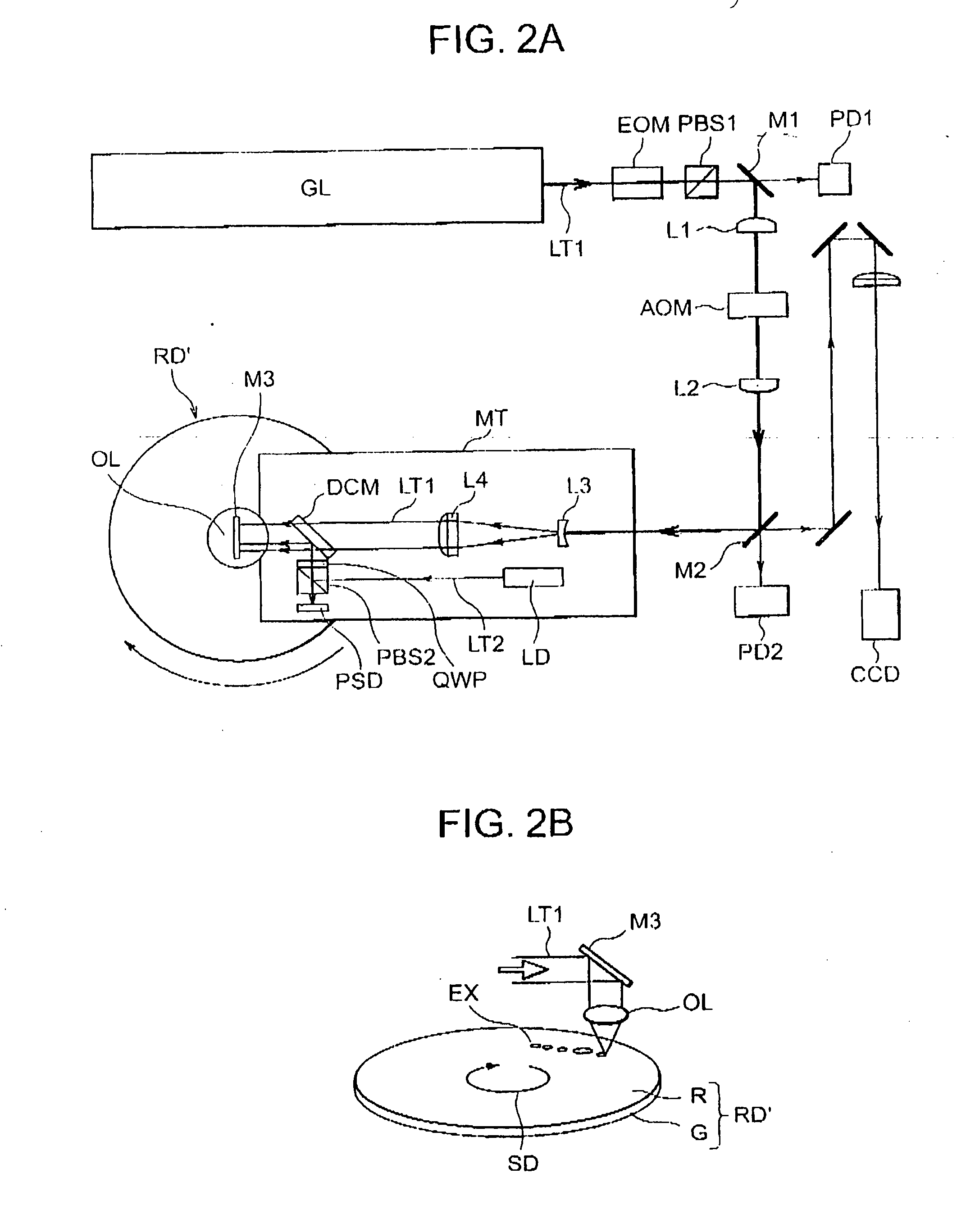

Stamper for producing optical recording medium, optical recording medium, and methods of producing the same

InactiveUS20050219992A1Reduce low frequency noiseReduce focusRecord carriersElectron beam carrier recordingResistUltraviolet

Owner:SONY CORP

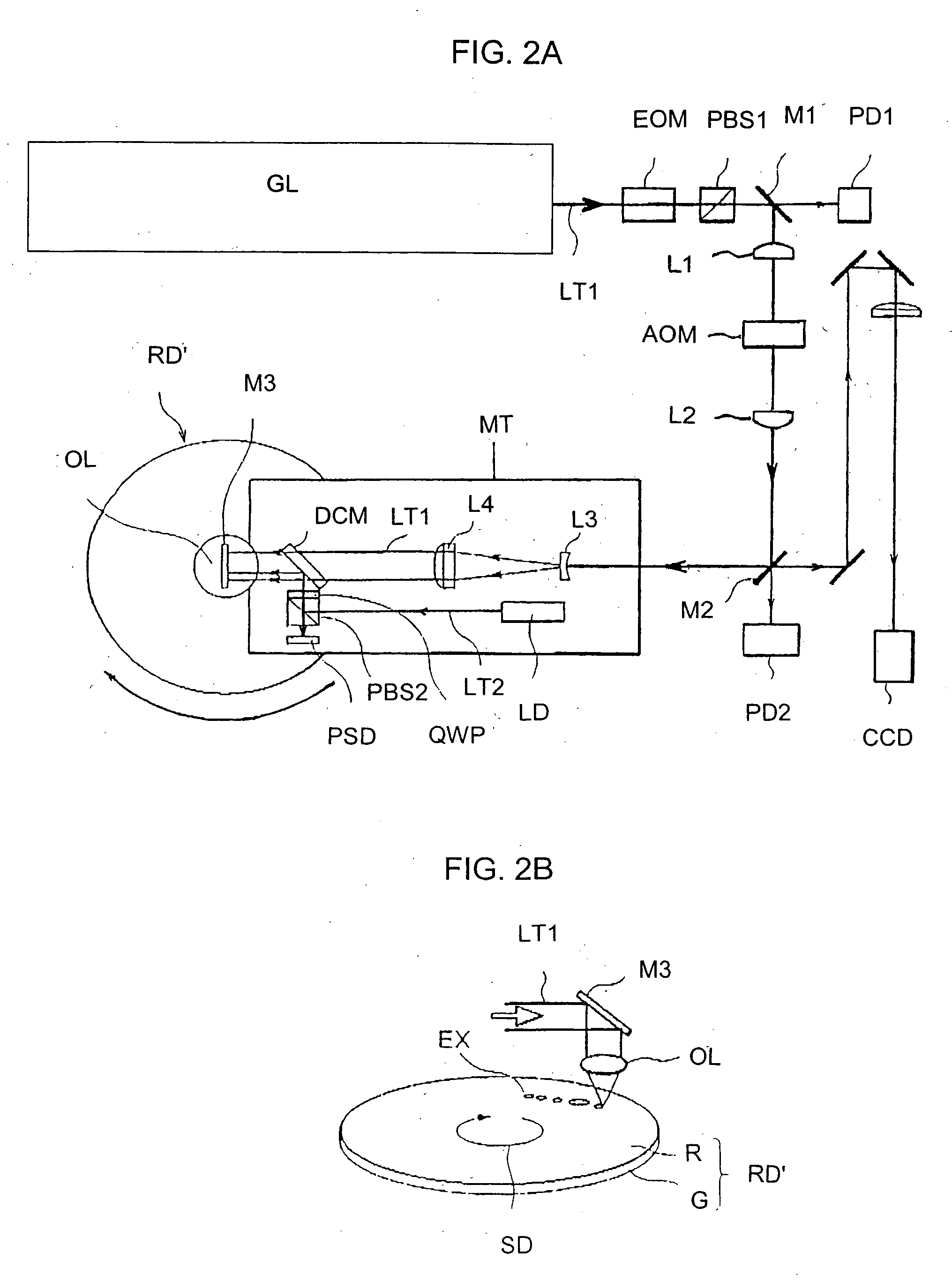

Manufacturing method and manufacturing apparatus for an optical data recording medium, and an optical data recording medium

InactiveUS20070020561A1Suppress roughnessSuppress thickness variationPhotomechanical apparatusRecord information storageOptoelectronicsRadiation

A manufacturing method for an optical data recording medium having a substrate with at least one signal recording layer and a resin layer for passing light, the manufacturing method includes: coating a radiation-curable resin on the substrate; and forming the resin layer by curing at least a part of the radiation-curable resin by increasing the rotational speed of the substrate to a first speed, then decreasing the rotational speed of the substrate, and emitting radiation while the rotational speed of the substrate is decreasing.

Owner:PANASONIC CORP

Stamper for producing optical recording medium, optical recording medium, and methods of producing the same

InactiveUS20050167868A1Reduce low frequency noiseImproving crosstalk characteristicRecord carriersVacuum evaporation coatingResistUltraviolet

A stamper suppressed in surface roughness, uneven thickness, and deviation of circularity in inner circumference, a method of producing the same, an optical recording medium produced by molding using the stamper, and a method of producing the same, wherein a base member having a mirror polished main surface and comprising silicon or glass is formed with a resist film; the resist film is exposed by a focused electron beam, an ultraviolet ray laser, etc. and developed so as to form a resist film of a pattern corresponding to relief shapes; the mirror surface of the base member is processed to relief shapes (projecting regions and recessed regions) by dry etching etc. using the obtained resist film as a mask so as to obtain a stamper; the obtained stamper is used for injection molding to form a medium substrate; and an optical recording multilayer film and a protective layer are formed to thereby produce an optical recording medium.

Owner:SONY CORP

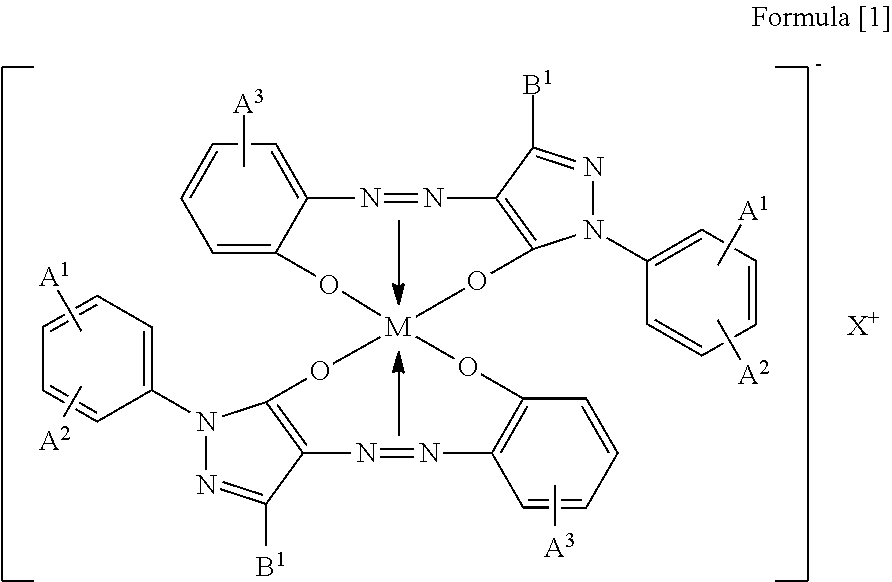

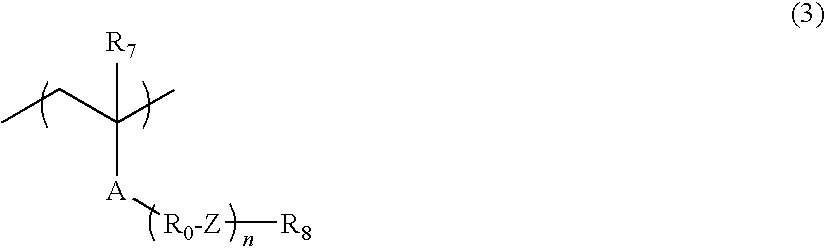

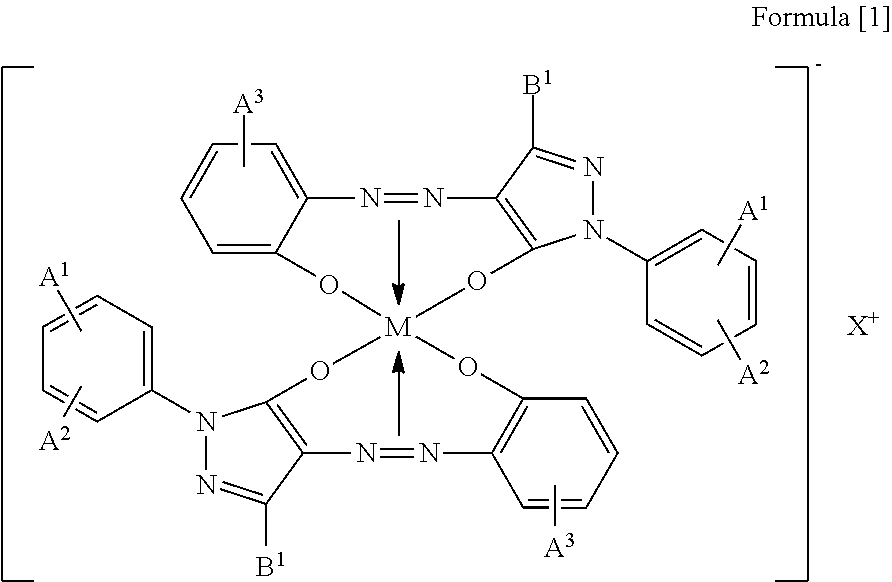

Toner and two-component developer

ActiveUS9606466B2Excellent low temperature fixabilitySuppress roughnessDevelopersPolyesterChemical compound

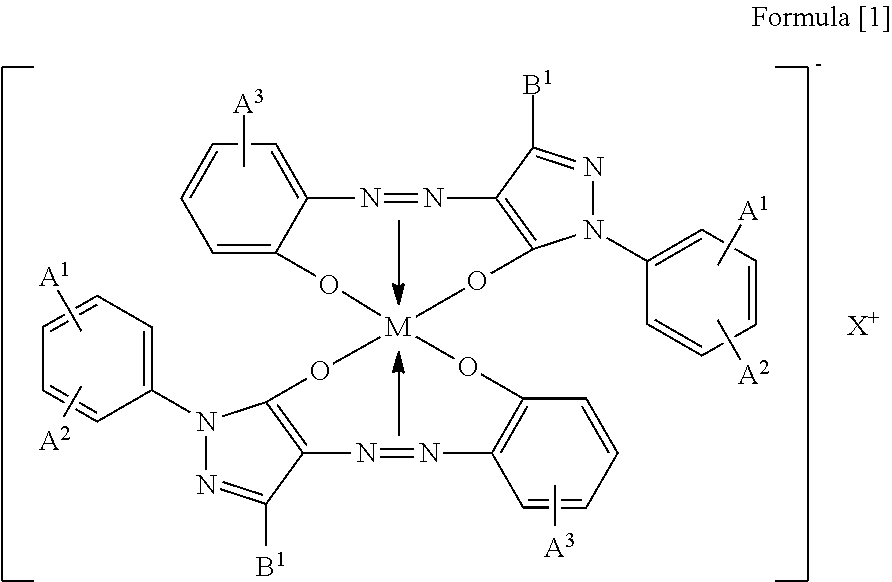

The present invention is a toner including a toner particle containing a binder resin and a charge control agent, wherein the binder resin includes a resin having a polyester unit with at least one aliphatic compound condensed to the terminal thereof, the at least one aliphatic compound being selected from the group consisting of aliphatic monocarboxylic acids each having 30 or more and 102 or less carbon atoms and aliphatic monoalcohols each having 30 or more and 102 or less carbon atoms; and the charge control agent includes a specific compound (a pyrazolone monoazo metal compound).

Owner:CANON KK

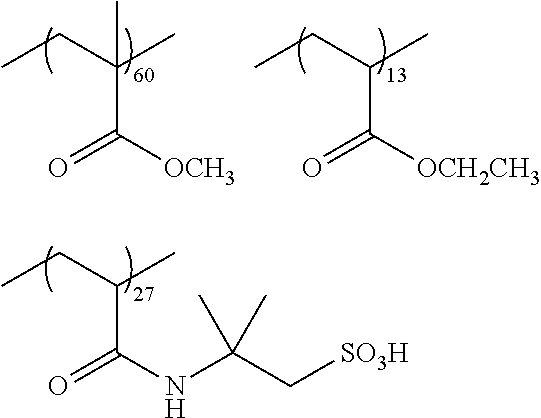

Actinic ray-sensitive or radiation-sensitive resin composition and pattern forming method using the same

ActiveUS20100183980A1Improve performanceWide exposure latitudePhotosensitive materialsPhotomechanical exposure apparatusActinic RaysPolymer chemistry

An actinic ray-sensitive or radiation-sensitive resin composition includes: (A) a compound capable of generating an acid upon irradiation with an actinic ray or radiation; (B) a resin capable of increasing a dissolution rate of the resin (B) in an alkali developer by an action of an acid, the resin (B) containing a specific repeating unit having a lactone structure; and (D) a low molecular compound having a group capable of leaving by an action of an acid, and a pattern forming method uses the composition.

Owner:FUJIFILM CORP

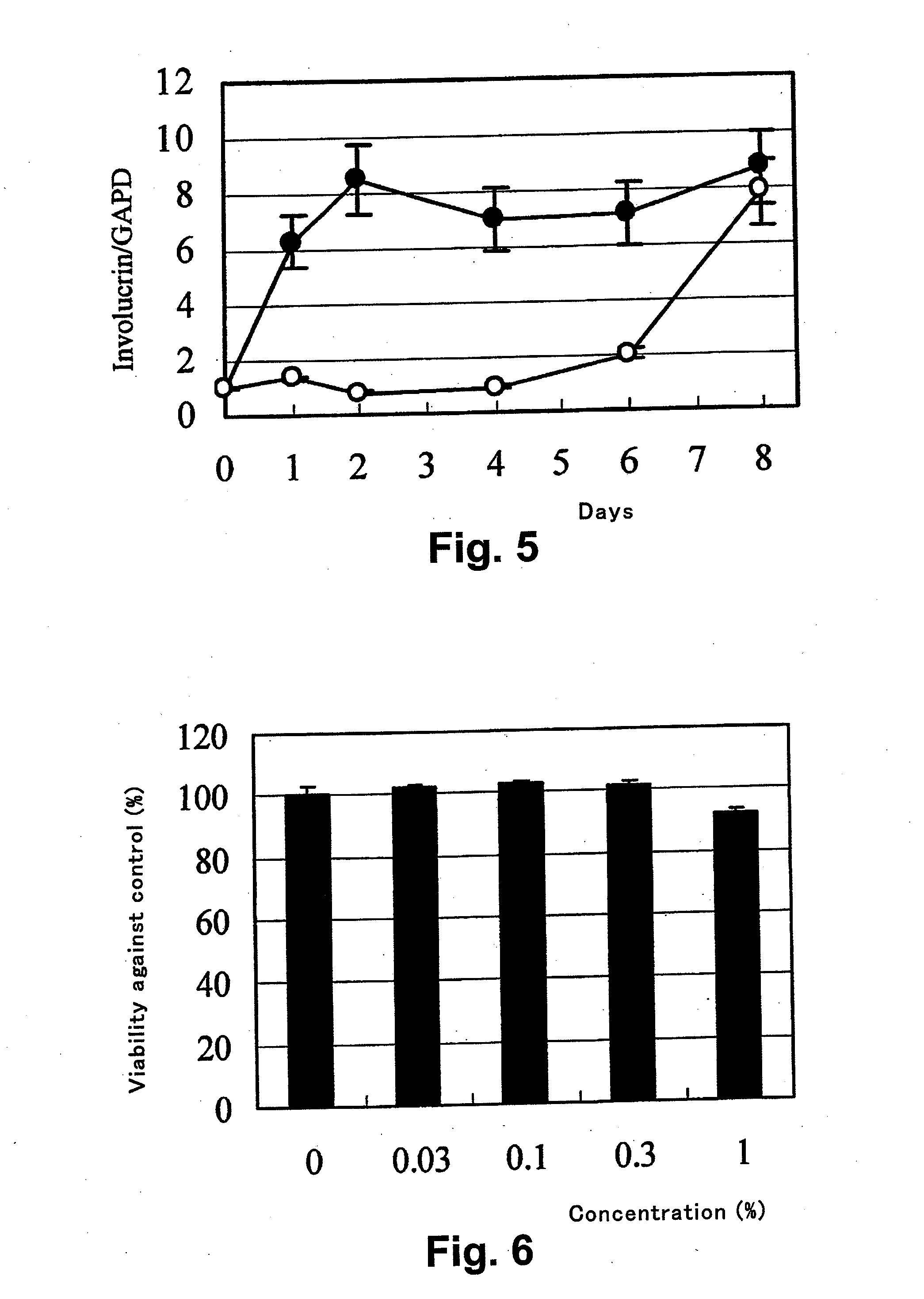

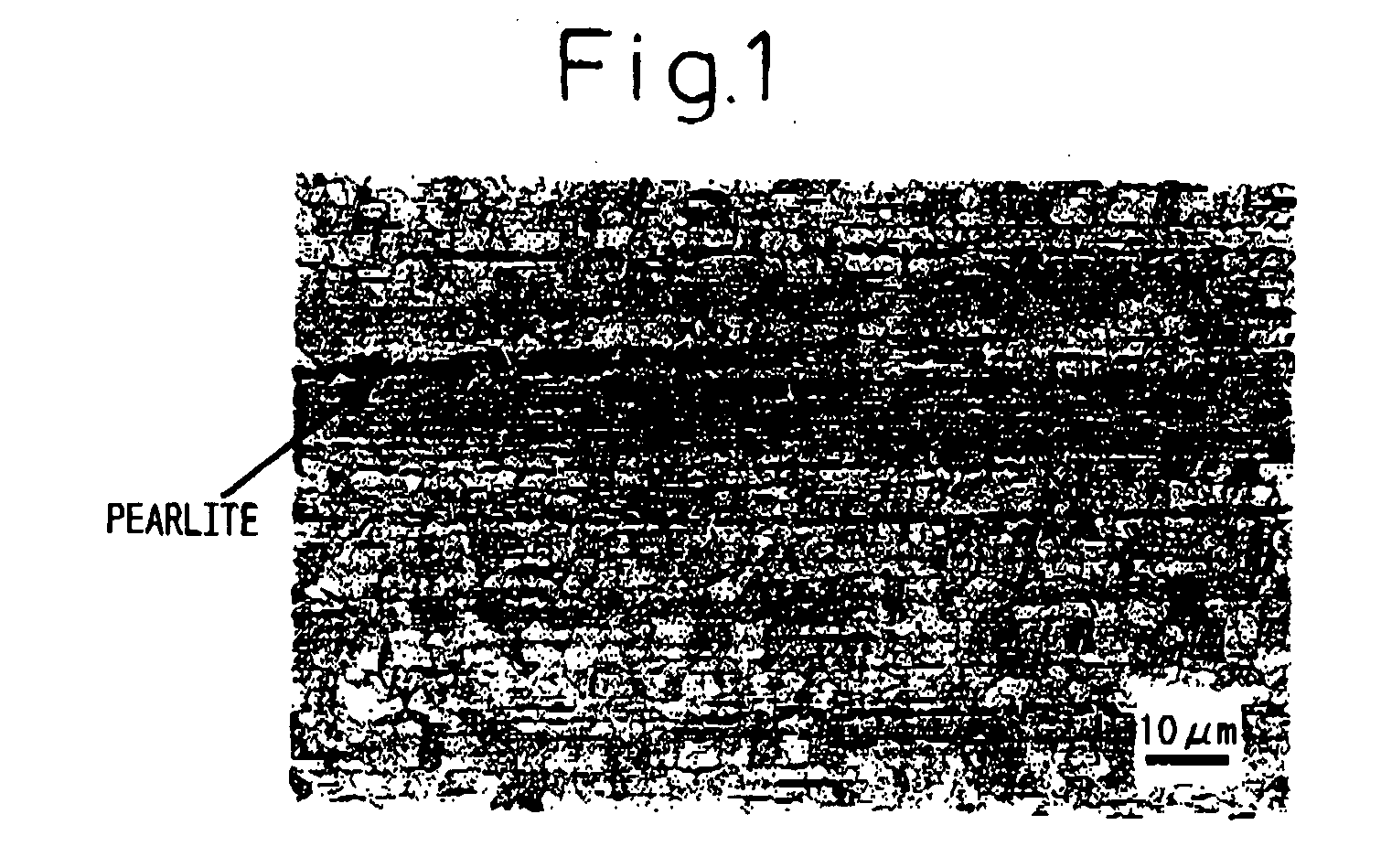

Promoter of differentiation and keratinization of epidermic cell and functional beverage/food for promotion of keratinization of epidermis

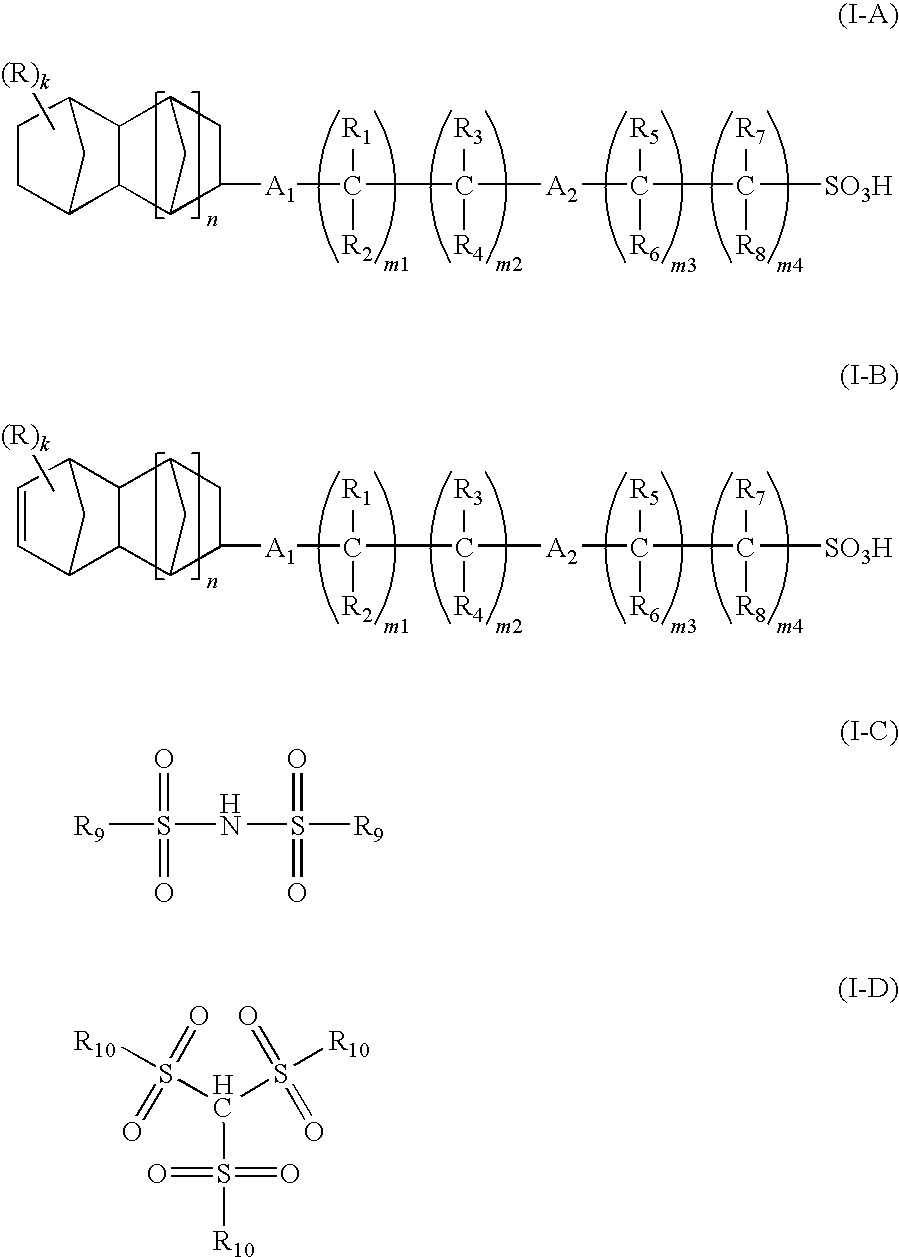

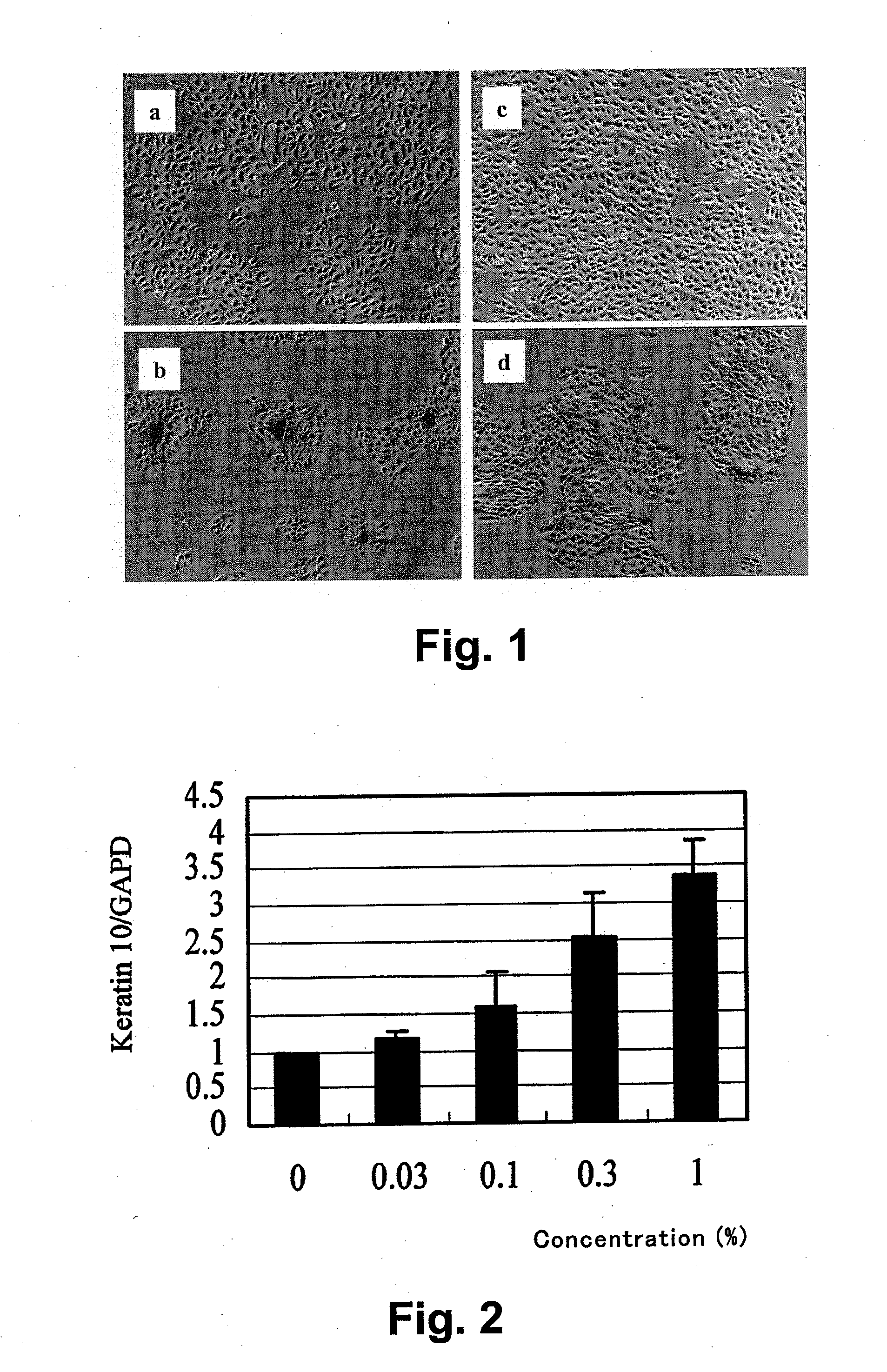

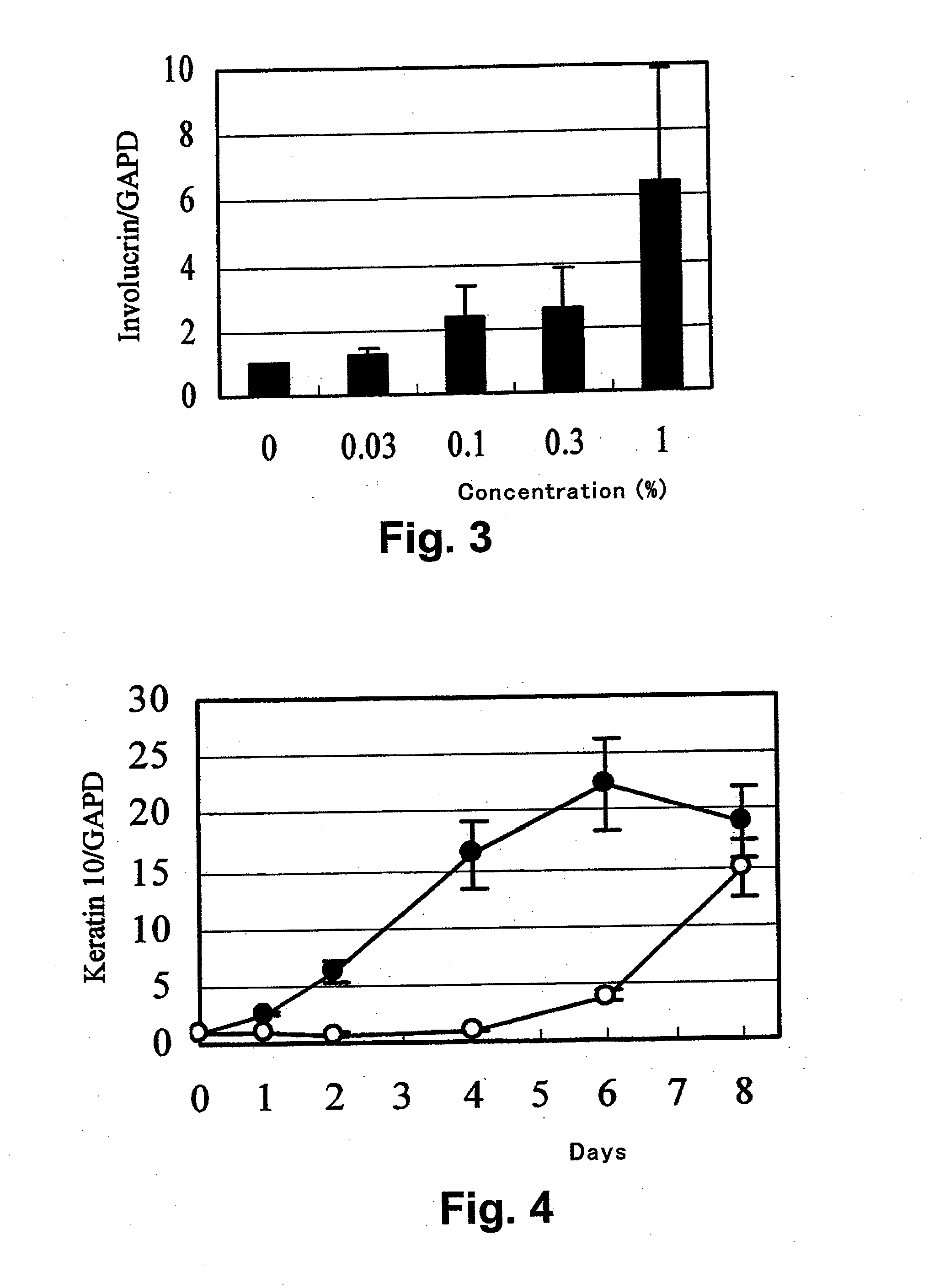

InactiveUS20100166877A1Excellent promote effectImprovement in symptomCosmetic preparationsBiocideFunctional foodCuticle

The invention provides functional food and beverage that produce, through oral intake, a promotive effect on normal epidermal keratinization, and an epidermal differentiation and keratinization promoter for use in such functional food and beverage. The epidermal differentiation and keratinization promoter of the present invention contains, as an active component, fermented milk whey obtained by fermentation of milk with bacteria including lactic acid bacteria, such as Latobacillus helveticus. The functional food and beverage for promoting epidermal keratinization of the present invention contains the epidermal differentiation and keratinization promoter.

Owner:CALPIS

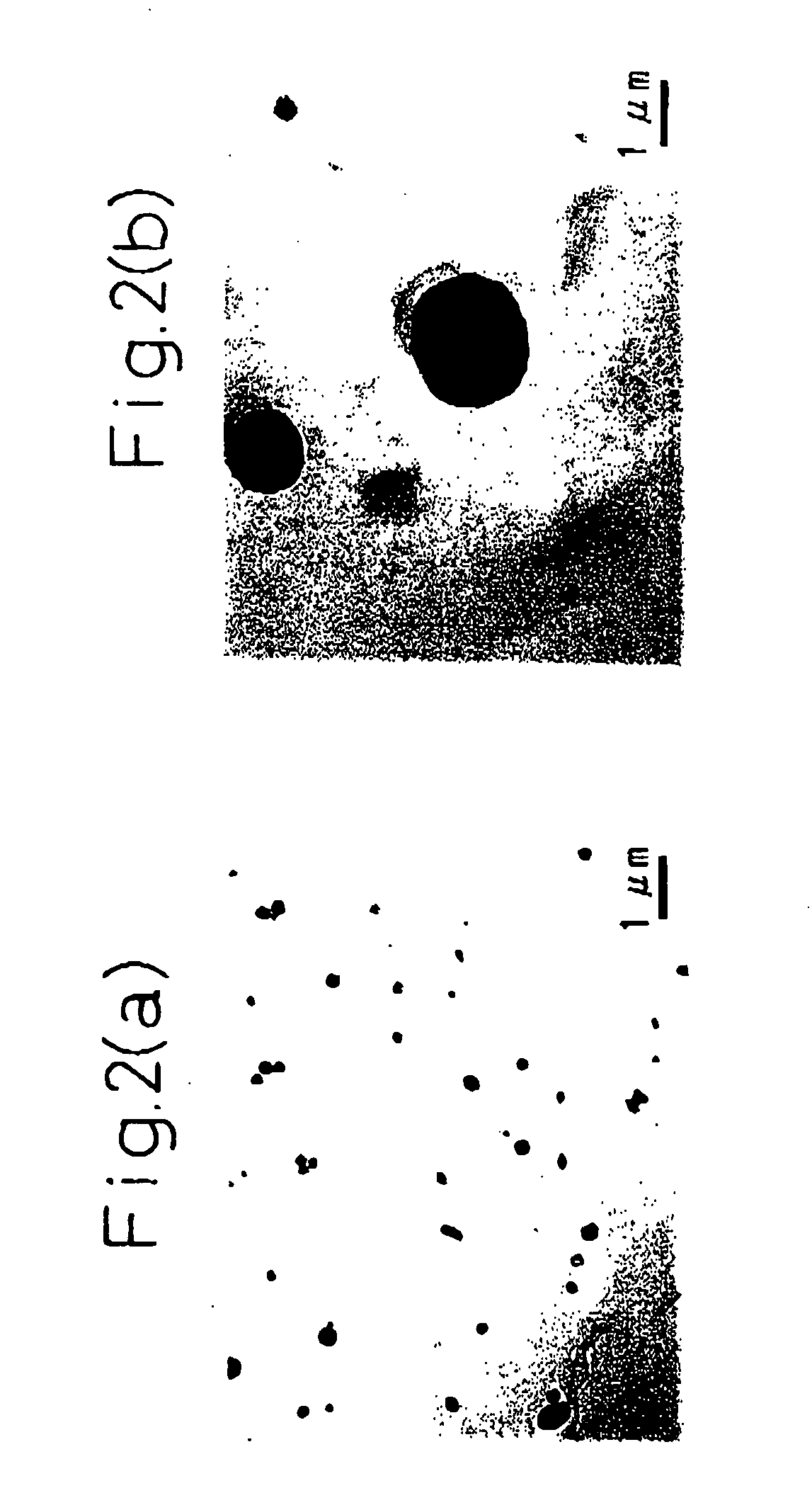

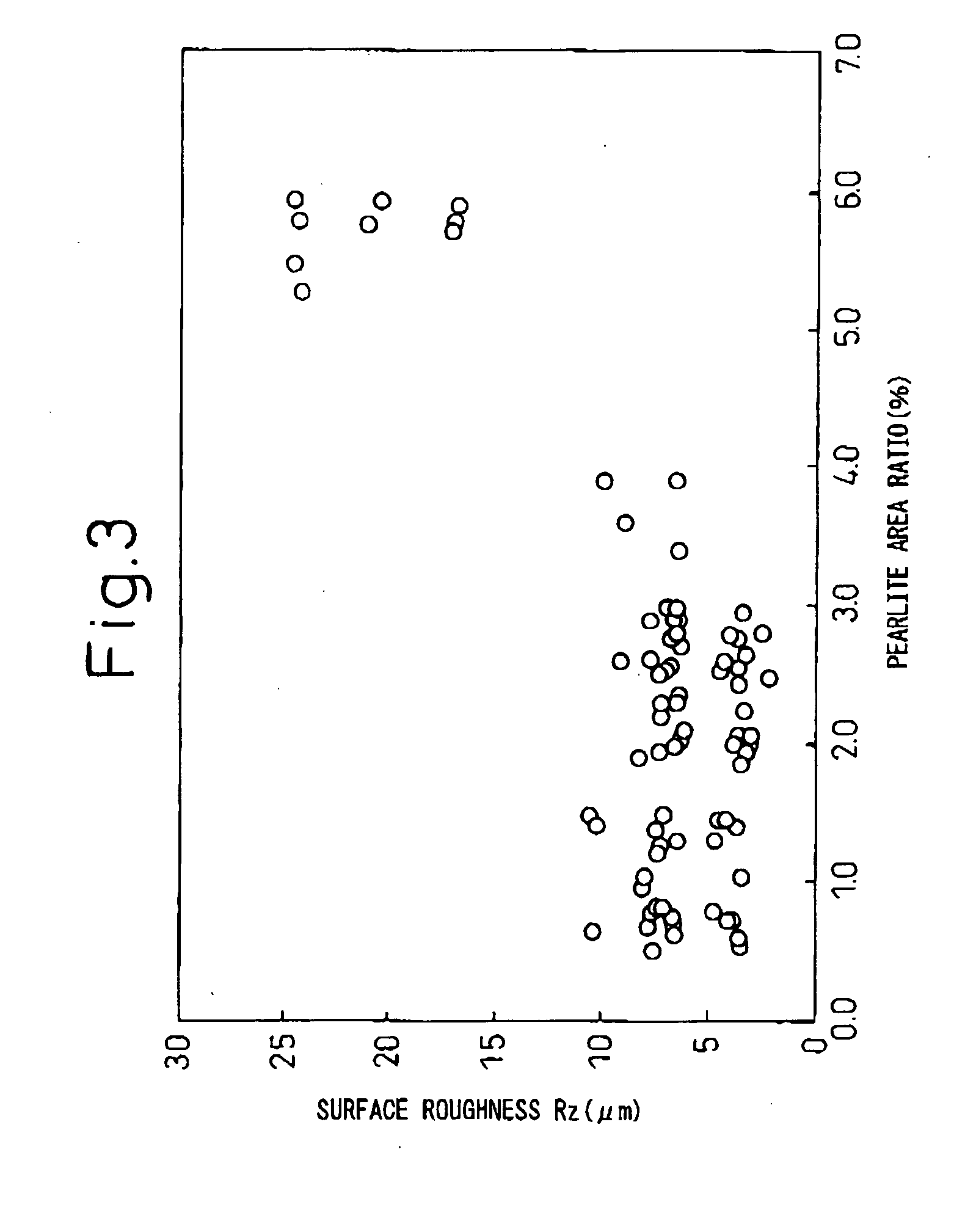

Steel superior in machinability and method of production of same

The present invention provides steel superior in machinability comprised of, by wt %, C: 0.005 to 0.2%, Si: 0.001 to 0.5%, Mn: 0.2 to 3.0%, P: 0.001 to 0.2%, S: 0.03 to 1.0%, T.N: 0.002 to 0.02%, T.O: 0.0005 to 0.035%, and the balance of Fe and unavoidable impurities, said steel satisfying one or both of Mn / S in the steel being 1.2 to 2.8 or an area ratio of pearlite over a grain size of 1 μm in a microstructure of the steel being not more than 5%.

Owner:NIPPON STEEL CORP

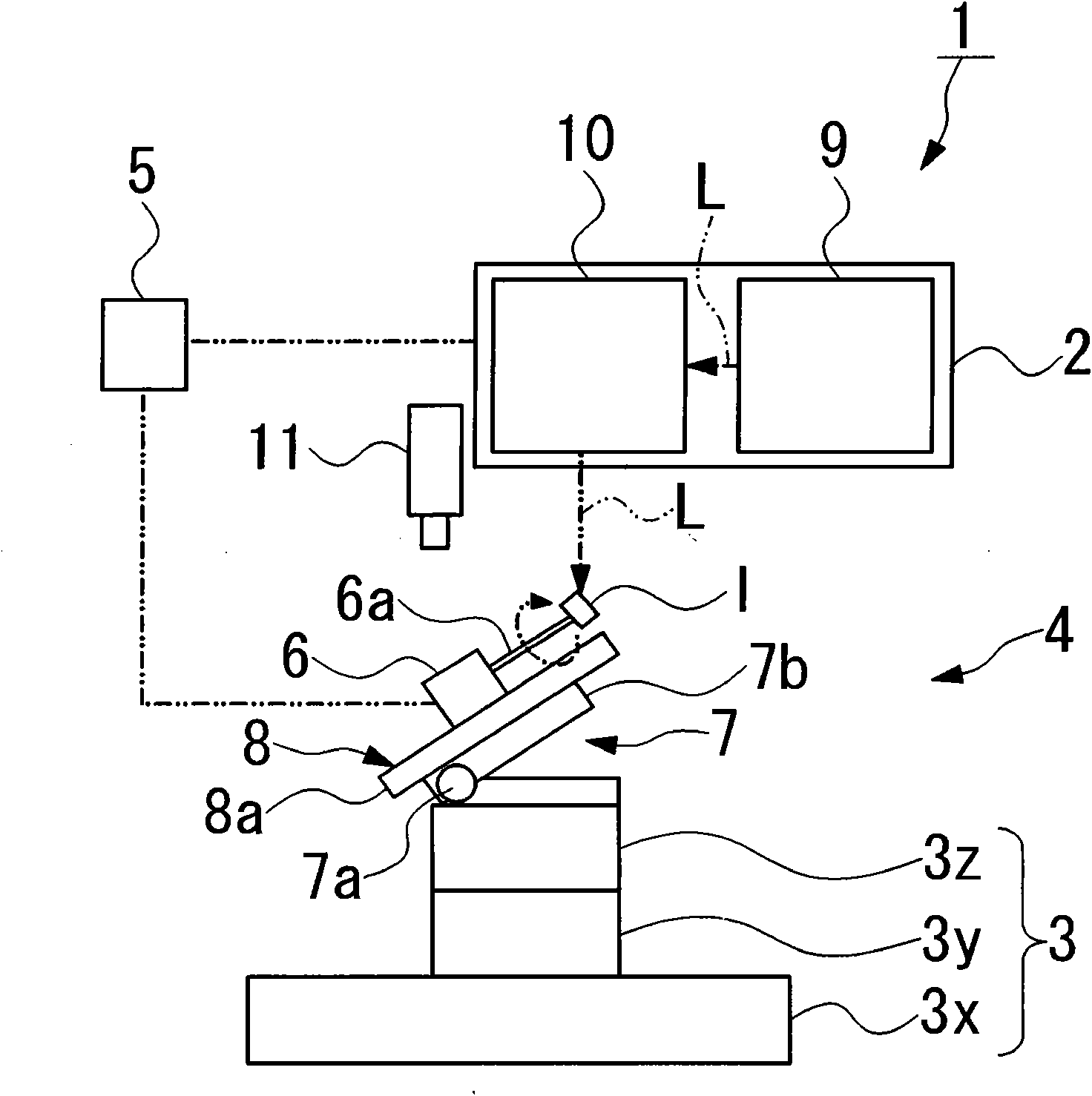

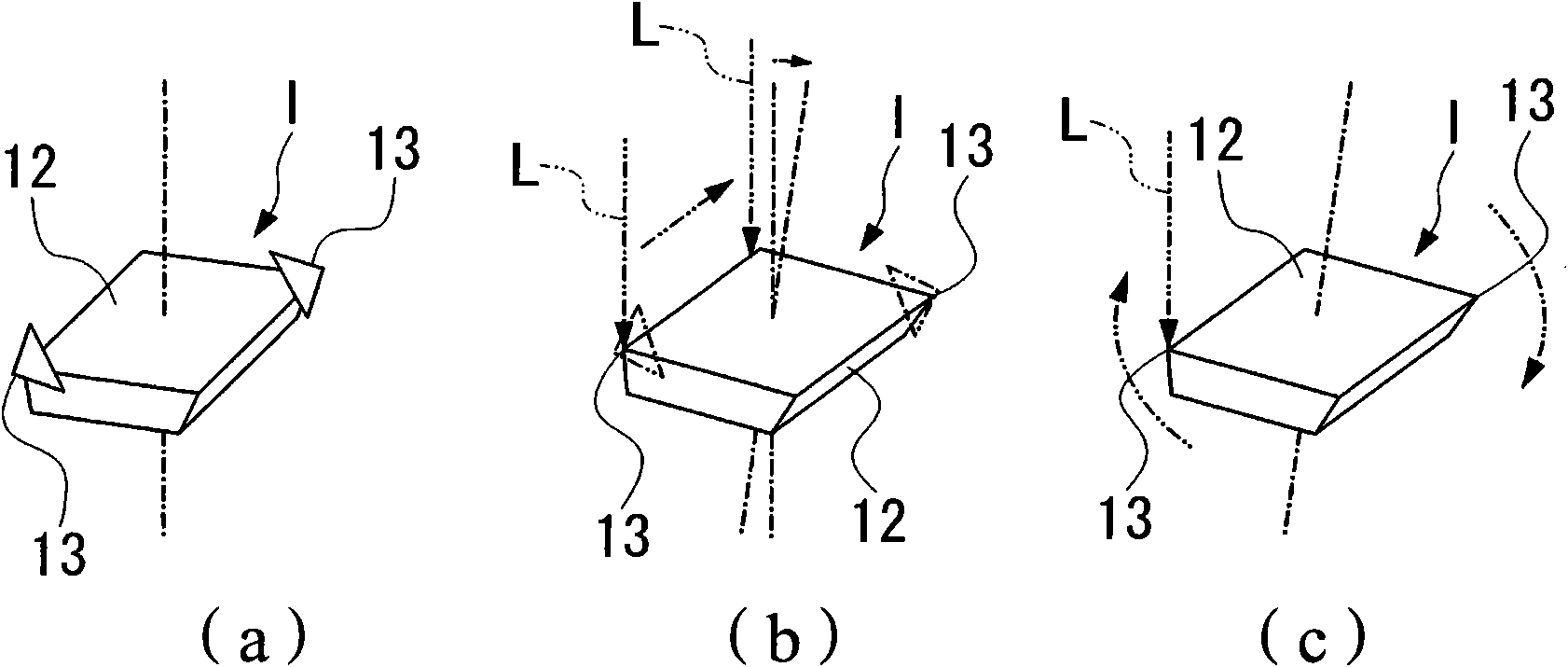

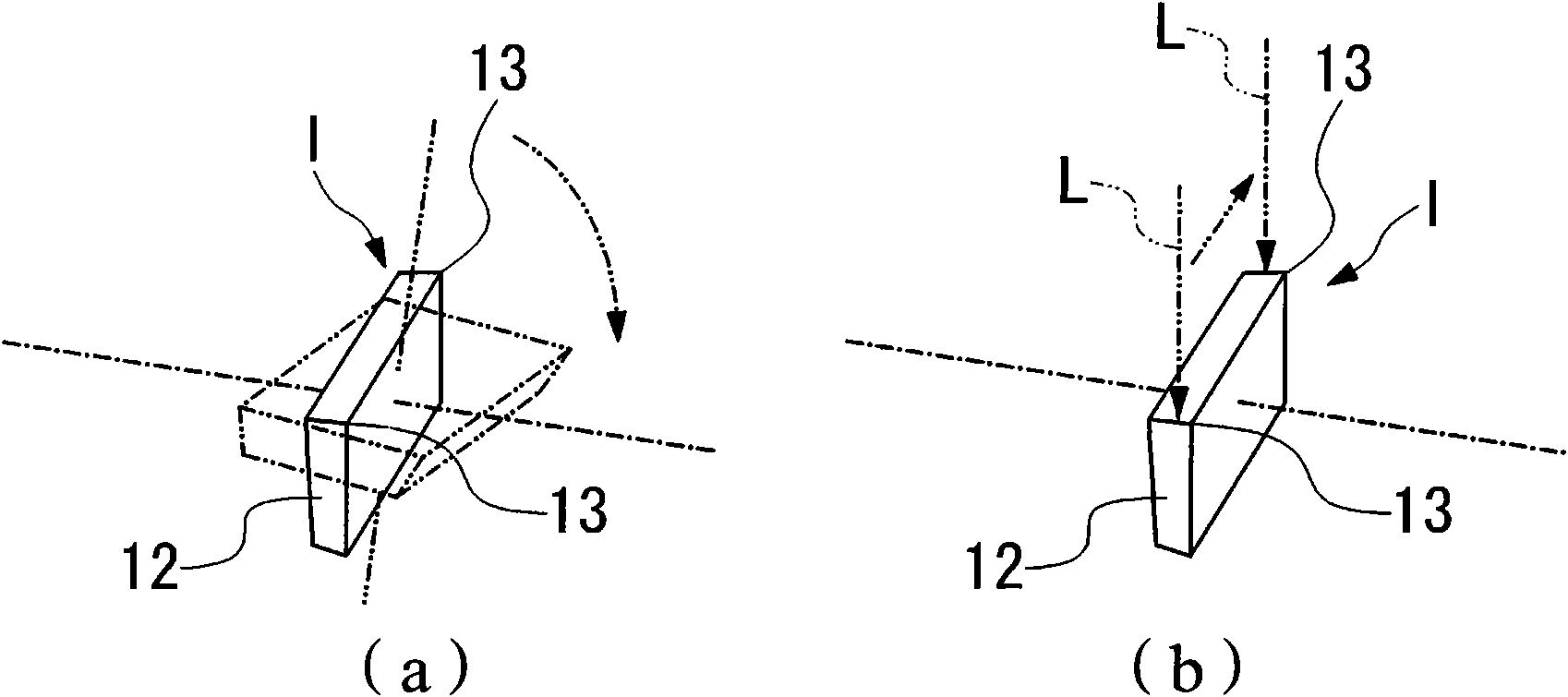

Laser processing device and laser processing method using tool of the laser processing device

InactiveCN102091864ASuppress roughnessHigh dimensional accuracyLaser beam welding apparatusLaser processingLaser light

The invention provides a laser processing device and a laser processing method using a tool of the laser processing device, the laser processing device obtains high size precision via laser processing according to moving and rotating states of tools, etc. A device performing processing via irradiating laser light (L) to a waiting-to-be-processed image (I) is provided with: a laser illuminating mechanism (2) performing illuminating upon the waiting-to-be-processed image (I) via oscillating the laser light according to input trigger signals; a moving mechanism (4) capable of keeping the waiting-to-be-processed image at a rotary shaft (6a) to make the rotary shaft move or rotate, when a moving displacement amount of a moving objective table or a rotating displacement amount of the rotary shaft (6a) is outputted as coder signals; and a trigger signal generation circuit part (5) outputting trigger signals to the laser illuminating mechanism according to set counting amount while counting encoder signals.

Owner:MITSUBISHI MATERIALS CORP

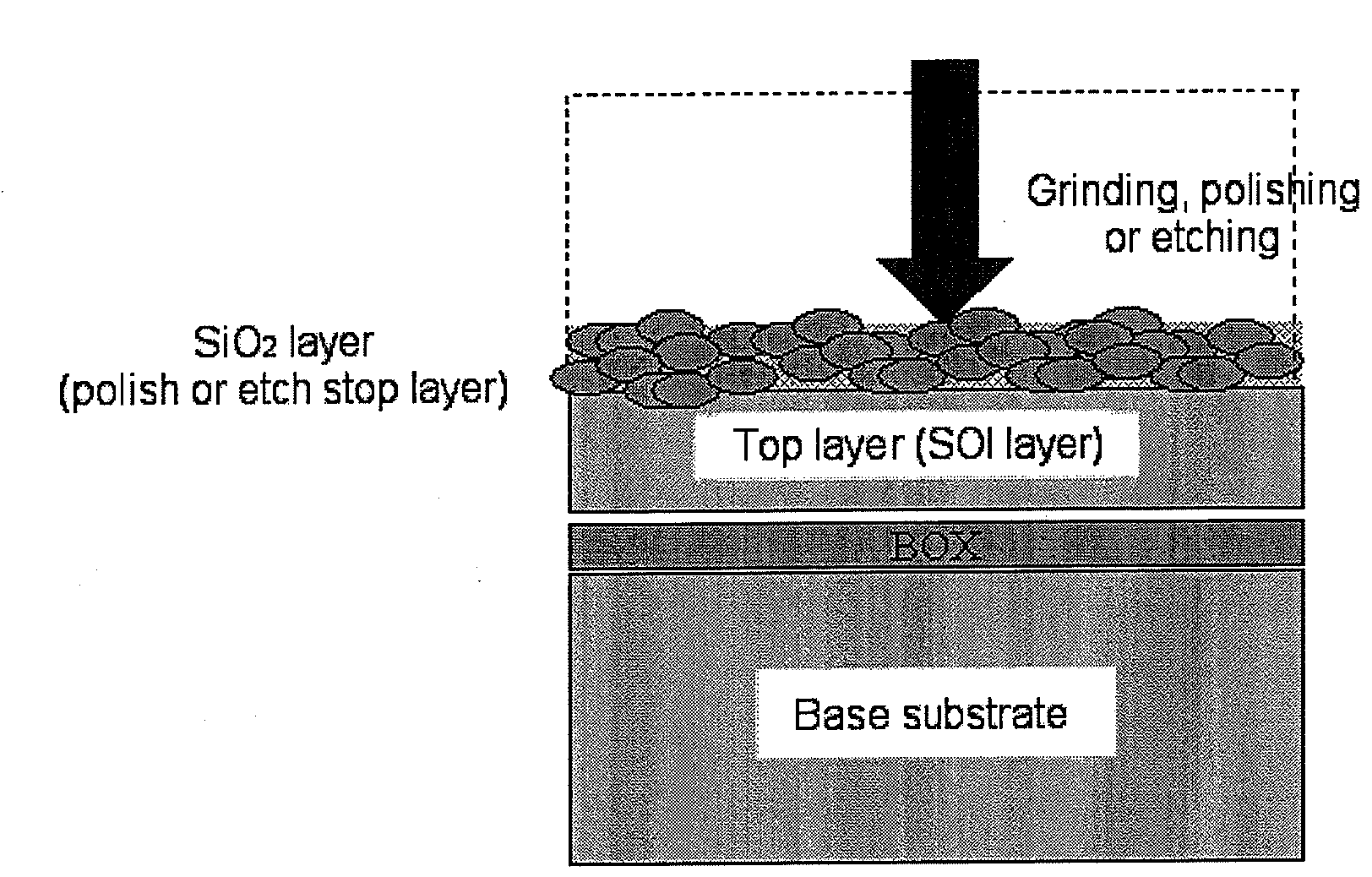

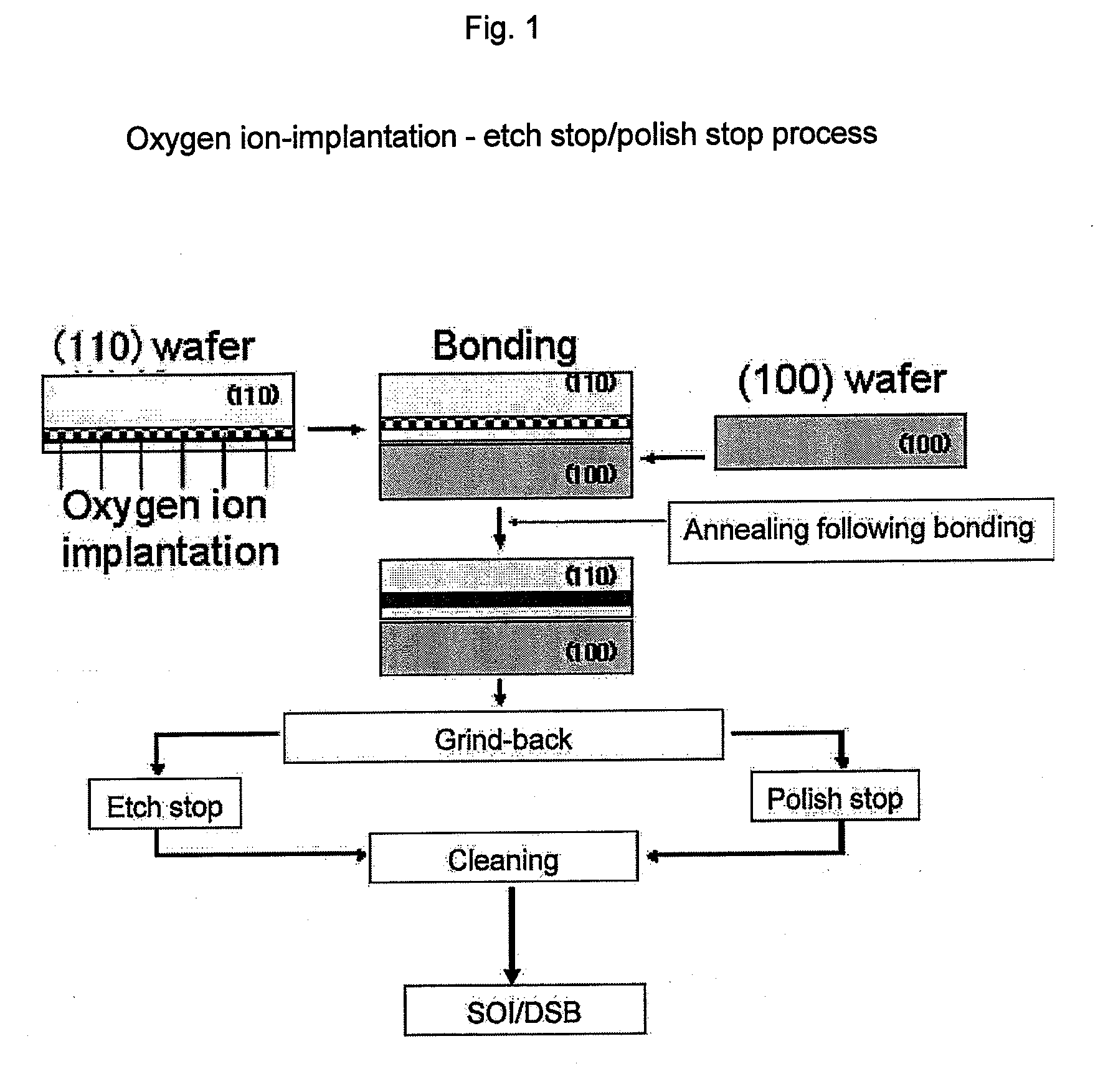

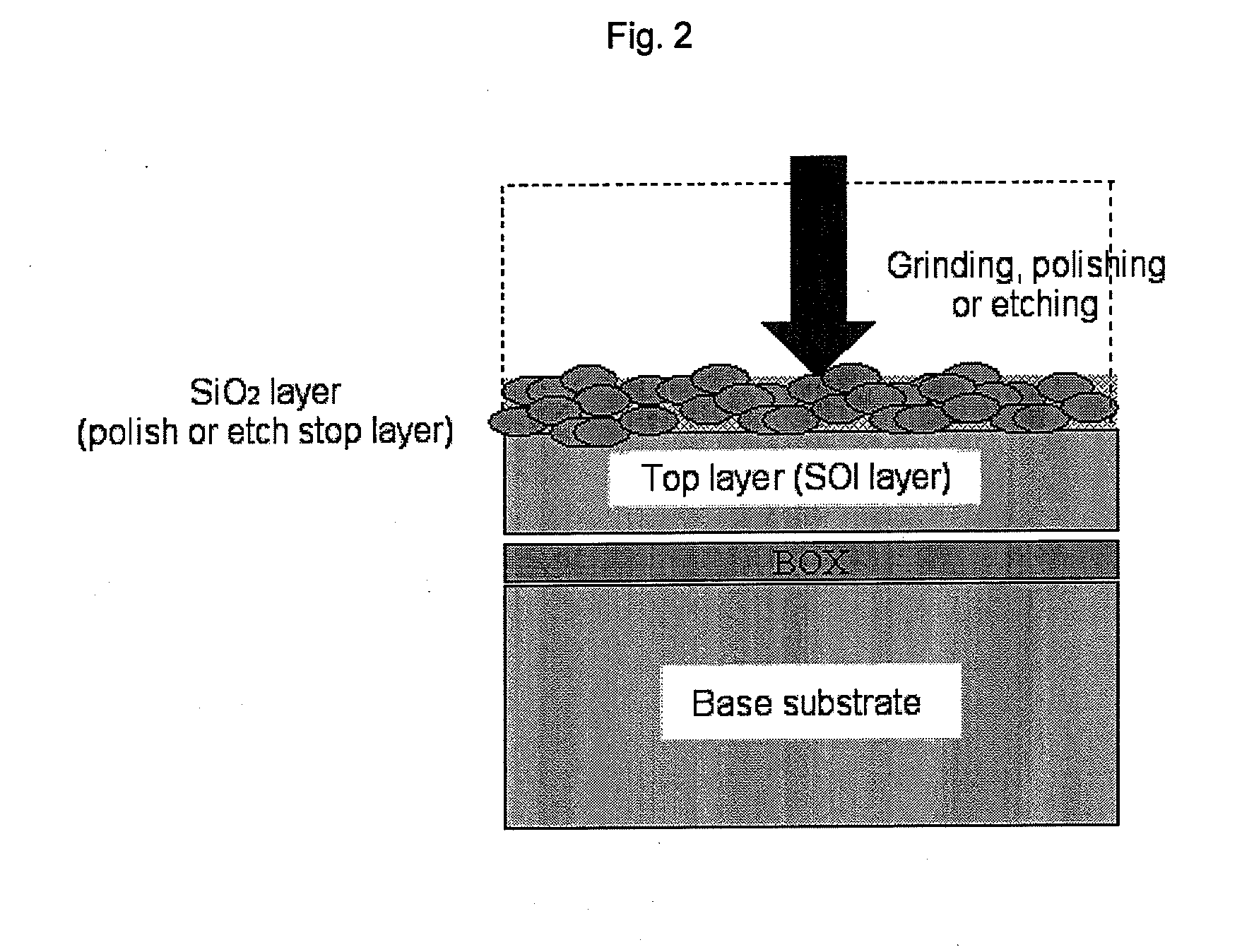

Method of manufacturing bonded wafer

ActiveUS20080248630A1Reduce surface roughnessSuppressing interface roughnessSemiconductor/solid-state device manufacturingSubstrate resistivityOxygen ions

The present invention provides a method of manufacturing a bonded wafer. The method includes forming an oxygen ion implantation layer in an active layer wafer having a substrate resistivity of 1 to 100 mΩcm by implanting oxygen ions in the active layer wafer, bonding a base wafer and the active layer wafer directly or through an insulating layer to form a bonded wafer, heat treating the bonded wafer to strengthen the bond and convert the oxygen ion implantation layer into a stop layer, grinding, polishing, and / or etching, from the active layer wafer surface side, the bonded wafer in which the bond has been strengthened to expose the stop layer on a surface of the bonded wafer, removing the stop layer, and subjecting the bonded wafer from which the stop layer has been removed to a heat treatment under a reducing atmosphere to diffuse an electrically conductive component comprised in the active layer wafer.

Owner:SUMCO CORP

Actinic ray-sensitive or radiation-sensitive resin composition and pattern forming method using the same

ActiveUS8617785B2Improve performanceWide exposure latitudePhotosensitive materialsSemiconductor/solid-state device manufacturingActinic RaysFluence

An actinic ray-sensitive or radiation-sensitive resin composition includes: (A) a compound capable of generating an acid upon irradiation with an actinic ray or radiation; (B) a resin capable of increasing a dissolution rate of the resin (B) in an alkali developer by an action of an acid, the resin (B) containing a specific repeating unit having a lactone structure; and (D) a low molecular compound having a group capable of leaving by an action of an acid, and a pattern forming method uses the composition.

Owner:FUJIFILM CORP

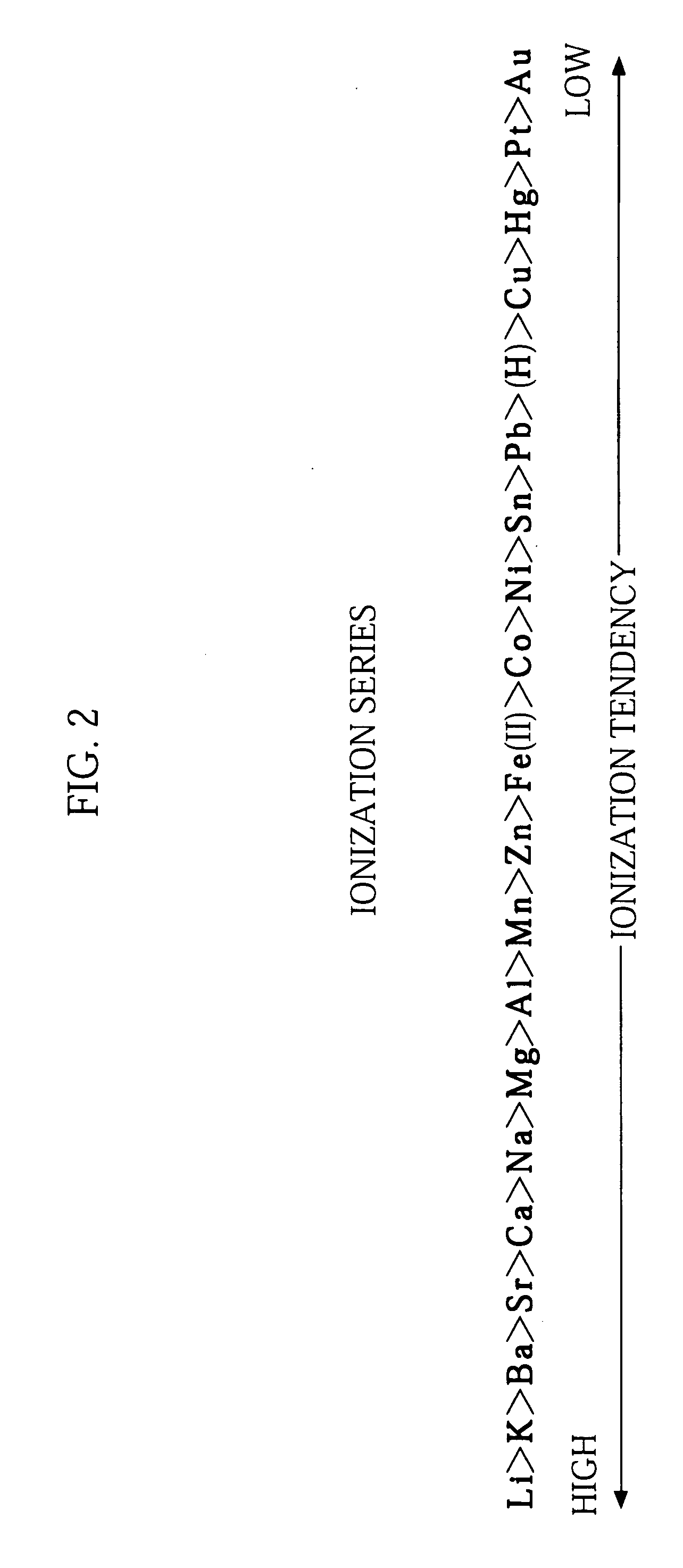

Recording medium substrate and recording medium having an electroless plating film with a good film quality

InactiveUS20060019122A1Increase resistanceInappropriate unevennessRecord information storageMagnetic recordingAlloyMaterials science

A recording medium substrate has on a surface thereof a foundation film for electroless plating film formation, or has such a foundation film and an electroless plating film formed thereon. The foundation film includes an alloy containing one metallic element selected from Co and Cu, and an element having a greater ionization tendency than the metallic element. A recording medium may be manufactured, for example, using such a recording medium substrate.

Owner:SHOWA DENKO KK

Method of manufacturing CMOS semiconductor device

ActiveUS20040132240A1Sufficient activationReduce effective thicknessTransistorSolid-state devicesCMOSImpurity

A method of manufacturing a CMOS semiconductor device able to reduce the effective thickness of the gate insulating film and able to secure stable performance is provided. The method in one embodiment comprises the steps of: forming a polycrystalline silicon film on a gate insulating film; introducing an n-type impurity into the polycrystalline silicon film in an nMOS formation region before gate processing of the polycrystalline silicon film; performing heat treatment so that the impurity diffuses in the polycrystalline silicon film and is activated; and patterning the polycrystalline silicon to form a gate pattern before introducing an impurity into the polycrystalline silicon film at a pMOS formation region.

Owner:FUJITSU SEMICON LTD

Toner and two-component developer

ActiveUS20150268577A1Excellent low-temperature fixabilitySuppress in scatter and roughnessDevelopersHydrocarbons.aliphaticChemical compound

The present invention is a toner including a toner particle containing a binder resin and a charge control agent, wherein the binder resin includes a resin having a polyester unit with at least one aliphatic compound condensed to the terminal thereof, the at least one aliphatic compound being selected from the group consisting of aliphatic monocarboxylic acids each having 30 or more and 102 or less carbon atoms and aliphatic monoalcohols each having 30 or more and 102 or less carbon atoms; and the charge control agent includes a specific compound (a pyrazolone monoazo metal compound).

Owner:CANON KK

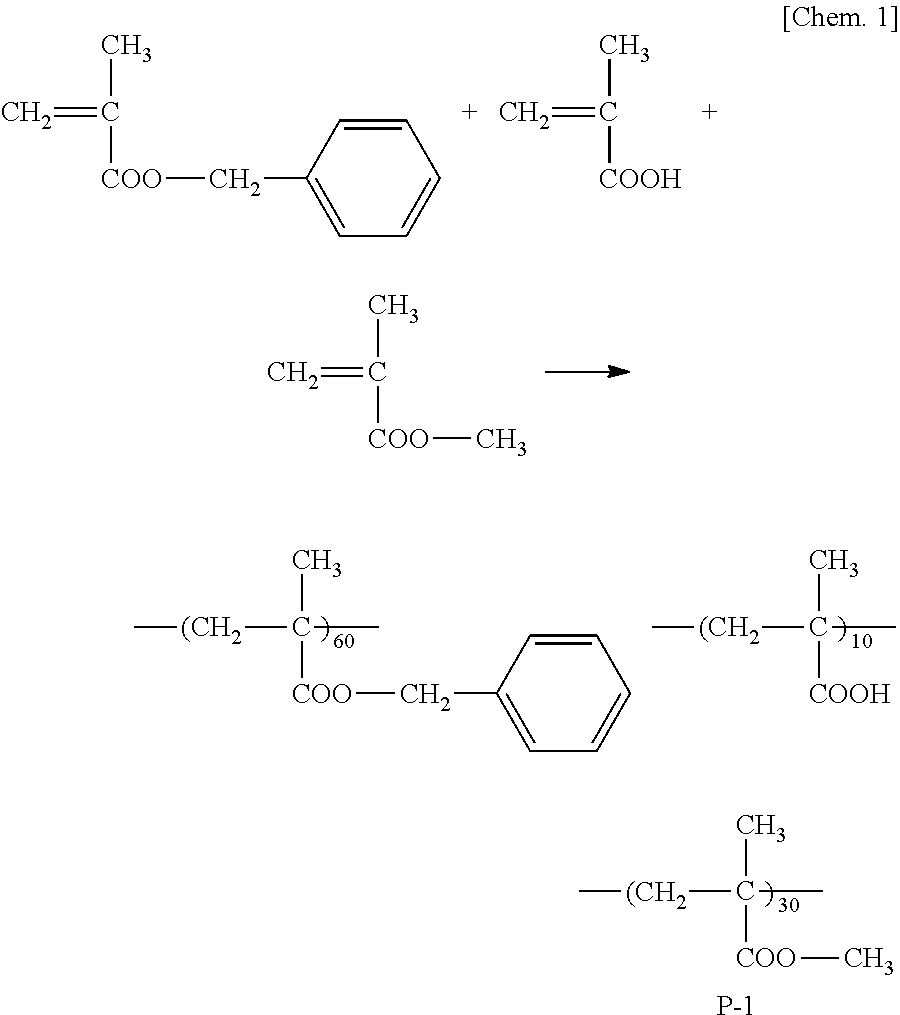

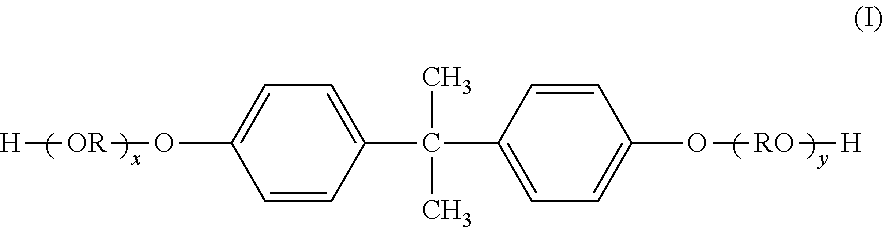

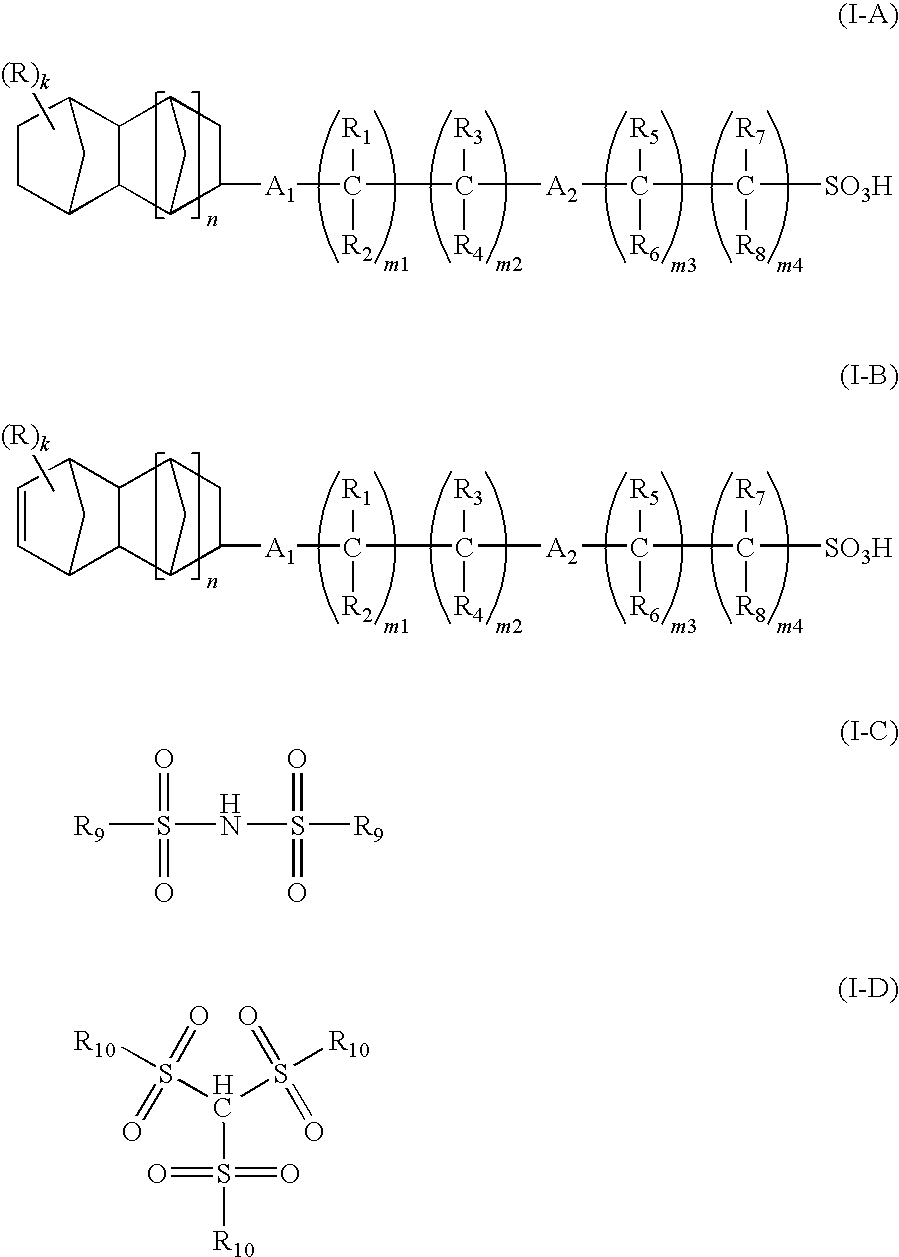

Resist material and pattern formation method using the same

InactiveUS7455950B2Increase contrastSuppress roughnessPhotosensitive materialsSemiconductor/solid-state device manufacturingResistCarbon number

Owner:PANASONIC CORP

Resist material and pattern formation method using the same

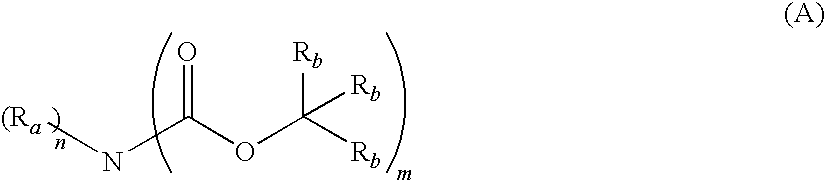

InactiveUS20070248894A1Suppress roughness pattern roughnessSuppress surface roughnessPhotosensitive materialsPhotomechanical apparatusResistPhotochemistry

A resist material includes a polymeric material made of a unit represented by a general formula of the following Chemical Formula; and an acid generator for generating an acid through irradiation with light:wherein R1, R2 and R3 are the same or different and are a hydrogen atom, a fluorine atom, or a straight-chain alkyl group, a branched or cyclic alkyl group or a fluoridated alkyl group with a carbon number not less than 1 and not more than 20; R is a hydrogen atom, a straight-chain alkyl group, a branched or cyclic alkyl group or a fluoridated alkyl group with a carbon number not less than 1 and not more than 20; m≧0, n≧0, s>0 (whereas excluding m=n=0) and 1≦k≦3.

Owner:PANASONIC CORP

Conductive sheet, touch panel, display device, method for producing said conductive sheet, and non-transitory recording medium

ActiveUS9642245B2Easy to seeRoughness easilyConductive layers on insulating-supportsDigital data processing detailsRelative refractive indexDisplay device

Owner:FUJIFILM CORP

Soi substrate and manufacturing method thereof

InactiveUS20110124179A1Suppress surface roughnessIncrease productionSemiconductor/solid-state device manufacturingSemiconductor packageEngineering

The semiconductor substrate provided with a groove portion is irradiated with ions so that an embrittled region is formed in the semiconductor substrate, the semiconductor substrate and a base substrate are bonded to each other with an insulating layer interposed therebetween and a space which is surrounded by the groove portion in the semiconductor substrate and the base substrate is formed, and heat treatment is performed to separate the semiconductor substrate at the embrittled region, so that the semiconductor layer is formed over the base substrate with the insulating layer interposed therebetween.

Owner:SEMICON ENERGY LAB CO LTD

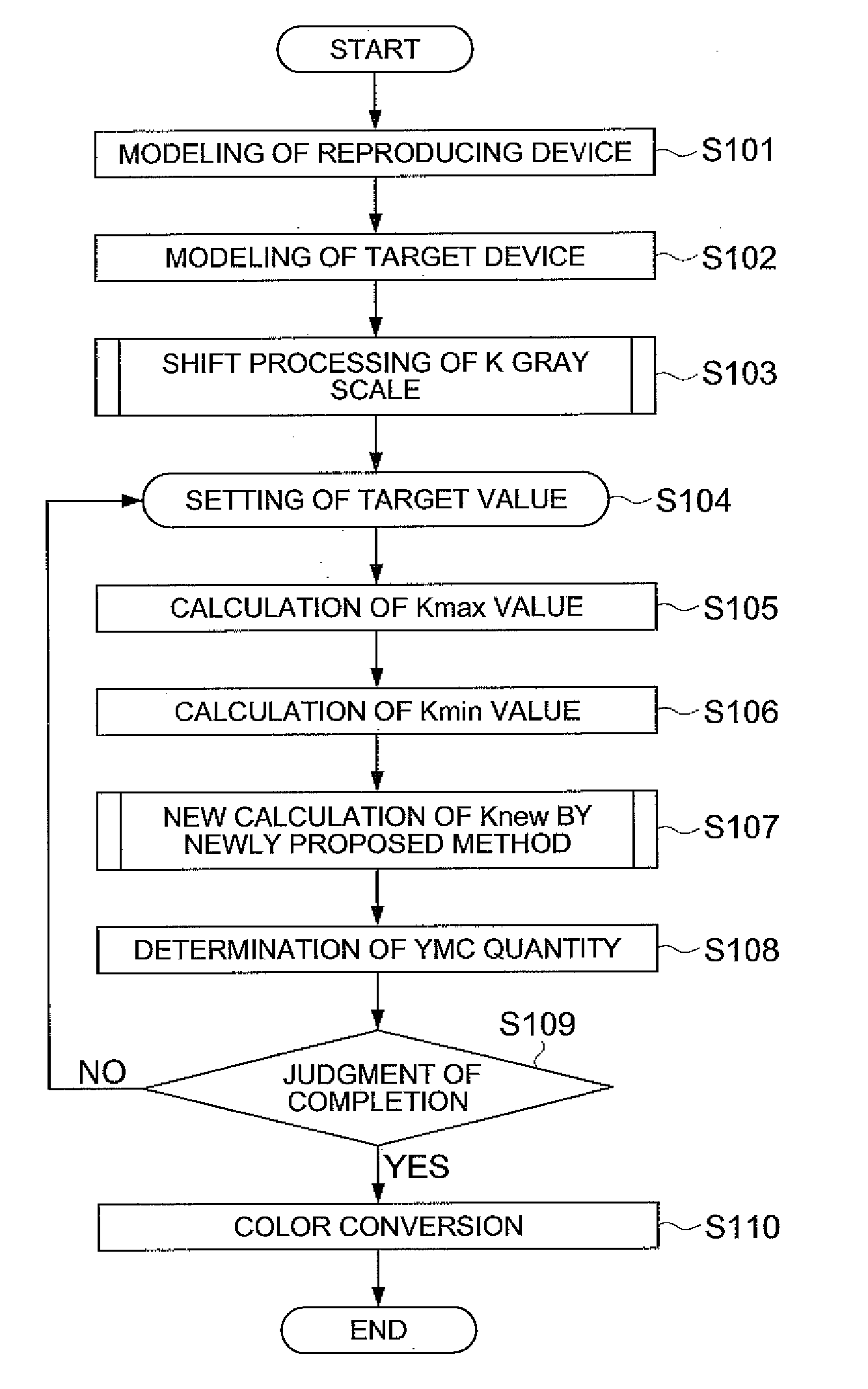

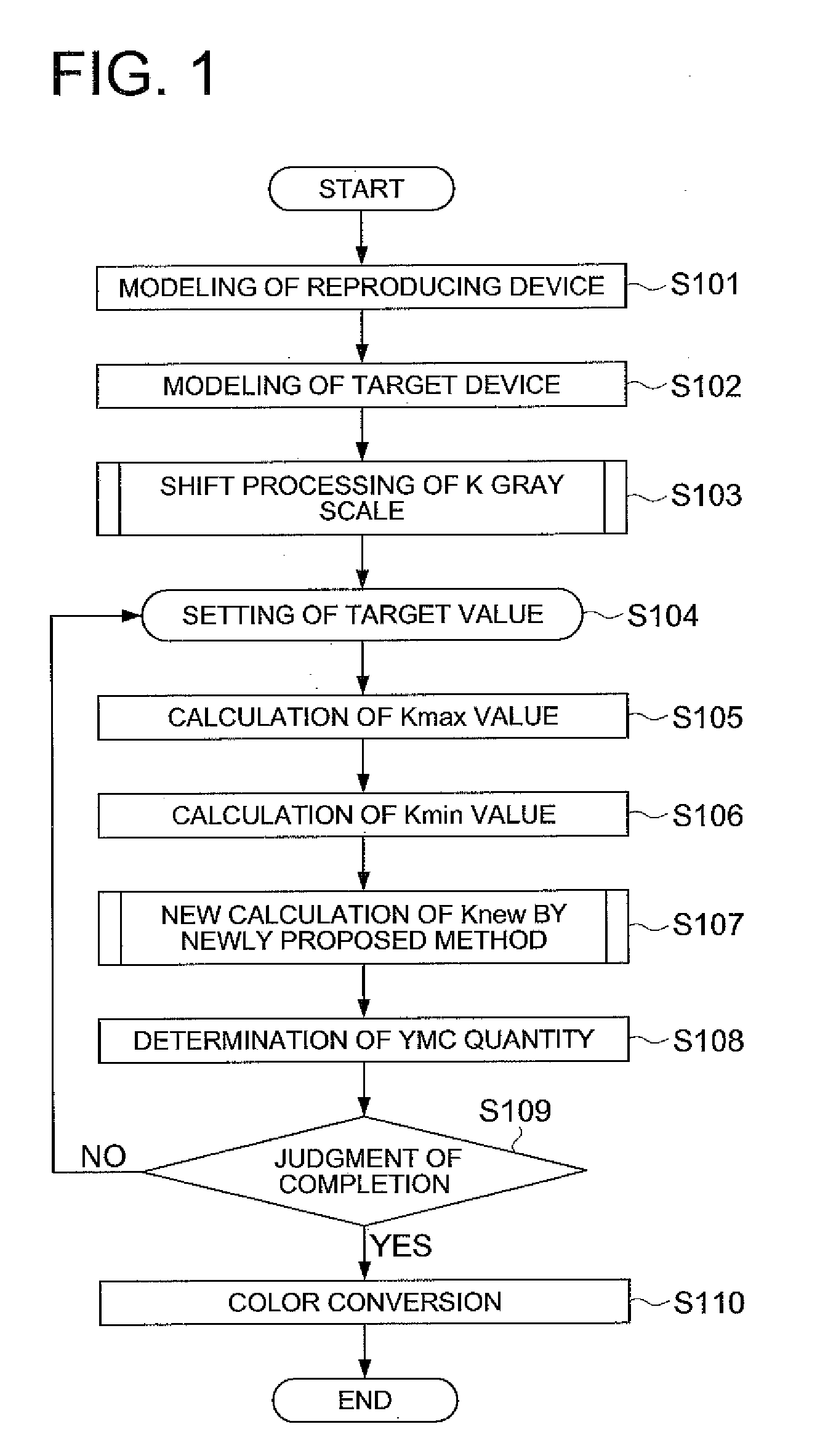

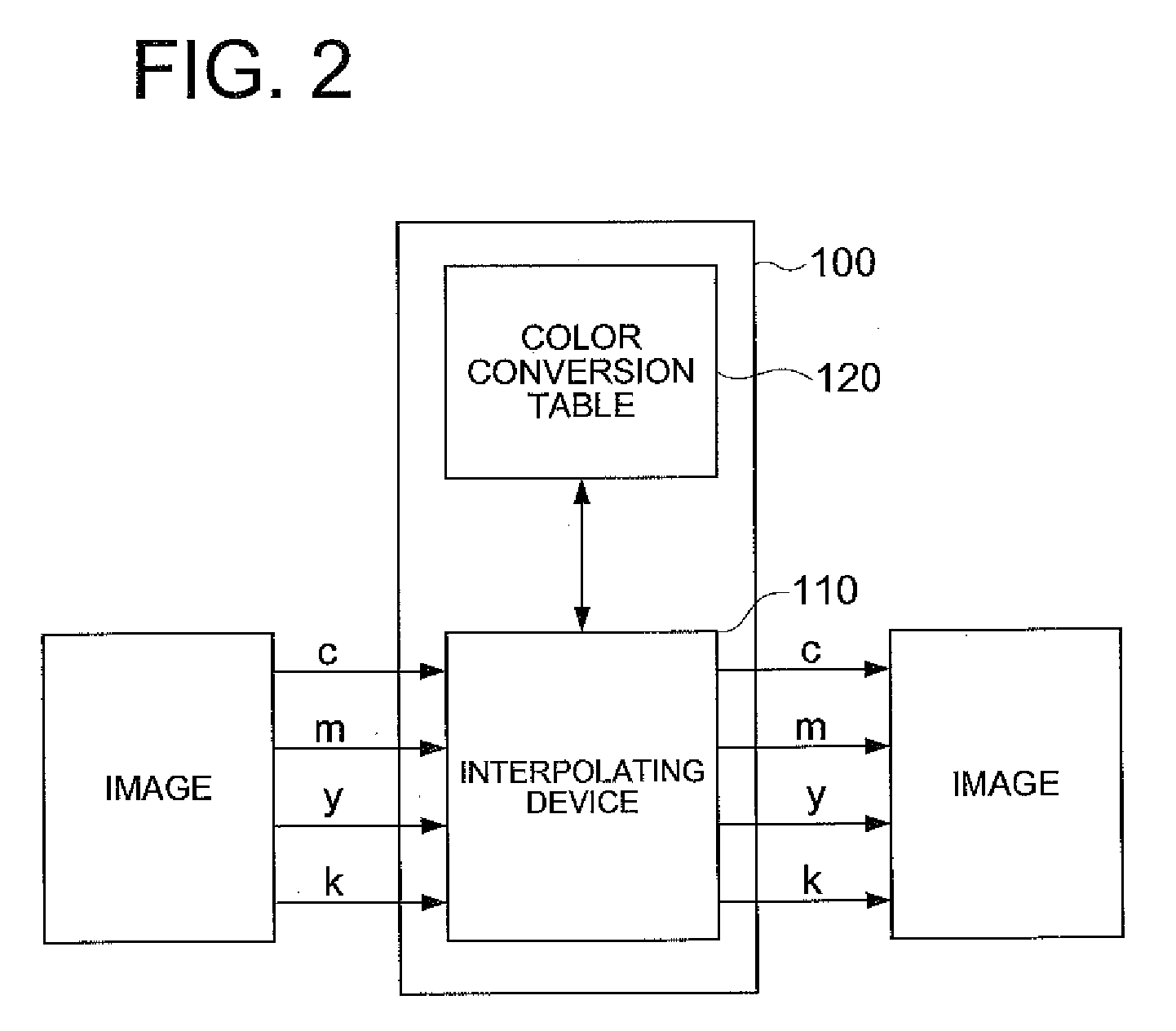

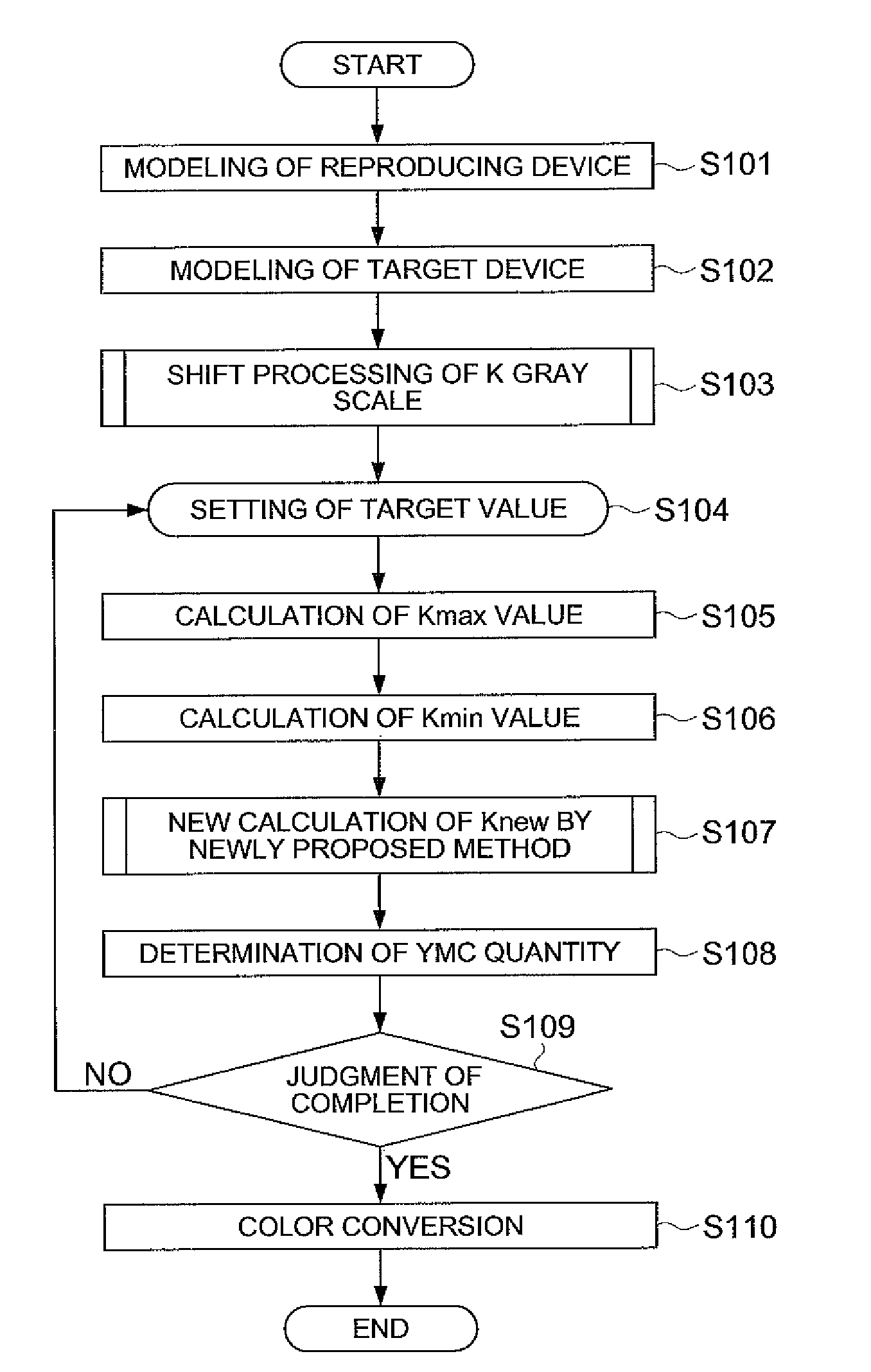

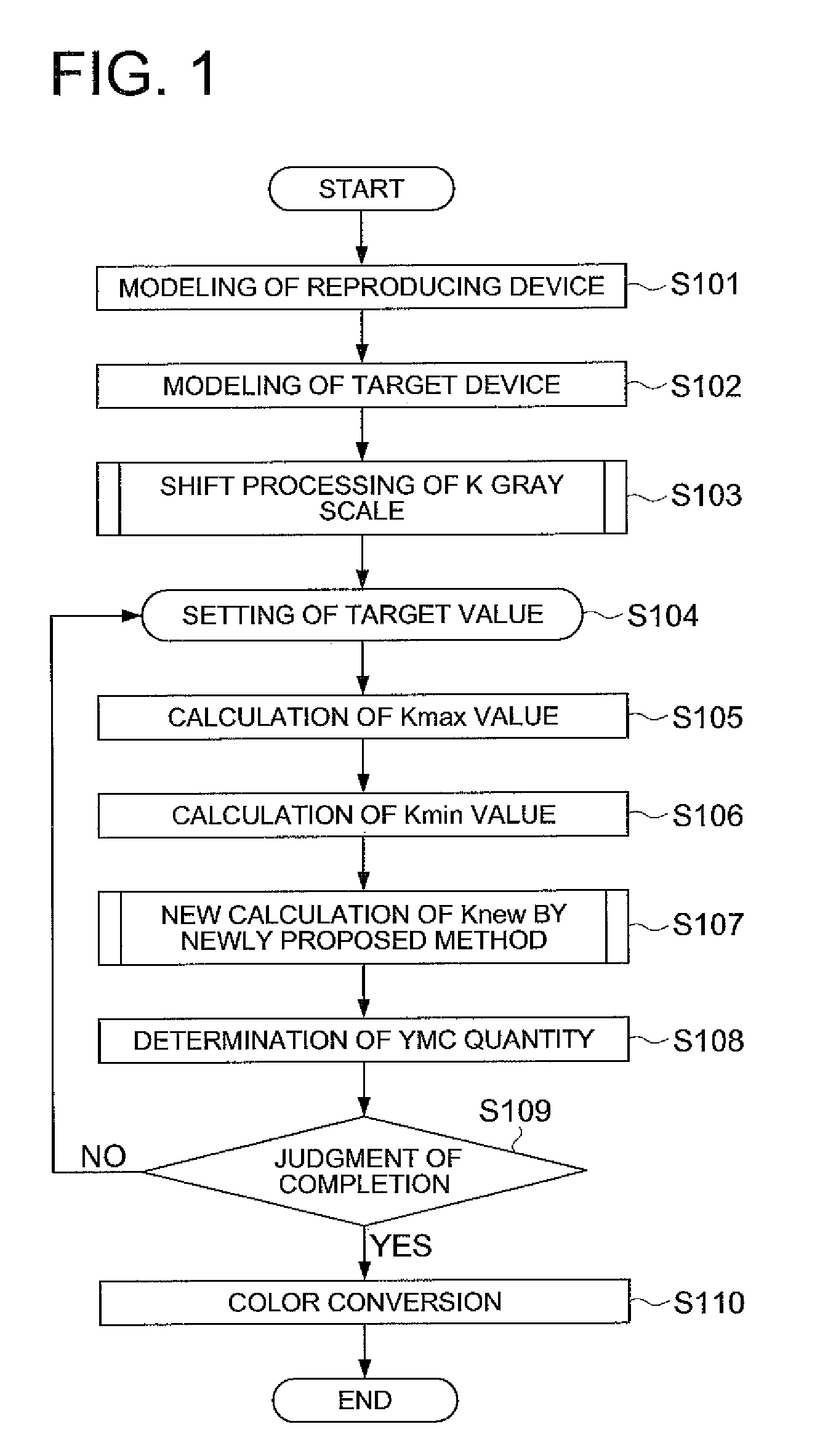

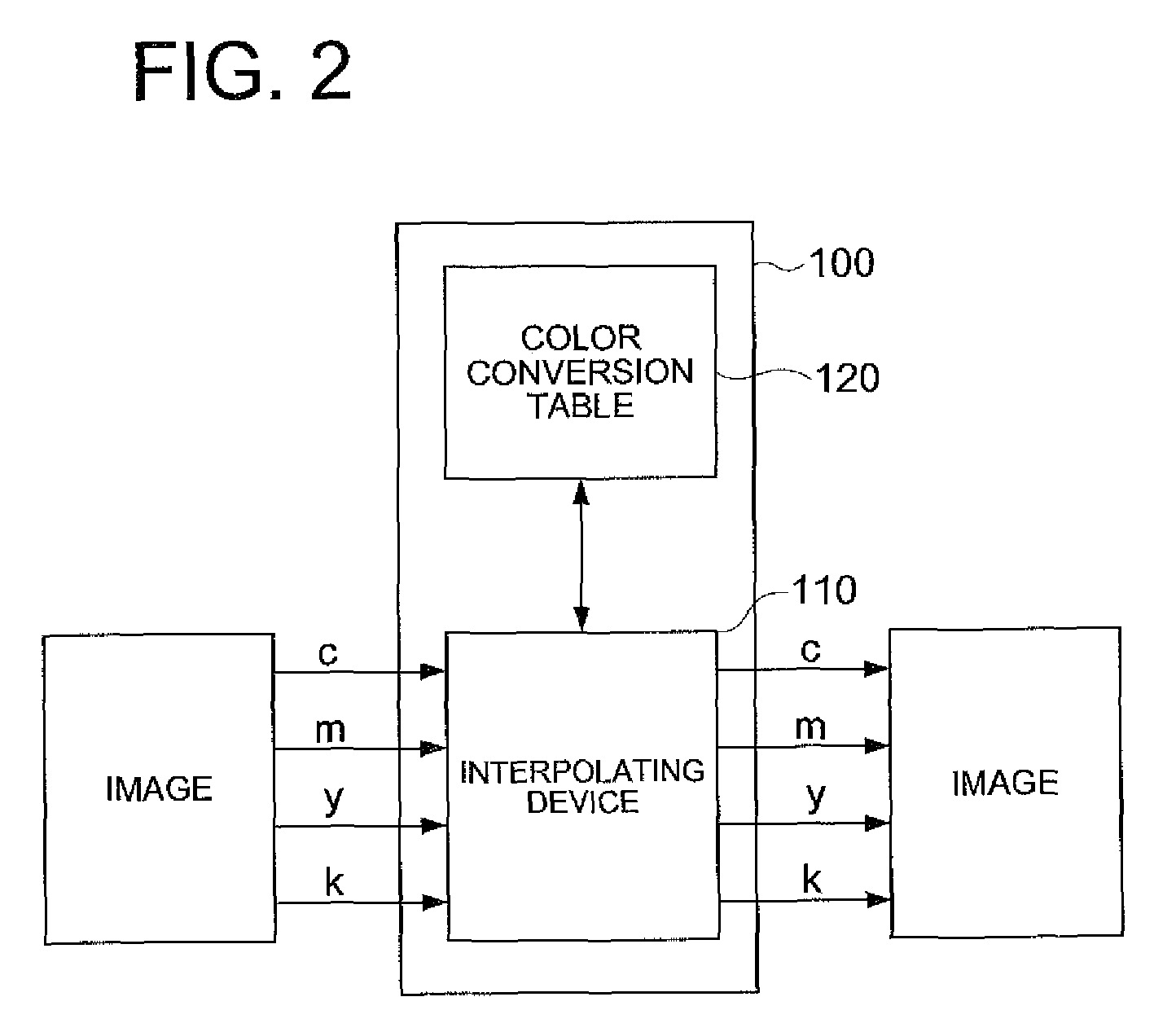

Image processing method and device

InactiveUS20090116070A1Suppress roughnessGrowth inhibitionDigitally marking record carriersDigital computer detailsPattern recognitionImaging processing

An image processing method for forming a color conversion table to convert plural input colors into output colors, the method including the steps of: extracting color values of plural gray scales wherein in input and output characteristic data, a signal value of one color is variable and signal values of other colors are fixed; creating a model with which difference values between input and output color values are outputted by inputting the extracted color values; and estimating the output color values corresponding to the input color values to create the color conversion table to convert plural input colors into output colors, after shifting the color values by adding or subtracting the difference values which are obtained by inputting the color values into the model with respect to every output color values.

Owner:KONICA MINOLTA BUSINESS TECH INC

Image processing method and device

InactiveUS8174728B2Continuity is not deterioratedGrowth inhibitionDigitally marking record carriersDigital data processing detailsPattern recognitionImaging processing

Owner:KONICA MINOLTA BUSINESS TECH INC

Pattern forming method, composition for forming protective film, method for manufacturing electronic device, and electronic device

ActiveUS20170176862A1Suppressed line edge roughnessAdd depthSemiconductor/solid-state device manufacturingPhotomechanical coating apparatusActinic RaysOrganic solvent

A pattern forming method includes coating an actinic ray-sensitive or radiation-sensitive resin composition onto a substrate to form an actinic ray-sensitive or radiation-sensitive film, coating a composition for forming a protective film onto the actinic ray-sensitive or radiation-sensitive film to form a protective film, exposing the actinic ray-sensitive or radiation-sensitive film covered with the protective film, and developing the exposed actinic ray-sensitive or radiation-sensitive film using a developer containing an organic solvent, in which the protective film contains a compound (A) including at least one group or bond selected from the group consisting of an ether bond, a thioether bond, a hydroxyl group, a thiol group, a carbonyl bond, and an ester bond, and a resin (X).

Owner:FUJIFILM CORP

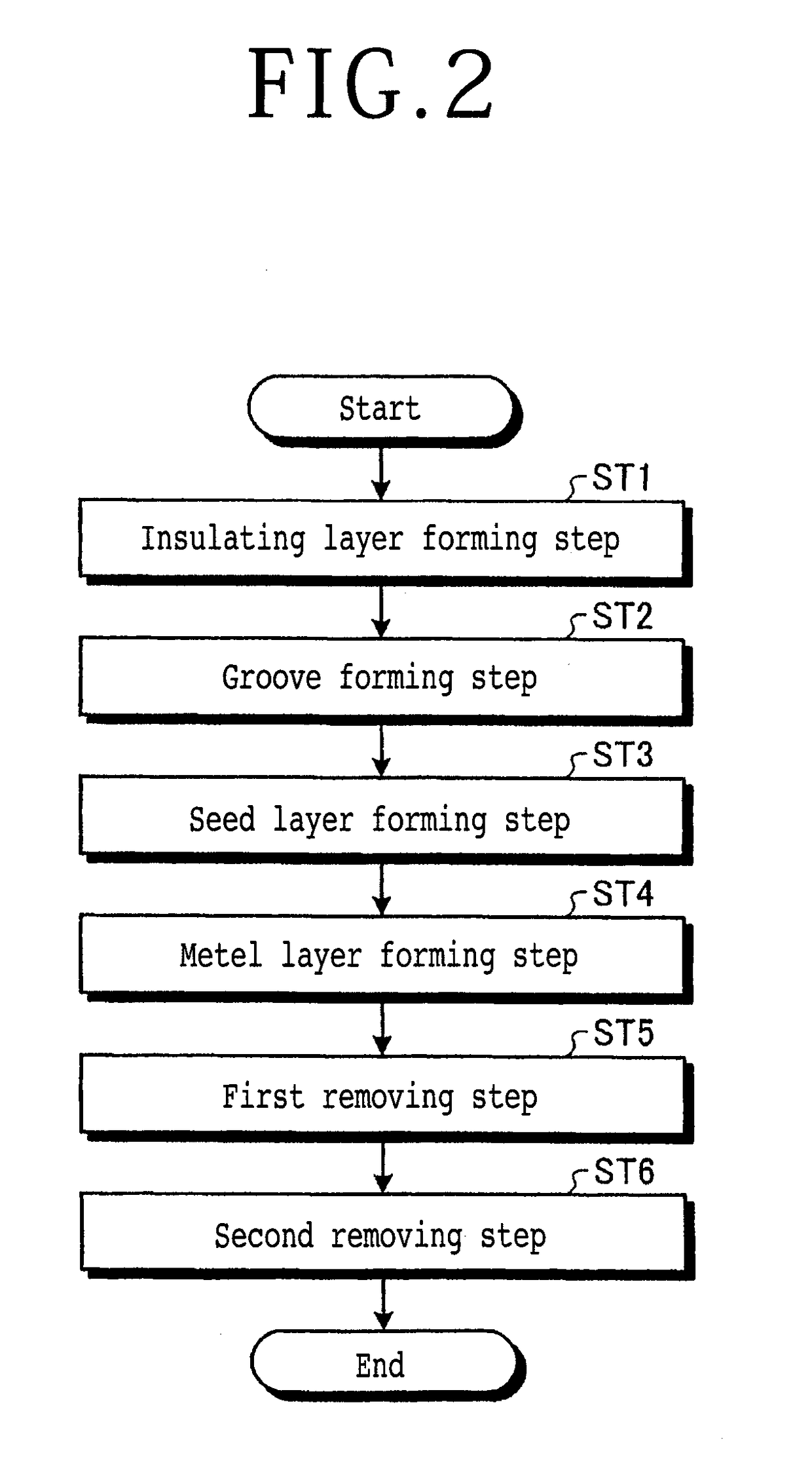

Manufacturing method for wiring board

ActiveUS20180103547A1InhibitionAllow for any formSemiconductor/solid-state device detailsSolid-state devicesMachiningElectroplating

A method for manufacturing a wiring board that has a rewiring layer on a surface thereof includes forming an insulating layer on a core substrate, forming a groove, in which a wiring layer of a circuit pattern is to be provided, on the insulating layer, forming a metal seed layer on an exposed face of the insulating layer on which the groove is formed, electrodepositing metal, which is to form the wiring layer, by plating to fill the groove with the metal to form a metal layer on the seed layer, machining the metal layer by a cutting tool to remove the metal layer up to a position not reaching the top of the insulating layer, and performing etching or a CMP process to expose the top of the insulating layer thereby to form the wiring layer in the groove and flatten an exposed face of the wiring layer.

Owner:DISCO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com