Semiconductor device and electric power converter, drive inverter, general-purpose inverter and super-power high-frequency communication equipment using the semiconductor device

a technology of semiconductor devices and electric power converters, which is applied in the direction of semiconductor devices, basic electric elements, electrical equipment, etc., can solve the problems of increased roughness of silicon carbide surfaces, increased leak current, and reduced channel mobility, so as to improve the electrical characteristics of semiconductor devices and suppress roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

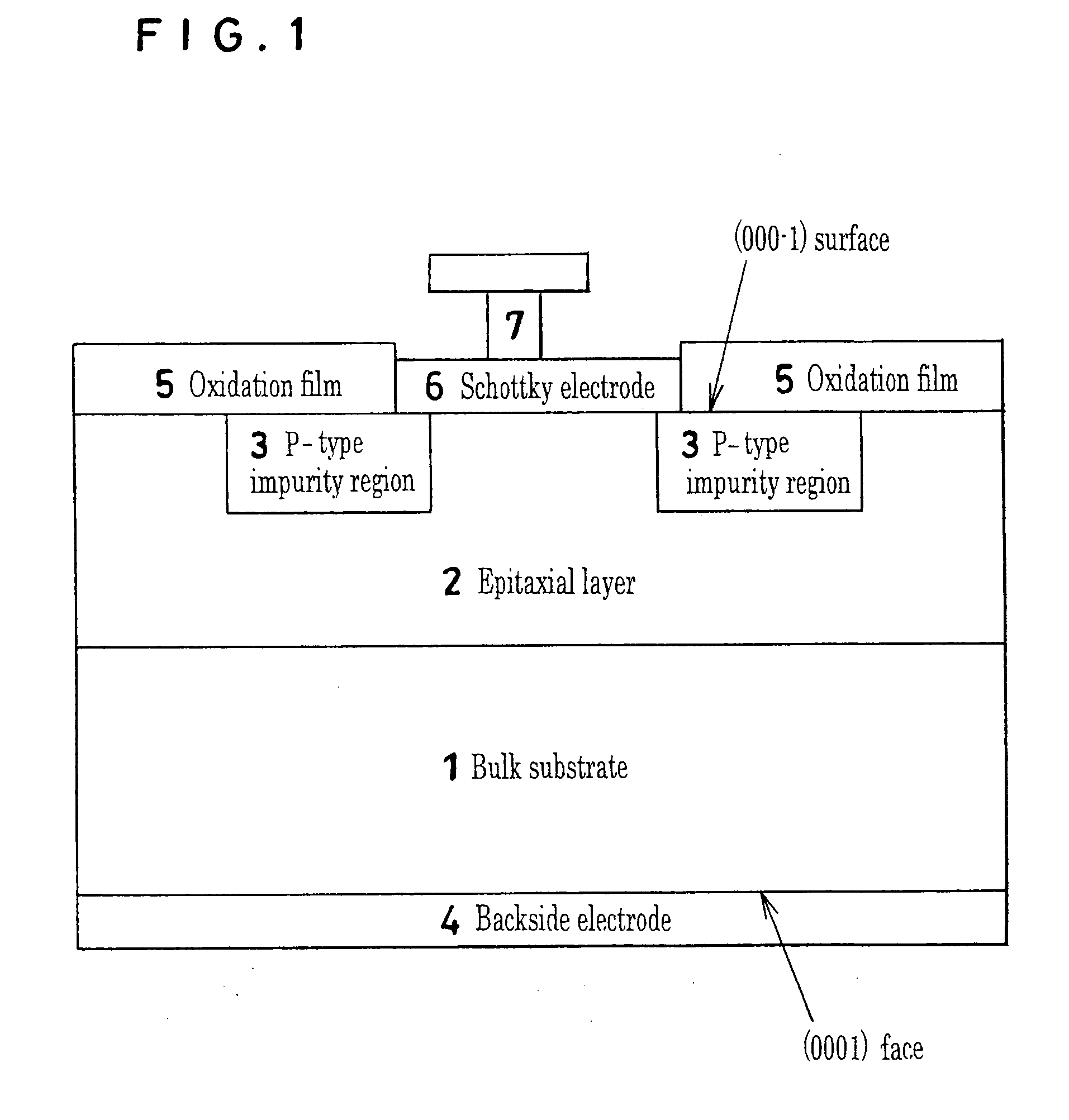

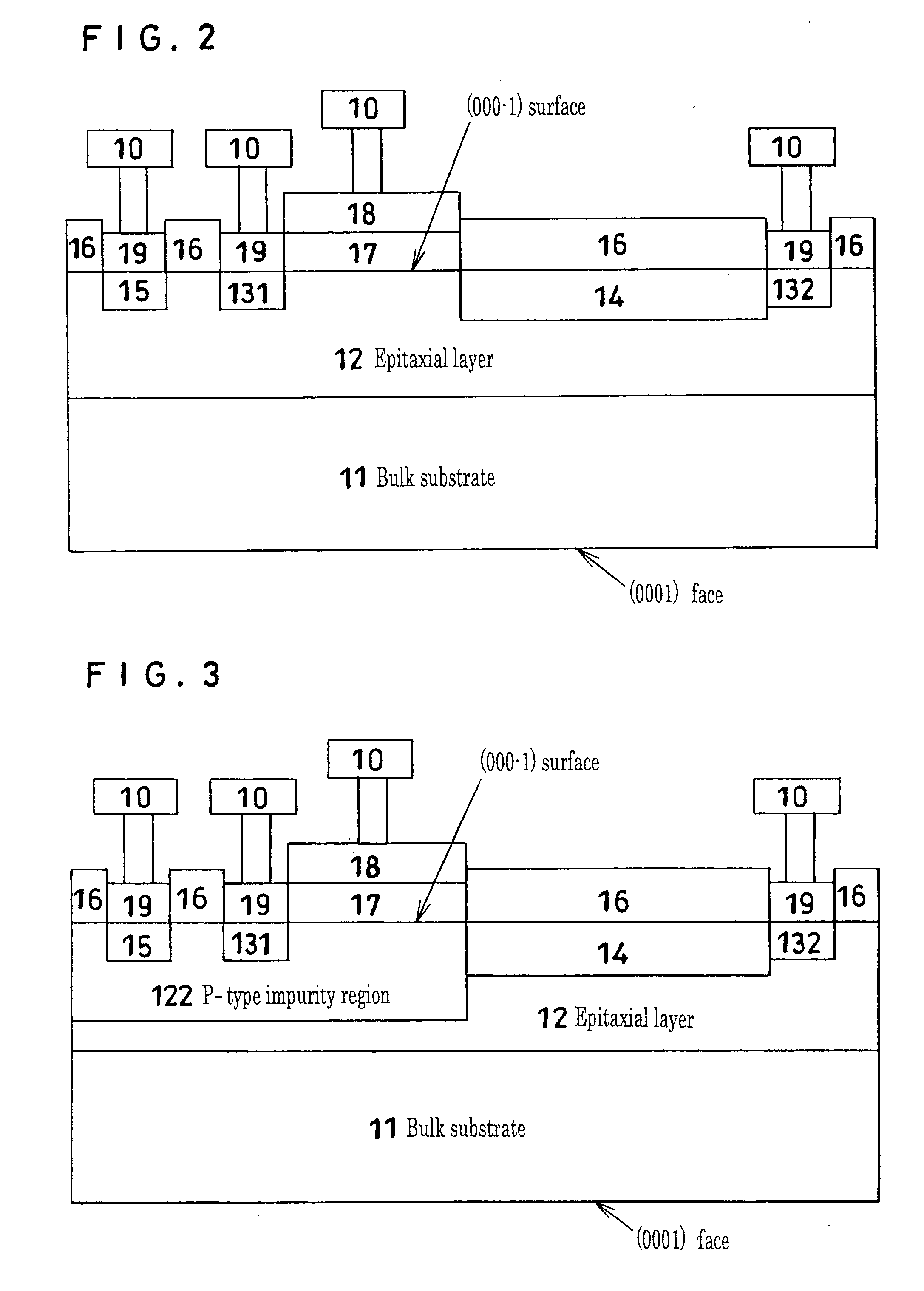

[0022]A method of manufacturing a Schottky barrier diode, a lateral type MIS field-effect transistor and a vertical type MIS field-effect transistor that are examples of a semiconductor device formed using the (000-1) surface of a silicon carbide substrate will be described. This will be followed by showing the results of measurements, by an atomic force microscope, of the surface roughness of substrates that have been heat-treated following ion implantation in the (0001) face used in a semiconductor device that uses a normal silicon carbide semiconductor substrate and in the (000-1) surface proposed by the present invention.

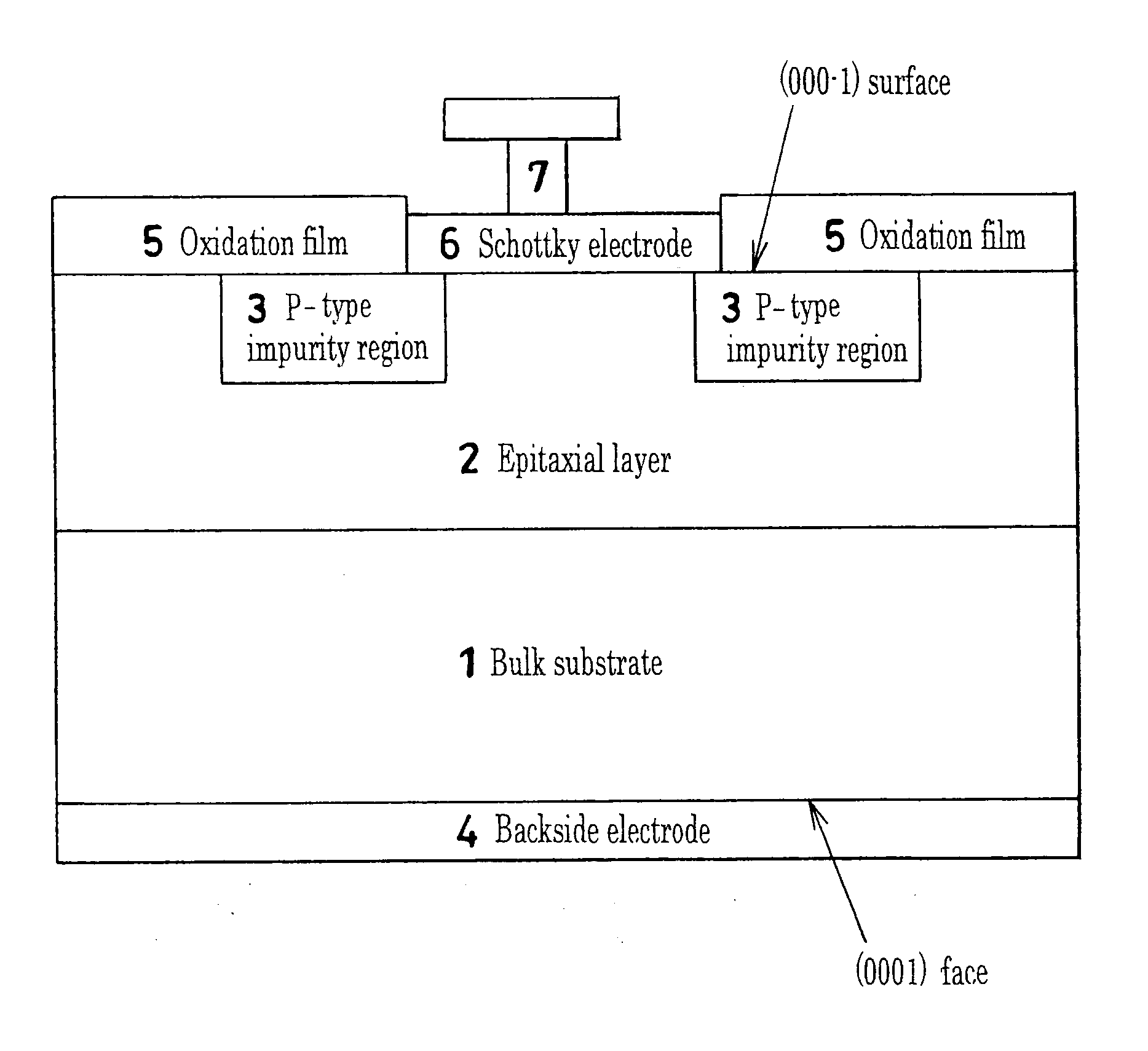

[0023]FIG. 1 is a cross-sectional schematic diagram of a Schottky barrier diode that is an example of the semiconductor device of the present invention.

[0024]This Schottky barrier diode was manufactured by the following procedure. First, the chemical vapor method was used to grow a 10 μm n type epitaxial layer 2 having a nitrogen impurity concentration of 1×1016...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com